CN1084656C - 摩擦搅动焊接的焊根密接方法 - Google Patents

摩擦搅动焊接的焊根密接方法 Download PDFInfo

- Publication number

- CN1084656C CN1084656C CN97113492A CN97113492A CN1084656C CN 1084656 C CN1084656 C CN 1084656C CN 97113492 A CN97113492 A CN 97113492A CN 97113492 A CN97113492 A CN 97113492A CN 1084656 C CN1084656 C CN 1084656C

- Authority

- CN

- China

- Prior art keywords

- welding

- workpiece

- groove

- accordance

- substrate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K37/00—Auxiliary devices or processes, not specially adapted to a procedure covered by only one of the preceding main groups

- B23K37/06—Auxiliary devices or processes, not specially adapted to a procedure covered by only one of the preceding main groups for positioning the molten material, e.g. confining it to a desired area

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K20/00—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating

- B23K20/12—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding

- B23K20/122—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding using a non-consumable tool, e.g. friction stir welding

- B23K20/1245—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding using a non-consumable tool, e.g. friction stir welding characterised by the apparatus

- B23K20/126—Workpiece support, i.e. backing or clamping

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2103/00—Materials to be soldered, welded or cut

- B23K2103/08—Non-ferrous metals or alloys

- B23K2103/10—Aluminium or alloys thereof

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Pressure Welding/Diffusion-Bonding (AREA)

Abstract

一种对所有类型的搅动可焊材料、尤其是难焊材料的摩擦搅动焊接的焊根密接方法,该方法包括设置一个基件,该基件开有一个槽,其尺寸大小能容纳下焊具的杆尖与形成的焊道,该工件放置在基件上,计划焊线与槽对准。形成焊缝时,材料被挤进槽中完成焊根的密接并在工件后侧上形成小焊道。这个焊道可通过机加工除掉。基件可以是一块板或被放置在摩擦搅动焊具的旋转杆下方的辊,其上加工有一凹槽,使焊缝与该凹槽对准。

Description

本发明涉及摩擦搅动焊接,尤其涉及一种确保不可挤压合金工件的焊根密接的方法。

摩擦搅动焊接(FSW)是一种把例如金属和塑料材质的两个工件焊接在一起的较新的焊接工艺,FSW设备和工艺的详细说明可在专利出版物WO93/10935、美国专利5,460,317及专利出版物WO95/26254中找到,所有这些在此全部作为本案参考文献。图1A和1B示出了其中一个FSW实用的设备,如图1A所示,将两工件例如板10A′和10B′对准,使要焊在一起的两板边缘以直接接触方式固定在基板12′上。一FSW焊具W′在其末端具有台肩14′,一个非熔化焊接杆16′由台肩中央向下延伸,当旋转焊具W′与板10B′和10A′之间的接触面接触时,该杆16′如所示的那样被迫与两板材接触,该杆在材料中的旋转在焊杆和板接触面两者中都产生大量的摩擦热,这个热会软化在旋转杆的附近的板材,引起两板材料混合而形成一焊缝。该焊具沿板10A′和10B′之间的接触面纵向移动,从而沿整个板间的接触面形成一细长焊缝。焊具的台肩14′阻止软化的板材向上漏出并迫使材料流入到焊接接缝中,当完成焊接时,将焊具回位。

在搅动焊接过程中,杆16′的尖不完全透过到工件的后侧,这样少量的工件材料在杆的下边通过并不被杆搅动,被称为焊根的该焊缝的这个区域的密接取决于焊杆在其上通过时的加热和塑性变形情况,对那些易焊的铝合金,焊根的密接容易实现,然而对于那些难焊的材料如不可挤压铝合金,为了获得焊根的密接,焊杆必须在非常靠近工件后表面处通过。

对于难焊的合金,甚至在焊杆尖和工件后侧之间的间隙上的小变化都可以引起不完全的焊根密接。焊接上的这个缺点尤其严重,因为用无损检测技术检测实际上是不可能的。这就需要改进摩擦搅动焊接工艺,以消除这种焊根的不完全密接并确保难焊合金的完全焊接。

本发明提供在摩擦搅动焊接期间,尤其对于“难摩擦焊接材料”如不可挤压铝合金的密接焊根的方法,从而提供一个贯穿这种材料工件的焊缝。然而,该发明也可便利地被用于其它材料如可挤压铝合金材料。

按照本发明,将一工件定位在一基件上,使一条计划焊线与基件上的槽对准,该基件在摩擦搅动焊杆的下方支撑着工件。所述槽最好截面为半圆形,其尺寸大小能容纳焊杆的尖和计划焊缝。工件用旋转杆焊接,杆的尖穿进工件的材料中,使焊杆尖至少与工件的后表面一般高,贴近基件上的槽。通常,这样沿着焊根产生一沿工件后表面形成的小焊道,加工焊道可在工件的后表面上产生光滑的焊接表面。

