CN1214934C - 用于重载设备的轮胎 - Google Patents

用于重载设备的轮胎 Download PDFInfo

- Publication number

- CN1214934C CN1214934C CNB008045968A CN00804596A CN1214934C CN 1214934 C CN1214934 C CN 1214934C CN B008045968 A CNB008045968 A CN B008045968A CN 00804596 A CN00804596 A CN 00804596A CN 1214934 C CN1214934 C CN 1214934C

- Authority

- CN

- China

- Prior art keywords

- carcass plies

- carcass

- work

- plies

- reinforcement

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

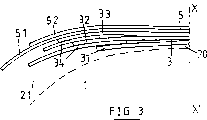

- B60C9/00—Reinforcements or ply arrangement of pneumatic tyres

- B60C9/18—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers

- B60C9/20—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel

- B60C9/2003—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel characterised by the materials of the belt cords

- B60C9/2006—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel characterised by the materials of the belt cords consisting of steel cord plies only

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C9/00—Reinforcements or ply arrangement of pneumatic tyres

- B60C9/18—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers

- B60C9/20—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel

- B60C9/2003—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel characterised by the materials of the belt cords

- B60C9/2009—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel characterised by the materials of the belt cords comprising plies of different materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C9/00—Reinforcements or ply arrangement of pneumatic tyres

- B60C9/18—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers

- B60C9/20—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel

- B60C2009/2038—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel using lateral belt strips at belt edges, e.g. edge bands

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C9/00—Reinforcements or ply arrangement of pneumatic tyres

- B60C9/18—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers

- B60C9/20—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel

- B60C2009/2041—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel with an interrupted belt ply, e.g. using two or more portions of the same ply

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T152/00—Resilient tires and wheels

- Y10T152/10—Tires, resilient

- Y10T152/10495—Pneumatic tire or inner tube

- Y10T152/10765—Characterized by belt or breaker structure

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T152/00—Resilient tires and wheels

- Y10T152/10—Tires, resilient

- Y10T152/10495—Pneumatic tire or inner tube

- Y10T152/10765—Characterized by belt or breaker structure

- Y10T152/10792—Structure where each bias angle reinforcing cord ply has no opposingly angled ply

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T152/00—Resilient tires and wheels

- Y10T152/10—Tires, resilient

- Y10T152/10495—Pneumatic tire or inner tube

- Y10T152/10765—Characterized by belt or breaker structure

- Y10T152/10801—Structure made up of two or more sets of plies wherein the reinforcing cords in one set lie in a different angular position relative to those in other sets

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Tires In General (AREA)

Abstract

Description

Claims (7)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR9903416A FR2791001B1 (fr) | 1999-03-17 | 1999-03-17 | Pneumatique pour engin lourd |

| FR99/03416 | 1999-03-17 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1342117A CN1342117A (zh) | 2002-03-27 |

| CN1214934C true CN1214934C (zh) | 2005-08-17 |

Family

ID=9543383

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB008045968A Expired - Fee Related CN1214934C (zh) | 1999-03-17 | 2000-02-28 | 用于重载设备的轮胎 |

Country Status (14)

| Country | Link |

|---|---|

| US (1) | US6598639B2 (zh) |

| EP (1) | EP1163119B1 (zh) |

| JP (1) | JP4659221B2 (zh) |

| CN (1) | CN1214934C (zh) |

| AU (1) | AU760462B2 (zh) |

| BR (1) | BR0009002A (zh) |

| CA (1) | CA2361904C (zh) |

| DE (1) | DE60001718T2 (zh) |

| ES (1) | ES2190957T3 (zh) |

| FR (1) | FR2791001B1 (zh) |

| ID (1) | ID30443A (zh) |

| RU (1) | RU2235649C2 (zh) |

| WO (1) | WO2000054992A1 (zh) |

| ZA (1) | ZA200001294B (zh) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2824295A1 (fr) * | 2001-05-03 | 2002-11-08 | Michelin Soc Tech | Armature de sommet pour pneumatique de genie-civil |

| FR2827221A1 (fr) | 2001-07-16 | 2003-01-17 | Michelin Soc Tech | Pneumatique pour engin lourd |

| FR2845640A1 (fr) * | 2002-10-10 | 2004-04-16 | Michelin Soc Tech | Pneumatique pour engin lourd |

| FR2857619B1 (fr) * | 2003-07-18 | 2005-08-19 | Michelin Soc Tech | Pneumatique pour vehicules lourds |

| US7086440B2 (en) * | 2003-11-14 | 2006-08-08 | The Goodyear Tire & Rubber Company | Pneumatic tire with annular reinforcing strip layer |

