CN1134330C - 层状结构件 - Google Patents

层状结构件 Download PDFInfo

- Publication number

- CN1134330C CN1134330C CNB961976969A CN96197696A CN1134330C CN 1134330 C CN1134330 C CN 1134330C CN B961976969 A CNB961976969 A CN B961976969A CN 96197696 A CN96197696 A CN 96197696A CN 1134330 C CN1134330 C CN 1134330C

- Authority

- CN

- China

- Prior art keywords

- buttress

- sheet

- stack

- hole

- piece

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B7/00—Layered products characterised by the relation between layers; Layered products characterised by the relative orientation of features between layers, or by the relative values of a measurable parameter between layers, i.e. products comprising layers having different physical, chemical or physicochemical properties; Layered products characterised by the interconnection of layers

- B32B7/04—Interconnection of layers

- B32B7/08—Interconnection of layers by mechanical means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C51/00—Shaping by thermoforming, i.e. shaping sheets or sheet like preforms after heating, e.g. shaping sheets in matched moulds or by deep-drawing; Apparatus therefor

- B29C51/16—Lining or labelling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C63/00—Lining or sheathing, i.e. applying preformed layers or sheathings of plastics; Apparatus therefor

- B29C63/18—Lining or sheathing, i.e. applying preformed layers or sheathings of plastics; Apparatus therefor using tubular layers or sheathings

- B29C63/20—Lining or sheathing, i.e. applying preformed layers or sheathings of plastics; Apparatus therefor using tubular layers or sheathings using pressure difference, e.g. vacuum

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/68—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts by incorporating or moulding on preformed parts, e.g. inserts or layers, e.g. foam blocks

- B29C70/70—Completely encapsulating inserts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B27/08—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04C—STRUCTURAL ELEMENTS; BUILDING MATERIALS

- E04C2/00—Building elements of relatively thin form for the construction of parts of buildings, e.g. sheet materials, slabs, or panels

- E04C2/02—Building elements of relatively thin form for the construction of parts of buildings, e.g. sheet materials, slabs, or panels characterised by specified materials

- E04C2/26—Building elements of relatively thin form for the construction of parts of buildings, e.g. sheet materials, slabs, or panels characterised by specified materials composed of materials covered by two or more of groups E04C2/04, E04C2/08, E04C2/10 or of materials covered by one of these groups with a material not specified in one of the groups

- E04C2/284—Building elements of relatively thin form for the construction of parts of buildings, e.g. sheet materials, slabs, or panels characterised by specified materials composed of materials covered by two or more of groups E04C2/04, E04C2/08, E04C2/10 or of materials covered by one of these groups with a material not specified in one of the groups at least one of the materials being insulating

- E04C2/296—Building elements of relatively thin form for the construction of parts of buildings, e.g. sheet materials, slabs, or panels characterised by specified materials composed of materials covered by two or more of groups E04C2/04, E04C2/08, E04C2/10 or of materials covered by one of these groups with a material not specified in one of the groups at least one of the materials being insulating composed of insulating material and non-metallic or unspecified sheet-material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B27—WORKING OR PRESERVING WOOD OR SIMILAR MATERIAL; NAILING OR STAPLING MACHINES IN GENERAL

- B27N—MANUFACTURE BY DRY PROCESSES OF ARTICLES, WITH OR WITHOUT ORGANIC BINDING AGENTS, MADE FROM PARTICLES OR FIBRES CONSISTING OF WOOD OR OTHER LIGNOCELLULOSIC OR LIKE ORGANIC MATERIAL

- B27N3/00—Manufacture of substantially flat articles, e.g. boards, from particles or fibres

- B27N3/005—Manufacture of substantially flat articles, e.g. boards, from particles or fibres and foam

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B27—WORKING OR PRESERVING WOOD OR SIMILAR MATERIAL; NAILING OR STAPLING MACHINES IN GENERAL

- B27N—MANUFACTURE BY DRY PROCESSES OF ARTICLES, WITH OR WITHOUT ORGANIC BINDING AGENTS, MADE FROM PARTICLES OR FIBRES CONSISTING OF WOOD OR OTHER LIGNOCELLULOSIC OR LIKE ORGANIC MATERIAL

- B27N5/00—Manufacture of non-flat articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2791/00—Shaping characteristics in general

- B29C2791/004—Shaping under special conditions

- B29C2791/006—Using vacuum

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C51/00—Shaping by thermoforming, i.e. shaping sheets or sheet like preforms after heating, e.g. shaping sheets in matched moulds or by deep-drawing; Apparatus therefor

- B29C51/10—Forming by pressure difference, e.g. vacuum

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2009/00—Layered products

- B29L2009/001—Layered products the layers being loose

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/726—Permeability to liquids, absorption

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2419/00—Buildings or parts thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2590/00—Signboards, advertising panels, road signs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63B—SHIPS OR OTHER WATERBORNE VESSELS; EQUIPMENT FOR SHIPPING

- B63B32/00—Water sports boards; Accessories therefor

- B63B32/57—Boards characterised by the material, e.g. laminated materials

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/10—Methods of surface bonding and/or assembly therefor

- Y10T156/1002—Methods of surface bonding and/or assembly therefor with permanent bending or reshaping or surface deformation of self sustaining lamina

- Y10T156/1028—Methods of surface bonding and/or assembly therefor with permanent bending or reshaping or surface deformation of self sustaining lamina by bending, drawing or stretch forming sheet to assume shape of configured lamina while in contact therewith

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/10—Methods of surface bonding and/or assembly therefor

- Y10T156/1002—Methods of surface bonding and/or assembly therefor with permanent bending or reshaping or surface deformation of self sustaining lamina

- Y10T156/1028—Methods of surface bonding and/or assembly therefor with permanent bending or reshaping or surface deformation of self sustaining lamina by bending, drawing or stretch forming sheet to assume shape of configured lamina while in contact therewith

- Y10T156/103—Encasing or enveloping the configured lamina

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/10—Methods of surface bonding and/or assembly therefor

- Y10T156/1002—Methods of surface bonding and/or assembly therefor with permanent bending or reshaping or surface deformation of self sustaining lamina

- Y10T156/1028—Methods of surface bonding and/or assembly therefor with permanent bending or reshaping or surface deformation of self sustaining lamina by bending, drawing or stretch forming sheet to assume shape of configured lamina while in contact therewith

- Y10T156/1031—Methods of surface bonding and/or assembly therefor with permanent bending or reshaping or surface deformation of self sustaining lamina by bending, drawing or stretch forming sheet to assume shape of configured lamina while in contact therewith with preshaping of lamina

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/10—Methods of surface bonding and/or assembly therefor

- Y10T156/1002—Methods of surface bonding and/or assembly therefor with permanent bending or reshaping or surface deformation of self sustaining lamina