在本发明的一个实例中,基件是块底板,工件按传统方式被固定到该底板上以用于焊接过程。然而,按照本发明,计划的焊线与基板上的浅坡口对准。典型的坡口深约为0.01至0.02英寸,宽约为0.1至0.2英寸。另外最好坡口截面为半圆形或半椭圆形,如通过用球-头端机床加工而产生,最好坡口半径与焊杆尖的半径相同。在焊接期间,焊杆尖近似地与被焊工件的后表面对准,这样通常使得挤进焊杆下边的坡口中的材料量少,使焊道沿着焊根突出并被容纳在坡口中。比照现有技术的要求,为了补偿少量材料被挤进坡口中这一方面,通常有必要插入焊具的深度加约0.003英寸的小距离。

在另一实例中,被焊工件被一安装在焊具的转杆和台肩下方的旋转辊子连续地拉进摩擦搅动焊接设备中。按照本发明,该辊子有一连续的环形坡口,最好其宽度和深度如上所述并位于焊杆尖下方,以致焊杆尖至少能穿入直至工件的后表面。在摩擦搅动焊接期间,工件的一些材料被挤压进坡口中沿工件后侧上的焊根形成一条焊缝,这个方法也确保了焊根的密接。

通过结合附图的详细说明,本发明的上述方面和很多伴随的优点将变得更容易理解,更加清楚,其中:

图1A是说明一现有技术的摩擦搅动焊接过程的示意图;

图1B是图1A的侧视图,表明摩擦搅动焊具的尖部插入到工件中产生一焊缝;

图2是一摩擦搅动焊具的侧视图的示意说明,表现了本发明开坡口基板的一实施例;

图3是一工件的说明实例,表明了按照本发明的沿工件后侧延伸的焊缝;

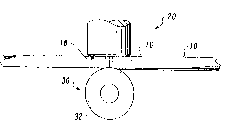

图4A是表明按照本发明,使用开坡口辊作为基件形成一密接根部焊缝的示意透视图;

图4B是图4A的侧视图。

本发明提供了在摩擦搅动焊接期间,搅动可焊材料尤其是难摩擦搅动焊接材料如不可挤压铝合金的焊根密接的方法。人们认为当焊接这种类型材料时,直接在旋转杆下面的材料区域保持相对平静,以致不会发生通常形成焊缝的混合,这种效应也可以在其它搅动可焊材料中发生,虽然不普遍。结果,焊根不容易完全密接。为了产生理想的密接焊根,本发明的方法使焊具的杆比较深地穿进工件中,到达工件的最后面,这样做,被摩擦焊具的旋转杆产生的软化材料可挤压到焊缝后侧上的有限范围,以产生一焊缝,从而焊缝由工件的上表面延伸稍微突出超出工件的后侧,在工件的上表面焊缝由旋转焊具的台肩成形,如果需要的话,工件的后面然后被选择加工产生一光滑的焊接表面。

在说明书和权利要求书中,术语“难(摩擦搅动)焊接材料”和“难(摩擦搅动)焊接合金”指的是那些在现有技术中不容易得到完全的焊根密接的摩擦搅动焊接的成分。以不可挤压铝合金为例,这些成份的一些非限制性实例包括铝合金2024、7075、2014和2090。

为实现本发明的方法,用来在摩擦搅动焊接设备中支撑工件的基件被加工出一个凹槽,槽尺寸的大小与焊具的杆尖相应并在焊缝成形时容纳该焊道。在工件是平的并被固定到基件上时,那么该基件最好是一个开坡口的板并且计划的焊线与该坡口对准。另外,如果该基件相对于工件是可动的,那么凹槽被开在基件的搅动焊具的旋转杆下方位置,使得当用旋转杆焊接工件材料时,在凹槽中形成一连续焊缝。在这个实例中,基件最好是定位在旋转焊具尖下方的一可水平旋转的带环形坡口的辊子,该辊的坡口与焊具尖对准以在焊接过程中接纳焊道。

