WO2022030426A1 - たばこ製品用の香味成分含有溶液の製造方法及び製造装置 - Google Patents

たばこ製品用の香味成分含有溶液の製造方法及び製造装置 Download PDFInfo

- Publication number

- WO2022030426A1 WO2022030426A1 PCT/JP2021/028547 JP2021028547W WO2022030426A1 WO 2022030426 A1 WO2022030426 A1 WO 2022030426A1 JP 2021028547 W JP2021028547 W JP 2021028547W WO 2022030426 A1 WO2022030426 A1 WO 2022030426A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- aerosol

- plant material

- tobacco

- producing

- flavor component

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24B—MANUFACTURE OR PREPARATION OF TOBACCO FOR SMOKING OR CHEWING; TOBACCO; SNUFF

- A24B15/00—Chemical features or treatment of tobacco; Tobacco substitutes, e.g. in liquid form

- A24B15/10—Chemical features of tobacco products or tobacco substitutes

- A24B15/16—Chemical features of tobacco products or tobacco substitutes of tobacco substitutes

- A24B15/167—Chemical features of tobacco products or tobacco substitutes of tobacco substitutes in liquid or vaporisable form, e.g. liquid compositions for electronic cigarettes

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24B—MANUFACTURE OR PREPARATION OF TOBACCO FOR SMOKING OR CHEWING; TOBACCO; SNUFF

- A24B15/00—Chemical features or treatment of tobacco; Tobacco substitutes, e.g. in liquid form

- A24B15/18—Treatment of tobacco products or tobacco substitutes

- A24B15/24—Treatment of tobacco products or tobacco substitutes by extraction; Tobacco extracts

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24B—MANUFACTURE OR PREPARATION OF TOBACCO FOR SMOKING OR CHEWING; TOBACCO; SNUFF

- A24B15/00—Chemical features or treatment of tobacco; Tobacco substitutes, e.g. in liquid form

- A24B15/18—Treatment of tobacco products or tobacco substitutes

- A24B15/24—Treatment of tobacco products or tobacco substitutes by extraction; Tobacco extracts

- A24B15/26—Use of organic solvents for extraction

Definitions

- the present invention relates to a method and an apparatus for producing a flavor component-containing solution for tobacco products.

- Patent Document 1 discloses a process for obtaining a tobacco-flavored extract, in which the process heats a tobacco mixture to a temperature of about 30 ° C to about 90 ° C for about 30 seconds to about 1 hour for conditioning. Includes the process of doing.

- Patent Document 2 discloses a method of extracting a volatile component from a tobacco material and a method of producing a pre-vapor preparation containing the extracted volatile component, in which the method uses the tobacco material at about 50 ° C to about 250 ° C. It is described to include heating to a temperature in the range of, recovering the volatile matter from the heated tobacco material, and combining the volatile matter with the prevapor formulation after the recovery step.

- the tobacco material is heated at a low temperature (about 30 ° C to about 90 ° C), and it is expected that the flavor component contained in the tobacco material cannot be sufficiently recovered.

- the recovery of the volatile component generated by heating the tobacco material is carried out by adsorbing and absorbing the volatile component on an absorbent material such as an activated carbon absorbent material or other microporous material. Or by condensing volatile components.

- an absorbent material such as an activated carbon absorbent material or other microporous material.

- a separate absorbent material may be required, or volatile components may be lost during the process of condensation.

- the high heating temperature may generate unwanted flavor components.

- the present invention provides a method for producing a flavor component-containing solution for tobacco products, which can efficiently collect flavor components derived from plant materials and does not contain undesired flavor components as much as possible, and an apparatus for producing the same.

- the task is to do.

- the present inventor has made a step of bringing an aerosol composed of an aerosol substrate containing at least one of glycerin and propylene glycol into contact with a plant material heated to 180 ° C. to 220 ° C., and the said plant material.

- the method including the step of collecting the aerosol after contact the flavor component derived from the plant material can be efficiently collected, and the flavor component derived from the plant material is not contained as much as possible for the tobacco product.

- the gist of the present invention is as follows. [1] A step of bringing an aerosol composed of an aerosol base material containing at least one of glycerin and propylene glycol into contact with a plant material heated to 180 ° C. to 220 ° C., and an aerosol after contacting with the plant material. A method for producing an aerosol containing an aerosol for a tobacco product, including a collection step. [2] The method for producing a flavor component-containing solution for a tobacco product according to [1], wherein the aerosol base material is at least one selected from glycerin, propylene glycol and a mixture thereof.

- [6] The method for producing a flavor component-containing solution for a tobacco product according to any one of [1] to [5], wherein the plant material contains a flavor expression aid.

