WO2021054286A1 - 空調室内機 - Google Patents

空調室内機 Download PDFInfo

- Publication number

- WO2021054286A1 WO2021054286A1 PCT/JP2020/034722 JP2020034722W WO2021054286A1 WO 2021054286 A1 WO2021054286 A1 WO 2021054286A1 JP 2020034722 W JP2020034722 W JP 2020034722W WO 2021054286 A1 WO2021054286 A1 WO 2021054286A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- air

- indoor unit

- mode

- wind direction

- adjusting plate

- Prior art date

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F1/00—Room units for air-conditioning, e.g. separate or self-contained units or units receiving primary air from a central station

- F24F1/0007—Indoor units, e.g. fan coil units

- F24F1/0011—Indoor units, e.g. fan coil units characterised by air outlets

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F11/00—Control or safety arrangements

- F24F11/30—Control or safety arrangements for purposes related to the operation of the system, e.g. for safety or monitoring

- F24F11/41—Defrosting; Preventing freezing

- F24F11/43—Defrosting; Preventing freezing of indoor units

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F11/00—Control or safety arrangements

- F24F11/62—Control or safety arrangements characterised by the type of control or by internal processing, e.g. using fuzzy logic, adaptive control or estimation of values

- F24F11/63—Electronic processing

- F24F11/65—Electronic processing for selecting an operating mode

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F11/00—Control or safety arrangements

- F24F11/70—Control systems characterised by their outputs; Constructional details thereof

- F24F11/72—Control systems characterised by their outputs; Constructional details thereof for controlling the supply of treated air, e.g. its pressure

- F24F11/74—Control systems characterised by their outputs; Constructional details thereof for controlling the supply of treated air, e.g. its pressure for controlling air flow rate or air velocity

- F24F11/755—Control systems characterised by their outputs; Constructional details thereof for controlling the supply of treated air, e.g. its pressure for controlling air flow rate or air velocity for cyclical variation of air flow rate or air velocity

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F11/00—Control or safety arrangements

- F24F11/70—Control systems characterised by their outputs; Constructional details thereof

- F24F11/72—Control systems characterised by their outputs; Constructional details thereof for controlling the supply of treated air, e.g. its pressure

- F24F11/79—Control systems characterised by their outputs; Constructional details thereof for controlling the supply of treated air, e.g. its pressure for controlling the direction of the supplied air

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F11/00—Control or safety arrangements

- F24F11/70—Control systems characterised by their outputs; Constructional details thereof

- F24F11/80—Control systems characterised by their outputs; Constructional details thereof for controlling the temperature of the supplied air

- F24F11/81—Control systems characterised by their outputs; Constructional details thereof for controlling the temperature of the supplied air by controlling the air supply to heat-exchangers or bypass channels

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F11/00—Control or safety arrangements

- F24F11/70—Control systems characterised by their outputs; Constructional details thereof

- F24F11/80—Control systems characterised by their outputs; Constructional details thereof for controlling the temperature of the supplied air

- F24F11/83—Control systems characterised by their outputs; Constructional details thereof for controlling the temperature of the supplied air by controlling the supply of heat-exchange fluids to heat-exchangers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F13/00—Details common to, or for air-conditioning, air-humidification, ventilation or use of air currents for screening

- F24F13/08—Air-flow control members, e.g. louvres, grilles, flaps or guide plates

- F24F13/10—Air-flow control members, e.g. louvres, grilles, flaps or guide plates movable, e.g. dampers

- F24F13/14—Air-flow control members, e.g. louvres, grilles, flaps or guide plates movable, e.g. dampers built up of tilting members, e.g. louvre

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F13/00—Details common to, or for air-conditioning, air-humidification, ventilation or use of air currents for screening

- F24F13/08—Air-flow control members, e.g. louvres, grilles, flaps or guide plates

- F24F13/10—Air-flow control members, e.g. louvres, grilles, flaps or guide plates movable, e.g. dampers

- F24F13/14—Air-flow control members, e.g. louvres, grilles, flaps or guide plates movable, e.g. dampers built up of tilting members, e.g. louvre

- F24F13/15—Air-flow control members, e.g. louvres, grilles, flaps or guide plates movable, e.g. dampers built up of tilting members, e.g. louvre with parallel simultaneously tiltable lamellae

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F2120/00—Control inputs relating to users or occupants

- F24F2120/10—Occupancy

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F2120/00—Control inputs relating to users or occupants

- F24F2120/10—Occupancy

- F24F2120/12—Position of occupants

Definitions

- This disclosure relates to an air conditioning indoor unit.

- Patent Document 1 a circulation airflow or a vertical airflow is used as an airflow that evenly air-conditions the entire room without the person feeling the wind, in order to prevent the wind of the air conditioner indoor unit from causing a draft feeling to the person.

- a circulation airflow or a vertical airflow is used as an airflow that evenly air-conditions the entire room without the person feeling the wind, in order to prevent the wind of the air conditioner indoor unit from causing a draft feeling to the person.

- the air-conditioning indoor unit of Patent Document 1 performs air-conditioning by circulating airflow throughout the room, it is not suitable for the user to immediately warm or cool the body. Further, in order to evenly air-condition the entire room by the air-conditioning indoor unit of Patent Document 1, there are restrictions on the floor plan, furniture arrangement, installation location of the air-conditioning indoor unit, and the like.

