CN100359137C - 涡轮机级的第一级护罩结构和加强维护的方法 - Google Patents

涡轮机级的第一级护罩结构和加强维护的方法 Download PDFInfo

- Publication number

- CN100359137C CN100359137C CNB2004100282019A CN200410028201A CN100359137C CN 100359137 C CN100359137 C CN 100359137C CN B2004100282019 A CNB2004100282019 A CN B2004100282019A CN 200410028201 A CN200410028201 A CN 200410028201A CN 100359137 C CN100359137 C CN 100359137C

- Authority

- CN

- China

- Prior art keywords

- guard shield

- shield

- uncinus

- outer shield

- trailing edge

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000034 method Methods 0.000 title claims description 14

- 238000012423 maintenance Methods 0.000 title description 2

- 230000001681 protective effect Effects 0.000 title 1

- 230000011218 segmentation Effects 0.000 claims description 26

- 238000011144 upstream manufacturing Methods 0.000 claims description 7

- 239000004744 fabric Substances 0.000 claims description 5

- 238000007789 sealing Methods 0.000 claims description 5

- 238000001816 cooling Methods 0.000 claims description 4

- 239000002826 coolant Substances 0.000 claims 2

- 238000013461 design Methods 0.000 description 4

- 230000002787 reinforcement Effects 0.000 description 3

- 238000010276 construction Methods 0.000 description 2

- 238000007796 conventional method Methods 0.000 description 2

- 238000003754 machining Methods 0.000 description 2

- NMFHJNAPXOMSRX-PUPDPRJKSA-N [(1r)-3-(3,4-dimethoxyphenyl)-1-[3-(2-morpholin-4-ylethoxy)phenyl]propyl] (2s)-1-[(2s)-2-(3,4,5-trimethoxyphenyl)butanoyl]piperidine-2-carboxylate Chemical compound C([C@@H](OC(=O)[C@@H]1CCCCN1C(=O)[C@@H](CC)C=1C=C(OC)C(OC)=C(OC)C=1)C=1C=C(OCCN2CCOCC2)C=CC=1)CC1=CC=C(OC)C(OC)=C1 NMFHJNAPXOMSRX-PUPDPRJKSA-N 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D11/00—Preventing or minimising internal leakage of working-fluid, e.g. between stages

- F01D11/08—Preventing or minimising internal leakage of working-fluid, e.g. between stages for sealing space between rotor blade tips and stator

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D25/00—Component parts, details, or accessories, not provided for in, or of interest apart from, other groups

- F01D25/24—Casings; Casing parts, e.g. diaphragms, casing fastenings

- F01D25/246—Fastening of diaphragms or stator-rings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2240/00—Components

- F05D2240/10—Stators

- F05D2240/11—Shroud seal segments

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2260/00—Function

- F05D2260/20—Heat transfer, e.g. cooling

- F05D2260/201—Heat transfer, e.g. cooling by impingement of a fluid

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49316—Impeller making

- Y10T29/49318—Repairing or disassembling

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49316—Impeller making

- Y10T29/4932—Turbomachine making

- Y10T29/49323—Assembling fluid flow directing devices, e.g., stators, diaphragms, nozzles

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

Abstract

本发明提供一种定子护罩分段,包括一外护罩116,其具有一进气边凹槽126和一出气边凹槽128,外护罩的两个凹槽沿着第一轴向开口;以及多个内护罩118,每个内护罩都具有一进气边钩状物110和一出气边钩状物112。内护罩的钩状物沿第二轴向突出,正好与第一轴向相反,且每个内护罩的进气和出气钩状物都分别与外护罩的进气和出气边凹槽接合,从而沿轴向和径向将内护罩锁紧到外护罩上。该组件易于接触和易于拆卸内护罩,而没有增加复杂性。

Description

背景技术

在工业燃气轮机中,护罩分段以围绕涡轮机转子轴线环形排列的方式固定到涡轮机壳体钩状物上,以形成径向向外且邻近构成涡轮机转子一部分的叶片(bucket)端部的环形护罩。护罩内壁形成气体通路的一部分。通常,护罩分段由内和外护罩组成,该内和外护罩设置有邻近其进气和排气边、将内和外护罩彼此连接起来的互补的钩和凹槽。外护罩再与涡轮机壳或箱体钩固定。在典型结构中,每个护罩分段具有一个外护罩和二或三个内护罩。

过去,内护罩结构采用两种常用的方式,即一相反钩方案和一C卡圈方案。相反钩方案是更传统的方法且包括由外护罩限制的进气和出气边上相反的突出钩。该方案维护方面主要的不利之处在于:内护罩不能沿轴向移动,只能沿圆周方向滑出壳体。这一方案的限制在于:在接触到所关心的护罩之前,需先将一些配合的护罩组件拆下来。

因此,对于传统的相反钩方案而言,为了拆卸特定的内护罩,不得不拆下所有相关的护罩,其方法是卸下它们的抗转销、然后沿圆周方向逐个将它们滑出,直到接触到所关心的护罩。对于有66个元件的6C发动机而言,在接触到所关心的内护罩之前,需拆下5个额外的外护罩以及15个内护罩之多。