- Y10T156/1028—Methods of surface bonding and/or assembly therefor with permanent bending or reshaping or surface deformation of self sustaining lamina by bending, drawing or stretch forming sheet to assume shape of configured lamina while in contact therewith

- Y10T156/1033—Flexible sheet to cylinder lamina

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/10—Methods of surface bonding and/or assembly therefor

- Y10T156/1002—Methods of surface bonding and/or assembly therefor with permanent bending or reshaping or surface deformation of self sustaining lamina

- Y10T156/1034—Overedge bending of lamina about edges of sheetlike base

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/23—Sheet including cover or casing

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/23—Sheet including cover or casing

- Y10T428/233—Foamed or expanded material encased

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/23—Sheet including cover or casing

- Y10T428/234—Sheet including cover or casing including elements cooperating to form cells

- Y10T428/236—Honeycomb type cells extend perpendicularly to nonthickness layer

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/23—Sheet including cover or casing

- Y10T428/237—Noninterengaged fibered material encased [e.g., mat, batt, etc.]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/23—Sheet including cover or casing

- Y10T428/239—Complete cover or casing

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24008—Structurally defined web or sheet [e.g., overall dimension, etc.] including fastener for attaching to external surface

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24273—Structurally defined web or sheet [e.g., overall dimension, etc.] including aperture

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24273—Structurally defined web or sheet [e.g., overall dimension, etc.] including aperture

- Y10T428/24322—Composite web or sheet

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24273—Structurally defined web or sheet [e.g., overall dimension, etc.] including aperture

- Y10T428/24322—Composite web or sheet

- Y10T428/24331—Composite web or sheet including nonapertured component

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Architecture (AREA)

- Structural Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Composite Materials (AREA)

- Civil Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Laminated Bodies (AREA)

- Toys (AREA)

- Materials For Medical Uses (AREA)

- Glass Compositions (AREA)

- Pallets (AREA)

Abstract

基于1995年2月28日提出的国际专利申请PCT/AU95/00100的W095/23682A1,涉及一种制造由一层或多层的热塑性板材,例如无定形聚对苯二甲酸乙二醇酯(APET)包覆的内在强度低的材料,例如发泡聚苯乙烯制造结构强度高的物件的方法。本发明是上述方法的一种改进并提供或是本身可透过流体或是可以被穿孔变成透过流体的内部件。这些内部件为装饰、增加强度和其他各别的性质而提供,并被可加热变形的外层所夹心或包封。该成型层状结构件的方法包括,选择许多本身不是承载的、但至少是流体可部分渗透的形状确定的件(81,82,83),将形状确定的件(81,82,83)的一层放在另一层之上而形成垛(80),加热作为外皮(87)的一层或多层的热塑性材料片,将加热的片(87)相对于垛(80)移动而使片处于叠加在垛(80)上的位置,在垛(80)的相对两端施加流体压力差以使垛(80)的形状确定的件(81,82,83)受压并使片(87)与垛(80)的形状相一致,将被夹在垛(80)和片(87)以及在垛(80)内的空气从垛(80)排出,然后冷却热塑性材料片(87)。最后的产品是在全方位上受到拉伸的覆盖片或外皮(87)。用于结构物,即,建筑构件、广告牌、汽车用板、台板、黄铜制品板、托板、冲浪板和帆板的各种应用也被公开。

Description

技术领域

本发明涉及由内在强度低的材料制造内在强度高的物件的方法,并涉及对在转让给本申请人的国际专利申请PCT/AU95/00100中公开的内容的改型或改进,该申请在本申请的优先权日尚未被公布。因此该国际申请的内容在本申请中引入作为参考。

背景技术

上面提到的PCT申请的公开内容主要涉及由涂覆有一层或多层热塑性塑料片,例如APET(无定形聚对苯二甲酸乙二醇酯)的内在强度低的材料,例如发泡聚苯乙烯(EPS)制造结构强度高的物件。然而,就这样本身具有可忽略的强度的材料而言,通过实施上述PCT申请所述的方法可以制造出强度非常高的材料。各种结构件材料的某些例子在该PCT申请中公开。

发明内容

本发明的目的是,特别是通过提供许多本身是流体可渗透的或被穿孔而成为流体可渗透的内部件,来进一步改进上述公开的结构强度高的物件。例如,为了装饰和/或额外的强度和/或它们个别的性质而提供内部件,并且该内部件被可加热变形的外层所夹心或包覆。

根据本发明的第一方面,此处公开一种成型具有承载能力的层状结构件的方法,该层状结构件是由许多形状确定的内部件和至少一层的外皮层形成的,所述的许多形状确定的内部件中的每一个本身是不承载的并且至少是部份可渗透流体的,所述方法包括以下步骤:

(1)将所述许多内部件的一层放在另一层上而形成垛;

(2)加热用来形成为所述外皮层的热塑性材料片;

(3)相对于所述垛移动所述加热片而使加热片进入覆盖所述垛的位置;

(4)在所述片的远离所述垛的那一侧与所述垛远离所述片的那一侧之间施加流体压力差,以压缩所述垛的各组件并使所述片与所述被压缩的垛的形状相一致而且使所述片与被压缩的垛相互接合,初始被夹在所述垛与片之间和在所述垛内的空气通过所述垛排出;

(5)冷却所述热塑性材料片,或使其冷却,于是在所述片中在所有的方向上产生拉伸力;和

(6)保持所述流体压力差直至所述的片已被冷却后。

根据本发明的第二方面,此处公开一种具有承载能力的层状结构件,该层状结构件是由许多形状确定的内部件形成的,这些内部件一层在另一层之上而形成垛,所述许多形状确定的内部件中的每一个本身是不承载的并且至少是部分可渗透流体的,所述垛是至少部分被至少一层的热塑性塑料片所包封的,热塑性塑料片将所述垛的所述组件压在一起并与所述垛的受压形状相一致。

附图说明

现参照附图对本发明的实施方案进行介绍,在附图中:

图1为本发明的第一种实施方案的多层结构件的示意剖面图,

图2为本发明的第二种实施方案的金属增强的结构件的示意透视图,

图3和4类似于图1,但用来说明成型第三种实施方案的结构件的方法,

图5为穿过包括灯的广告牌的剖面图,

图6为穿过汽车零件的剖面图,用来说明二种不同的安装固定件的方法,

图7为例如在医生办公室处使用的黄铜牌的局部示意透视图,

图8为安装有固定件的多层物件的透视图,

图9为沿图8的IX-IX线的局部剖视图,

图10为三层物件的剖视图,

图11为由多层纸板形成的平板架透视图,

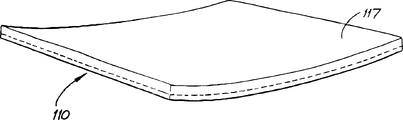

图12为由缺乏平衡而引起弯曲的板的透视图,

图13为提供适当平衡的大致穹形基板的透视图,

图14为根据本发明制造的冲浪板或帆板的横截面图。

具体实施方式

在图1所示的方案中,基本上可渗透空气的材料例如发泡聚苯乙烯(EPS)块1被放置在基板2上,基板2具有一系列从其中穿过的小孔3并且它起支持块1的作用。位于块1上的是一层具有从其中穿过的孔眼5的不渗透材料4的穿孔层。

