JP2004286016A - タービンエンジンを組み立てる方法及び装置 - Google Patents

タービンエンジンを組み立てる方法及び装置 Download PDFInfo

- Publication number

- JP2004286016A JP2004286016A JP2003411122A JP2003411122A JP2004286016A JP 2004286016 A JP2004286016 A JP 2004286016A JP 2003411122 A JP2003411122 A JP 2003411122A JP 2003411122 A JP2003411122 A JP 2003411122A JP 2004286016 A JP2004286016 A JP 2004286016A

- Authority

- JP

- Japan

- Prior art keywords

- bucket assembly

- rotor

- assembly

- bucket

- dovetail

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000000034 method Methods 0.000 title claims abstract description 14

- 238000011144 upstream manufacturing Methods 0.000 claims abstract description 33

- 230000000712 assembly Effects 0.000 claims description 11

- 238000000429 assembly Methods 0.000 claims description 11

- 230000008878 coupling Effects 0.000 abstract description 2

- 238000010168 coupling process Methods 0.000 abstract description 2

- 238000005859 coupling reaction Methods 0.000 abstract description 2

- 238000003780 insertion Methods 0.000 description 20

- 230000037431 insertion Effects 0.000 description 20

- 210000002105 tongue Anatomy 0.000 description 12

- 238000005553 drilling Methods 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 238000010079 rubber tapping Methods 0.000 description 2

- 239000012530 fluid Substances 0.000 description 1

- 238000003754 machining Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/30—Fixing blades to rotors; Blade roots ; Blade spacers

- F01D5/32—Locking, e.g. by final locking blades or keys

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/005—Repairing methods or devices

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/30—Fixing blades to rotors; Blade roots ; Blade spacers

- F01D5/3023—Fixing blades to rotors; Blade roots ; Blade spacers of radial insertion type, e.g. in individual recesses

- F01D5/303—Fixing blades to rotors; Blade roots ; Blade spacers of radial insertion type, e.g. in individual recesses in a circumferential slot

- F01D5/3038—Fixing blades to rotors; Blade roots ; Blade spacers of radial insertion type, e.g. in individual recesses in a circumferential slot the slot having inwardly directed abutment faces on both sides

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/30—Fixing blades to rotors; Blade roots ; Blade spacers

- F01D5/3053—Fixing blades to rotors; Blade roots ; Blade spacers by means of pins

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/60—Assembly methods

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/60—Assembly methods

- F05D2230/64—Assembly methods using positioning or alignment devices for aligning or centring, e.g. pins

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

Abstract

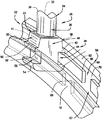

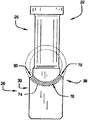

【解決手段】 タービン10を組み立てる方法は、少なくとも1つのバケット組立体22を結合する段階を含む。バケット組立体は、上流側面38と、下流側面39と、それらの間で延びるブレード26と、ブレードからロータ12まで半径方向内向きに延びるダブテール28とを含む。この方法は更に、バケット組立体の上流側面から該バケット組立体の下流側面まで延びる剪断ピン74を用いて、少なくとも1つのバケット組立体をロータにしっかり固定する段階を含む。

【選択図】 図4

Description

26 ブレード

28 ダブテール

40 第1の接線方向面

41 第2の接線方向面

76 第1の溝

82 第2の溝

Claims (10)

- タービン(10)を組み立てる方法であって、

上流側面(38)と、下流側面(39)と、前記上流及び下流側面間で延びるブレード(26)と、前記ブレードからロータ(12)まで半径方向内向きに延びるダブテール(28)とを備える少なくとも1つのバケット組立体(22)を結合する段階と、

前記バケット組立体の上流側面から該バケット組立体の下流側面まで延びる剪断ピン(74)を用いて、前記少なくとも1つのバケット組立体を前記ロータにしっかりと固定する段階と、

を含むことを特徴とする方法。 - 前記バケット組立体の上流側面(38)から該バケット組立体の下流側面(39)まで延びるように溝(76)を形成する段階を更に含むことを特徴とする、請求項1に記載の方法。

- 前記少なくとも1つのバケット組立体(22)を前記ロータ(12)にしっかりと固定する前記段階が、弓形断面形状を有する剪断ピン(74)を前記溝(76)に挿入する段階を含むことを特徴とする、請求項2に記載の方法。