上述第二种C卡圈方案的传统方法,提供了一种能够沿轴向接触内护罩加强对相反钩维护的方法。传统的C卡圈方案如图1所示。

从图中可以看出,和传统的相反钩方法相同,该方案也包括反向突出的进气和出气边钩状物10、12。但是,出气边钩状物12在由外护罩16反向限制时,用单独的C卡圈14再对它们进行限制。通过移开C卡圈14,就可以沿轴线方向(图中箭头A所示)将内护罩18拆下来,因而只将所关心的护罩18拆下来,就能够加强维护操作。然而,应该注意到,每一侧(未示出)上大约一到三个护罩中至少一个相邻内护罩,还必需保持沿圆周向移动以清除织物密封。

上述C卡圈方案存在两个主要缺点。第一是附加的C卡圈元件和装置增加的复杂性。这些元件和装置包括C卡圈本身、抗转销和要求提供轴向和径向定位面、C卡圈的轴承面和固定销孔的机加工装置。C卡圈方案的第二个缺点是,为了接近C卡圈销进行维护,必须沿圆周方向移动所关心区域内的涡轮机级的第二级喷嘴,这一操作要求拆去喷嘴抗转销。

发明内容

因此,希望进一步加强维护,例如改进维护方法和降低复杂性。

本发明推荐一种与传统的反向钩方案和C卡圈方案相比,将涡轮机级的第一级内护罩改进为逆置进气边钩状物,从而能够轴向移动所关心的护罩,而无需移动另外的护罩。根据本发明实施例提供的逆置钩状物的方案,不会增加C卡圈方案的复杂性,使接触方法简化。

因此,本发明具体的定子护罩分段包括:一外护罩,该外护罩具有一进气边和一出气边,以及径向内和径向外面,所说外护罩包括一进气边钩状物和一出气边钩状物,所说外护罩的两个所说钩状物沿第一轴向突出;多个内护罩,每个内护罩都具有一进气边和一出气边,以及径向内和径向外面,所说内护罩包括一进气边钩状物和一出气边钩状物,所说内护罩的两个所说钩状物沿第二轴向突出,该第二轴向与所说第一轴向正好相反;每个所说内护罩的所说进气和出气钩状物都分别与所说外护罩的所说进气和出气钩状物接合,所说接合沿轴向和径向将所说内护罩锁紧到所说外护罩上;和一抗转销,其穿过所述外护罩的进气边内形成的孔,伸入在所述内护罩的所述进气边钩状物内形成的对应插孔,沿圆周方向将所述内护罩锁紧到所述外护罩上,所述孔通过所述外护罩而被限定,以便当所述内护罩被径向地锁紧到所述外护罩上时所述销从所述外护罩是易于移动。

本发明还提供一种多级燃气轮机的定子护罩,其特征在于,包括:一具有一表面的护罩分段,该表面部分地形成贯穿一个涡轮级的热气体通道,且该表面整体布置在构成涡轮转子一部分的所说一个涡轮级的叶片的端部,所说护罩分段具有一进气边和一出气边;所说护罩分段包括一个外护罩和至少一个与外护罩相连接的内护罩;所说外护罩具有由相邻的且沿着每个所说进气边和出气边形成的凹槽,所说凹槽沿轴向同向开口;所说内护罩具有一进气边轴向伸出的短小突出部和一出气边轴向伸出的短小突出部,该突出部分别与所说外护罩的所说凹槽接合,所说接合沿轴向和径向将所说内护罩锁紧到所说外护罩上;和一抗转销,该抗转销穿过所说外护罩内形成的孔,伸入在所说内护罩内形成的对应插孔,沿圆周方向将所说内护罩锁紧到所说外护罩上,所述孔通过所述外护罩而被限定,以便当所述内护罩被径向地锁紧到所述外护罩上时所述销从所述外护罩是易于移动。

本发明还具体为一种从外护罩分离和拆下第一内护罩的方法,其中,内护罩具有进气边钩状物和出气边钩状物,外护罩具有与所说第一内护罩的所说进气和出气边钩状物相互接合的进气边凹槽和出气边凹槽,所说第一内护罩的所说进气和出气边钩状物沿同一轴向突出,所说方法包括:拆下或沿轴向移动在所说第一内护罩上游侧上的配合件;拆下与所说第一内护罩和所说外护罩接合的第一内护罩抗转销;从周边邻近的内护罩取出抗转销,且滑动周边邻近的内护罩,直到它们之间的织物密封脱开为止;沿轴向滑动所说第一内护罩,将所说进气和出气边钩状物从所说外护罩的所说进气和出气边钩状物上拆下;以及沿轴向移动所说第一护罩,脱开和拆下所说第一内护罩。

附图说明

通过认真研究下面结合附图对本发明优选典型实施例的详细说明,可以更彻底地理解和重视本发明的这些和其它目的和优点,中:

图1是示意性的护罩分段沿圆周向的端视图,表示出传统的C卡圈内护罩保持方案;

图2是本发明具体的护罩分段的示意性沿圆周向的端视图;