- [7] The method for producing a flavor component-containing solution for a tobacco product according to any one of [1] to [6], wherein the plant material contains a polyol.

- [8] The method for producing a flavor component-containing solution for a tobacco product according to any one of [1] to [7], wherein the plant material is in a chopped state or a crushed state.

- [9] The method for producing a flavor component-containing solution for a tobacco product according to [8], wherein the plant material is reconstituted into a granule shape or a sheet shape after being chopped or crushed. ..

- the method for producing a flavor component-containing solution for a tobacco product (hereinafter, also simply referred to as the production method of the present invention), which is an embodiment of the present invention, is composed of an aerosol substrate containing at least one of glycerin and propylene glycol. It comprises a step of contacting the aerosol with a plant material heated to 180 ° C. to 220 ° C. and a step of collecting the aerosol after contacting the plant material.

- an aerosol composed of an aerosol substrate containing at least one of glycerin and propylene glycol is brought into contact with a plant material heated to a predetermined temperature.

- the aerosol can be produced by converting the aerosol base material into an aerosol with an appropriate aerosol generator.

- the aerosol substrate is a liquid that produces an aerosol when heated and contains at least one of glycerin and propylene glycol. At least one of glycerin and propylene glycol means that the embodiment is selected from glycerin alone, propylene glycol alone and a mixture thereof.

- the total content of glycerin and propylene glycol in the aerosol substrate is preferably 90% by weight or more, more preferably 95% by weight or more, and particularly preferably 100% by weight. The above weight% does not consider water as an impurity.

- the aerosol substrate is composed of glycerin alone, propylene glycol alone, or a mixture of glycerin and propylene glycol.

- the aerosol base material is a mixture of glycerin and propylene glycol.

- the mixing ratio of glycerin and propylene glycol is not particularly limited, but it is preferable to mix them so that the weight of propylene glycol is 1 to 9 when the weight of glycerin is 1. It is more preferable to mix them so as to be.

- the aerosol generator is not particularly limited as long as it can aerosolize the above aerosol base material, but for example, a reservoir for storing the generated base material, an electric load for atomizing the aerosol base material, and a reservoir. It includes a wick that draws the aerosol base material from the load onto the load, and an aerosol flow path that flows the aerosol generated by atomizing the aerosol base material and connects to the plant material filling layer filled with the plant material described later. Can be mentioned.

- the reservoir stores the aerosol substrate.

- the reservoir may contain a porous body such as a resin web or cotton, and the aerosol base material may be impregnated into the porous body.

- the reservoir may not contain the porous material on the resin web or cotton, but may contain only the aerosol substrate.

- the load is a member that atomizes the aerosol base material with electric power supplied from an appropriate power source without combustion.

- the load can be exemplified as a load composed of a heating wire (coil) wound at a predetermined pitch.

- the load may be any element that can generate aerosol by atomizing the aerosol base material, and is, for example, a heat generating element or an ultrasonic generator. Examples of the heat generating element include a heat generating resistor, a ceramic heater, an induction heating type heater, and the like.

- the temperature of the aerosol obtained by atomizing the aerosol base material is usually 20 ° C. or higher and lower than 290 ° C. Among them, the temperature is particularly preferably 30 ° C. or higher, and more preferably 38 ° C. or higher.

- the upper limit is preferably a temperature lower than the boiling point of the aerosol substrate. For example, assuming that glycerin is contained alone as the aerosol base material, the upper limit may be less than 290 ° C. On the other hand, assuming that propylene glycol is contained alone as the aerosol base material, the upper limit may be less than 188 ° C.

- the upper limit temperature of the atomized aerosol can be, for example, less than 188 ° C., which is the boiling point of propylene glycol. Further, the upper limit of the temperature of the aerosol may be less than 180 ° C. Further, it is preferable to set the aerosol temperature lower than the heating temperature of the plant material so that the temperature of the plant material does not become higher than the set heating temperature.

- the wick may be a liquid holding member that draws an aerosol base material into a load from a reservoir by utilizing a capillary phenomenon, and may be made of, for example, glass fiber or a porous ceramic.

- the aerosol flow path is arranged on the downstream side of the load and is connected to a packed bed filled with the plant material so as to come into contact with the plant material described later.

- the temperature of the above aerosol is such that the thermocouple is inserted from the outside of the flow path at the position just before the inlet of the packed bed filled with the plant material in the aerosol flow path connecting the aerosol generator and the packed bed filled with the plant material. Can be found at. According to this method, the temperature of the mixed fluid of aerosol and air is measured, and in the present specification, this temperature is referred to as the temperature of the aerosol.

- the aerosol produced from the aerosol base material is brought into contact with the plant material heated to a predetermined temperature.