- the purpose of this disclosure is to enable the user's body to be immediately warmed or cooled while suppressing the feeling of draft.

- the first aspect of the present disclosure is an air-conditioning indoor unit installed in an air-conditioned space and configured to be able to change the direction of the air flow blown out from the outlet (15), and can be switched between a normal mode and a wide mode.

- the control unit (40) is provided with a control unit (40) for performing the above, and the control unit (40) expands the range reached by the air conditioner in the air-conditioned space in the wide mode at least in the vertical direction as compared with the normal mode.

- It is an air-conditioning indoor unit characterized in that the air-conditioning capacity in the wide mode is lower than the air-conditioning capacity in the normal mode.

- the speed of the wind hitting the user is lowered to suppress the draft feeling, and the user's body is immediately warmed by the widened airflow.

- a second aspect of the present disclosure is an air-conditioning indoor unit according to the first aspect, wherein the control unit (40) switches to the normal mode when the wide mode continues for a predetermined time or longer during cooling. Is.

- a third aspect of the present disclosure is, in the first or second aspect, the control unit (40) is based on the presence or absence of a person inside or outside the range reached by the airflow in the wide mode in the air-conditioned space.

- the air-conditioning indoor unit is characterized by switching between the normal mode and the wide mode.

- appropriate air conditioning can be performed based on the presence state of a person in the air conditioning target space.

- a fourth aspect of the present disclosure is a heat exchanger that adjusts the temperature of the air by exchanging heat with the air sucked from the air-conditioned space in any one of the first to third aspects. (13) is further provided, and the control unit (40) lowers the temperature of at least a part of the heat exchanger (13) to be lower than the dew point temperature of the air-conditioned space in the wide mode during cooling. It is an air-conditioning indoor unit characterized by.

- cooling can be performed while dehumidifying.

- a fifth aspect of the present disclosure is, in any one of the first to fourth aspects, the air conditioning chamber, wherein the control unit (40) changes the blowing speed of the air flow in the wide mode. It is a machine.

- an air flow similar to a comfortable natural wind can be blown out.

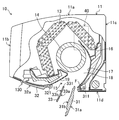

- FIG. 1 is a cross-sectional view of the air conditioner indoor unit according to the embodiment when the operation is stopped.

- FIG. 2 is a cross-sectional view of the air conditioner indoor unit according to the embodiment during operation in the top-blowing mode.

- FIG. 3 is a cross-sectional view of the air conditioner indoor unit according to the embodiment during operation in the oblique blowing mode.

- FIG. 4 is a cross-sectional view of the air conditioner indoor unit according to the embodiment during operation in the wide mode.

- FIG. 5 is a cross-sectional view of the air conditioner indoor unit according to the embodiment during operation in the underblow mode.

- FIG. 6 is a diagram showing the difference between the wide mode and the normal mode in the air conditioner indoor unit according to the embodiment.

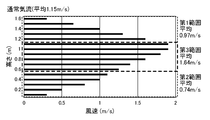

- FIG. 7 is a diagram showing an example of the wind speed distribution of the airflow blown out in the wide mode in the air conditioner indoor unit according to the embodiment.

- FIG. 8 is a diagram showing an example of the wind speed distribution of the airflow blown out in the normal mode in the air conditioner indoor unit according to the embodiment.

- FIG. 9 is a cross-sectional view of the air conditioner indoor unit according to the modified example during operation in the wide mode.

- FIG. 1 is a cross-sectional view of the air-conditioning indoor unit (10) of the present embodiment when the operation is stopped

- FIG. 2 is a cross-sectional view of the air-conditioning indoor unit (10) when the operation is stopped.

- the air-conditioning indoor unit (10) is a wall-mounted type installed on the side wall of the air-conditioning target space.

- the air-conditioning indoor unit (10) mainly includes a main body casing (11), a heat exchanger (13), a fan (14), a bottom frame (16), and a control unit (40).

- the air conditioner indoor unit (10) is configured so that the direction of the airflow blown out from the outlet (15) can be changed.

- the main body casing (11) has a top surface portion (11a), a front panel (11b), a back surface plate (11c), and a bottom surface plate (11d).

- a heat exchanger (13), a fan (14), a bottom frame (16), a control unit (40), etc. are housed inside the main body casing (11).

- the top surface (11a) is located above the main body casing (11).

- a suction port (not shown) is provided on the front portion of the top surface portion (11a).

- the front panel (11b) constitutes the front part of the air conditioning indoor unit (10) and has a flat shape without a suction port.

- the upper end of the front panel (11b) is rotatably supported by the top surface (11a), which allows the front panel (11b) to be hinged.

- the heat exchanger (13) and fan (14) are attached to the bottom frame (16).

- the heat exchanger (13) regulates the temperature of the air by exchanging heat with the passing air.

- the heat exchanger (13) has an inverted V-shape in which both ends are bent downward in a side view, and a fan (14) is located below the heat exchanger (13).