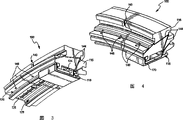

图3是图2中护罩分段具有两个内护罩分段、没有显示外护罩的径向内部结构的透视图;

图4是上述图3所示组件的透视图;以及

图5是根据本发明实施例的内护罩的透视图。

具体实施方式

如上所述,图1示意性地表示出一种传统的C卡圈方案。如图所示,内护罩18包括一内护罩进气边或上游边内护罩钩状物10和内护罩出气边或下游边钩状物12,它们分别与对应的外护罩16的进气和出气边钩状物20、22接合。内护罩出气边钩状物12用一单独的C卡圈14与外护罩16的出气边钩状物22固定,而不是由外护罩结构保持。为了拆下内护罩,必需把C卡圈14移开,让内护罩18沿径向(箭头R)运动,或者更确切地讲是围绕进气边钩状物10转动,直到内护罩的出气边脱开外护罩16,然后,内护罩18沿轴向(箭头A)移动,直到完全脱开外护罩16。如上所述,除了附加的C卡圈元件和装置增加了复杂性外,C卡圈的设计要求拆去喷嘴抗转销,让在所关心区域内涡轮机级的第二级喷嘴沿圆周方向移动,以便能接近C卡圈销(未示出)进行维护。

参照图2-5,图中表示出一个护罩分段(通常用100表示),其由外护罩116和多个内护罩118组成。通常设置两个或三个内护罩。图中所示的护罩分段100包括三个内护罩118,图中为了清楚只表示出其中一个。如下面所详细描述的,内护罩具有分别接近其进气和出气边的钩状物110和112,用于在最后组装时沿圆周方向可滑动的与外护罩116的钩状物120、122形成的凹槽126和128接合。在所示实施例中,采用了传统方法中将冲击冷却板124安装在内护罩之间的结构,以对护罩分段100的内壁表面进行冲击冷却。

在所说明的实施例中,外护罩116具有一径向的外楔形榫130,其与由进气和出气钩状物134、136形成的楔形槽132接合,其中进气和出气钩状物形成将护罩分段固定到箱体上的固定涡轮机壳体或箱体的部分。可以理解,作为已说明结构的可替换方案,外护罩上可设置一径向外楔形槽,以接收构成涡轮机箱体一部分的对应形状的楔形榫。值得重视的是,护罩分段100的环形排列,围绕燃气轮机的转子和围绕转子上叶片的顶部形成,从而为流过涡轮机热气体通路的热气体形成一外壁或边界。在图2中,完整和可参考的表示出内护罩密封槽170、涡轮机级的一级喷嘴结构172、涡轮机级叶片174和涡轮机级的二级喷嘴结构176。

如上所述,本发明的一个实施例提供了一种反向钩护罩结构,该结构使内护罩118与外护罩1 16接合和固紧,从而提高维护和组装能力。参见图2,该图为表示出匹配元件的护罩分段100的详细的沿圆周方向的端视图,可以看出上述外护罩116与进气和出气箱体钩状物134、136接合,并且所提供的外护罩抗转销138伸入对应的槽140(图4),以沿圆周方向将外护罩116与箱体142锁定。在所说明的实施例中,外护罩密封槽144表示为空气测量孔146和冲击板124。在外护罩的进气边上还设置了内护罩抗转销钉孔148,该孔与对应孔150在一条直线上且接收内护罩抗转销152。

与上面描述的和图1所示的传统结构相比,外护罩116的进气边钩状物120是逆向的,包括一沿轴向向上游、远离出气边伸出的短小突出部154。外护罩116的出气边钩状物122也包括一沿轴向向上游、朝向出气边伸出的短小突出部156,其与进气边缘钩状物120的短小突出部154同方向。因此,外护罩116的两个凹槽126和128都沿轴向向上游方向开口。

内护罩118的钩状物110和112与进气和出气边钩状物120、122接合,特别是与外护罩116的凹槽126、128接合。更准确地说,在所说明的实施例中,内护罩的进气边钩状物110包括一沿轴向向下游、向出气边伸出的短小突出部158,从而轴向和径向地与外护罩116的钩状物120接合,进而轴向和径向地锁紧外和内护罩。应该注意到,涡轮机级第一级保持环(即涡轮机级第一级喷嘴金属构件)也有助于锁定内护罩。也就是说,保持环阻止护罩向前移动的太远,以致脱出外护罩的进气边钩状物。而且,在上面说明的实施例中,在内护罩的进气边钩状物内形成的塞孔或孔150用于接收内护罩抗转销152,该销穿过在外护罩进气边部分形成的对应孔148而插入。

内护罩的出气边钩状物同样包括一短小突出部160,该突出部沿轴向向下游、朝出气边延伸,其与进气边短小突出部158同方向,以沿轴向和径向与外护罩的出气边钩状物122锁紧。