如图2的示意说明中所示,将作为例子的平面工件10固定到支撑用的平基板12上,该基板被加工出一道凹槽14,最好凹槽14的截面为半圆形或半椭圆形,其尺寸大小要能容纳下所计划的焊道,而且形状要适合于计划的焊线,典型的凹槽的尺寸大小要能容纳下焊具20的杆16的尖部。这样凹槽14最好宽度约为0.1-0.2英寸、深度约为0.01-0.02英寸,为说明起见在图中凹槽的尺寸被放大了。焊接期间,摩擦搅动焊具20的旋转杆16的尖部伸过工件材料,直到该尖部伸到材料后侧并且至少接近凹槽14的口为止,最好焊杆16的尖部与工件10的后侧22对准,即与该凹槽两侧上的基板12的两个边对准。如图3所示,由于受到旋转焊具20的台肩18和杆16施加到软化材料上的压力,材料被迫向下并且其中一部分挤进凹槽14中形成了半椭圆形截面的焊道24之后把被焊工件选择加工以清理焊道24并产生一大体上平滑的焊接表面。

在图4A和4B中示意性地示出了另一个实施例,被焊材料没有固定到一支撑基板上。在这个实施例中,在焊具20的杆16下方定位一水平旋转的柱体或辊30,该辊30具有一按上述尺寸确定的坡口32,以容纳焊杆16的尖部和容纳所形成的焊道。坡口最好截面为半圆形或半椭圆形并围绕着辊30的圆周延伸,为了说明起见在图中坡口32的尺寸被放大了。为焊接,计划的焊线与这个坡口32对准,将辊30与焊具20的转杆16的尖部间隔开,使得该尖部至少在坡口32的口处与柱体30的两个边同高,这样杆16的尖部至少延伸到工件10的后侧,并且最好达到后侧。最好辊30在电力下旋转,按某一方向以某控制速度牵引着工件通过焊具20以形成焊缝。

虽然上面已经详细描述了本发明的仅仅几个典型具体实施例,但本领域的技术人员很容易认识到,有可能在典型具体实施例中作出很多变型而不从本质上背离本发明的新颖性和优点,因此所有这此变型都意味着被包括在如下述权利要求所限定的本发明范围之内。

Claims (20)

1.一种摩擦搅动焊接工件的方法,所述方法包括:

(a)使一计划焊线与基件中的槽对准来定位所述工件;

(b)使用一焊具焊接所述工件,所述焊具包括一具有尖的旋转杆,该焊杆的尖穿进工件材料中至少到达工件的后表面贴近基件中的槽处;以及

(c)加工焊道以在工件的后表面上产生出平滑的焊接表面。

2.按照权利要求1所述的方法,其特征在于,用一焊具的焊接包括使所述焊杆的尖大致与工件的后表面对准来焊接。

3.按照权利要求1所述的方法,其特征在于,焊接步骤包括焊接一暂时被固定到一基板上的工件,所述基板具有一容纳焊道的坡口。

4.按照权利要求1所述的方法,其特征在于,所述焊接包括使所述工件在一旋转基件上、在焊具下面连续地移动来焊接,所述旋转基件包括一具有环形坡口的辊子。

5.按照权利要求1所述的方法,其特征在于,所述基件中的槽的大小尺寸与所述旋转焊杆的尖相配合。

6.一种摩擦搅动焊接的方法,所述方法包括:

(a)将工件的计划焊线与基件中的槽对准,所述槽的尺寸能容纳焊杆的尖部用于形成焊缝;

(b)使用一包括具有尖的旋转焊杆的焊具焊接,所述焊杆的尖穿入工件至少直到材料的后侧。

7.按照权利要求6所述的方法,其特征在于,焊接步骤包括焊接时使焊杆的尖与所述槽两侧上的基件的两边对准。

8.按照权利要求6所述的方法,其特征在于,所述焊接包括形成焊道,所述焊道至少部分地填满基件中的槽。

9.按照权利要求8所述的方法,其特征在于,还包括加工焊道以产生大致平滑的焊接表面。

10.按照权利要求6所述的方法,其特征在于,所述槽的截面是半圆形的。

11.按照权利要求6所述的方法,其特征在于,所述基件是一暂时被固定到工件上的板。

12.按照权利要求6所述的方法,其特征在于,与基件中的槽对准包括对准在一旋转辊上,所述辊在它的外表面上有一环形凹槽。

13.按照权利要求12所述的方法,其特征在于,所述对准包括对准在一驱动辊上,所述辊把工件拉到并通过所述旋转焊杆。

14.一种摩擦搅动焊接工件产生焊根密接的方法,所述方法包括:

用一旋转焊具摩擦搅动焊接一工件,所述焊具包括一旋转焊杆和靠近所述焊杆的台肩,所述焊杆穿入一被焊工件,该焊杆的尖穿进工件材料中至少到达工件的后表面贴近基件中的槽处以沿焊缝的后表面形成向外突出的焊道。