覆盖在块1和材料4上的是聚对苯二甲酸乙二醇酯(APET)片7,片7的周边通过夹具8被夹到基板2上。

当块1处在基板2上而且不渗透材料层4处在块1上时,通过加热器(未示出)将片7加热直至其至少软化或可塑性变形时为止,然后片7被置于组合的块1和材料4上并被夹持在一对夹圈8之间(如图中所示)。或是夹具8以箭头A方向向下移动,或是基板、块1、材料4以箭头B方向移动,或是两者都移动。然后将处于片7与基板2之间的空气或气体从片7底下抽出,以使片7与由块1和材料4所确定的形状相一致。这类似于真空成型,但主要差别在于块1是可渗透的并因此使处于材料4与块1之间的空气能穿过块1并从图1中由箭头所示的孔3中排出。

而且,由于不渗透的材料层4不能通过这样的空气,因此在材料4中设置孔眼5,以便使处于片7与材料4之间的空气能透过孔眼5并由此穿过块1并通过孔3排出。如在上述的PCT申请说明书中所解释的那样,可以通过对孔3施加减压或真空、或通过向片7的上侧面施加正压、或通过同时用此二种方法来排除空气。为了冷却而对片7施加足够长时间的压力差并由此达到最终位置,在最终位置时片7与块1和材料4的形状相一致,并且通过在片7中的所有方向上产生的拉伸力而将它们连接在一起。在松开夹具8后,可对片7的边界进行修整以使它具有与块1一样的边界。可以理解,在这种连接中为了形成与基板2的有效封合,夹具8应自始至终围绕块1边界延伸。

各种类型的不渗透材料均可使用,它们包括ABS塑料片、金属片和金属箔。为了能使位于片7与材料4之间的空气通过块1和孔3被抽出,此处所用的不渗透材料4具有孔眼或排气孔。然而,因为在材料可充分渗透而无需孔眼的情况中也可以使用薄木单板、纸板片、或类似的纤维素材料那样的能渗透材料,因此材料4不必要是不渗透的。

另外,如果需要的话,可在材料4与块1之间和/或材料4与片7之间使用粘合剂,例如热粘合剂或压敏粘合剂。

在图2所示的类似实施方案中,块1基本如前,然而夹心材料采取由金属片制造的杯14形式,并具有冲压在杯14上表面的矩形孔16的有规则阵列15。杯14的侧边被折叠以与块1的周边整齐地配合。

如由图2中的点划线所示,块1的底侧最好首先以类似于在图1和上述PCT申请中的所述方式用第一层片17覆盖。然后在块1的底侧上对片17穿孔,以使第二层片27能以图1和上述PCT申请中所示的方式与块的上表面相符合。对第二层片27修边使其具有由图2中虚线所示的边界,而使上层片27叠加在下层片17上。如果需要,施加片17和片27的顺序可以巅倒,在此情况下上层片27被穿孔。

结果得到强度特别高的结构件,其中杯14的刚性远远超过人们所预期的具有1mm厚度金属片和其中可插入例如自攻螺丝(未示出)的紧固件的杯的刚性。因此发现图2中的物件作为冷藏室门或壁板是特别有用的,在此类应用中防止物件的误用与磨耗是有重要意义的。另一种应用是作为广告牌,其中杯14形成牌1的后侧而图2中所示的块1的底侧成为侧面的前表面。此前表面可以在短期内粘贴定期更换的广告纸。不仅此广告牌制作便宜并能经受由大风引起的强负荷,而且广告牌本身用塑料片例如APET覆盖,而APET能被配制成耐天侯性的,并且无须采用涂料涂覆等措施。

现参看图3和4,此二图显示类似方法中的序列步骤,其中如前所述的规则形状的块31被设计成符合不规则形状的最终外形。在此连接中,具有孔33的不规则形状的阴模32被支承在穿孔的基板2上。块31被片37和夹具38以与上述图1中和上述PCT申请中所述大致相同的方式覆盖。然而,在片37与基板2之间施加压力差以便从基板2与片37之间抽出空气期间,块31的形状与阴模32外形相符合。只要阴膜3 2没有任何特别尖锐的角隅,块1的EPS或类似材料,特别在它当被加热片加温到某种程度时,是能够符合阴模32的外形的。如果需要的话,还可以在施加压力的同时进行加热。

由于真空被施加到基板2的孔3而且/或者正压被施加到片37的上表面,而片37被冷却到其最终位置,一旦在冷却完成后真空或压力被解除,块31就会保持图4中所示的最终形状。在图4中还可看出,如果需要的话,装饰材料例如穿孔的铝箔34可以夹在片37与块31之间。片37的内表面还可进行印刷或涂敷。

应当理解,图3中的原料是有规则形成的块31,在制造过程中它采取基板32的不规则的外形。然而,块32开始时不必是矩形块料。特别是,块31可被模塑成易于从模具中挤出的中间形状,而最终所需的形状是不易从模具中挤得的。根据这些准则,在制造过程中,阴模32可以具有最终所需的外形,而预成型的模塑块31可被成型为最终所需的形状。这使得有可能在初始模塑步骤中使用廉价和不复杂的模具,从而降低了总费用。

对本领域的专业人员来说,阴模32可以是多孔的-例如由烧结的或加气的黄铜制造的阴模,而不使用具有孔33的阴模。还可向阴模施以压缩空气,以用来从阴模32中吹出成品件。

现参见图5,在制造广告牌时,特别是在制造那些包括气体放电灯例如霓虹灯的广告牌时,必须对气体放电灯的灯泡进行支持。就霓虹灯来说,灯本身可以具有覆盖几平方米表面的非常大的尺寸。于是,支持灯泡所需的框架、特别是抗强风负荷的框架,既是大尺寸的又是大重量的。迄今为止这种框架已以一定费用并在相当长的时间内被制造出来。