为了拆卸所关心的内护罩,可以将第一固定环178(配合件)拆下来,或者向前或沿上游方向滑动大约1英寸。然后,将内护罩进气边W密封180拆下,且将内护罩抗转销152拧下来。而后,将在每个侧面上至少一个相邻内护罩的抗转销拆下,并且让那些内护罩沿圆周向滑动直到织物密封脱开为止。通过沿轴向滑动使进气和出气边钩状物110、112松开再沿径向滑动,这样就把目标内护罩拆下来。然后,通过沿径向插入、再沿轴向滑动安装一个新的内护罩,使与织物密封接合的相邻内护罩复位且重新装配内护罩抗转销。

与C卡圈设计相比,逆向钩状物结构省略了需要拆下C卡圈和涡轮机级第二级喷嘴抗转销的步骤。即,在C卡圈方案中,必须沿圆周方向充分地滑动涡轮机级第二级喷嘴,直到接触到C卡圈为止。这就需要拆下所有处理中的汽轮机第二级喷嘴抗转销。这些步骤在所说明实施例的逆向钩状物的设计中都可以省略掉。

与传统的C卡圈设计相比,所说明的护罩组件可利用逆置进气边钩状物110实现轴向安装和拆卸。从维护和组装的角度讲,沿轴向拆下内护罩的技巧,可以省略或减少包括配合外护罩、C卡圈和汽轮机第二级喷嘴抗转销拆卸的维护步骤。通过减少与C卡圈设计相比所需机加工装置的数量,本方案还使生产简化,同时能够达到同样的加强维护的目的。

从结合目前认为最实际和优选的实施例对本发明进行描述中,可以理解本发明不仅局限于已公开的实施例,相反,本发明试图覆盖包含在从属权利要求的精神和范围内的各种变型和等同方案。

Claims (13)

1.一种多级燃气轮机的定子护罩,其特征在于,包括:

一具有一表面的护罩分段(100),该表面部分地形成贯穿一个涡轮级的热气体通道,且该表面整体布置在构成涡轮转子一部分的所说一个涡轮级的叶片(174)的端部,所说护罩分段具有一进气边和一出气边;

所说护罩分段包括一个外护罩(116)和至少一个与外护罩相连接的内护罩(118);

所说外护罩(116)具有由相邻的且沿着每个所说进气边和出气边形成的凹槽(126、128),所说凹槽沿轴向同向开口;

所说内护罩(118)具有一进气边轴向伸出的短小突出部(154)和一出气边轴向伸出的短小突出部(156),该突出部分别与所说外护罩的所说凹槽(126、128)接合,所说接合沿轴向和径向将所说内护罩(118)锁紧到所说外护罩(116)上;和

一抗转销(152),该抗转销穿过所说外护罩(116)内形成的孔(148),伸入在所说内护罩(118)内形成的对应插孔(150),沿圆周方向将所说内护罩锁紧到所说外护罩上,所述孔通过所述外护罩而被限定,以便当所述内护罩被径向地锁紧到所述外护罩上时所述销从所述外护罩是易于移动。

2.根据权利要求1所述的定子护罩,其特征是:所说凹槽(126、128)沿轴向上游方向开口。

3.根据权利要求1所述的定子护罩,包括三个与所说外护罩(116)固定的所说内护罩(118)。

4.根据权利要求1所述的定子护罩,还包括由所说内和外护罩的内壁表面形成的冷却剂腔以及一冲击板(124),该冲击板置于所说内和外护罩(118、116)之间,以冲击冷却所说内护罩的所说内壁表面。

5.根据权利要求1所述的定子护罩,其特征是:所说外护罩的径向外部具有一楔形榫结构(130),该结构与相邻的涡轮机壳体(142)的楔形槽结构(132)接合。

6.一定子护罩分段,其特征在于,包括:

一外护罩(116),该外护罩具有一进气边和一出气边,以及径向内和径向外面,所说外护罩包括一进气边钩状物(120)和一出气边钩状物(122),所说外护罩的两个所说钩状物沿第一轴向突出;

多个内护罩(118),每个内护罩都具有一进气边和一出气边,以及径向内和径向外面,所说内护罩包括一进气边钩状物(110)和一出气边钩状物(112),所说内护罩的两个所说钩状物沿第二轴向突出,该第二轴向与所说第一轴向正好相反;

每个所说内护罩的所说进气和出气钩状物都分别与所说外护罩的所说进气和出气钩状物接合,所说接合沿轴向和径向将所说内护罩锁紧到所说外护罩上;和

一抗转销(152),其穿过所述外护罩的进气边内形成的孔(148),伸入在所述内护罩(118)的所述进气边钩状物(110)内形成的对应插孔(150),沿圆周方向将所述内护罩锁紧到所述外护罩上,所述孔通过所述外护罩而被限定,以便当所述内护罩被径向地锁紧到所述外护罩上时所述销从所述外护罩是易于移动。

7.根据权利要求7所述的定子护罩分段,其特征在于,所述第一轴向是上游方向。

8.根据权利要求7所述的定子护罩分段,还包括三个被固定到所述外护罩上的内护罩(118)。

9.根据权利要求7所述的定子护罩分段,还包括形成在所述外护罩的径向内表面和所述内护罩的径向外表面之间的冷却剂腔,以及一种冲击板(124),该冲击板置于所述内和外护罩之间,以冲击冷却所述内护置的径向外表面。