15.按照权利要求14所述的方法,其特征在于,所述焊接将形成的焊道容纳在基板上的槽中。

16.按照权利要求15所述的方法,其特征在于,所述焊接将焊道容纳在半圆形截面的凹槽中。

17.按照权利要求14所述的方法,其特征在于,所述焊接将形成的焊道容纳在一旋转辊的环形坡口中,所述旋转辊设置在旋转焊具的旋转焊杆的下方。

18.按照权利要求14所述的方法,其特征在于,所述焊接包括通过把工件支撑在一驱动辊上而将工件拉到并通过所述旋转焊杆和旋转焊具的台肩,所述辊在它的外表面上有一尺寸大小与旋转焊杆的尖相适应的环形坡口。

19.按照权利要求1所述的方法,其特征在于,所述定位包括定位不可挤压铝合金工件。

20.按照权利要求6所述的方法,其特征在于,所述对准是对准不可挤压铝合金工件。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US655840 | 1991-02-15 | ||

| US655,840 | 1996-05-31 | ||

| US08/655,840 US5769306A (en) | 1996-05-31 | 1996-05-31 | Weld root closure method for friction stir welds |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1169348A CN1169348A (zh) | 1998-01-07 |

| CN1084656C true CN1084656C (zh) | 2002-05-15 |

Family

ID=24630596

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN97113492A Expired - Lifetime CN1084656C (zh) | 1996-05-31 | 1997-05-28 | 摩擦搅动焊接的焊根密接方法 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US5769306A (zh) |

| EP (1) | EP0810054B1 (zh) |

| JP (1) | JP3488594B2 (zh) |

| KR (1) | KR100492836B1 (zh) |

| CN (1) | CN1084656C (zh) |

| CA (1) | CA2204955C (zh) |

| DE (1) | DE69702636T2 (zh) |

Families Citing this family (93)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6581819B1 (en) * | 1996-03-19 | 2003-06-24 | Hitachi, Ltd. | Panel structure, a friction stir welding method, and a panel |

| JP3598204B2 (ja) * | 1997-06-26 | 2004-12-08 | 昭和電工株式会社 | 摩擦撹拌接合法及び摩擦撹拌接合装置 |

| JP3070735B2 (ja) | 1997-07-23 | 2000-07-31 | 株式会社日立製作所 | 摩擦攪拌接合方法 |

| US6045027A (en) * | 1998-03-04 | 2000-04-04 | The Boeing Company | Friction stir welding interlocking joint design and method |

| US5971247A (en) * | 1998-03-09 | 1999-10-26 | Lockheed Martin Corporation | Friction stir welding with roller stops for controlling weld depth |

| US6138895A (en) * | 1998-06-25 | 2000-10-31 | The Boeing Company | Manual adjustable probe tool for friction stir welding |

| US6070784A (en) * | 1998-07-08 | 2000-06-06 | The Boeing Company | Contact backup roller approach to FSW process |

| US6199745B1 (en) * | 1998-07-09 | 2001-03-13 | Mts Systems Corporation | Welding head |

| US6247633B1 (en) * | 1999-03-02 | 2001-06-19 | Ford Global Technologies, Inc. | Fabricating low distortion lap weld construction |

| US6168066B1 (en) | 1999-04-21 | 2001-01-02 | Lockheed Martin Corp. | Friction stir conduction controller |

| US6722286B2 (en) | 1999-12-14 | 2004-04-20 | Hitachi, Ltd. | Structure and railway car |

| JP3575748B2 (ja) * | 2000-03-06 | 2004-10-13 | 株式会社日立製作所 | 摩擦攪拌接合方法 |

| US6460752B1 (en) * | 2000-04-04 | 2002-10-08 | The Boeing Company | Method of friction stir welding with grooved backing member |

| JP3400409B2 (ja) * | 2000-04-28 | 2003-04-28 | マツダ株式会社 | 接合方法及び接合装置 |

| US6302315B1 (en) * | 2000-05-01 | 2001-10-16 | General Tool Company | Friction stir welding machine and method |

| AU2001264580A1 (en) | 2000-05-08 | 2001-11-20 | Brigham Young University | Friction stir welding using a superabrasive tool |

| US6352193B1 (en) | 2000-08-01 | 2002-03-05 | General Electric Company | Apparatus for joining electrically conductive materials |

| JP3553012B2 (ja) * | 2000-11-17 | 2004-08-11 | 株式会社日立製作所 | 摩擦攪拌接合方法 |

| DE10063920C2 (de) * | 2000-12-20 | 2003-01-16 | Thyssenkrupp Stahl Ag | Verfahren zum Fügen von zwei Werkstücken aus einem durch Erwärmen plastifizierbaren Werkstoff, insbesondere Metall, insbesondere in Form von Blechen, im Stumpfstoß |