- the flavor component contained in the plant material can be transferred to the aerosol.

- a method of preparing a packed bed filled with the plant material and distributing the aerosol in the packed bed can be used.

- a packed bed an embodiment in which various forms of plant materials described below are filled in a cylindrical container having an inlet and an outlet for circulating an aerosol can be mentioned as a packed bed.

- the cross-sectional (cross-sectional) shape of the tubular container may be a circle, an ellipse, a polygon, or the like.

- the contact of the aerosol with the plant material may be performed in an environment such as a fluidized bed in which the aerosol is jetted into the container from the lower part and the plant material comes into contact with the aerosol at a high frequency in the container.

- the plant material to be brought into contact with the aerosol needs to be heated to 180 ° C to 220 ° C. When the plant material is below 180 ° C., the flavor components contained in the plant material are not sufficiently transferred to the aerosol.

- the temperature of the tobacco material can be controlled by heating the heater by arranging a heater around the packed bed.

- the temperature of the tobacco material can be adjusted by adjusting the temperature of the container in which the aerosol and the plant material come into contact.

- the production method of the present invention comprises the step of collecting the aerosol after contact with the plant material.

- the step of collecting the aerosol may be, for example, a step of condensing the aerosol into a liquid and collecting the aerosol.

- the aerosol may be condensed by means of cooling the aerosol.

- a cooling device using a known refrigerant can be used, or a means using a cooling agent such as liquid nitrogen or dry ice can be mentioned, and the temperature thereof may be about ⁇ 200 ° C. to 10 ° C. can.

- the aerosol may be efficiently collected in the collecting step by setting the system to negative pressure.

- Plant material In the production method of the present invention, the flavor component contained in the plant material is transferred to the aerosol by bringing the aerosol into contact with the plant material.

- Plant materials include tobacco ingredients, acai berries, alfalfa, all spices, anato seeds, Vietnamese oil, basil, bee balm, wild bergamot, black pepper, blue berries, borage oil, ezo white root, cacao, caramas root, dog mint, cuttlefish, kaien.

- Pepper Charga, Charville, Cinnamon, Dark Chocolate, Potato Peel, Rooibos, Ginkgo, Peppermint, Rooibos, Green Tea, Black Tea, Black Cohosh, Kaien, Chamomile, Chome, Cocoa, Cranberry, Dandelion, Grapefruit, Honey Bush, Echinacea, Garlic, pine yoigusa, nutshirogiku, ginger, golden seal, sanzashi, hibiscus flower, sweet kudzu, cava, lavender, kanzo, mayorana, azalea, mint (mainte), oolong tea, orange, oregano, papaya, penny royal, peppermint, red clover , Rooibos (red or green), rose hips, rosemary, sage, clary sage, savory, speppermint, spirulina, sorghum blanc high tannin species, sorghum grain high tannin species , Wild yam roots, winter greens, yacon roots,

- the plant material contains at least one selected from the mesophyll, veins, stems, roots, flowers, seeds and fruits of the above plants.

- grape seeds, beet roots, comfrey bark, comfrey leaves and roots, wild yam roots, yacon roots can also be used.

- a tobacco material is used as a plant material, various types of tobacco can be used. For example, yellow varieties, Burley varieties, Orient varieties, native varieties, other Nicotiana-Tabacam varieties, Nicotiana rustica varieties, and mixtures thereof can be mentioned. Also, these types of tobacco lamina, middle bones, stems, flowers or roots can be used.

- nicotine can be mentioned as the main flavor component.

- the carved state is a plant material carved by an appropriate means, and examples of the size thereof include a width of 0.5 mm or more and a width of 2.0 mm or less. Further, the length of the carved plant material may be in the range of 0.5 mm or more and 30.0 mm or less.

- the crushed state is a state in which the individual size of the plant material is crushed to a state smaller than the above-mentioned chopped state by an appropriate means, and the particle size thereof is, for example, 200 ⁇ m or more.

- the average particle size is preferably 300 ⁇ m or less.

- This average particle size can be measured using a particle size distribution measuring device (for example, a master sizer manufactured by Spectris).

- the pulverization can also be performed through a plurality of steps such as coarse pulverization and then fine pulverization.

- the mixed state of the plant materials can be easily made uniform by coarsely pulverizing the plant materials and then finely pulverizing the plant materials.

- the average particle size after coarse pulverization can be, for example, 300 ⁇ m or more and 2 mm or less.

- the average particle size when coarsely pulverized can be measured using a multi-stage sieve. It is also possible to use the plant material after coarse grinding without going through the fine grinding step.