| JP4747773B2 (ja) * | 2005-10-11 | 2011-08-17 | 横浜ゴム株式会社 | 空気入りタイヤ |

| CN100411891C (zh) * | 2006-03-06 | 2008-08-20 | 江苏通用科技股份有限公司 | 全钢丝子午线结构轻型卡车胎 |

| FR2909587B1 (fr) * | 2006-12-06 | 2009-01-16 | Michelin Soc Tech | Pneumatique pour vehicule lourd. |

| JP5759134B2 (ja) * | 2010-09-28 | 2015-08-05 | 株式会社ブリヂストン | 空気入りタイヤ |

| KR101212228B1 (ko) | 2010-12-06 | 2012-12-13 | 한국타이어월드와이드 주식회사 | 중하중용 타이어 |

| DE102012112452A1 (de) | 2012-12-17 | 2014-06-18 | Continental Reifen Deutschland Gmbh | Fahrzeugluftreifen |

| CN104527330A (zh) * | 2014-12-09 | 2015-04-22 | 杭州朝阳橡胶有限公司 | 一种单层高伸长钢丝加强的带束层结构及设计方法 |

| WO2019150041A1 (fr) * | 2018-01-30 | 2019-08-08 | Compagnie Generale Des Etablissements Michelin | Pneumatique comportant trois couches de travail |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1605639A1 (de) * | 1967-11-30 | 1970-01-29 | Continental Gummi Werke Ag | Fahrzeugluftreifen |

| JPS5445004A (en) * | 1977-09-16 | 1979-04-10 | Bridgestone Corp | Pneumatic radial tire that has durability at high speed |

| FR2421742A1 (fr) | 1978-04-07 | 1979-11-02 | Michelin & Cie | Pneumatique a carcasse radiale |

| JPS55132306A (en) * | 1979-03-28 | 1980-10-15 | Sumitomo Rubber Ind Ltd | Radial tire |

| JPS5977906A (ja) * | 1982-10-27 | 1984-05-04 | Sumitomo Rubber Ind Ltd | 重車両用ラジアルタイヤ |

| DE3327670A1 (de) * | 1983-07-30 | 1985-02-07 | Continental Gummi-Werke Ag, 3000 Hannover | Fahrzeugluftreifen |

| JPH0199703U (zh) * | 1987-12-25 | 1989-07-04 | ||

| JPH02200502A (ja) * | 1989-01-30 | 1990-08-08 | Yokohama Rubber Co Ltd:The | 空気入りタイヤおよびその製造法 |

| JPH0367704A (ja) * | 1989-08-07 | 1991-03-22 | Bridgestone Corp | 重荷重用空気入りラジアルタイヤ |

| JPH0833201B2 (ja) * | 1989-12-19 | 1996-03-29 | ユニバーサルトレーデング株式会社 | 燃焼器具用安定足と再使用可能な燃焼器具用安定足を有する燃焼器具 |

| JPH03231003A (ja) * | 1990-02-05 | 1991-10-15 | Bridgestone Corp | 二輪車用空気入りラジアルタイヤ |

| JPH04154404A (ja) * | 1990-10-18 | 1992-05-27 | Toyo Tire & Rubber Co Ltd | ベルト補強層を有するラジアルタイヤ |

| JPH0524413A (ja) * | 1991-07-25 | 1993-02-02 | Bridgestone Corp | 重荷重用空気入りラジアルタイヤ |

| DE4240278A1 (de) * | 1992-12-01 | 1994-06-09 | Uniroyal Englebert Gmbh | Fahrzeugluftreifen mit asymmetrischen Gürteleigenschaften |

| FR2719257B1 (fr) * | 1994-04-28 | 1996-07-19 | Dunlop Sa | Pneumatique radial renforcé pour poids lourd. |

| US5830295A (en) | 1997-02-14 | 1998-11-03 | The Goodyear Tire & Rubber Company | Pneumatic tire with belt structure including reinforced gum strips |

| JP3755051B2 (ja) * | 1997-05-29 | 2006-03-15 | 東洋ゴム工業株式会社 | 空気入りラジアルタイヤ |

-

1999

- 1999-03-17 FR FR9903416A patent/FR2791001B1/fr not_active Expired - Fee Related

-

2000

- 2000-02-28 ES ES00915156T patent/ES2190957T3/es not_active Expired - Lifetime

- 2000-02-28 WO PCT/EP2000/001669 patent/WO2000054992A1/fr active IP Right Grant

- 2000-02-28 RU RU2001128065/11A patent/RU2235649C2/ru not_active IP Right Cessation

- 2000-02-28 BR BR0009002-6A patent/BR0009002A/pt not_active IP Right Cessation

- 2000-02-28 CA CA002361904A patent/CA2361904C/fr not_active Expired - Fee Related

- 2000-02-28 DE DE60001718T patent/DE60001718T2/de not_active Expired - Lifetime

- 2000-02-28 CN CNB008045968A patent/CN1214934C/zh not_active Expired - Fee Related