| US6769595B2 (en) * | 2000-12-20 | 2004-08-03 | Alcoa Inc. | Friction plunge riveting |

| JP3761786B2 (ja) * | 2001-01-17 | 2006-03-29 | 株式会社日立製作所 | 摩擦攪拌接合方法および装置 |

| US6676004B1 (en) | 2001-02-13 | 2004-01-13 | Edison Welding Institute, Inc. | Tool for friction stir welding |

| EP1372898A4 (en) * | 2001-03-07 | 2008-02-27 | Showa Denko Kk | REINFORCEMENT CONNECTION METHOD, METHOD FOR PRODUCING PILLAR-LINKED COMPONENTS AND REFRACTOR CONNECTION DEVICE |

| US7210610B2 (en) * | 2001-06-04 | 2007-05-01 | Brigham Young University | Apparatus and method for performing non-linear friction stir welds on either planar or non-planar surfaces |

| US6732901B2 (en) | 2001-06-12 | 2004-05-11 | Brigham Young University Technology Transfer Office | Anvil for friction stir welding high temperature materials |

| US6484924B1 (en) * | 2001-08-14 | 2002-11-26 | The Boeing Company | Method and apparatus for backing up a friction stir weld joint |

| US6660106B1 (en) * | 2001-08-22 | 2003-12-09 | The Boeing Company | Methods of manufacture of spin-forming blanks, particularly for fabrication of rocket domes |

| US6543671B2 (en) * | 2001-09-05 | 2003-04-08 | Lockheed Martin Corporation | Apparatus and method for friction stir welding using filler material |

| US6910616B2 (en) | 2002-03-07 | 2005-06-28 | The Boeing Company | Preforms for forming machined structural assemblies |

| US6732900B2 (en) | 2002-04-02 | 2004-05-11 | Mts Systems Corporation | Friction stir welding spindle with axially displaceable spindle shaft |

| RU2325981C2 (ru) * | 2002-08-07 | 2008-06-10 | Иклипс Эйвиейшн Корпорейшн | Сварные швы с полимерным уплотнителем |

| JP3864888B2 (ja) * | 2002-10-28 | 2007-01-10 | マツダ株式会社 | 摩擦撹拌を用いた接合方法 |

| GB0225518D0 (en) | 2002-11-01 | 2002-12-11 | Airbus Uk Ltd | Welding method |

| US6779708B2 (en) * | 2002-12-13 | 2004-08-24 | The Boeing Company | Joining structural members by friction welding |

| US7093745B2 (en) * | 2003-01-14 | 2006-08-22 | Honda Motor Co., Ltd. | Method of and apparatus for friction stir welding |

| CA2514913C (en) * | 2003-01-30 | 2014-11-18 | Smith International, Inc. | Out-of-position friction stir welding of high melting temperature alloys |

| US7530486B2 (en) * | 2003-05-05 | 2009-05-12 | Sii Megadiamond, Inc. | Applications of friction stir welding using a superabrasive tool |

| US6933057B2 (en) * | 2003-07-17 | 2005-08-23 | The Boeing Company | Friction stir welded assembly and method of forming a friction stir welded assembly |

| JP4916879B2 (ja) * | 2003-08-04 | 2012-04-18 | エスアイアイ・メガダイアモンド・インコーポレーテッド | 金属母材複合材料、鉄合金、非鉄合金、及び超合金を含む材料での、摩擦攪拌接合を使用したクラック修復システム及び方法 |

| US6955283B2 (en) * | 2003-09-08 | 2005-10-18 | The Boeing Company | Adaptable mandrel for spin forming |

| US8266800B2 (en) | 2003-09-10 | 2012-09-18 | Siemens Energy, Inc. | Repair of nickel-based alloy turbine disk |

| US20050070374A1 (en) * | 2003-09-29 | 2005-03-31 | Technology Licensing, Llc | Enhanced golf club performance via friction stir processing |

| US7128948B2 (en) * | 2003-10-20 | 2006-10-31 | The Boeing Company | Sprayed preforms for forming structural members |

| US20050116012A1 (en) * | 2003-11-26 | 2005-06-02 | Packer Scott M. | Method for metal and alloy joining using bulk friction stir welding |

| US7225967B2 (en) * | 2003-12-16 | 2007-06-05 | The Boeing Company | Structural assemblies and preforms therefor formed by linear friction welding |

| US7398911B2 (en) | 2003-12-16 | 2008-07-15 | The Boeing Company | Structural assemblies and preforms therefor formed by friction welding |

| WO2005094274A2 (en) * | 2004-03-24 | 2005-10-13 | Smith International, Inc. | Solid state processing of hand-held knife blades to improve blade performance |