- the above-mentioned carved state or crushed state may be a processed one that has been reconstructed into a sheet shape described later. In that case, the size can be the same as the range described above.

- the plant material preferably further contains a polyol.

- the flavor component contained in the plant material can be more efficiently transferred to the aerosol. This is because the partial pressure of the polyol in the packed bed of the plant material increases during extraction due to the inclusion of the polyol, the volatilization of the flavor component is promoted, and the extraction efficiency is increased.

- the polyol is preferably added to the plant material by external addition. Examples of the polyol include glycerin, propylene glycol, 1,3-butanediol and the like, and a combination of glycerin and propylene glycol is preferable.

- the amount of the polyol added is preferably 1 to 20% by weight, preferably 5 to 10% by weight, based on the dry weight of the plant material, even when any of the above-exemplified ones or a mixture thereof is used. Is more preferable.

- the plant material preferably containing a polyol is the same in any of the following aspects, such as chopped state, crushed state, granule form, or sheet form.

- a flavor-developing aid can be added to the plant material.

- the flavor-developing aid can include at least one of carbonates, bicarbonates, oxides and hydroxides of alkali metals and / or alkaline earth metals.

- the flavoring aid is potassium carbonate or sodium carbonate.

- a plant material For example, 2 to 10 g of a plant material is added with 10 times the weight of distilled water, and water is added at room temperature (for example, 25 ° C.). After shaking the mixture of the mixture with the plant material at 200 rpm for 10 minutes and allowing it to stand for 5 minutes, the pH of the obtained extract can be measured with a pH meter.

- the flavor expression aid may also contain sugars, salts and amino acids.

- sugars, salts and amino acids By including these components as a flavor expression aid, when the plant material is brought to the treatment temperature of the embodiment of the present application, not only the components volatilize but also the reaction of the components is likely to occur, so that a suitable flavor component volatilizes. Can be done.

- the amount of the flavor-developing aid added is preferably 1 to 20% by weight, more preferably 5 to 10% by weight, based on the dry weight of the plant material.

- the tobacco material may be moistened prior to heating or treated with additives, or may be in the form of a slurry or moist tobacco mass.

- Additives may include at least one of a solvent, a flavoring aid, and a flavoring agent.

- Flavoring aids can be added to the tobacco material to release the salt-bound flavoring agent, to cause hydrolysis of the flavoring agent precursor, or both.

- Flavor-developing aids can also accelerate the reaction of components contained in plants. Examples of the reaction include the Maillard reaction. It should be noted that the plant material preferably containing the flavor-developing aid is the same in any of the aspects described below in the chopped state, the crushed state, or the form of the sheet. In the form of the tobacco granules described below, an embodiment containing a flavor-developing aid as the component (c) can be exemplified.

- the plant material is preferably in a state of being pulverized and then reconstituted into granules or sheet shapes.

- the sheet can be appropriately produced by a known method such as papermaking, slurry, rolling, or the like. In addition, all the methods shown below can be suitably applied when tobacco is used as a plant material.

- papermaking it can be manufactured by a method including the following steps. 1) The plant material is coarsely crushed, extracted with water and separated into a water extract and a residue. 2) The water extract is dried under reduced pressure and concentrated. 3) Pulp is added to the residue, fiberized with a refiner, and then made into paper. 4) A concentrated solution of water extract is added to the paper-made sheet and dried to obtain a sheet.

- the slurry method it can be produced by a method including the following steps. 1) Mix water, pulp and binder with crushed plant material. 2) The mixture is thinly spread (cast) and dried.

- a non-woven fabric-like sheet produced by a method including the following steps can also be used. 1) Mix the powdery plant material and the binder. 2) The mixture is sandwiched between non-woven fabrics. 3) The laminate is formed into a constant shape by heat welding to obtain a non-woven fabric-like sheet. Tobacco can be exemplified as the plant material in this case.

- the composition of the sheet is not particularly limited, but for example, the content of the plant material is preferably 50 to 95% by weight based on the total weight of the sheet.

- the sheet may contain a binder, and examples of the binder include guar gum, xanthan gum, CMC (carboxymethyl cellulose), CMC-Na (sodium salt of carboxymethyl cellulose) and the like.

- the amount of binder is preferably 1 to 20% by weight based on the total weight of the sheet.

- the sheet may further contain other additives. Examples of the additive include a filler such as pulp. The content of the filler is not particularly limited, but is preferably 1% by weight or more and 10% by weight or less with respect to the total weight of the tobacco sheet.

- the sheet may contain a polyol, and examples of the polyol include glycerin, propylene glycol, 1,3-butanediol, and the like, and a combination of glycerin and propylene glycol is preferable.