在图5所示的方案中,霓虹灯40的支承件采取如前所述的片47覆盖块41的形式。如果需要的话,灯泡40可被间隔开的支座49支持。在图5中为了使片47可见而在灯泡40、块41、支座49、与片47之间示出小的间隙。然而,实际上片47正好与霓虹灯40、块41和支座49的外表面相贴,因此实际上不存在这样的间隙。。特别是,片47紧贴霓虹灯40的灯泡并且整个是透明的。结果霓虹灯40的光发射能力未减弱。反之,如图5中所示,块41能被构形成为霓虹灯40后面的反射表面,特别是如果需要的话,可在霓虹灯40的后面设置反射的铝箔44,以大大地增强其光发射能力。如前所述,铝箔44优选具有许多微小的孔眼(未示出)。一般说,这样的孔眼的尺寸或直径为0.1mm并且不在意的观察者是完全看不见的。

如从图6中可见,现对挡泥板的一部分,例如汽车制造中所用的膝形支承架进行说明。支承架50是由GECET(注册商标),一种高级型发泡聚苯乙烯,或类似材料形成的,并且优选用二层片材57包覆,由此为车身板的汽车工业标准提供“A级装饰”。图中示出了二种安装固定配合件的方法。在第一种方法中,在支承架中形成盲孔52而且片57沿侧面向下延伸并进入到盲孔52的底部。此孔中可以拧入一个双头螺栓53,螺栓长度约为盲孔52深度的二倍。螺栓53上的外螺纹能拧紧片材57并由此形成紧牢的锚式固定。然后使用螺母(未示出)或类似物将螺栓固定到例如车辆底盘上。

在另一种方法中,类似的盲孔55具有插在其中的带内螺纹的螺丝套56中,螺丝套56通过摩擦配合和/或胶接先被固定在其位置上。螺丝套56具有带小孔59的突缘58。然后放上片57并覆盖螺丝套56,部分片57被吸到小孔59中并将螺丝套锁进在其位置。然后切断或拉断覆盖螺丝套56的螺纹孔的片57。然后,带内螺纹的螺丝套56就可以接受带螺纹的紧固螺栓或用于固定支承架50的类似装置。

在图7中说明另一种实施方案。此处的黄铜板74,例如用于医生房间或手术室的通知牌,其上刻有字母70。早先,这样的板会失去光泽而必须定期抛光。然而。通过用合适的一层透明塑料片包覆板74就可避免这种工作。从主要方面说,板74相对于图1的材料4,板74被定位在稍小的可渗透的块71上。在板74和块71之间未用胶或其它粘结剂。还有,在字母70所形成的每个凹槽中设置小孔眼或钻孔75。这就有可能将覆盖片(未示出)与板74之间的空气抽出。然后施加覆盖片并在冷却后对着黄铜板74的底侧围绕块71边界刻划。这就切割覆盖片并能除掉块71。结果得到高反射性的抛光的铭牌,这种铭牌不会失去光泽,因为它受到覆盖层的保护而不受环境的影响。

在另一种方法中,块71可作为背件保留。

如图8中所示,本发明的层状结构件,在另一种实施方案中,可由处于如纸板的纸形成的两外层82、83之间的发泡聚苯乙烯(EPS)中央层81的层压材料制成的平板80组成。每一层所示的外层82、83是由三层平片材与两层波纹板形成的。纸板制造领域的专业人员知道,其他的组合,例如四层平的片材与三层波纹形成的外层,也是可能的。

如前所述,平板80是用一层或多层片状材料87包覆而成的,在图8中它以剖切方式以显示其内部。产物是由内在强度低的材料,例如发泡聚苯乙烯和纸板形成的高结构强度板80。由于纸板的强度低、严重地受到水分的不良影响并且未被作为食品级材料考虑,所以制成板有许多用途,因为它结构强度高,不会被水和流体所透过,而且片状材料易达到食品级的质量。

此外,在迄今由纸或纸板制造的物件中,安装任何类型的附件是非常困难的。任何胶接附件的作法都会在施加低的外力时导致最外层纸板片的撕裂或脱层,从而得到强度非常弱的配合产物。同样,使用螺丝固定装置,例如自攻螺丝的企图结果只不过是造成固定件从纸板材料中被拔出。

然而,这些与现有技术相关的问题已根据本发明通过将内螺纹附件(例如惯用的管附件)包封在片材87之下而得到克服。附件84可由塑料例如PVC或聚丙烯,或由金属例如黄铜或马口铁制成。在使用金属附件84的情况中,在施加片状材料87期间最好在随着施加压差而使被加热的片材87与附件84接触之前,加热附件84。这可防止附件84从片87中吸收热量并由此防止软化片87的适度移动。

如在图9的剖面中所见(此处只图示出纸板层82的上部),加热片材87被紧紧地粘合在外纸板层82外表面和附件84的外表面上。采取在外纸板片中设置二个小孔的措施,是为了使来自于附件84的螺纹85附近区域内的空气穿过外纸板层并进入到最上面的波纹层,在该处空气易于被排出。这使得片材87被紧紧地吸到螺纹85上并与层82的上表面紧密地接触。在此种连接中,应考虑到在片材87与其余层82和附件84之间所示的间隙,实际上是不存在的。

片材87与螺纹85的紧密粘合意味着,带外螺纹的阳固定件86能拧入到附件84中而形成对板80的强机械连接。尽管被吸到螺纹85上的片材87是非常薄的,但此厚度足以改进螺纹85的螺距,而这需要在选择阳固定件86螺纹85的螺距时加以考虑。

在此替代方案中,如果小孔88不存在的话,如图9中的虚线89所示,片材87只能部分地被吸入到螺纹85中。在此情况下,可将封闭附件84孔的片材切断,使能够与阳固定件86正确啮合。这与图6的带螺纹的螺丝套56的情况相似。无论选择哪种装置,片材87将附件84紧紧地固定到高强度板80上,并由此形成牢固并通用的固定连接。

图10显示另一种实施方案。在图10中板90装有如前所述的外皮层片材97。部分的片材97被切去以显示板90的内部,板90是由EPS或GECET形成的二个外泡沫层92、93,和一层由纸板形成的中央层91组成的。虽然如图10中所示作为中央层91的仅仅是单一的波纹层,但是,如果需要的话,显然中央层91能由许多纸板层制成。还有,如果需要的话,可以提供二个纸板层与一个夹在其间的中央EPS层。

图10的结构特别适于用作冰箱、冷藏室等的墙体材料。

本发明的另一实施方案示于图11中。此处,板台100是由完全回收的材料形成的。板台100是由一层堆叠在另一层之上的许多纸板层101制成的。纸板被包封在如前所述的片材107中,片材107优选是由从回收的软饮料瓶获得的回收PET形成的。于是板台100的强度是由当片材107被冷却时在其所有方向上产生的拉伸力引起的,而板台100的形状是由纸板层101的形状、厚度和层数确定的。二种材料均是低成本并重量轻的,而制成的板台101本身是可回收的。如前所述,为了显示板台101内部的纸板层而在图11中将部份片材107切去。