| CA2560053A1 (en) * | 2004-03-24 | 2005-10-13 | Scott M. Packer | Solid state processing of materials through friction stir processing and friction stir mixing |

| JP4628774B2 (ja) * | 2004-03-31 | 2011-02-09 | 川崎重工業株式会社 | 摩擦撹拌接合装置 |

| US20100078224A1 (en) | 2004-05-21 | 2010-04-01 | Smith International, Inc. | Ball hole welding using the friction stir welding (fsw) process |

| US20060049234A1 (en) * | 2004-05-21 | 2006-03-09 | Flak Richard A | Friction stirring and its application to drill bits, oil field and mining tools, and components in other industrial applications |

| CN100584510C (zh) * | 2004-10-05 | 2010-01-27 | Sii米加钻石公司 | 用在搅拌摩擦焊中的可扩张心轴和提供该心轴的方法 |

| WO2006066237A2 (en) * | 2004-12-17 | 2006-06-22 | Sii Megadiamond, Inc. | Single body friction stir welding tool for high melting temperature materials |

| US7357292B2 (en) * | 2005-02-01 | 2008-04-15 | Battelle Energy Alliance, Llc | Friction stir welding tool |

| US7597236B2 (en) * | 2005-08-16 | 2009-10-06 | Battelle Energy Alliance, Llc | Method for forming materials |

| US9511445B2 (en) | 2014-12-17 | 2016-12-06 | Aeroprobe Corporation | Solid state joining using additive friction stir processing |

| US9266191B2 (en) | 2013-12-18 | 2016-02-23 | Aeroprobe Corporation | Fabrication of monolithic stiffening ribs on metallic sheets |

| US20080041921A1 (en) | 2005-09-26 | 2008-02-21 | Kevin Creehan | Friction stir fabrication |

| US9511446B2 (en) | 2014-12-17 | 2016-12-06 | Aeroprobe Corporation | In-situ interlocking of metals using additive friction stir processing |

| US8632850B2 (en) | 2005-09-26 | 2014-01-21 | Schultz-Creehan Holdings, Inc. | Friction fabrication tools |

| US8397974B2 (en) | 2005-09-26 | 2013-03-19 | Aeroprobe Corporation | Self-reacting friction stir welding tool with the ability to add filler material |

| US8875976B2 (en) | 2005-09-26 | 2014-11-04 | Aeroprobe Corporation | System for continuous feeding of filler material for friction stir welding, processing and fabrication |

| US8550326B2 (en) | 2005-10-05 | 2013-10-08 | Megastir Technologies Llc | Expandable mandrel for use in friction stir welding |

| US8056797B2 (en) * | 2005-10-05 | 2011-11-15 | Megastir Technologies | Expandable mandrel for use in friction stir welding |

| DE102005049865A1 (de) * | 2005-10-11 | 2007-04-12 | Gkss-Forschungszentrum Geesthacht Gmbh | Reibrührschweißwerkzeug mit Gegenlager zur Montage an einer Handhabungseinrichtung |

| WO2007089890A2 (en) * | 2006-01-31 | 2007-08-09 | Sii Megadiamond, Inc. | Thermally enhanced tool for friction stirring |

| US7837082B2 (en) | 2006-05-23 | 2010-11-23 | Federal-Mogul World Wide, Inc. | Powder metal friciton stir welding tool and method of manufacture thereof |

| US8196797B2 (en) * | 2006-05-23 | 2012-06-12 | Federal-Mogul Corporation | Powder metal ultrasonic welding tool and method of manufacture thereof |

| KR100986934B1 (ko) * | 2007-07-13 | 2010-10-08 | 현대자동차주식회사 | 연료전지의 금속분리판 용접장치 |

| CN101157157B (zh) * | 2007-11-13 | 2010-06-16 | 江苏科技大学 | L型铝合金型材搅拌摩擦焊的焊接方法 |

| US9015948B2 (en) * | 2008-01-19 | 2015-04-28 | The Boeing Company | Joining fuselage skins using friction stir welding |

| DE102008045456A1 (de) * | 2008-09-02 | 2010-03-04 | Mahle International Gmbh | Kolben für einen Verbrennungsmotor |

| US7832613B2 (en) * | 2009-01-15 | 2010-11-16 | General Electric Company | Friction stir welding system |

| US20110127311A1 (en) * | 2009-11-02 | 2011-06-02 | Jeremy Peterson | Out of position friction stir welding of casing and small diameter tubing or pipe |

| US8141764B1 (en) | 2010-04-06 | 2012-03-27 | United Launch Alliance, Llc | Friction stir welding apparatus, system and method |