- the amount of the polyol added is preferably 1 to 20% by weight based on a dry weight sheet, even when any of the above-exemplified ones or a mixture thereof is used.

- the plant material may be in the form of granules. Hereinafter, it is also simply referred to as granules.

- the raw materials for the granules are, for example, at least one flavor-developing aid selected from the group consisting of (a) ground plant material, (b) water, (c) potassium carbonate and sodium hydrogen carbonate, and (d). ) At least one binder selected from the group consisting of pullulan and hydroxypropyl cellulose can be mentioned.

- the plant material is preferably tobacco.

- the crushed plant material (component (a)) contained in the raw material of the granules includes the plant material and the above-mentioned crushed sheet. If the plant material is a tobacco material, the types of tobacco include Burley, Yellow and Oriental.

- the crushed plant material is preferably crushed to a size of 20 ⁇ m or more and 300 ⁇ m or less. This average particle size can be measured using a particle size distribution measuring device (for example, a master sizer manufactured by Spectris).

- the water content (component (b)) contained in the granules is for maintaining the integrity of the granules.

- the raw material mixture of granules usually contains water in an amount of 3% by weight or more and 13% by weight or less.

- the granules may contain water in an amount such that the value of dry weight loss is usually 5% by weight or more and 17% by weight or less. Dry weight loss is when a part of the sample is taken for measurement and the sample is completely dried by evaporating the total water content in the collected sample (for example, at a constant temperature (105 ° C.) for 15 minutes.

- the dry weight loss (% by weight) can be expressed by the following formula (1).

- Weight loss by drying (% by weight) ⁇ (Weight of sample before complete drying)-(Weight of sample after complete drying) ⁇ x 100 / Weight of sample before complete drying (1)

- flavor expression aid component (c)

- these flavor-developing aids promote the release of the flavor components contained in the granules from the granules, resulting in a satisfying taste to the user.

- the raw material mixture of granules may contain a flavor-developing aid in an amount of usually 5% by weight or more and 20% by weight or less.

- the binder (component (d)) contained in the granules binds the raw materials of the granules to maintain the integrity of the granules.

- the binder is composed of pullulan, gellan gum, carrageenan, agar, guar gum, roasted bean gum, hydroxypropyl cellulose (HPC), hydroxypropylmethyl cellulose (HPMC), carboxymethyl cellulose (CMC), starch starch, modified starch, or a mixture thereof.

- the raw material mixture of granules may usually contain a binder in an amount of 0.5% by weight or more and 15% by weight or less.

- Granules can be composed of the above components (a), (b), (c) and (d), but may further include additional components.

- the raw material mixture of the granules usually contains the component (a) in an amount of about 20% by weight or more (about 80% by weight). Can be contained in the amount of (below).

- the components (a), (c) and (d) are mixed, the component (b) is added to the mixture and kneaded, and the obtained kneaded product is granulated by a wet extrusion granulator (long). It is obtained by sizing the granules into short columns or spheres after (columnar). In extruding granulation, it is preferable to extrude the kneaded product at an ambient temperature and a pressure of 2 kN or more.

- the temperature of the kneaded product at the outlet of the extruder and granulator rises instantaneously from the ambient temperature to, for example, 90 ° C or higher and 100 ° C or lower, and the water content and volatile components are 2% by weight or more. Evaporates at 4% by weight or less. Therefore, the water to be blended to make the kneaded product can be used in an amount larger than the desired water content in the obtained tobacco granules by the above-mentioned evaporation amount.

- Granules obtained by extrusion granulation may be further dried if necessary for moisture adjustment. For example, if the dry weight loss of the granules obtained by extrusion granulation is measured and it is higher than the desired dry weight loss (eg 5% by weight or more, 17% by weight or less), the tobacco granules to obtain the desired dry weight loss. May be further dried.

- the drying conditions (temperature and time) for obtaining the desired drying weight loss shall be set in advance based on the drying conditions (temperature and time) required to reduce the drying weight loss by a predetermined value. Can be done.

- the apparatus for producing a flavor component-containing solution for a tobacco product of the present invention includes an apparatus for producing an aerosol from an aerosol base material containing at least one of glycerin and propylene glycol, and an apparatus in which a plant material is arranged inside, and the produced aerosol is the said.

- the heater that heats the plant material packing layer to 180 ° C. to 220 ° C., and the aerosol that has passed through the plant material filling layer are captured. It is equipped with a collecting device for collecting.

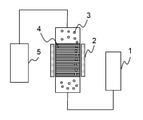

- FIG. 3 shows an outline of one aspect of the manufacturing apparatus.

- the aerosol 3 generated by the aerosol generating device 1 passes through the plant material packed bed 4 heated by the heater 2 and passes through the plant material packed bed 4.