- the fan (14) is, for example, a cross-flow fan, and the air taken in from the room is passed through the heat exchanger (13) and then blown out into the room.

- the bottom plate (11d) is provided with an outlet (15).

- the outlet (15) is a rectangular opening having a long side in the horizontal direction (direction orthogonal to the paper surface in FIG. 1).

- the first wind direction adjusting plate (hereinafter, also referred to as blown air) that changes the direction of the airflow (hereinafter, also referred to as blown air) blown out from the blowout port (15) along the long side of the blowout port (15) on the back plate (11c) side. 31) is rotatably attached.

- the first wind direction adjusting plate (31) may have a length similar to that of the outlet (15) and may be composed of an undivided single plate.

- the first wind direction adjusting plate (31) is driven by a motor (not shown), and can not only change the direction of the blown air but also open and close the blowout port (15).

- the first wind direction adjusting plate (31) can take a plurality of postures having different inclination angles.

- a second wind direction adjustment plate (32) is provided along the long side of the air outlet (15) on the front panel (11b) side.

- the second wind direction adjusting plate (32) may have a length similar to that of the outlet (15) and may be composed of an undivided single plate.

- the second wind direction adjusting plate (32) can take a plurality of postures having different inclination angles in the front-rear direction depending on a motor (not shown).

- the second wind direction adjusting plate (32) is accommodated in the accommodating portion (130) provided on the bottom plate (11d) when the operation is stopped.

- the outlet (15) is connected to the inside of the main body casing (11) by the outlet flow path (18).

- the blowout flow path (18) is formed from the blowout port (15) along the back side scroll (17) of the bottom frame (16).

- the rear scroll (17) is a partition wall forming a part of the bottom frame (16) and is curved so as to face the fan (14).

- the end (F) of the rear scroll (17) is located near the periphery of the outlet (15).

- the main body casing (11) is provided with a front side scroll (19) so as to face the back side scroll (17) with the blowout flow path (18) interposed therebetween.

- the indoor air is sucked into the fan (14) from the suction port of the top surface (11a) via the heat exchanger (13) by the operation of the fan (14), and blows out from the fan (14) to the outlet flow path (18). After that, it is blown out from the outlet (15).

- the air passing through the blowout flow path (18) travels along the rear side scroll (17) and is sent in the tangential direction of the end (F) of the rear side scroll (17).

- the control unit (40) is located, for example, on the side of the heat exchanger (13) and the fan (14) when the main body casing (11) is viewed from the front panel (11b) side.

- the control unit (40) switches the blowout mode described later, controls the rotation speed of the fan (14), controls the operation of the first wind direction adjusting plate (31) and the second wind direction adjusting plate (32), and heat exchanger (13). Temperature control etc.

- a vertical wind direction adjusting plate may be provided closer to the fan (14) than the first wind direction adjusting plate (31) in the blowout flow path (18).

- the vertical wind direction adjusting plate has a plurality of blade pieces and a connecting rod for connecting the plurality of blade pieces.

- the plurality of blade pieces swing left and right around a state perpendicular to the longitudinal direction by horizontally reciprocating the connecting rod along the longitudinal direction of the outlet (15) by a motor (not shown). To do.

- a rotation shaft (311) of the first wind direction adjusting plate (31) is provided on the back plate (11c) side (position below the rear scroll (17)) on the periphery of the outlet (15).

- the root portion of the first wind direction adjusting plate (31) and the rotating shaft (311) are connected at a predetermined interval.

- the rotating shaft (311) is connected to the rotating shaft of a motor (not shown) fixed to the main body casing (11).

- the tip of the first wind direction adjusting plate (31) By rotating the rotating shaft (311) counterclockwise in the front view of FIG. 1, the tip of the first wind direction adjusting plate (31) operates so as to move away from the outlet (15). ) Is opened. On the contrary, when the rotation shaft (311) rotates clockwise in the front view of FIG. 1, the tip of the first wind direction adjusting plate (31) operates so as to approach the outlet (15). Close (15).

- the blown air blown out from the outlet (15) generally reaches the inner surface (31b) of the first wind direction adjusting plate (31). It flows along. That is, the wind direction of the airflow blown out along the tangential direction of the end (F) of the rear scroll (17) is changed by the first wind direction adjusting plate (31).

- the outer surface (32a) of the second wind direction adjusting plate (32) is on an extension of the outer surface of the bottom plate (11d). It is finished like.

- the inner surface (32b) of the second wind direction adjusting plate (32) is finished along the surface of the accommodating portion (130).

- a rotation shaft (321) of the second wind direction adjusting plate (32) is provided on the front panel (11b) side (near the end of the front scroll (19)) on the periphery of the outlet (15). That is, the second wind direction adjusting plate (32) is provided so as to be continuous with the front scroll (19). The root portion of the second wind direction adjusting plate (32) and the rotating shaft (321) are connected.

- the rotating shaft (321) is connected to the rotating shaft of a motor (not shown) fixed to the main body casing (11).

- the tip of the second wind direction adjusting plate (32) is separated from the accommodating portion (130) by rotating the rotating shaft (321) counterclockwise in the front view of FIG. On the contrary, by rotating the rotation shaft (321) clockwise in the front view of FIG. 1, the tip of the second wind direction adjusting plate (32) approaches the accommodating portion (130), and finally the accommodating portion (120). It is housed in 130).