| US7866532B1 (en) | 2010-04-06 | 2011-01-11 | United Launch Alliance, Llc | Friction stir welding apparatus, system and method |

| US8123104B1 (en) | 2010-04-06 | 2012-02-28 | United Launch Alliance, Llc | Friction welding apparatus, system and method |

| DE102010027291A1 (de) * | 2010-07-16 | 2012-01-19 | Airbus Operations Gmbh | Verfahren und Vorrichtung zum Rührreibschweissen |

| EP2812146B1 (en) * | 2012-02-09 | 2021-07-07 | Esab AB | Backing arrangement for use in friction stir welding |

| RU2509637C1 (ru) * | 2012-08-28 | 2014-03-20 | Федеральное государственное унитарное предприятие "Государственный космический научно-производственный центр имени М.В. Хруничева" | Способ фрикционной сварки перемешиванием |

| FR2995237B1 (fr) * | 2012-09-07 | 2015-05-01 | Airbus Operations Sas | Systeme ameliore de soudage par friction malaxage comprenant un contre-appui mobile. |

| RU2527563C2 (ru) * | 2012-10-03 | 2014-09-10 | Федеральное государственное унитарное предприятие "Государственный космический научно-производственный центр имени М.В. Хруничева" | Способ фрикционной сварки с перемешиванием на опорном ролике с профильной канавкой |

| US8678268B1 (en) | 2012-11-21 | 2014-03-25 | Fluor Technologies Corporation | Friction stir welding using a sacrificial anvil |

| EP2808117B8 (de) | 2013-05-28 | 2016-06-15 | MAGNA STEYR Fahrzeugtechnik AG & Co KG | Verfahren zum Herstellen einer Schweißverbindung zwischen einer hochfesten Aluminiumlegierung mit Kupferanteil und einem anderen Teil unter Verwendung von CMT-Schweissen |

| CN103894726A (zh) * | 2014-03-13 | 2014-07-02 | 哈尔滨工业大学 | 背部增厚消除弱连接且适应板厚变化的搅拌摩擦焊方法 |

| FR3030370B1 (fr) * | 2014-12-17 | 2018-04-20 | Saint Jean Industries | Procede de fabrication d'une roue hybride en deux parties en alliage leger notamment aluminium comportant des evidements dans un des sieges de talons de pneumatique |

| US20170120373A1 (en) * | 2015-11-03 | 2017-05-04 | The Boeing Company | Friction stir welding machine having a rotatable anvil and associated method |

| US10279423B2 (en) * | 2016-08-17 | 2019-05-07 | The Boeing Company | Apparatuses and methods for fabricating metal matrix composite structures |

| KR102273514B1 (ko) | 2017-10-31 | 2021-07-06 | 멜드 매뉴팩쳐링 코포레이션 | 고체-상태의 첨가제 제조 시스템 및 재료 조성물 및 구조 |

| CN109570737A (zh) * | 2019-01-16 | 2019-04-05 | 苏州市哈工万洲自动化有限公司 | 一种长焊缝搅拌摩擦焊设备及搅拌摩擦焊接方法 |

| JP7270149B2 (ja) * | 2019-02-26 | 2023-05-10 | 冨士端子工業株式会社 | 異種金属接合体の製造方法 |

| CN115647562B (zh) * | 2022-11-04 | 2023-06-23 | 哈尔滨工业大学 | 一种搅拌摩擦隧道成形装置及方法 |

| CN116037726A (zh) * | 2023-02-01 | 2023-05-02 | 江苏江海机床集团有限公司 | 一种卷板机用的托板机构及使用方法 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1993010935A1 (en) * | 1991-12-06 | 1993-06-10 | The Welding Institute | Improvements relating to friction welding |

| WO1995026254A1 (en) * | 1994-03-28 | 1995-10-05 | The Welding Institute | Friction stir welding |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2102020A1 (de) * | 1971-01-16 | 1972-09-21 | Luc J | Klebeverfahren, Einrichtungen zur Durchfuhrung des Verfahrens und Anwen düngen des Verfahrens |

| SU361052A1 (ru) * | 1971-10-05 | 1972-12-07 | Лапнт1ш-кхя1!''!{ .иди | |

| JPS51110455A (en) * | 1975-03-25 | 1976-09-30 | Maruma Tractor & Equip | Junkatsuzaifunyugatatoratsukurinkuno nikumoryosetsuhoho oyobi sonoreikyakuhogosochi |

| GB9220273D0 (en) * | 1992-09-25 | 1992-11-11 | Welding Inst | Improvements relating to friction jointing and surfacing |

| US5624067A (en) * | 1995-09-26 | 1997-04-29 | The Babcock & Wilcox Company | Method and apparatus for weld joining pipe sections |

| US5611479A (en) * | 1996-02-20 | 1997-03-18 | Rockwell International Corporation | Friction stir welding total penetration technique |