由于片材7、17、27、37、47、57、87、97、107等是随其冷却而收缩的,并由此施加全方位的拉伸力,因此冷却的片材易于收缩、弯曲或扭曲底下的物体。这在图12中示出,图12显示片材117仅被施加在泡沫材料,例如EPS的矩形块110的上表面时的情况。在覆盖了片材117后,块110被放置在如图1中底板2的平底座上。

尽管施加另一层片材到块110的底侧会由于力的平衡而在某种程度上减轻此问题,但这样做不总是理想的或切合实际。

反之,如在图13中所示,更好的办法是通过形成一穿孔的基板112以使它具有稍为升起的中央部来提供平衡。此外,还施加长时间的压力差或真空,直至片材7、17、27、37、47、57、87、97、107等已被冷却时为止。这样,基板112的形状就会抵销或平衡由于片材7、17、27、37、47、57、87、97、107等在其冷却和收缩时产生的拉伸力的扭曲作用。

现参见图14,在近代的冲浪板或帆板中,使软弹性材料的外缘围绕板边缘延伸以防止在事故中板碰撞落水的人而发生伤人事件,这一点是很重要的。在本发明的另一实施方案中,板120的板体121可由发泡的泡沫体例如EPS形成,并且带有在其中嵌有软橡胶外缘123的水平延伸的槽。此种构造形成由外缘123、板体121和外缘123形成的三层水平延伸的垛。

为了将垛的组件包封和保持在其位置上,整个板120被如前所述的片材127所覆盖。当被冷却时,片材127是充分柔软的,以使被包封的外缘123仍显示弹性和减震性。

此外,上述图8与9中所述的工艺在包封冲浪板的桅具和帆板的脚绳附件中是有用的。还有,尽管在图14中在板120与片127之间显示出使片127可被看出的间隙,但是这样的间隙事实上是不存在的。在下表中提出的是能被用于上述物件中的材料的各种组合。

内部材料

发泡聚苯乙烯(EPS)

用戊烷浸渍的聚苯醚(PPE)与聚苯乙烯(PS)的共混料(GECET-商品名)

用戊烷浸渍的聚苯醚(PPE)与聚苯乙烯(PS)的共混料(CARIL-商品名)

聚乙烯(PE)

聚氨酯(PU)

回收或新的纤维素材料(纸,纸板,木材)

具有包括飞灰和加气混凝土的矿物填料的树脂

聚丙烯(PP)

热塑性片材

无定形聚对苯二甲酸乙二醇酯(APET)

聚对苯二甲酸乙二醇酯(PET)

二醇类改性聚对苯二甲酸乙二醇酯(PETG)

聚碳酸酯(PC)

聚碳酸酯/聚对苯二甲酸丁二醇酯(PC/聚酯)

丙烯腈/丁二烯/苯乙烯(ABS)

高冲击强度聚苯乙烯(HIPS)

苯乙烯/丙烯腈(SAN)

低密度聚苯乙烯(LDPE)

高密度聚苯乙烯(HDPE)

聚丙烯(PP)

非增塑聚氯乙烯(乙烯基类-UPVC)

聚甲基丙烯酸甲酯(PMMA-丙烯酸类)

乙酸纤维素

聚对苯二甲酸丁二醇酯(PBT)

聚苯醚(PPE)

聚甲醛(ACETAL)

聚氯乙烯(PVC)

掺有高冲击强度聚苯乙烯的聚苯醚(NORYL-商品名)

应当理解,上列的每一种内部材料可被上列的每一种片材所包覆。

前面仅介绍了本发明的某些实施方案,但对本技术领域的专业人员来说,在不背离本发明范围的前提下,显然能够作出种种的改进。

例如,由多层纸板并用片材包封而制成的屋顶瓦重量太轻而在强风下不能保持在屋顶上的适当位置。为了克服此问题,在包封之前可在波纹纸板之间的空间充填砂子。这种低成本的对策可生产出与惯用的陶瓷或混凝土屋顶瓦重量相当的屋顶瓦。

Claims (13)

1.一种成型具有承载能力的层状结构件的方法,该层状结构件是由许多形状确定的内部件和至少一层的外皮层形成的,所述许多形状确定的内部件中的每一个本身是不承载的并且至少是可部分渗透流体的,所述方法包括以下步骤:

(1)将所述许多内部件的一层在另一层之上而形成垛;

(2)加热用来形成为所述外皮层的热塑性材料片;

(3)相对于所述垛移动所述加热片而使加热片进入覆盖所述垛的位置;

(4)在所述片的远离所述垛的那一侧与所述垛远离所述片的那一侧之间施加流体压力差,以压缩所述垛的各组件并使所述片与所述被压缩的垛的形状相一致而且使所述片与被压缩的垛相互接合,初始被夹在所述垛与片之间和在所述垛内的空气通过所述垛排出;

(5)冷却所述热塑性材料片,或使其冷却,于是在所述片中在所有的方向上产生拉伸力;和

(6)保持所述流体压力差直至所述的片已被冷却后。

2.如权利要求1所述的方法,其特征在于,还包括将所述的垛定位在有孔眼的基板上的步骤。

3.如权利要求1所述的方法,其特征在于,将所述的基板在与所述的垛在由冷却的片所产生的所述拉伸力引起弯曲的相反方向上弯曲。

4.如权利要求2所述的方法,其特征在于,所述基板被构形成为具有预定的形状并且所述垛与所述预定形状相一致。

5.如权利要求1所述的方法,其特征在于,某些或全部的垛组件是由不同材料形成的。

6.如权利要求5所述的方法,其特征在于,还包括对任何一个不是由本身至少是可部份透过流体的材料形成的所述的垛组件进行穿孔的步骤。

7.如权利要求1所述的方法,其特征在于,还包括在所述的垛与所述的片之间定出灯位置的步骤。

8.如权利要求1所述的方法,其特征在于,还包括以下步骤:

(a)在所述的垛与片之间定出容纳固定件的有孔附件的位置,所述附件的孔面对所述片;和

(b)通过施加所述的片将所述的附件夹持到所述的垛上。

9.如权利要求8所述的方法,其特征在于,所述的孔至少部分被所述的冷却片封闭,并且从所述的孔中切断所述的冷却片而使所述的孔能容纳固定件。

10.如权利要求8所述的方法,其特征在于,所述的孔与所述的垛是流体相通的,而且所述的片是与所述孔的内部相符合的,以使所述孔的内部能容纳固定件。

11.如权利要求9所述的方法,其特征在于,所述的孔是带内螺纹的而且所述的固定件是带外螺纹的。

12.如权利要求8所述的方法,其特征在于,在与所述的片开始接触之前加热所述的附件。

13.如权利要求1至12中任何一项权利要求所述的方法,其特征在于,所述形状确定的内部件选自由发泡聚苯乙烯(EPS)、GECET、CARIL、聚乙烯、聚氨酯、回收或新的纤维素材料、纸、纸板、木材、具有包括飞灰和加气混凝土的矿物填料的树脂组成的组中;而聚丙烯和所述的热塑性材料片选自APET、PET、PETG、聚碳酸酯、聚碳酸酯/聚酯共混料、ABS/聚苯乙烯共混料、HIPS/聚苯乙烯共混料、SAN/聚苯乙烯共混料、LDPE/聚苯乙烯共混料、HDPE/聚苯乙烯共混料、聚丙烯、乙烯基树脂、PMMA/丙烯酸共混料、乙酸纤维素、PBT、PPE、聚甲醛、PVC、和NORYL组成的组中。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AUPN5167 | 1995-09-01 | ||

| AUPN5167A AUPN516795A0 (en) | 1995-09-01 | 1995-09-01 | Layered structural article |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB2003101143610A Division CN1265959C (zh) | 1995-09-01 | 1996-08-30 | 层状结构件 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1200070A CN1200070A (zh) | 1998-11-25 |

| CN1134330C true CN1134330C (zh) | 2004-01-14 |

Family

ID=3789495

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB2003101143610A Expired - Fee Related CN1265959C (zh) | 1995-09-01 | 1996-08-30 | 层状结构件 |

| CNB961976969A Expired - Fee Related CN1134330C (zh) | 1995-09-01 | 1996-08-30 | 层状结构件 |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB2003101143610A Expired - Fee Related CN1265959C (zh) | 1995-09-01 | 1996-08-30 | 层状结构件 |

Country Status (15)

| Country | Link |

|---|---|

| US (1) | US6224706B1 (zh) |

| EP (1) | EP0853544B1 (zh) |

| JP (1) | JPH11512038A (zh) |

| KR (1) | KR100450829B1 (zh) |

| CN (2) | CN1265959C (zh) |

| AT (1) | ATE236778T1 (zh) |

| AU (2) | AUPN516795A0 (zh) |

| DE (1) | DE69627358T2 (zh) |

| ES (1) | ES2197245T3 (zh) |

| MY (1) | MY138635A (zh) |

| PT (1) | PT853544E (zh) |

| SI (1) | SI0853544T1 (zh) |

| TW (1) | TW424053B (zh) |

| WO (1) | WO1997009166A1 (zh) |

| ZA (1) | ZA967356B (zh) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2010017672A1 (en) * | 2008-08-11 | 2010-02-18 | Tzongin Yeh | Foam product having an accessory and method of making |

| WO2012040888A1 (zh) * | 2010-10-01 | 2012-04-05 | Huang Zuliang | 航空托盘及其制造方法 |

Families Citing this family (62)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AUPP950399A0 (en) * | 1999-03-30 | 1999-04-22 | Armacel Pty Limited | An improved method for forming structural articles |

| US6561118B2 (en) | 2000-01-14 | 2003-05-13 | Kirby J. Mead | Flexible male/female mold for custom surfboard production |

| GB0002837D0 (en) * | 2000-02-08 | 2000-03-29 | British Aerospace | Assembling composite structures |

| US6403195B1 (en) * | 2000-03-10 | 2002-06-11 | Durakon Industries, Inc. | Composite panel structure and method of making same |

| US6627018B1 (en) | 2000-10-17 | 2003-09-30 | Advance Usa, Llc | System and method of forming composite structures |

| US6331028B1 (en) * | 2000-10-17 | 2001-12-18 | Advance Usa, Inc. | Fiber-reinforced composite structure |

| ES2187362B1 (es) * | 2001-07-18 | 2004-06-16 | Maria Isabel Cervantes Gallego | Cobertor para respaldos, asientos y apoyos de maquinas deportivas. |

| US20040247801A1 (en) * | 2001-07-25 | 2004-12-09 | Dennis Schober | Solid surface products |

| US20060147655A1 (en) * | 2001-07-25 | 2006-07-06 | Lumicor | Solid surface products |

| US6743327B2 (en) | 2001-07-25 | 2004-06-01 | Schober, Inc. | Solid surface products |

| US20060046034A1 (en) * | 2001-07-25 | 2006-03-02 | Schober, Inc. | Solid surface products |

| AUPR957401A0 (en) * | 2001-12-18 | 2002-01-24 | Hillspan Pty Ltd | Panels |

| WO2003066322A1 (en) * | 2002-02-05 | 2003-08-14 | Wham-O, Inc. | Laminate inlay process for sports boards |

| US6668748B2 (en) | 2002-03-01 | 2003-12-30 | H2Eye (International) Limited | Submersible articles and method of manufacture thereof |

| US6786992B2 (en) * | 2002-06-11 | 2004-09-07 | Airdex International, Inc. | Method of making a dunnage platform |

| CN100348409C (zh) * | 2003-01-08 | 2007-11-14 | 雅马哈发动机株式会社 | 装饰用板、成形品、机动车辆及成形品的制造方法 |

| US7368031B2 (en) * | 2003-02-04 | 2008-05-06 | Wham-O, Inc. | Laminate inlay process for sports boards |

| AU2003901369A0 (en) * | 2003-03-25 | 2003-04-10 | Armacel Pty Limited | An encapsulated structural article |

| US6908351B2 (en) * | 2003-06-24 | 2005-06-21 | Wham-O, Inc. | Expanded polystyrene core sports board |

| AU2003903211A0 (en) * | 2003-06-25 | 2003-07-10 | Armacel Pty Limited | Method of, and Apparatus for, Forming an Article and an Article Formed Thereby |

| AU2003904119A0 (en) * | 2003-08-06 | 2003-08-21 | Armacel Pty Limited | Functional expansion of existing components |

| AU2003904118A0 (en) * | 2003-08-06 | 2003-08-21 | Armacel Pty Limited | Refurbishment of load bearing transport accessories |

| CN100448752C (zh) * | 2003-11-06 | 2009-01-07 | 艾尔戴克斯国际公司 | 垫板平台 |

| US20050142333A1 (en) * | 2003-12-30 | 2005-06-30 | Montagna John C. | Method of manufacturing composite vehicle panels |

| US7163253B2 (en) * | 2003-12-30 | 2007-01-16 | Durakon Industries, Inc. | Method of manufacturing composite vehicle panels |

| US7837911B2 (en) * | 2004-01-26 | 2010-11-23 | Sabic Innovative Plastics Ip B.V. | Methods of forming a layered article |

| US20050164023A1 (en) * | 2004-01-26 | 2005-07-28 | Davis Scott M. | Structurally reinforced resinous article and method of making |