10.根据权利要求7所述的定子护罩分段,其特征在于,所述外护罩的径向外部具有一楔形榫结构(130),该结构与相邻的涡轮机壳体(142)的相应的楔形槽结构(132)接合。

11.根据权利要求6所述的定子护罩分段,其特征是:所说外护罩的所说进气边钩状物和出气边钩状物(120、122)分别形成进气和出气凹槽(126、128),该凹槽沿所说第一方向开口,以分别容纳所说内护罩的所说进气和出气边钩状物(110、112)。

12.一种从外护罩分离和拆下第一内护罩(118)的方法,其中,内护罩具有进气边钩状物(110)和出气边钩状物(112),外护罩具有与所说第一内护罩的所说进气和出气边钩状物相互接合的进气凹槽(126)和出气凹槽(128),所说第一内护罩的所说进气和出气边钩状物沿同一轴向突出,所说方法包括:

拆下或沿轴向移动在所说第一内护罩(118)上游侧上的配合件(172);

拆下与所说第一内护罩和所说外护罩接合的第一内护罩抗转销(152);

从周边相近的内护罩取出抗转销,且滑动周边相近的内护罩,直到它们之间的织物密封脱开为止;

沿轴向(箭头A)滑动所说第一内护罩,将所说进气和出气边钩状物从所说外护罩的所说进气和出气边钩状物上拆下;以及

沿径向(箭头R)移动所说第一内护罩,脱开和拆下所说第一内护罩。

13.根据权利要求12所说的方法,其特征是:所说第一内护罩的所说钩状物沿轴向向下游方向突出,并且所说沿轴向滑动所说第一内护罩的步骤包括向上游方向滑动所说第一内护罩。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/348010 | 2003-01-22 | ||

| US10/348,010 US6814538B2 (en) | 2003-01-22 | 2003-01-22 | Turbine stage one shroud configuration and method for service enhancement |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1532376A CN1532376A (zh) | 2004-09-29 |

| CN100359137C true CN100359137C (zh) | 2008-01-02 |

Family

ID=31495629

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB2004100282019A Expired - Lifetime CN100359137C (zh) | 2003-01-22 | 2004-01-22 | 涡轮机级的第一级护罩结构和加强维护的方法 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US6814538B2 (zh) |

| JP (1) | JP4375027B2 (zh) |

| KR (1) | KR100836978B1 (zh) |

| CN (1) | CN100359137C (zh) |

| CZ (1) | CZ306302B6 (zh) |

| RU (1) | RU2335640C2 (zh) |

| SE (1) | SE527552C2 (zh) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106321170A (zh) * | 2015-05-11 | 2017-01-11 | 通用电气公司 | 具有键接固持夹的护罩固持系统 |

| US9932901B2 (en) | 2015-05-11 | 2018-04-03 | General Electric Company | Shroud retention system with retention springs |

Families Citing this family (59)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ITMI20022418A1 (it) * | 2002-11-15 | 2004-05-16 | Nuovo Pignone Spa | Assieme migliorato di cassa interna a dispositivo di |

| US6942203B2 (en) * | 2003-11-04 | 2005-09-13 | General Electric Company | Spring mass damper system for turbine shrouds |

| FR2869070B1 (fr) * | 2004-04-15 | 2008-10-17 | Snecma Moteurs Sa | Anneau de turbine |

| FR2869943B1 (fr) * | 2004-05-04 | 2006-07-28 | Snecma Moteurs Sa | Ensemble a anneau fixe d'une turbine a gaz |

| ITMI20041779A1 (it) * | 2004-09-17 | 2004-12-17 | Nuovo Pignone Spa | Dispositivo di protezione di uno statore di una turbina |

| US7296966B2 (en) * | 2004-12-20 | 2007-11-20 | General Electric Company | Methods and apparatus for assembling gas turbine engines |

| US7452183B2 (en) * | 2005-08-06 | 2008-11-18 | General Electric Company | Thermally compliant turbine shroud assembly |

| US7338253B2 (en) * | 2005-09-15 | 2008-03-04 | General Electric Company | Resilient seal on trailing edge of turbine inner shroud and method for shroud post impingement cavity sealing |

| FR2891583B1 (fr) * | 2005-09-30 | 2010-06-18 | Snecma | Turbine comportant des secteurs d'etancheite demontables par l'amont |

| FR2891862B1 (fr) * | 2005-10-12 | 2011-02-25 | Snecma | Plaque perforee a disposer dans une cavite de refroidissement d'anneau de turbine |

| US7811054B2 (en) * | 2007-05-30 | 2010-10-12 | General Electric Company | Shroud configuration having sloped seal |

| US8240980B1 (en) | 2007-10-19 | 2012-08-14 | Florida Turbine Technologies, Inc. | Turbine inter-stage gap cooling and sealing arrangement |

| US8616827B2 (en) | 2008-02-20 | 2013-12-31 | Rolls-Royce Corporation | Turbine blade tip clearance system |