- その各々が前記バケット組立体の上流側面(38)から該バケット組立体の下流側面(39)まで延びる複数の溝(76、82)を形成する段階を更に含むことを特徴とする、請求項1に記載の方法。

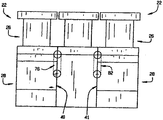

- タービン(10)用のロータ組立体(12)であって、

ロータに固定され、少なくとも第1のバケット組立体と少なくとも第2のバケット組立体とを含み、その各々が、上流側面(38)と、下流側面(39)と、ブレード(26)と、ダブテール(28)とを含み、前記ブレードの各々が前記ダブテールの各々から半径方向に延びている複数のバケット組立体(22)と、

前記バケット組立体の上流側面から該バケット組立体の下流側面まで延びた状態で、前記第1のバケット組立体を前記ロータに固定するための少なくとも1つの剪断ピン(74)と、

を含むことを特徴とするロータ組立体。 - 前記剪断ピン(74)が、弓形断面形状を備えることを特徴とする、請求項5に記載のロータ組立体(12)。

- 前記第2のバケット組立体(22)が、前記ダブテール(28)によって前記ロータに固定されていることを特徴とする、請求項6に記載のロータ組立体(12)。

- 少なくとも1つのロータを含む少なくとも1つのロータ組立体(12)と、

前記ロータに固定され、少なくとも1つの第1のバケット組立体と少なくとも1つの第2のバケット組立体とを含み、その各々が、上流側面(38)と、下流側面(39)と、ブレード(26)と、ダブテール(28)とを含み、前記ブレードの各々が前記ダブテールから半径方向に延びている複数のバケット組立体(22)と、

前記バケット組立体の上流側面から該バケット組立体の下流側面まで延びた状態で、前記少なくとも1つの第1のバケット組立体を前記ロータに固定するための少なくとも1つの剪断ピン(74)と、

を含むことを特徴とするタービン(10)。 - 前記少なくとも1つの剪断ピン(74)が、弓形断面形状を備えることを特徴とする、請求項8に記載のタービン(10)。

- 前記少なくとも1つの第2のバケット組立体(22)が、前記バケット組立体のダブテール(28)によって前記ロータ(12)のフック(66)に固定されていることを特徴とする、請求項8に記載のタービン(10)。

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/316,473 US6893224B2 (en) | 2002-12-11 | 2002-12-11 | Methods and apparatus for assembling turbine engines |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2004286016A true JP2004286016A (ja) | 2004-10-14 |

| JP2004286016A5 JP2004286016A5 (ja) | 2007-02-01 |

Family

ID=32505953

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003411122A Ceased JP2004286016A (ja) | 2002-12-11 | 2003-12-10 | タービンエンジンを組み立てる方法及び装置 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US6893224B2 (ja) |

| JP (1) | JP2004286016A (ja) |

| CN (1) | CN100343489C (ja) |

| IT (1) | ITMI20032387A1 (ja) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008534841A (ja) * | 2005-03-24 | 2008-08-28 | シーメンス デマーク デラヴァル ターボマシナリー インコーポレイテッド | 半径方向差込みタービン翼の固定装置 |

| JP2012067746A (ja) * | 2010-09-21 | 2012-04-05 | General Electric Co <Ge> | タービンエンジンで用いるロータ組立体及びこの組立方法 |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7517195B2 (en) * | 2006-04-25 | 2009-04-14 | General Electric Company | Nested turbine bucket closure group |

| US7704044B1 (en) * | 2006-11-28 | 2010-04-27 | Florida Turbine Technologies, Inc. | Turbine blade with attachment shear inserts |

| EP2075417B1 (fr) * | 2007-12-27 | 2016-04-06 | Techspace Aero | Plateforme pour une roue aubagée de turbomachine, roue aubagée et compresseur ou turbomachine comportant une telle roue aubagée |

| JP4929316B2 (ja) * | 2009-07-13 | 2012-05-09 | 三菱重工業株式会社 | 回転体 |

| US20120244002A1 (en) * | 2011-03-25 | 2012-09-27 | Hari Krishna Meka | Turbine bucket assembly and methods for assembling same |