- 2000-02-28 AU AU36567/00A patent/AU760462B2/en not_active Ceased

- 2000-02-28 ID IDW00200102025A patent/ID30443A/id unknown

- 2000-02-28 EP EP00915156A patent/EP1163119B1/fr not_active Expired - Lifetime

- 2000-02-28 JP JP2000605044A patent/JP4659221B2/ja not_active Expired - Fee Related

- 2000-03-14 ZA ZA200001294A patent/ZA200001294B/xx unknown

-

2001

- 2001-09-17 US US09/953,647 patent/US6598639B2/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| AU3656700A (en) | 2000-10-04 |

| AU760462B2 (en) | 2003-05-15 |

| ID30443A (id) | 2001-12-06 |

| CN1342117A (zh) | 2002-03-27 |

| EP1163119A1 (fr) | 2001-12-19 |

| EP1163119B1 (fr) | 2003-03-19 |

| BR0009002A (pt) | 2002-01-02 |

| RU2235649C2 (ru) | 2004-09-10 |

| CA2361904A1 (fr) | 2000-09-21 |

| US6598639B2 (en) | 2003-07-29 |

| ZA200001294B (en) | 2000-10-11 |

| JP4659221B2 (ja) | 2011-03-30 |

| FR2791001B1 (fr) | 2001-05-04 |

| CA2361904C (fr) | 2008-04-22 |

| FR2791001A1 (fr) | 2000-09-22 |

| DE60001718T2 (de) | 2003-12-18 |

| DE60001718D1 (de) | 2003-04-24 |

| WO2000054992A1 (fr) | 2000-09-21 |

| US20020007894A1 (en) | 2002-01-24 |

| JP2002539022A (ja) | 2002-11-19 |

| ES2190957T3 (es) | 2003-09-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1750944B (zh) | 用于子午线轮胎的胎冠加强件 | |

| RU2205107C2 (ru) | Арматура гребня пневматической шины для большегрузных транспортных средств | |

| RU2335411C2 (ru) | Пневматическая шина для тяжелых транспортных средств | |

| RU2337014C2 (ru) | Пневматическая шина для тяжелых транспортных средств | |

| CN1214934C (zh) | 用于重载设备的轮胎 | |

| US8555942B2 (en) | Heavy vehicle tire | |

| JP5269812B2 (ja) | 重車両用タイヤ | |

| RU2507082C2 (ru) | Шина для транспортных средств большой грузоподъемности, содержащая слой окружных усиливающих элементов | |

| US7093637B2 (en) | Radial tire sidewall reinforcement | |

| CN1840366A (zh) | 用于特级单宽载重轮胎的带束层包 | |

| RU2219067C2 (ru) | Арматура гребня пневматической шины | |

| CN1284030A (zh) | 带有周向加强元件的轮胎胎圈 | |

| BRPI0612385A2 (pt) | pneumático com armadura de carcaça radial | |

| CN1840367A (zh) | 用于特级单宽载重轮胎的带束层包 | |

| JP2002514538A (ja) | ラジアルタイヤのクラウン補強体 | |

| JPS63279907A (ja) | 重量車用空気入りタイヤ | |

| JP4315473B2 (ja) | 重荷重用空気入りラジアルタイヤ | |

| US20110232818A1 (en) | Tire for Heavy Vehicles Comprising at Least in Each Shoulder, at Least Two Additional Layers in the Crown Reinforcement | |

| CN1103295C (zh) | 轮胎的胎冠加强件 | |

| CN1750947A (zh) | 子午线轮胎的胎冠增强件 | |

| CN1151928C (zh) | 具有径向胎体加强件的轮胎 | |

| US7213626B2 (en) | Heavy vehicle tire with crown reinforcement half-plies | |

| JP3808595B2 (ja) | 重荷重用空気入りラジアルタイヤ | |

| JPS62137207A (ja) | 空気入りラジアルタイヤ | |

| JP3009671B2 (ja) | 重荷重用空気入りタイヤ |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| EE01 | Entry into force of recordation of patent licensing contract |

Assignee: Shanghai Michelin tire Limited by Share Ltd Assignor: Michelin Research & Technology Co., Ltd.|Michelin Co., Ltd. Contract fulfillment period: The duration of the contract is from 2007.01.31 to 2026.12.13 Contract record no.: Contract filing No. 2007990000027 Denomination of invention: Name of invention used in heavy duty equipment tires Granted publication date: 20050817 License type: Common License Record date: 20070813 |

|

| LIC | Patent licence contract for exploitation submitted for record |

Free format text: COMMON LICENCE; TIME LIMIT OF IMPLEMENTING CONTACT: 2007.1.31 TO 2026.12.13 Name of requester: SHANGHAI MIQILIN BOOST TYRE CO., LTD. Effective date: 20070813 |

|

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20050817 Termination date: 20190228 |