| US8500394B2 (en) | 2008-02-20 | 2013-08-06 | United Technologies Corporation | Single channel inner diameter shroud with lightweight inner core |

| US8256228B2 (en) * | 2008-04-29 | 2012-09-04 | Rolls Royce Corporation | Turbine blade tip clearance apparatus and method |

| US20100290891A1 (en) * | 2009-05-14 | 2010-11-18 | General Electric Company | Component Cooling Through Seals |

| US8317465B2 (en) * | 2009-07-02 | 2012-11-27 | General Electric Company | Systems and apparatus relating to turbine engines and seals for turbine engines |

| US20110044803A1 (en) * | 2009-08-18 | 2011-02-24 | Pratt & Whitney Canada Corp. | Blade outer air seal anti-rotation |

| US9062565B2 (en) * | 2009-12-31 | 2015-06-23 | Rolls-Royce Corporation | Gas turbine engine containment device |

| US8753073B2 (en) * | 2010-06-23 | 2014-06-17 | General Electric Company | Turbine shroud sealing apparatus |

| US8998573B2 (en) * | 2010-10-29 | 2015-04-07 | General Electric Company | Resilient mounting apparatus for low-ductility turbine shroud |

| US8985944B2 (en) * | 2011-03-30 | 2015-03-24 | General Electric Company | Continuous ring composite turbine shroud |

| EP2508713A1 (en) * | 2011-04-04 | 2012-10-10 | Siemens Aktiengesellschaft | Gas turbine comprising a heat shield and method of operation |

| US8647055B2 (en) * | 2011-04-18 | 2014-02-11 | General Electric Company | Ceramic matrix composite shroud attachment system |

| US20130034436A1 (en) * | 2011-08-02 | 2013-02-07 | General Electric Company | Systems, Method, and Apparatus for Modifying a Turbine Casing |

| US9810086B2 (en) * | 2011-11-06 | 2017-11-07 | General Electric Company | Asymmetric radial spline seal for a gas turbine engine |

| US9890648B2 (en) | 2012-01-05 | 2018-02-13 | General Electric Company | Turbine rotor rim seal axial retention assembly |

| US8845285B2 (en) | 2012-01-10 | 2014-09-30 | General Electric Company | Gas turbine stator assembly |

| US8905708B2 (en) | 2012-01-10 | 2014-12-09 | General Electric Company | Turbine assembly and method for controlling a temperature of an assembly |

| US9316109B2 (en) * | 2012-04-10 | 2016-04-19 | General Electric Company | Turbine shroud assembly and method of forming |

| JP5997834B2 (ja) * | 2012-04-27 | 2016-09-28 | ゼネラル・エレクトリック・カンパニイ | ガスタービンエンジンのシュラウドアセンブリおよびシール |

| US20140064969A1 (en) * | 2012-08-29 | 2014-03-06 | Dmitriy A. Romanov | Blade outer air seal |

| US9238977B2 (en) | 2012-11-21 | 2016-01-19 | General Electric Company | Turbine shroud mounting and sealing arrangement |

| US9863264B2 (en) * | 2012-12-10 | 2018-01-09 | General Electric Company | Turbine shroud engagement arrangement and method |

| EP2959117B1 (en) | 2013-02-23 | 2019-07-03 | Rolls-Royce North American Technologies, Inc. | Blade clearance control for gas turbine engine |

| CN103133063A (zh) * | 2013-03-01 | 2013-06-05 | 哈尔滨汽轮机厂有限责任公司 | 重型中低热值燃机涡轮第一级动叶护环冷却机构 |

| US9488110B2 (en) * | 2013-03-08 | 2016-11-08 | General Electric Company | Device and method for preventing leakage of air between multiple turbine components |

| US20140271142A1 (en) | 2013-03-14 | 2014-09-18 | General Electric Company | Turbine Shroud with Spline Seal |

| EP2835500A1 (de) * | 2013-08-09 | 2015-02-11 | Siemens Aktiengesellschaft | Einsatzelement und Gasturbine |

| EP2907977A1 (de) * | 2014-02-14 | 2015-08-19 | Siemens Aktiengesellschaft | Heißgasbeaufschlagbares Bauteil für eine Gasturbine sowie Dichtungsanordnung mit einem derartigen Bauteil |

| BR112016028858A2 (pt) | 2014-06-12 | 2017-08-22 | Gen Electric | ?conjuntos de suspensor e tubo base? |

| WO2016133486A1 (en) * | 2015-02-16 | 2016-08-25 | Siemens Aktiengesellschaft | Ring segment system for gas turbine engines |

| US9863265B2 (en) | 2015-04-15 | 2018-01-09 | General Electric Company | Shroud assembly and shroud for gas turbine engine |

| US9945242B2 (en) * | 2015-05-11 | 2018-04-17 | General Electric Company | System for thermally isolating a turbine shroud |

| JP5886465B1 (ja) * | 2015-09-08 | 2016-03-16 | 三菱日立パワーシステムズ株式会社 | シール部材の組付構造及び組付方法、シール部材、ガスタービン |