| FR2975124B1 (fr) * | 2011-05-09 | 2013-05-24 | Snecma | Virole annulaire de moteur d'aeronef comportant une fenetre d'introduction d'aubes |

| US9068465B2 (en) * | 2012-04-30 | 2015-06-30 | General Electric Company | Turbine assembly |

| US9212559B2 (en) * | 2012-09-07 | 2015-12-15 | United Technologies Corporation | Electrical grounding for blades |

| EP2808490A1 (en) * | 2013-05-29 | 2014-12-03 | Alstom Technology Ltd | Turbine blade with locking pin |

| CN104696021B (zh) * | 2015-02-27 | 2016-09-28 | 北京全四维动力科技有限公司 | 汽轮机动叶片锁口装置和方法、采用其的叶片及汽轮机 |

| US10738626B2 (en) | 2017-10-24 | 2020-08-11 | General Electric Company | Connection assemblies between turbine rotor blades and rotor wheels |

| CN110145372B (zh) * | 2019-05-25 | 2021-08-10 | 立德动力设备(浙江)有限公司 | 一种汽轮机转子叉形叶片安装结构及其安装方法 |

| US11555407B2 (en) | 2020-05-19 | 2023-01-17 | General Electric Company | Turbomachine rotor assembly |

| CN112943381B (zh) * | 2021-03-17 | 2023-07-04 | 中国航发动力股份有限公司 | 一种用于带凸肩转子叶片装配的防护装置 |

Family Cites Families (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2220918A (en) * | 1938-08-27 | 1940-11-12 | Gen Electric | Elastic fluid turbine bucket wheel |

| US2445154A (en) * | 1944-03-04 | 1948-07-13 | Ingersoll Rand Co | Blade mounting |

| GB706618A (en) * | 1950-06-22 | 1954-03-31 | Power Jets Res & Dev Ltd | Improvements in or relating to rotors for turbines and similarly bladed fluid flow machines |

| US2800298A (en) * | 1951-04-19 | 1957-07-23 | Schellens True Corp | Turbine wheel |

| CH408056A (de) * | 1962-11-23 | 1966-02-28 | Goerlitzer Maschinenbau Veb | Befestigung der Laufschaufeln von Kreiselmaschinen, insbesondere für trommelartige Verdichterläufer von Gasturbinen |

| US3737250A (en) * | 1971-06-16 | 1973-06-05 | Us Navy | Fiber blade attachment |

| JPS57151004A (en) * | 1981-03-13 | 1982-09-18 | Hitachi Ltd | Fall-off stopper of moving blade |

| US4702673A (en) | 1985-10-18 | 1987-10-27 | General Electric Company | Method for assembly of tangential entry dovetailed bucket assemblies on a turbomachine bucket wheel |

| US4676723A (en) | 1986-03-26 | 1987-06-30 | Westinghouse Electric Corp. | Locking system for a turbine side entry blade |

| US4767275A (en) | 1986-07-11 | 1988-08-30 | Westinghouse Electric Corp. | Locking pin system for turbine curved root side entry closing blades |

| US4711007A (en) | 1986-09-29 | 1987-12-08 | Westinghouse Electric Corp. | Method and apparatus for installing free standing turbine blades |

| US4767273A (en) | 1987-02-24 | 1988-08-30 | Westinghouse Electric Corp. | Apparatus and method for reducing blade flop in steam turbine |

| US4767247A (en) | 1987-02-24 | 1988-08-30 | Westinghouse Electric Corp. | Apparatus and method for preventing relative blade motion in steam turbine |

| US4915587A (en) | 1988-10-24 | 1990-04-10 | Westinghouse Electric Corp. | Apparatus for locking side entry blades into a rotor |

| US5062769A (en) * | 1989-11-22 | 1991-11-05 | Ortolano Ralph J | Connector for turbine element |

| GB2313162B (en) * | 1996-05-17 | 2000-02-16 | Rolls Royce Plc | Bladed rotor |

| US5720596A (en) | 1997-01-03 | 1998-02-24 | Westinghouse Electric Corporation | Apparatus and method for locking blades into a rotor |

| US6030178A (en) | 1998-09-14 | 2000-02-29 | General Electric Co. | Axial entry dovetail segment for securing a closure bucket to a turbine wheel and methods of installation |