- the aerosol 3 is connected so as to be collected by the collecting device 5.

- an aerosol generating apparatus having the configuration described in the above manufacturing method can be mentioned.

- the configuration described in the above manufacturing method can be used.

- the plant material is arranged inside.

- the plant material to be filled various embodiments described in the above-mentioned production method can be used.

- tobacco is preferred as the plant material.

- the plant material is preferably in contact with the aerosol in the form of chopped, ground, granules, or sheets, and any of these embodiments can form a packed bed. Then, it is preferable to distribute the aerosol in the packed bed.

- the size and shape of the packed bed are not particularly limited. The size and shape of the packed bed may depend on the size and shape of the container for filling the plant material.

- Examples of the container for filling the plant material include a cylindrical container, and examples thereof include a container in which an aerosol inlet and outlet are provided on the bottom surface and the top surface of the tubular container, respectively.

- the cross-sectional (cross-sectional) shape of the tubular container may be a circle, an ellipse, a polygon, or the like.

- the packing density is usually 150 mg / cm 3

- the above is preferably 250 mg / cm 3 or more, and is usually 600 mg / cm 3 or less, preferably 350 mg / cm 3 or less.

- too high a packing density will impede the flow of aerosol into the packed bed. If the filling density is too low, the amount of the object to be extracted is small with respect to the size of the container, which is inefficient.

- the packed bed of plant material is heated to 180 ° C. to 220 ° C. by a heater.

- the heater is capable of directly or indirectly heating the packed bed of plant material.

- it may be a sheet heater, an infrared heater, or an IH heater.

- the sheet-shaped heater is a flexible sheet-shaped heater, and examples thereof include a ribbon heater that generates heat due to electric resistance.

- an IH heater by mixing a susceptor such as metal powder in the packed bed of plant material, it is possible to heat not only from the metal container into which the packed bed is inserted but also from the inside of the packed bed.

- the above-mentioned sheet-shaped heater, infrared heater, and IH heater can be used.

- an IH heater or the like can be used.

- the set temperature of the heater is not particularly limited as long as the temperature at which the packed bed of the plant material is heated to 180 ° C to 220 ° C.

- the temperature of the packed bed of plant material (product temperature) can be measured by inserting a thermometer into the packed bed of plant material.

- the aerosol produced by the aerosol generator passes through the inside of the packed bed of the plant material heated to 180 ° C. to 220 ° C., so that the plant material and the aerosol come into contact with each other. Then, the flavor component contained in the plant material is transferred to the aerosol, and the aerosol is collected by the collecting device described below.

- the aerosol collection device collects the aerosol that has passed through the packed bed of plant material. Examples of the device for collecting the aerosol include a device including a means for cooling the aerosol and a container for containing the liquid condensed by the cooling. As such a device, a so-called cold trap can be mentioned.

- the means for cooling is not particularly limited, and examples thereof include a method using a cooling device using a known refrigerant and a method using a cooling agent such as liquid nitrogen and dry ice.

- a cooling temperature about ⁇ 200 ° C. to 10 ° C. can be mentioned.

- the condensed aerosol becomes a liquid and is collected in the contained solution provided in the collecting device.

- Engraved sheet tobacco (thickness approx. 300 ⁇ m, engraved width 0.8 mm, length 0.5 to 30.0 mm)

- Engraved sheet The raw material composition of the excised sheet is 66% by weight of crushed tobacco.

- An electric furnace manufactured by Oji Shokai

- the heating temperature was controlled by a temperature controller (Temperature controller TJA-50 manufactured by AS ONE), and when the temperature reached a predetermined temperature, the predetermined carriers shown in Table 1 were allowed to flow through the tobacco packed bed at a flow rate of 55 mL / 2 sec.

- the temperature of the aerosol circulated in the tobacco packed bed was 30 ° C.

- the temperature of the aerosol was determined by inserting a thermocouple from the outside of the pipe at a position immediately before the inlet of the tobacco filling layer of the pipe connecting the aerosol generator and the tobacco filling layer, and measuring the temperature of the mixed fluid of the aerosol and air. Further, in Examples 1 to 3, the experiment was carried out after adjusting the aerosol concentration in the carrier so as to be substantially uniform. The air, vapor or aerosol that circulated through the packed bed of tobacco was trapped in an ice-bathed tube, and the liquid was recovered for analysis.

- Nicotine contained in the recovered liquid was quantified using GC-MS (Agilent 7890B).

- nicotine in the packed bed was extracted from the tobacco packing with a solvent (methanol), and then nicotine was quantified using GC-MS (7890B manufactured by Agilent).