| US9988936B2 (en) * | 2015-10-15 | 2018-06-05 | General Electric Company | Shroud assembly for a gas turbine engine |

| US10184342B2 (en) * | 2016-04-14 | 2019-01-22 | General Electric Company | System for cooling seal rails of tip shroud of turbine blade |

| US20180340437A1 (en) * | 2017-02-24 | 2018-11-29 | General Electric Company | Spline for a turbine engine |

| US10655495B2 (en) | 2017-02-24 | 2020-05-19 | General Electric Company | Spline for a turbine engine |

| US10648362B2 (en) * | 2017-02-24 | 2020-05-12 | General Electric Company | Spline for a turbine engine |

| US20180355741A1 (en) * | 2017-02-24 | 2018-12-13 | General Electric Company | Spline for a turbine engine |

| US11466700B2 (en) * | 2017-02-28 | 2022-10-11 | Unison Industries, Llc | Fan casing and mount bracket for oil cooler |

| US10280801B2 (en) * | 2017-06-15 | 2019-05-07 | General Electric Company | Turbine component and turbine shroud assembly |

| US10502093B2 (en) * | 2017-12-13 | 2019-12-10 | Pratt & Whitney Canada Corp. | Turbine shroud cooling |

| US11111806B2 (en) * | 2018-08-06 | 2021-09-07 | Raytheon Technologies Corporation | Blade outer air seal with circumferential hook assembly |

| US10982559B2 (en) * | 2018-08-24 | 2021-04-20 | General Electric Company | Spline seal with cooling features for turbine engines |

| US10907487B2 (en) | 2018-10-16 | 2021-02-02 | Honeywell International Inc. | Turbine shroud assemblies for gas turbine engines |

| US10927694B2 (en) * | 2019-03-13 | 2021-02-23 | Raytheon Technologies Corporation | BOAS carrier with cooling supply |

| US11959389B2 (en) * | 2021-06-11 | 2024-04-16 | Pratt & Whitney Canada Corp. | Turbine shroud segments with angular locating feature |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5169287A (en) * | 1991-05-20 | 1992-12-08 | General Electric Company | Shroud cooling assembly for gas turbine engine |

| US5993150A (en) * | 1998-01-16 | 1999-11-30 | General Electric Company | Dual cooled shroud |

| US6126389A (en) * | 1998-09-02 | 2000-10-03 | General Electric Co. | Impingement cooling for the shroud of a gas turbine |

Family Cites Families (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1484936A (en) | 1974-12-07 | 1977-09-08 | Rolls Royce | Gas turbine engines |

| US4177004A (en) * | 1977-10-31 | 1979-12-04 | General Electric Company | Combined turbine shroud and vane support structure |

| US4551064A (en) | 1982-03-05 | 1985-11-05 | Rolls-Royce Limited | Turbine shroud and turbine shroud assembly |

| US4573866A (en) | 1983-05-02 | 1986-03-04 | United Technologies Corporation | Sealed shroud for rotating body |

| US4752184A (en) | 1986-05-12 | 1988-06-21 | The United States Of America As Represented By The Secretary Of The Air Force | Self-locking outer air seal with full backside cooling |

| US5022816A (en) | 1989-10-24 | 1991-06-11 | United Technologies Corporation | Gas turbine blade shroud support |

| JPH03213602A (ja) | 1990-01-08 | 1991-09-19 | General Electric Co <Ge> | ガスタービンエンジンの当接セグメントを連結する自己冷却式ジョイント連結構造 |

| US5127793A (en) | 1990-05-31 | 1992-07-07 | General Electric Company | Turbine shroud clearance control assembly |

| GB9103809D0 (en) | 1991-02-23 | 1991-04-10 | Rolls Royce Plc | Blade tip clearance control apparatus |

| US5165847A (en) | 1991-05-20 | 1992-11-24 | General Electric Company | Tapered enlargement metering inlet channel for a shroud cooling assembly of gas turbine engines |

| US5197853A (en) | 1991-08-28 | 1993-03-30 | General Electric Company | Airtight shroud support rail and method for assembling in turbine engine |

| FR2691749B1 (fr) | 1992-05-27 | 1994-07-22 | Snecma | Dispositif d'etancheite entre des etages d'aubes et un tambour tournant notamment pour eviter les fuites autour des etages d'aubes de redresseur . |

| US5333992A (en) | 1993-02-05 | 1994-08-02 | United Technologies Corporation | Coolable outer air seal assembly for a gas turbine engine |

| US5423659A (en) | 1994-04-28 | 1995-06-13 | United Technologies Corporation | Shroud segment having a cut-back retaining hook |

| US5609469A (en) | 1995-11-22 | 1997-03-11 | United Technologies Corporation | Rotor assembly shroud |

| US6116852A (en) * | 1997-12-11 | 2000-09-12 | Pratt & Whitney Canada Corp. | Turbine passive thermal valve for improved tip clearance control |

| US6113349A (en) | 1998-09-28 | 2000-09-05 | General Electric Company | Turbine assembly containing an inner shroud |

| US6315519B1 (en) | 1998-09-28 | 2001-11-13 | General Electric Company | Turbine inner shroud and turbine assembly containing such inner shroud |

| US6402466B1 (en) | 2000-05-16 | 2002-06-11 | General Electric Company | Leaf seal for gas turbine stator shrouds and a nozzle band |

| US6340285B1 (en) * | 2000-06-08 | 2002-01-22 | General Electric Company | End rail cooling for combined high and low pressure turbine shroud |