| US6168377B1 (en) | 1999-01-27 | 2001-01-02 | General Electric Co. | Method and apparatus for eliminating thermal bowing of steam turbine rotors |

| US6158102A (en) | 1999-03-24 | 2000-12-12 | General Electric Co. | Apparatus and methods for aligning holes through wheels and spacers and stacking the wheels and spacers to form a turbine rotor |

| US6287079B1 (en) | 1999-12-03 | 2001-09-11 | Siemens Westinghouse Power Corporation | Shear pin with locking cam |

| US6439844B1 (en) | 2000-12-11 | 2002-08-27 | General Electric Company | Turbine bucket cover and brush seal |

| US6416286B1 (en) | 2000-12-28 | 2002-07-09 | General Electric Company | System and method for securing a radially inserted integral closure bucket to a turbine rotor wheel assembly having axially inserted buckets |

-

2002

- 2002-12-11 US US10/316,473 patent/US6893224B2/en not_active Expired - Fee Related

-

2003

- 2003-12-05 IT IT002387A patent/ITMI20032387A1/it unknown

- 2003-12-10 JP JP2003411122A patent/JP2004286016A/ja not_active Ceased

- 2003-12-11 CN CNB2003101204027A patent/CN100343489C/zh not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008534841A (ja) * | 2005-03-24 | 2008-08-28 | シーメンス デマーク デラヴァル ターボマシナリー インコーポレイテッド | 半径方向差込みタービン翼の固定装置 |

| JP2012067746A (ja) * | 2010-09-21 | 2012-04-05 | General Electric Co <Ge> | タービンエンジンで用いるロータ組立体及びこの組立方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1512037A (zh) | 2004-07-14 |

| ITMI20032387A1 (it) | 2004-06-12 |

| CN100343489C (zh) | 2007-10-17 |

| US6893224B2 (en) | 2005-05-17 |

| US20040115052A1 (en) | 2004-06-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4375027B2 (ja) | 整備性を向上させるためのタービンステージ1のシュラウド構成及び方法 | |

| CN1894485B (zh) | 用于在轴向方向上拆下和安装燃气涡轮机的所选喷嘴段的装置和方法 | |

| JP2004286016A (ja) | タービンエンジンを組み立てる方法及び装置 | |

| US9238970B2 (en) | Blade outer air seal assembly leading edge core configuration | |

| JP6408888B2 (ja) | タービンバケット閉鎖組立体及びその組立方法 | |

| KR101643476B1 (ko) | 터빈의 교체용 버켓 조립체 및 이의 교체방법 | |

| US8894372B2 (en) | Turbine rotor insert and related method of installation | |

| JP6412112B2 (ja) | ターボ機械ロータ組立体及び方法 | |

| JP2006083849A (ja) | ガスタービンエンジンロータ組立体を組立てるための方法及び装置 | |

| US10533425B2 (en) | Doublet vane assembly for a gas turbine engine | |

| US6364613B1 (en) | Hollow finger dovetail pin and method of bucket attachment using the same | |

| US20150064008A1 (en) | Turbomachine bucket having angel wing for differently sized discouragers and related methods | |

| US6761537B1 (en) | Methods and apparatus for assembling turbine engines | |

| JP2015117698A (ja) | 軸方向挿入式バケットをロータアセンブリに固定するシステム及び方法 | |

| EP2540988B1 (en) | Blade outer air seal with a plug assembly and method | |

| EP2372085A2 (en) | Internal reaction steam turbine cooling arrangement | |

| US9540955B2 (en) | Stator assembly | |

| JP2008051101A (ja) | 蒸気タービン用のロータ及びタービンエンジン | |

| US20150104320A1 (en) | Turbine with bucket fixing means | |

| JP2005195021A (ja) | 高温蒸気タービン用の低重量コントロール段 | |

| US8668439B2 (en) | Inserts for turbine cooling circuit | |

| EP3061909A1 (en) | Rotor shaft with cooling bore inlets |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20061211 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20061211 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090409 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090414 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20090714 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20090714 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20090714 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20090721 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20090814 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20090819 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20090911 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20090916 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091013 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100216 |

|

| A045 | Written measure of dismissal of application [lapsed due to lack of payment] |

Free format text: JAPANESE INTERMEDIATE CODE: A045 Effective date: 20100622 |