- Table 1 shows the recovery rate of nicotine at each carrier and each temperature. In conclusion, it was found that nicotine can be recovered most efficiently by circulating propylene glycol and glycerin aerosols as compared to air.

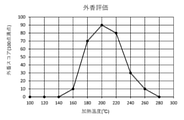

- FIG. 1 shows the relationship between the heating temperature of the packed bed and the amount of nicotine recovered when each carrier was used.

- the horizontal axis shows the heating temperature of the packed bed

- the vertical axis shows the amount of nicotine recovered. From the results of FIG. 1, it can be seen that the amount of nicotine recovered increases when the temperature of the packed bed is 180 ° C. or higher.

- the packed bed used in each test was prepared by filling the same tobacco raw material with the same packed amount.

- the amount of nicotine recovered is the weight of nicotine in the liquid trapped in the ice-cooled tube. Nicotine extracted from the packed bed of tobacco partially adheres to the inner wall of the pipe connecting the ice-cooled tube, which is the collecting device, and the packed bed. Therefore, in this experiment, all the nicotine extracted from the packed bed of tobacco is used. Was not counted as a nicotine recovery.

- Aerosol generator 1 Aerosol generator 2 Heater 3 Aerosol 4 Plant material packed bed 5 Collection device

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Manufacture Of Tobacco Products (AREA)

- Vaporization, Distillation, Condensation, Sublimation, And Cold Traps (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2022541522A JP7436681B2 (ja) | 2020-08-03 | 2021-08-02 | たばこ製品用の香味成分含有溶液の製造方法及び製造装置 |

| EP21852168.0A EP4190423B1 (en) | 2020-08-03 | 2021-08-02 | Production method and production apparatus for solution containing flavor ingredient for tobacco product |

| JP2024017750A JP2024050860A (ja) | 2020-08-03 | 2024-02-08 | たばこ製品用の香味成分含有溶液の製造方法及び製造装置 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020-131388 | 2020-08-03 | ||

| JP2020131388 | 2020-08-03 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2022030426A1 true WO2022030426A1 (ja) | 2022-02-10 |

Family

ID=80117997

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2021/028547 Ceased WO2022030426A1 (ja) | 2020-08-03 | 2021-08-02 | たばこ製品用の香味成分含有溶液の製造方法及び製造装置 |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP4190423B1 (enExample) |

| JP (2) | JP7436681B2 (enExample) |

| TW (1) | TW202215987A (enExample) |

| WO (1) | WO2022030426A1 (enExample) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2023188331A1 (ja) * | 2022-03-31 | 2023-10-05 | 日本たばこ産業株式会社 | ポリオールを含むたばこ抽出組成物およびその製造方法 |

| JPWO2023188342A1 (enExample) * | 2022-03-31 | 2023-10-05 | ||

| WO2023188340A1 (ja) * | 2022-03-31 | 2023-10-05 | 日本たばこ産業株式会社 | たばこ抽出組成物およびその製造方法 |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN119745106A (zh) * | 2024-12-31 | 2025-04-04 | 湖北中烟工业有限责任公司 | 一种烟草薄片及其制备方法和加热卷烟 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014104078A1 (ja) | 2012-12-28 | 2014-07-03 | 日本たばこ産業株式会社 | 非燃焼吸引型たばこ製品用香味源及び非燃焼吸引型たばこ製品 |

| WO2015129098A1 (ja) * | 2014-02-26 | 2015-09-03 | 日本たばこ産業株式会社 | たばこ原料の製造方法 |

| JP2020519274A (ja) * | 2017-05-15 | 2020-07-02 | ブリティッシュ アメリカン タバコ (インヴェストメンツ) リミテッドBritish American Tobacco (Investments) Limited | タバコ抽出物を作製する方法 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5074319A (en) * | 1990-04-19 | 1991-12-24 | R. J. Reynolds Tobacco Company | Tobacco extraction process |

| CA2069687A1 (en) * | 1991-06-28 | 1992-12-29 | Chandra Kumar Banerjee | Tobacco smoking article with electrochemical heat source |

| GB201418817D0 (en) * | 2014-10-22 | 2014-12-03 | British American Tobacco Co | Apparatus and method for generating an inhalable medium, and a cartridge for use therewith |

| CN109567260A (zh) * | 2019-01-25 | 2019-04-05 | 四川三联新材料有限公司 | 一种热释烟草颗粒的制备方法以及热释烟草颗粒 |

| HUE064418T2 (hu) * | 2019-06-05 | 2024-03-28 | Philip Morris Products Sa | Javított eljárás folyékony dohányextraktum elõállítására |