-

2003

- 2003-01-22 US US10/348,010 patent/US6814538B2/en not_active Expired - Lifetime

-

2004

- 2004-01-13 CZ CZ2004-57A patent/CZ306302B6/cs not_active IP Right Cessation

- 2004-01-16 SE SE0400080A patent/SE527552C2/sv not_active IP Right Cessation

- 2004-01-20 KR KR1020040004108A patent/KR100836978B1/ko active IP Right Grant

- 2004-01-21 RU RU2004101931/06A patent/RU2335640C2/ru active

- 2004-01-22 CN CNB2004100282019A patent/CN100359137C/zh not_active Expired - Lifetime

- 2004-01-22 JP JP2004013751A patent/JP4375027B2/ja not_active Expired - Lifetime

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5169287A (en) * | 1991-05-20 | 1992-12-08 | General Electric Company | Shroud cooling assembly for gas turbine engine |

| US5993150A (en) * | 1998-01-16 | 1999-11-30 | General Electric Company | Dual cooled shroud |

| US6126389A (en) * | 1998-09-02 | 2000-10-03 | General Electric Co. | Impingement cooling for the shroud of a gas turbine |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106321170A (zh) * | 2015-05-11 | 2017-01-11 | 通用电气公司 | 具有键接固持夹的护罩固持系统 |

| US9932901B2 (en) | 2015-05-11 | 2018-04-03 | General Electric Company | Shroud retention system with retention springs |

| CN106321170B (zh) * | 2015-05-11 | 2018-07-03 | 通用电气公司 | 具有键接固持夹的护罩固持系统 |

Also Published As

| Publication number | Publication date |

|---|---|

| RU2004101931A (ru) | 2005-07-10 |

| JP2004225698A (ja) | 2004-08-12 |

| SE0400080L (sv) | 2004-07-23 |

| JP4375027B2 (ja) | 2009-12-02 |

| KR20040067995A (ko) | 2004-07-30 |

| CZ306302B6 (cs) | 2016-11-23 |

| SE0400080D0 (sv) | 2004-01-16 |

| US20040141838A1 (en) | 2004-07-22 |

| SE527552C2 (sv) | 2006-04-04 |

| KR100836978B1 (ko) | 2008-06-10 |

| CZ200457A3 (cs) | 2005-05-18 |

| US6814538B2 (en) | 2004-11-09 |

| RU2335640C2 (ru) | 2008-10-10 |

| CN1532376A (zh) | 2004-09-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN100359137C (zh) | 涡轮机级的第一级护罩结构和加强维护的方法 | |

| US10450951B2 (en) | Cyclonic separator for a turbine engine | |

| US7354241B2 (en) | Rotor assembly with cooling air deflectors and method | |

| EP0626036B1 (en) | Improved cooling fluid ejector | |

| US20110070074A1 (en) | Gas turbine with a shroud and labyrinth-type sealing arrangement | |

| CN108252748B (zh) | 涡轮发动机诱导器组件 | |

| US7811054B2 (en) | Shroud configuration having sloped seal | |

| EP3002410B1 (en) | A bladed rotor arrangement with lock plates and seal plates | |

| EP2586996B1 (en) | Turbine bucket angel wing features for forward cavity flow control and related method | |

| US8657574B2 (en) | System and method for cooling a turbine bucket | |

| CN101684736A (zh) | 用于涡轮机械的护罩 | |

| CN110735667B (zh) | 用于涡轮机的涡轮转子的密封组件以及相应的涡轮 | |

| EP2415971B1 (en) | A seal assembly | |

| US9784116B2 (en) | Turbine shroud assembly | |

| US20110318187A1 (en) | Sealing device | |

| EP1229213A1 (en) | Stationary blade shroud of a gas turbine | |

| US5333992A (en) | Coolable outer air seal assembly for a gas turbine engine | |

| KR102482623B1 (ko) | 침입 손실을 제어하기 위한 터빈 버킷 플랫폼 | |

| EP2904241B1 (en) | Combustor seal mistake-proofing for a gas turbine engine | |

| US20120114458A1 (en) | Shroud leakage cover | |

| EP2649279B1 (en) | Fluid flow machine especially gas turbine penetrated axially by a hot gas stream | |

| CN103573300A (zh) | 静止燃气涡轮布置和用于执行维护工作的方法 | |

| JP2004286016A (ja) | タービンエンジンを組み立てる方法及び装置 | |

| US10816014B2 (en) | Systems and methods for turbine engine particle separation | |

| US6375417B1 (en) | Moisture removal pocket for improved moisture removal efficiency |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CX01 | Expiry of patent term | ||

| CX01 | Expiry of patent term |

Granted publication date: 20080102 |