| WO2005105433A1 (en) * | 2004-04-30 | 2005-11-10 | Armacel Pty Limited | A timber substitute |

| US8079470B2 (en) * | 2004-05-18 | 2011-12-20 | Anthony Trajkovich | Heat sealable laminating film |

| US7413698B2 (en) * | 2004-06-01 | 2008-08-19 | Novo Foam Products Llc | Method of molding load-bearing articles from compressible cores and heat malleable coverings |

| US20060038320A1 (en) * | 2004-08-17 | 2006-02-23 | Straub Martin L | Convertible boot system and method of making same |

| US7419565B2 (en) * | 2005-02-01 | 2008-09-02 | Eastman Kodak Company | Method for encapsulating |

| US7945531B2 (en) * | 2005-09-16 | 2011-05-17 | Microsoft Corporation | Interfaces for a productivity suite application and a hosted user interface |

| US7963397B2 (en) * | 2006-02-09 | 2011-06-21 | Seagle Vance L | Modular, knock-down, light weight, thermally insulating, tamper proof shipping container and fire retardant shipping container bag |

| US7689481B2 (en) * | 2006-02-15 | 2010-03-30 | Airdex International, Inc. | Light weight, strong, fire retardant dunnage platform bag and system of loading, dispensing and using bag |

| DE102007002997A1 (de) * | 2007-01-20 | 2008-07-31 | Robert Bürkle GmbH | Heißpresse zur Beschichtung von Werkstücken, insbesondere Möbelteilen, sowie Arbeitstisch hierfür |

| US20090011667A1 (en) * | 2007-03-26 | 2009-01-08 | Nova Chemicals Inc. | Sportsboard structures |

| WO2008135550A2 (de) * | 2007-05-08 | 2008-11-13 | Basf Se | Verfahren zum beidseitigen beschichten eines hartschaumstoff-formteils |

| US7985460B2 (en) * | 2008-02-05 | 2011-07-26 | David Polk | Composite contaminant vapor barrier system and method |

| US8654524B2 (en) * | 2009-08-17 | 2014-02-18 | Apple Inc. | Housing as an I/O device |

| US8597455B1 (en) | 2009-10-02 | 2013-12-03 | Metacomb, Inc. | Translucent building material comprising corrugated cardboard |

| PT2560811T (pt) | 2010-04-20 | 2023-03-29 | Fibracast Ltd | Característica de membrana em folha formada e sistema de filtração |

| FI20106169A (fi) | 2010-11-05 | 2012-05-06 | Zeroboards Oy | Tuote |

| UA112659C2 (uk) | 2011-09-09 | 2016-10-10 | Сералок Інновейшн Аб | Формування панелі |

| SG11201401561QA (en) | 2011-10-20 | 2014-05-29 | Fibracast Ltd | Coating device and process for coating formed sheet membrane element |

| CN103350745B (zh) * | 2013-06-03 | 2015-09-16 | 江苏科技大学 | 船舶舷侧复合夹层板结构及施工方法 |

| CN105705710B (zh) | 2013-11-01 | 2018-12-04 | 株式会社冈村制作所 | 板体 |

| JP6569113B2 (ja) * | 2013-11-01 | 2019-09-04 | 株式会社オカムラ | パネル体及びパネル体の製造方法 |

| DE102014106265A1 (de) * | 2014-05-06 | 2015-11-12 | Aha! Thermoforming Gmbh | Verfahren zum Verhauten von Schaumteilen mit einer Kunststofffolie |

| CN105197344A (zh) | 2014-06-25 | 2015-12-30 | 艾尔戴克斯国际公司 | 承载结构 |

| RU2613668C2 (ru) * | 2015-08-07 | 2017-03-21 | Общество с ограниченной ответственностью "АВТЭКС" | Плавательное средство сборно-разборного типа |

| IT201600128339A1 (it) * | 2016-12-19 | 2018-06-19 | Ferrario Roberto | Processo wrappatura materiali |

| FR3066134B1 (fr) * | 2017-05-15 | 2021-08-13 | Porcher Ind | Structure de conformation, piece composite comprenant une telle structure de conformation, procede de fabrication d'une telle piece composite |

| FR3068912B1 (fr) * | 2017-07-11 | 2019-08-23 | Faurecia Automotive Industrie | Procede de fabrication d'une piece d'equipement de vehicule automobile et piece d'equipement associee |

| WO2019239437A1 (en) * | 2018-06-15 | 2019-12-19 | Benassi, Gabriella | Automatic machine for coating panels with leather or fabrics |

| AU2019317217B2 (en) * | 2018-08-08 | 2021-11-11 | Fast Build Systems Pty Ltd | Preform, composite structure and panel, and methods of forming same |

| US11214964B2 (en) * | 2019-06-14 | 2022-01-04 | Nexii Building Solutions Inc. | Reinforced structural insulation panel with corner blocks |

| CN110356335A (zh) * | 2019-07-23 | 2019-10-22 | 扬州市邗江扬子汽车内饰件有限公司 | 一种双面表皮发泡汽车内饰件及其成型工艺 |

| US10814942B1 (en) * | 2020-02-05 | 2020-10-27 | Universal Brands, LLC | Methods and systems for manufacturing surfboards with enhanced strength and reduction of heat retention |

| CN114685953A (zh) * | 2020-04-30 | 2022-07-01 | 华润化学材料科技股份有限公司 | 改性聚酯材料及由其制成的复合夹芯板及其制备方法 |

| CN112793182B (zh) * | 2020-12-18 | 2023-03-14 | 江苏新扬新材料股份有限公司 | 一种用于机架的复合材料框架成型模具及其成型方法 |

| CN113246448B (zh) * | 2021-04-24 | 2022-11-29 | 武汉华迎汽车零部件有限公司 | 全自动折弯输送机 |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3929536A (en) * | 1972-05-10 | 1975-12-30 | Westvaco Corp | Moisture resistant corner post |

| US4024309A (en) * | 1975-03-17 | 1977-05-17 | Ronald P. Wilder | Foam glass structural element and method of producing |

| US4337116A (en) * | 1979-08-28 | 1982-06-29 | Keyes Fibre Company | Contoured molded pulp container with polyester liner |

| IT1169266B (it) | 1981-08-13 | 1987-05-27 | Pier Luigi Nava | Procedimento per la finitura di manufatti in resina armata,in particolare caschi,e manufatti realizzati con tale procedimento |

| US4880588A (en) | 1987-07-16 | 1989-11-14 | Davidson Textron Inc. | Method for producing a molded article having colored features |

| US5051144A (en) * | 1988-05-23 | 1991-09-24 | Sota Technology, Inc. | Method for encasing a porous body in an envelope of plastic material |