-

2021

- 2021-08-02 TW TW110128383A patent/TW202215987A/zh unknown

- 2021-08-02 WO PCT/JP2021/028547 patent/WO2022030426A1/ja not_active Ceased

- 2021-08-02 JP JP2022541522A patent/JP7436681B2/ja active Active

- 2021-08-02 EP EP21852168.0A patent/EP4190423B1/en active Active

-

2024

- 2024-02-08 JP JP2024017750A patent/JP2024050860A/ja active Pending

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014104078A1 (ja) | 2012-12-28 | 2014-07-03 | 日本たばこ産業株式会社 | 非燃焼吸引型たばこ製品用香味源及び非燃焼吸引型たばこ製品 |

| WO2015129098A1 (ja) * | 2014-02-26 | 2015-09-03 | 日本たばこ産業株式会社 | たばこ原料の製造方法 |

| JP2020519274A (ja) * | 2017-05-15 | 2020-07-02 | ブリティッシュ アメリカン タバコ (インヴェストメンツ) リミテッドBritish American Tobacco (Investments) Limited | タバコ抽出物を作製する方法 |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2023188331A1 (ja) * | 2022-03-31 | 2023-10-05 | 日本たばこ産業株式会社 | ポリオールを含むたばこ抽出組成物およびその製造方法 |

| JPWO2023188342A1 (enExample) * | 2022-03-31 | 2023-10-05 | ||

| WO2023188340A1 (ja) * | 2022-03-31 | 2023-10-05 | 日本たばこ産業株式会社 | たばこ抽出組成物およびその製造方法 |

| WO2023188342A1 (ja) * | 2022-03-31 | 2023-10-05 | 日本たばこ産業株式会社 | たばこ抽出組成物およびその製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP4190423B1 (en) | 2025-12-03 |

| JP7436681B2 (ja) | 2024-02-22 |

| JP2024050860A (ja) | 2024-04-10 |

| JPWO2022030426A1 (enExample) | 2022-02-10 |

| TW202215987A (zh) | 2022-05-01 |

| EP4190423A4 (en) | 2024-10-02 |

| EP4190423A1 (en) | 2023-06-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP7436681B2 (ja) | たばこ製品用の香味成分含有溶液の製造方法及び製造装置 | |

| JP6968974B2 (ja) | タバコ成分放出部材 | |

| RU2675474C1 (ru) | Материал, образующий аэрозоль, и устройства, включающие такой материал | |

| CN108366614B (zh) | 烟草组合物 | |

| JP2025011146A (ja) | エアロゾル生成材料 | |

| CN114554876B (zh) | 改进的烟草风味干粉制剂 | |

| JP2023523911A (ja) | エアロゾル生成材料 | |

| JP2025011167A (ja) | エアロゾル生成材料 | |

| KR20240032084A (ko) | 담배 제품의 향미료 담지 구성 부재 및 이의 제조 방법 | |

| JP2023546653A (ja) | 非燃焼型エアロゾル供給システムにおける使用のための物品 | |

| JP2022535507A (ja) | 改善された液体タバコ抽出物の生産方法 | |

| JP2024504277A (ja) | 乾燥エアロゾル生成材料及びその使用 | |

| KR102782712B1 (ko) | 비연소형 향미 흡인기용의 담배 마스터배치 및 이를 포함하는 담배 재료 | |

| JP2025500197A (ja) | エアロゾル生成材料 | |

| CN118119294A (zh) | 用于与不可燃气溶胶供应装置一起使用的消耗品 | |

| JP2024504989A (ja) | エアロゾル生成材料及びその使用 | |

| KR20230071786A (ko) | 담배 조성물들 및 이의 제조 | |

| RU2824928C1 (ru) | Сухой порошковый состав со вкусом табака и способ его получения, а также порошковая система (варианты) | |

| JP2023530843A (ja) | 送達システム及び送達システムに含まれる組成物 | |

| WO2021106040A1 (ja) | たばこ材料の製造方法、シート、非燃焼加熱型香味吸引器具及び非燃焼加熱型香味吸引システム | |

| RU2841143C1 (ru) | Способ получения жидкого табачного экстракта | |

| RU2815279C2 (ru) | Способ получения жидкого экстракта табака | |

| RU2845206C1 (ru) | Способ получения жидкого табачного экстракта | |

| TW202519134A (zh) | 乾燥賦形顆粒、製造其之方法及其用途 | |

| WO2025135105A1 (ja) | 香味発生物品の使用方法及び香味発生システム |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 21852168 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2022541522 Country of ref document: JP Kind code of ref document: A |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2021852168 Country of ref document: EP |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 2021852168 Country of ref document: EP Effective date: 20230303 |

|

| WWG | Wipo information: grant in national office |

Ref document number: 2021852168 Country of ref document: EP |