- the air conditioner indoor unit (10) controls the first wind direction adjusting plate (31), the second wind direction adjusting plate (32), etc. in any of the cooling operation, the heating operation, the dehumidifying operation, the humidifying operation, and the blowing operation.

- each blowing mode of "top blowing mode”, “diagonal blowing mode”, “wide mode” and “bottom blowing mode” can be switched between each other.

- top blow mode may be collectively referred to as "normal mode”.

- type of blowing mode and the blowing direction can be selected by the user via a remote controller or the like, or can be automatically set by the control unit (40).

- FIGS. 2 to 5 are cross-sectional views when the air conditioning indoor unit (10) is operated in the "top blow mode”, “diagonal blow mode”, “wide mode”, and “bottom blow mode”, respectively.

- the control unit (40) reaches a position where the inner surface (31b) of the first wind direction adjusting plate (31) faces slightly diagonally downward from the horizontal direction.

- the first wind direction adjusting plate (31) is rotated, and the second wind direction adjusting plate (32a) is directed to a position where the outer surface (32a) of the second wind direction adjusting plate (32) faces slightly diagonally upward from the horizontal direction. 32) is rotated.

- the airflow blown out from the outlet (15) passes between the first wind direction adjusting plate (31) and the second wind direction adjusting plate (32), and travels along the ceiling of the air-conditioned space, and is indoors. It becomes a circulation air flow that circulates throughout.

- the inner surface (31b) of the first wind direction adjusting plate (31) is approximately the end (F) of the rear scroll (17).

- the first wind direction adjusting plate (31) is rotated to a position facing the tangential direction of, and the second wind direction adjusting is adjusted to a position where the outer surface (32a) of the second wind direction adjusting plate (32) faces approximately in the horizontal direction. Rotate the plate (32).

- the airflow blown out from the outlet (15) passes between the first wind direction adjusting plate (31) and the second wind direction adjusting plate (32), and proceeds diagonally downward as it is.

- the amount of blown air can be maximized.

- the inner surface (31b) of the first wind direction adjusting plate (31) is tangent to the end (F) of the rear scroll (17).

- the first wind direction adjusting plate (31) is rotated to a position slightly downward from the direction

- the outer surface (32a) of the second wind direction adjusting plate (32) is slightly diagonally downward from the horizontal direction.

- the second wind direction adjusting plate (32) is rotated to a position facing the direction.

- the first wind direction adjusting plate (31) expands the airflow downward

- the second wind direction adjusting plate (32) expands the airflow upward.

- a first wind direction adjusting plate (31) and a second wind direction adjusting plate (32) are provided so that airflow can pass through the surface (31a) side and the inner surface (32b) side of the second wind direction adjusting plate (32). May be good.

- the inner surface (31b) of the first wind direction adjusting plate (31) is closer to the back plate (11c) side than the vertical downward direction.

- the first wind direction adjusting plate (31) is rotated to a position facing a slightly tilted direction

- the outer surface (32a) of the second wind direction adjusting plate (32) is closer to the back plate (11c) than the vertically downward direction.

- the second wind direction adjusting plate (32) is rotated to a position facing a slightly tilted direction.

- the airflow blown out from the outlet (15) passes between the first wind direction adjusting plate (31) and the second wind direction adjusting plate (32), and travels along the side wall of the air-conditioned space, and is indoors. It becomes a circulation air flow that circulates throughout.

- FIG. 6 is a diagram showing the difference between the “wide mode” and the “normal mode (“diagonal blowing mode”)” in the air conditioning indoor unit (10).

- the air-conditioning indoor unit (10) is installed so that the position of the air-conditioning outlet (15) is at a height of 2 m from the floor surface in the air-conditioned space, and is 1 m ahead of the air-conditioning outlet (15). Assuming that a person with a height of 1.6 m is standing in the above position, the air blown out only to the upper body of the person in the "normal mode".

- the range that the blown air reaches is expanded in the vertical direction compared to the "normal mode", so that the blown air can be applied to the whole body of the person.

- the reference height range is a range of 1600 mm in height from the floor surface at a position separated from the outlet (15) by an arbitrary distance within a range of 1000 mm or more and 2000 mm or less.

- the upper range is located in the first range, the lower range is located in the second range, and the center is located in the center.

- the range is the third range (3)

- the air-conditioning indoor unit (10) is provided on the side wall of the air-conditioning target space so that the center of the air outlet (15) is located 2000 mm above the floor surface.

- the average wind speed in the first range and the average wind speed in the second range are substantially the same, and the average wind speed in the third range is less than 1.5 times the average wind speed in the first range.

- the state of the blown air in the "wide mode” is achieved in a range of at least 1000 mm or more along the direction parallel to the long side of the blowout port (15).

- the average wind speed in the third range is more preferably 0.5 times or more and less than 1.1 times the average wind speed in the first range.

- the average wind speed in the reference height range may be 0.5 m / s or more.

- the width of the outlet (15) may be 150 mm or less.

- the ratio of the turbulent flow region to the entire blown air immediately after being blown out from the blowout port (15) is preferably less than 30%.

- FIG. 7 is a diagram showing an example of the wind speed distribution of the airflow blown out in the “wide mode” in the air conditioning indoor unit (10)

- FIG. 8 is a diagram showing an example of the wind speed distribution of the airflow blown out in the “normal mode” in the air conditioning indoor unit (10). It is a figure which shows an example of the wind speed distribution of an air flow.

- the range of height 1600 mm from the floor surface at a position 1000 mm forward from the outlet (15) is defined as the above-mentioned "reference height range", and the outlet (15) is used.

- the average wind speed in the reference height range is 0.76 m / s

- the average wind speeds in the first to third ranges are 0.84 m / s, 0.85 m / s, and 0.61 m, respectively. / S. Therefore, the average wind speed in the first range (0.84 m / s) and the average wind speed in the second range (0.85 m / s) are substantially the same as each other, and the average wind speed in the first range (0.84 m / s). ),

- the average wind speed (0.61 m / s) in the third range is about 0.73 times, which is less than 1.5 times. That is, the "wide mode" has been achieved.

- the average wind speed in the reference height range is 1.15 m / s

- the average wind speeds in the first to third ranges are 0.97 m / s and 0.74 m / s, respectively. It is .64 m / s. Therefore, the average wind speed in the first range (0.97 m / s) and the average wind speed in the second range (0.74 m / s) are different by 0.2 m / s or more, and the average wind speed in the first range (0.97 m / s) is different.

- the average wind speed (1.64 m / s) in the third range is about 1.69 times, which exceeds 1.5 times, with respect to 0.97 m / s). That is, it is not "wide mode".

- the air conditioning capacity is lowered compared to the "normal mode", thereby, for example, the wind speed of the blown air is increased. It can be made even smaller.

- the control unit (40) starts from the "normal mode".

- the air conditioning capacity of the "wide mode” is made lower than the air conditioning capacity of the "normal mode".

- control unit (40) controls the rotation speed of the fan (14) and the rotation speed of the compressor in the outdoor unit (not shown) so that the air conditioning capacity is reduced.

- the opening degree of the electric valve may be adjusted.

- the airflow area is expanded by using the Coanda effect, so that the airflow area is on the inner surface (31b) of the first wind direction adjusting plate (31) and the outer surface of the second wind direction adjusting plate (32). Airflow separation is likely to occur on (32a). Therefore, during cooling, the cold air and the room temperature air come into contact with each other on the inner surface (31b) of the first wind direction adjusting plate (31) and on the outer surface (32a) of the second wind direction adjusting plate (32), resulting in dew condensation. Is likely to occur.

- control unit (40) may switch to the "normal mode” when the "wide mode” continues for a predetermined time or longer during cooling.

- the air conditioning capacity of the "normal mode” may be increased to the air conditioning capacity before switching to the "wide mode”.

- the "normal mode”, particularly the “top blow mode” and the “bottom blow mode”, are suitable for heating or cooling the entire room by the circulation airflow circulating throughout the room.

- the air-conditioning indoor unit (10), the remote controller, and the like are provided with means for detecting a person, for example, an occupancy sensor, and the control unit (40) is reached by the blown air in the "wide mode” in the air-conditioned space.

- You may switch between "normal mode” and "wide mode” based on the presence or absence of a person inside or outside the range. For example, when the number of people in the room is two or more, the "wide mode" may be switched to the "normal mode”. Further, if there are people only in the "range”, the mode may be switched to the "wide mode", and if there are people in both the "range” and the “other range", the mode may be switched to the "normal mode”. Further, when the number of people in the room decreases, the mode may be switched from the "normal mode” to the "wide mode”.

- control unit (40) may set the temperature of at least a part of the heat exchanger (13) to be lower than the dew point temperature of the air-conditioned space in the “wide mode” during cooling. ..

- control unit (40) may change the blowing speed of the air flow in the "wide mode", for example, 1 / f fluctuation or wind speed jump.

- the blowing speed of the airflow may be changed in the range of 0 to 0.5 m / s.

- the airflow in "wide mode” is an airflow that blows through not only a part of the user's body but also the whole body, so that the user's feeling of comfort is improved.

- the airflow in the "wide mode” is applied to the entire body of the user, the variation in the temperature distribution in the user's body is reduced, so that the burden on the user's body is reduced.

- the reach of the airflow is wider than in the "normal mode”, so it is less likely to be restricted by the floor plan, furniture layout, installation location of the air conditioner indoor unit (10), etc. That is, even if there is an obstacle in the room, the airflow in the "wide mode” easily goes around the obstacle, so that the temperature unevenness in the room is reduced.

- the wind speed of the blown air is lower than in the "normal mode", so the wind can be felt warmer than when the wind speed is high, so even if the blown temperature is the same, you can experience it.

- the temperature can be raised.

- the temperature of the heat exchanger (13) can be lowered, which is effective in saving energy.

- the air conditioner indoor unit (10) of the present embodiment when the control unit (40) switches to the "normal mode” when the "wide mode” continues for a predetermined time or more during cooling, the air conditioner indoor unit is during cooling. It is possible to suppress the formation of dew condensation in (10).

- control unit (40) determines the "normal mode” based on the presence or absence of a person inside or outside the range where the blown air of the "wide mode” reaches in the air-conditioned space. By switching between "" and "wide mode", appropriate air conditioning can be performed based on the presence state of a person in the air-conditioned space.

- control unit (40) sets the temperature of at least a part of the heat exchanger (13) in the "wide mode" during cooling to the dew point temperature of the air-conditioning target space. If it is lower than, it is possible to cool while dehumidifying.

- control unit (40) when the control unit (40) fluctuates the speed of the blown air in the "wide mode", an air flow similar to a comfortable natural wind can be blown out.

- FIG. 9 is a cross-sectional view of the air-conditioning indoor unit (10) of this modified example during operation in the wide mode.

- the same components as those of the air-conditioning indoor unit (10) of the embodiment shown in FIG. 4 are designated by the same reference numerals.

- a third wind direction adjusting plate (33) is provided between the first wind direction adjusting plate (31) and the second wind direction adjusting plate (32) at the mouth (15).

- the outer surface (33a) of the third wind direction adjusting plate (33) faces the inner surface (31b) of the first wind direction adjusting plate (31), and the inner surface (33b) of the third wind direction adjusting plate (33).

- the third wind direction adjusting plate (33) may have a length similar to that of the outlet (15) and may be composed of an undivided single plate.

- a rotation shaft (331) of the third wind direction adjusting plate (33) is provided near the center of the outlet (15) in the short side direction.

- the root portion of the third wind direction adjusting plate (33) and the rotating shaft (331) are connected.

- the rotating shaft (331) is connected to the rotating shaft of a motor (not shown) fixed to the main body casing (11). With the motor, the third wind direction adjusting plate (33) can take a plurality of postures having different inclination angles in the front-rear direction.

- the tip of the third wind direction adjusting plate (33) By rotating the rotating shaft (331) counterclockwise in the front view of FIG. 1, the tip of the third wind direction adjusting plate (33) operates so as to move away from the outlet (15). On the contrary, by rotating the rotation shaft (331) clockwise in the front view of FIG. 1, the tip of the third wind direction adjusting plate (33) operates so as to approach the outlet (15).

- the curvature of the end portion of the front scroll (19) is increased in order to suppress the separation of the airflow from the front scroll (19).

- the Coanda effect is enhanced, and the third wind direction adjustment plate (33) is placed closer to the front scroll (19) than to the rear scroll (17).

- the first wind direction adjusting plate (31) is separated from the end (F) of the rear scroll (17), and the first wind direction adjusting plate is separated.

- An air flow path is provided on the outer surface (31a) side of (31).

- the control unit (40) changes the bending angle of the third wind direction adjusting plate (33) so that the airflow is divided into two at the tip of the third wind direction adjusting plate (33). Further, in order to suppress the separation of the airflow from the first wind direction adjusting plate (31), the control unit (40) sets the bending angle of the first wind direction adjusting plate (31) to, for example, "33 ° ⁇ 39 ° ⁇ 45 °". , "50 ° ⁇ 55 ° ⁇ 60 °", and the third so that the tip of the third wind direction adjustment plate (33) is located near the first wind direction adjustment plate (31). The bending angle of the wind direction adjusting plate (33) is changed.

- the same effect as that of the above-described embodiment can be obtained.

- the third wind direction adjusting plate (33) by adding the third wind direction adjusting plate (33), the airflow blown out from the outlet (15) is divided into two, which is similar to the case where two outlets are provided. Realize the configuration. Specifically, a second wind direction adjusting plate (32) is provided so as to be continuous with the front scroll (19), and a first wind direction adjusting plate is provided between the front scroll (19) and the rear scroll (17).

- the upper airflow is generated by the front side scroll (19) and the third wind direction adjusting plate (33), and the rear side scroll (17) and The lower airflow is generated by the first wind direction adjusting plate (31) and the third wind direction adjusting plate (33). This makes it possible to expand the range reached by the airflow in the air-conditioned space in the vertical direction.

- the blown air was expanded in the vertical direction by three horizontal wind direction adjusting plates (horizontal flaps), but instead, the blown air was expanded in the vertical direction by four or more horizontal flaps. May be good.

- the air conditioner indoor unit (10) has "top blowing mode”, “diagonal blowing mode”, “wide mode”, and “bottom blowing mode” as blowing modes. It may have other modes other than the above. Further, each mode such as “wide mode” may further have a plurality of submodes. Further, the range reached by the blown air in the "wide mode” in the air-conditioned space may be moved in the height direction or the lateral direction (the direction parallel to the long side of the blowout port (15)).

- the air-conditioning indoor unit (10) is a wall-mounted type installed on the side wall of the air-conditioning target space.

- the air-conditioning indoor unit (10) may be another type such as a ceiling-mounted type or a floor-standing type.

- this disclosure is useful for air conditioning indoor units.

- Air-conditioning indoor unit 11 Main body casing 11a Top surface 11b Front panel 11c Back plate 11d Bottom plate 13 Heat exchanger 14 Fan 15 Outlet 16 Bottom frame 17 Rear side scroll 18 Outlet flow path 19 Front side scroll 31 First wind direction adjustment plate 31a Outer surface 31b Inner surface 311 Rotating shaft 32 Second wind direction adjusting plate 32a Outer surface 32b Inner surface 321 Rotating shaft 33 Third wind direction adjusting plate 33a Outer surface 33b Inner surface 331 Rotating shaft 40 Control unit 130

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Signal Processing (AREA)

- Fuzzy Systems (AREA)

- Mathematical Physics (AREA)

- Air Conditioning Control Device (AREA)

- Air-Flow Control Members (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202080064352.7A CN114391079A (zh) | 2019-09-17 | 2020-09-14 | 空调室内机 |

| EP20865264.4A EP4012285A4 (de) | 2019-09-17 | 2020-09-14 | Innenraumeinheit einer klimaanlage |

| AU2020349932A AU2020349932B2 (en) | 2019-09-17 | 2020-09-14 | Indoor unit of air conditioner |

| US17/685,685 US20220186976A1 (en) | 2019-09-17 | 2022-03-03 | Indoor unit of air conditioner |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2019-168560 | 2019-09-17 | ||

| JP2019168560 | 2019-09-17 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US17/685,685 Continuation US20220186976A1 (en) | 2019-09-17 | 2022-03-03 | Indoor unit of air conditioner |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2021054286A1 true WO2021054286A1 (ja) | 2021-03-25 |

Family

ID=74883192

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2020/034722 WO2021054286A1 (ja) | 2019-09-17 | 2020-09-14 | 空調室内機 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20220186976A1 (de) |

| EP (1) | EP4012285A4 (de) |

| JP (2) | JP7025672B2 (de) |

| CN (1) | CN114391079A (de) |

| AU (1) | AU2020349932B2 (de) |

| WO (1) | WO2021054286A1 (de) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN118640521A (zh) * | 2024-08-19 | 2024-09-13 | 格力电器(赣州)有限公司 | 一种空调器、控制方法、控制装置及控制系统 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003021386A (ja) * | 2001-07-09 | 2003-01-24 | Mitsubishi Electric Corp | 空気調和機用室内機およびこれを用いた風向制御方法 |

| JP2013137162A (ja) * | 2011-12-28 | 2013-07-11 | Daikin Industries Ltd | 空調室内機 |

| JP2013238397A (ja) * | 2013-09-06 | 2013-11-28 | Mitsubishi Electric Corp | 空気調和機の室内機 |

| WO2017043492A1 (ja) | 2015-09-10 | 2017-03-16 | ダイキン工業株式会社 | 空調室内機 |

| JP2017067401A (ja) * | 2015-09-30 | 2017-04-06 | ダイキン工業株式会社 | 空調機 |

Family Cites Families (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3163100A (en) * | 1962-01-18 | 1964-12-29 | Carrier Corp | Control for an air distribution system |

| JPS62297654A (ja) * | 1986-06-17 | 1987-12-24 | Daikin Ind Ltd | 空気調和装置 |

| JPH0379943A (ja) * | 1989-08-21 | 1991-04-04 | Daikin Ind Ltd | 空気調和機 |

| JP3139071B2 (ja) * | 1991-09-04 | 2001-02-26 | 松下電器産業株式会社 | 空気調和機の風向制御方法 |

| JPH05203221A (ja) * | 1992-01-23 | 1993-08-10 | Matsushita Electric Ind Co Ltd | 空気調和機の風向制御方法 |

| JP2985755B2 (ja) * | 1995-12-29 | 1999-12-06 | ダイキン工業株式会社 | 壁掛形空気調和機 |

| JP3392644B2 (ja) * | 1996-06-26 | 2003-03-31 | 東芝キヤリア株式会社 | 空気調和装置の室内機 |

| ID19087A (id) * | 1996-09-12 | 1998-06-11 | Samsung Electronics Co Ltd | Alat kontrol arus angin dari dari mesin penyejuk udara dan metoda kerjanya |

| JP2001153431A (ja) * | 1999-12-01 | 2001-06-08 | Matsushita Electric Ind Co Ltd | 空気調和機の風向制御方法 |

| JP3861549B2 (ja) * | 2000-02-18 | 2006-12-20 | 松下電器産業株式会社 | 空気調和機の送風ファン制御方法 |

| JP4259822B2 (ja) * | 2002-08-05 | 2009-04-30 | シャープ株式会社 | 空気調和機 |

| WO2005043047A1 (ja) * | 2003-10-31 | 2005-05-12 | Daikin Industries, Ltd. | 空気調和機およびその制御方法 |

| JP5216519B2 (ja) * | 2008-10-06 | 2013-06-19 | 日立アプライアンス株式会社 | 空気調和機 |

| ES2822108T3 (es) * | 2009-09-28 | 2021-04-29 | Daikin Ind Ltd | Dispositivo de control |

| JP5365675B2 (ja) * | 2011-09-30 | 2013-12-11 | ダイキン工業株式会社 | 空調室内機 |

| JP5408227B2 (ja) * | 2011-10-31 | 2014-02-05 | ダイキン工業株式会社 | 空調室内機 |

| JP2013096639A (ja) * | 2011-10-31 | 2013-05-20 | Daikin Industries Ltd | 空調室内機 |

| JP5404758B2 (ja) * | 2011-12-20 | 2014-02-05 | 三菱電機株式会社 | 空気調和機の室内機 |

| JP5754429B2 (ja) * | 2012-09-13 | 2015-07-29 | ダイキン工業株式会社 | 空調室内機 |

| JP5734263B2 (ja) * | 2012-11-16 | 2015-06-17 | 三菱電機株式会社 | 空気調和機の室内機 |

| EP2966375B1 (de) * | 2013-03-04 | 2019-07-03 | Mitsubishi Electric Corporation | Gebläse und klimaanlage damit |

| JP6242300B2 (ja) * | 2014-06-25 | 2017-12-06 | 三菱電機株式会社 | 空気調和装置の室内機及び空気調和装置 |

| JP6317030B2 (ja) * | 2015-03-02 | 2018-04-25 | 三菱電機株式会社 | 空気調和機の室内機 |

| JP6296034B2 (ja) * | 2015-09-30 | 2018-03-20 | ダイキン工業株式会社 | 空調機 |

| JP7033392B2 (ja) * | 2017-03-10 | 2022-03-10 | 日立ジョンソンコントロールズ空調株式会社 | 空気調和機の室内機、及び空気調和機 |

| JP7077258B2 (ja) * | 2019-03-18 | 2022-05-30 | 株式会社長府製作所 | 貯湯式給湯装置 |

| JP6816807B1 (ja) * | 2019-09-17 | 2021-01-20 | ダイキン工業株式会社 | 送風機および空調室内機 |

-

2020

- 2020-09-14 WO PCT/JP2020/034722 patent/WO2021054286A1/ja unknown

- 2020-09-14 EP EP20865264.4A patent/EP4012285A4/de active Pending

- 2020-09-14 CN CN202080064352.7A patent/CN114391079A/zh active Pending

- 2020-09-14 JP JP2020153535A patent/JP7025672B2/ja active Active

- 2020-09-14 AU AU2020349932A patent/AU2020349932B2/en active Active

-

2022

- 2022-02-10 JP JP2022019214A patent/JP2022059635A/ja active Pending

- 2022-03-03 US US17/685,685 patent/US20220186976A1/en active Pending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003021386A (ja) * | 2001-07-09 | 2003-01-24 | Mitsubishi Electric Corp | 空気調和機用室内機およびこれを用いた風向制御方法 |

| JP2013137162A (ja) * | 2011-12-28 | 2013-07-11 | Daikin Industries Ltd | 空調室内機 |

| JP2013238397A (ja) * | 2013-09-06 | 2013-11-28 | Mitsubishi Electric Corp | 空気調和機の室内機 |

| WO2017043492A1 (ja) | 2015-09-10 | 2017-03-16 | ダイキン工業株式会社 | 空調室内機 |

| JP2017067401A (ja) * | 2015-09-30 | 2017-04-06 | ダイキン工業株式会社 | 空調機 |

Also Published As

| Publication number | Publication date |

|---|---|

| AU2020349932B2 (en) | 2023-03-16 |

| JP2022059635A (ja) | 2022-04-13 |

| JP2021050902A (ja) | 2021-04-01 |

| CN114391079A (zh) | 2022-04-22 |

| AU2020349932A1 (en) | 2022-03-24 |

| EP4012285A1 (de) | 2022-06-15 |

| EP4012285A4 (de) | 2023-09-06 |

| US20220186976A1 (en) | 2022-06-16 |

| JP7025672B2 (ja) | 2022-02-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6065184B2 (ja) | 空気調和機 | |

| WO2013088679A1 (ja) | 空気調和機 | |

| WO2023179024A1 (zh) | 空调室内机及其导风筒 | |

| WO2013035218A1 (ja) | 空気調和機 | |

| WO2013035236A1 (ja) | 空気調和機 | |

| WO2021054286A1 (ja) | 空調室内機 | |

| JP6947266B2 (ja) | 空調室内機 | |

| JP2014016132A (ja) | 空気調和機 | |

| JP5128698B1 (ja) | 空気調和機 | |

| WO2014002434A1 (ja) | 空気調和機 | |

| JPH09264557A (ja) | 空気調和装置 | |

| JP5166583B1 (ja) | 空気調和機 | |

| JP5128697B1 (ja) | 空気調和機 | |

| JP2013057500A (ja) | 空気調和機 | |

| JP2013057499A (ja) | 空気調和機 | |

| JP5166582B1 (ja) | 空気調和機 | |

| JP2013134005A (ja) | 空気調和機 | |

| WO2021054182A1 (ja) | 空調室内機および空気調和機 | |

| JP5138831B1 (ja) | 空気調和機 | |

| JP2013134007A (ja) | 空気調和機 | |

| JPH11287498A (ja) | 空気調和機 | |

| JP2002162091A (ja) | 空気調和機 | |

| JP2001241727A (ja) | 空気調和機 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 20865264 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 2020349932 Country of ref document: AU Date of ref document: 20200914 Kind code of ref document: A |

|

| ENP | Entry into the national phase |

Ref document number: 2020865264 Country of ref document: EP Effective date: 20220310 |