-

1996

- 1996-05-31 US US08/655,840 patent/US5769306A/en not_active Expired - Lifetime

-

1997

- 1997-05-09 CA CA002204955A patent/CA2204955C/en not_active Expired - Lifetime

- 1997-05-22 JP JP13200497A patent/JP3488594B2/ja not_active Expired - Lifetime

- 1997-05-28 CN CN97113492A patent/CN1084656C/zh not_active Expired - Lifetime

- 1997-05-29 DE DE69702636T patent/DE69702636T2/de not_active Expired - Lifetime

- 1997-05-29 EP EP97201577A patent/EP0810054B1/en not_active Expired - Lifetime

- 1997-05-30 KR KR1019970022166A patent/KR100492836B1/ko active IP Right Grant

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1993010935A1 (en) * | 1991-12-06 | 1993-06-10 | The Welding Institute | Improvements relating to friction welding |

| US5460317A (en) * | 1991-12-06 | 1995-10-24 | The Welding Institute | Friction welding |

| US5460317B1 (en) * | 1991-12-06 | 1997-12-09 | Welding Inst | Friction welding |

| WO1995026254A1 (en) * | 1994-03-28 | 1995-10-05 | The Welding Institute | Friction stir welding |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0810054B1 (en) | 2000-07-26 |

| US5769306A (en) | 1998-06-23 |

| CA2204955A1 (en) | 1997-11-30 |

| DE69702636T2 (de) | 2000-11-23 |

| JP3488594B2 (ja) | 2004-01-19 |

| CA2204955C (en) | 2005-07-12 |

| KR970073844A (ko) | 1997-12-10 |

| CN1169348A (zh) | 1998-01-07 |

| EP0810054A1 (en) | 1997-12-03 |

| KR100492836B1 (ko) | 2005-08-24 |

| JPH1052769A (ja) | 1998-02-24 |

| DE69702636D1 (de) | 2000-08-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1084656C (zh) | 摩擦搅动焊接的焊根密接方法 | |

| KR100496761B1 (ko) | 마찰교반접합법및마찰교반접합장치 | |

| US6460752B1 (en) | Method of friction stir welding with grooved backing member | |

| US5971247A (en) | Friction stir welding with roller stops for controlling weld depth | |

| US5718366A (en) | Friction stir welding tool for welding variable thickness workpieces | |

| US8196300B2 (en) | Manufacturing method of electric contact and manufacturing equipment of electric contact | |

| CN1103265C (zh) | 摩擦搅动焊接的方法和设备 | |

| JP4467723B2 (ja) | 摩擦撹拌接合法 | |

| US6892924B2 (en) | Precessing rivet and method for friction stir riveting | |

| US7210610B2 (en) | Apparatus and method for performing non-linear friction stir welds on either planar or non-planar surfaces | |

| WO1999058288A8 (en) | Friction stir welding tool | |

| JPH11320127A (ja) | 摩擦撹拌接合法及び摩擦撹拌接合装置 | |

| WO2009102583A2 (en) | Reducing sheet distortion in friction stir processing | |

| US10195686B2 (en) | Method for joining two essentially metal sheet-type workpieces using friction squeeze welding | |

| CN110023024B (zh) | 铝结构部件的制造方法 | |

| JP2001071155A (ja) | 疲労強度の高い摩擦攪拌接合材、その製造用の摩擦攪拌接合用回転ツール及び摩擦攪拌接合方法 | |

| US20170050263A1 (en) | Friction stir welding device and method of friction stir welding | |

| JP3993917B2 (ja) | 摩擦撹拌接合装置及び摩擦撹拌接合法 | |

| JP3398135B2 (ja) | スポット接合装置、付加材料、付加材料供給装置およびスポット接合方法 | |

| CN113478067B (zh) | 一种两段式异种材料搅拌摩擦焊方法 | |

| US8701968B2 (en) | Friction stir welder and method for friction stir welding | |

| JP2000176664A (ja) | アルミニウム合金部材のレ―ザ溶接方法 | |

| RU2289496C1 (ru) | Способ фрикционной сварки с перемешиванием материала заготовок (варианты) | |

| JPH06234089A (ja) | レーザシーム溶接機 | |

| CN111633321A (zh) | 一种异种金属对接接头搅拌摩擦焊焊接的方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CX01 | Expiry of patent term | ||

| CX01 | Expiry of patent term |

Granted publication date: 20020515 |