| FR2632240B1 (fr) * | 1988-06-01 | 1990-08-31 | Charriere Jean | Materiau et/ou produit composite constitue d'un corps central rendu resistant a l'aide d'une enveloppe apte a se retracter et ses applications |

| US4959189A (en) * | 1988-09-26 | 1990-09-25 | E. I. Du Pont De Nemours And Company | Process for forming a composite structure of thermoplastic polymer and sheet molding compound |

| SE464514B (sv) | 1989-03-20 | 1991-05-06 | Diab Barracuda Ab | Saett att tillverka baatskrov av plast i sandwichkonstruktion |

| TW222602B (zh) | 1990-04-30 | 1994-04-21 | American Standard Inc | |

| US5201981A (en) * | 1991-08-16 | 1993-04-13 | Citadel Architectural Products, Inc. | Method of forming synthetic plastic film-projected building siding |

| US5246757A (en) * | 1992-04-28 | 1993-09-21 | Minnesota Mining And Manufacturing Company | Architectural signs with raised graphics |

| ES2110524T3 (es) | 1992-05-12 | 1998-02-16 | American Standard Inc | Estructura moldeada compuesta acrilica reforzada con poliester y su metodo de fabricacion. |

| US5252164A (en) * | 1992-12-21 | 1993-10-12 | Davidson Textron Inc. | Method for making a supplemental impact restraint door and instrument panel system from single, unitary cover |

| ZA945883B (en) * | 1993-08-13 | 1995-03-16 | Plascon Tech | Composite board |

| CN1082882C (zh) * | 1994-03-04 | 2002-04-17 | 阿马塞尔有限公司 | 制造结构性制品的方法和器械 |

-

1995

- 1995-09-01 AU AUPN5167A patent/AUPN516795A0/en not_active Abandoned

-

1996

- 1996-08-30 MY MYPI96003606A patent/MY138635A/en unknown

- 1996-08-30 ES ES96928271T patent/ES2197245T3/es not_active Expired - Lifetime

- 1996-08-30 US US09/029,532 patent/US6224706B1/en not_active Expired - Fee Related

- 1996-08-30 CN CNB2003101143610A patent/CN1265959C/zh not_active Expired - Fee Related

- 1996-08-30 SI SI9630614T patent/SI0853544T1/xx unknown

- 1996-08-30 KR KR10-1998-0701547A patent/KR100450829B1/ko not_active IP Right Cessation

- 1996-08-30 AU AU67809/96A patent/AU698373B2/en not_active Ceased

- 1996-08-30 EP EP96928271A patent/EP0853544B1/en not_active Expired - Lifetime

- 1996-08-30 CN CNB961976969A patent/CN1134330C/zh not_active Expired - Fee Related

- 1996-08-30 WO PCT/AU1996/000541 patent/WO1997009166A1/en active IP Right Grant

- 1996-08-30 JP JP9510692A patent/JPH11512038A/ja active Pending

- 1996-08-30 PT PT96928271T patent/PT853544E/pt unknown

- 1996-08-30 DE DE69627358T patent/DE69627358T2/de not_active Expired - Fee Related

- 1996-08-30 TW TW085110628A patent/TW424053B/zh not_active IP Right Cessation

- 1996-08-30 AT AT96928271T patent/ATE236778T1/de not_active IP Right Cessation

- 1996-08-30 ZA ZA9607356A patent/ZA967356B/xx unknown

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2010017672A1 (en) * | 2008-08-11 | 2010-02-18 | Tzongin Yeh | Foam product having an accessory and method of making |

| WO2012040888A1 (zh) * | 2010-10-01 | 2012-04-05 | Huang Zuliang | 航空托盘及其制造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1500629A (zh) | 2004-06-02 |

| WO1997009166A1 (en) | 1997-03-13 |

| DE69627358D1 (de) | 2003-05-15 |

| KR19990044309A (ko) | 1999-06-25 |

| ZA967356B (en) | 1998-02-23 |

| ATE236778T1 (de) | 2003-04-15 |

| EP0853544B1 (en) | 2003-04-09 |

| JPH11512038A (ja) | 1999-10-19 |

| CN1265959C (zh) | 2006-07-26 |

| TW424053B (en) | 2001-03-01 |

| AUPN516795A0 (en) | 1995-09-28 |

| US6224706B1 (en) | 2001-05-01 |

| KR100450829B1 (ko) | 2004-12-09 |

| SI0853544T1 (en) | 2003-12-31 |

| EP0853544A4 (en) | 2000-08-23 |

| PT853544E (pt) | 2003-11-28 |

| AU698373B2 (en) | 1998-10-29 |

| DE69627358T2 (de) | 2004-04-08 |

| MY138635A (en) | 2009-07-31 |

| ES2197245T3 (es) | 2004-01-01 |

| CN1200070A (zh) | 1998-11-25 |

| EP0853544A1 (en) | 1998-07-22 |

| AU6780996A (en) | 1997-03-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1134330C (zh) | 层状结构件 | |

| EP0746458B1 (en) | A method and apparatus for forming structural articles | |

| JP3340084B2 (ja) | デザインを施しうるフィルム仕上げ材 | |

| US9415574B2 (en) | Method for manufacturing a plate shaped product and plate shaped product manufactured thereby | |

| JP2005531704A (ja) | 複合ドア構造物及びその製造方法 | |

| US11628650B2 (en) | Open area core sandwich structure assembly with vehicle exterior surface glass | |

| CN108883595B (zh) | 折叠式蜂窝状结构及其制造方法 | |

| CA2040364A1 (en) | Method of producing a cup-shaped, sterilisable container, as well as container | |

| US20150151519A1 (en) | Automotive Component Having a Film Surface and Method for Producing Said Automotive Component | |

| CN111315579A (zh) | 多叠层塑料承载板及其生产方法 | |

| CN111315578A (zh) | 具有多叠层塑料承载板的装饰面板及其生产方法 | |

| JPH03130134A (ja) | 輸送車両の内装向け熱成形可能な硬質化粧ラミナ | |

| CA2003319A1 (en) | Composite paper reinforced thermoplastic sheet | |

| CN205272696U (zh) | Pur、蜂窝夹芯、共挤塑料板复合的材料 | |

| JP7535126B2 (ja) | 乗り物構成要素ユニットおよび乗り物構成要素ユニットを製造するための方法 | |

| CN2353522Y (zh) | 瓦楞纸复合板 | |

| AU728778B3 (en) | A method and apparatus for forming structural articles | |

| JPS63319133A (ja) | 成形用多層シ−ト材 | |

| AU695394B2 (en) | A method and apparatus for forming structural articles |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C19 | Lapse of patent right due to non-payment of the annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee |