WO2019244766A1 - 冷凍サイクル装置 - Google Patents

冷凍サイクル装置 Download PDFInfo

- Publication number

- WO2019244766A1 WO2019244766A1 PCT/JP2019/023462 JP2019023462W WO2019244766A1 WO 2019244766 A1 WO2019244766 A1 WO 2019244766A1 JP 2019023462 W JP2019023462 W JP 2019023462W WO 2019244766 A1 WO2019244766 A1 WO 2019244766A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- refrigerant

- cooling

- temperature

- heat exchanger

- air

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H1/3204—Cooling devices using compression

- B60H1/3205—Control means therefor

- B60H1/3213—Control means therefor for increasing the efficiency in a vehicle heat pump

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H1/3204—Cooling devices using compression

- B60H1/3205—Control means therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/00271—HVAC devices specially adapted for particular vehicle parts or components and being connected to the vehicle HVAC unit

- B60H1/00278—HVAC devices specially adapted for particular vehicle parts or components and being connected to the vehicle HVAC unit for the battery

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/00642—Control systems or circuits; Control members or indication devices for heating, cooling or ventilating devices

- B60H1/00814—Control systems or circuits characterised by their output, for controlling particular components of the heating, cooling or ventilating installation

- B60H1/00878—Control systems or circuits characterised by their output, for controlling particular components of the heating, cooling or ventilating installation the components being temperature regulating devices

- B60H1/00899—Controlling the flow of liquid in a heat pump system

- B60H1/00921—Controlling the flow of liquid in a heat pump system where the flow direction of the refrigerant does not change and there is an extra subcondenser, e.g. in an air duct

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/02—Heating, cooling or ventilating [HVAC] devices the heat being derived from the propulsion plant

- B60H1/04—Heating, cooling or ventilating [HVAC] devices the heat being derived from the propulsion plant from cooling liquid of the plant

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H1/3204—Cooling devices using compression

- B60H1/3223—Cooling devices using compression characterised by the arrangement or type of the compressor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H1/3204—Cooling devices using compression

- B60H1/323—Cooling devices using compression characterised by comprising auxiliary or multiple systems, e.g. plurality of evaporators, or by involving auxiliary cooling devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60K—ARRANGEMENT OR MOUNTING OF PROPULSION UNITS OR OF TRANSMISSIONS IN VEHICLES; ARRANGEMENT OR MOUNTING OF PLURAL DIVERSE PRIME-MOVERS IN VEHICLES; AUXILIARY DRIVES FOR VEHICLES; INSTRUMENTATION OR DASHBOARDS FOR VEHICLES; ARRANGEMENTS IN CONNECTION WITH COOLING, AIR INTAKE, GAS EXHAUST OR FUEL SUPPLY OF PROPULSION UNITS IN VEHICLES

- B60K11/00—Arrangement in connection with cooling of propulsion units

- B60K11/02—Arrangement in connection with cooling of propulsion units with liquid cooling

- B60K11/04—Arrangement or mounting of radiators, radiator shutters, or radiator blinds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L1/00—Supplying electric power to auxiliary equipment of vehicles

- B60L1/02—Supplying electric power to auxiliary equipment of vehicles to electric heating circuits

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L3/00—Electric devices on electrically-propelled vehicles for safety purposes; Monitoring operating variables, e.g. speed, deceleration or energy consumption

- B60L3/0023—Detecting, eliminating, remedying or compensating for drive train abnormalities, e.g. failures within the drive train

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L58/00—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles

- B60L58/10—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries

- B60L58/24—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries for controlling the temperature of batteries

- B60L58/26—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries for controlling the temperature of batteries by cooling

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B25/00—Machines, plants or systems, using a combination of modes of operation covered by two or more of the groups F25B1/00 - F25B23/00

- F25B25/005—Machines, plants or systems, using a combination of modes of operation covered by two or more of the groups F25B1/00 - F25B23/00 using primary and secondary systems

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B5/00—Compression machines, plants or systems, with several evaporator circuits, e.g. for varying refrigerating capacity

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/00271—HVAC devices specially adapted for particular vehicle parts or components and being connected to the vehicle HVAC unit

- B60H2001/00307—Component temperature regulation using a liquid flow

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/00642—Control systems or circuits; Control members or indication devices for heating, cooling or ventilating devices

- B60H1/00814—Control systems or circuits characterised by their output, for controlling particular components of the heating, cooling or ventilating installation

- B60H1/00878—Control systems or circuits characterised by their output, for controlling particular components of the heating, cooling or ventilating installation the components being temperature regulating devices

- B60H2001/00928—Control systems or circuits characterised by their output, for controlling particular components of the heating, cooling or ventilating installation the components being temperature regulating devices comprising a secondary circuit

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H2001/3236—Cooling devices information from a variable is obtained

- B60H2001/3239—Cooling devices information from a variable is obtained related to flow

- B60H2001/3242—Cooling devices information from a variable is obtained related to flow of a refrigerant

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H2001/3236—Cooling devices information from a variable is obtained

- B60H2001/3248—Cooling devices information from a variable is obtained related to pressure

- B60H2001/325—Cooling devices information from a variable is obtained related to pressure of the refrigerant at a compressing unit

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H2001/3236—Cooling devices information from a variable is obtained

- B60H2001/3255—Cooling devices information from a variable is obtained related to temperature

- B60H2001/3257—Cooling devices information from a variable is obtained related to temperature of the refrigerant at a compressing unit

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H2001/3236—Cooling devices information from a variable is obtained

- B60H2001/3255—Cooling devices information from a variable is obtained related to temperature

- B60H2001/3263—Cooling devices information from a variable is obtained related to temperature of the refrigerant at an evaporating unit

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H2001/3269—Cooling devices output of a control signal

- B60H2001/328—Cooling devices output of a control signal related to an evaporating unit

- B60H2001/3283—Cooling devices output of a control signal related to an evaporating unit to control the refrigerant flow

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H2001/3269—Cooling devices output of a control signal

- B60H2001/3285—Cooling devices output of a control signal related to an expansion unit

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60K—ARRANGEMENT OR MOUNTING OF PROPULSION UNITS OR OF TRANSMISSIONS IN VEHICLES; ARRANGEMENT OR MOUNTING OF PLURAL DIVERSE PRIME-MOVERS IN VEHICLES; AUXILIARY DRIVES FOR VEHICLES; INSTRUMENTATION OR DASHBOARDS FOR VEHICLES; ARRANGEMENTS IN CONNECTION WITH COOLING, AIR INTAKE, GAS EXHAUST OR FUEL SUPPLY OF PROPULSION UNITS IN VEHICLES

- B60K1/00—Arrangement or mounting of electrical propulsion units

- B60K2001/003—Arrangement or mounting of electrical propulsion units with means for cooling the electrical propulsion units

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L2240/00—Control parameters of input or output; Target parameters

- B60L2240/10—Vehicle control parameters

- B60L2240/34—Cabin temperature

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L2240/00—Control parameters of input or output; Target parameters

- B60L2240/40—Drive Train control parameters

- B60L2240/54—Drive Train control parameters related to batteries

- B60L2240/545—Temperature

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2600/00—Control issues

- F25B2600/02—Compressor control

- F25B2600/025—Compressor control by controlling speed

- F25B2600/0253—Compressor control by controlling speed with variable speed

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2600/00—Control issues

- F25B2600/21—Refrigerant outlet evaporator temperature

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2700/00—Sensing or detecting of parameters; Sensors therefor

- F25B2700/19—Pressures

- F25B2700/195—Pressures of the condenser

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2700/00—Sensing or detecting of parameters; Sensors therefor

- F25B2700/19—Pressures

- F25B2700/197—Pressures of the evaporator

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2700/00—Sensing or detecting of parameters; Sensors therefor

- F25B2700/21—Temperatures

- F25B2700/2104—Temperatures of an indoor room or compartment

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2700/00—Sensing or detecting of parameters; Sensors therefor

- F25B2700/21—Temperatures

- F25B2700/2106—Temperatures of fresh outdoor air

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2700/00—Sensing or detecting of parameters; Sensors therefor

- F25B2700/21—Temperatures

- F25B2700/2115—Temperatures of a compressor or the drive means therefor

- F25B2700/21151—Temperatures of a compressor or the drive means therefor at the suction side of the compressor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2700/00—Sensing or detecting of parameters; Sensors therefor

- F25B2700/21—Temperatures

- F25B2700/2115—Temperatures of a compressor or the drive means therefor

- F25B2700/21152—Temperatures of a compressor or the drive means therefor at the discharge side of the compressor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2700/00—Sensing or detecting of parameters; Sensors therefor

- F25B2700/21—Temperatures

- F25B2700/2116—Temperatures of a condenser

- F25B2700/21163—Temperatures of a condenser of the refrigerant at the outlet of the condenser

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2700/00—Sensing or detecting of parameters; Sensors therefor

- F25B2700/21—Temperatures

- F25B2700/2117—Temperatures of an evaporator

- F25B2700/21171—Temperatures of an evaporator of the fluid cooled by the evaporator

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2700/00—Sensing or detecting of parameters; Sensors therefor

- F25B2700/21—Temperatures

- F25B2700/2117—Temperatures of an evaporator

- F25B2700/21175—Temperatures of an evaporator of the refrigerant at the outlet of the evaporator

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/70—Energy storage systems for electromobility, e.g. batteries

Definitions

- the present disclosure relates to a refrigeration cycle device applied to an air conditioner.

- Patent Literature 1 discloses a refrigeration cycle device that is applied to a vehicle air conditioner and adjusts the temperature of blast air that is blown into a vehicle interior, which is a space to be air conditioned.

- the refrigeration cycle device of Patent Document 1 is configured to be able to switch the refrigerant circuit. Specifically, the refrigeration cycle device of Patent Document 1 is configured to be able to switch between a refrigerant circuit in a cooling mode, a refrigerant circuit in a heating mode, a refrigerant circuit in a dehumidifying and heating mode, and the like.

- the cooling mode is an operation mode in which the blown air is cooled by the indoor evaporator.

- the heating mode is an operation mode in which the blast air is heated by the indoor condenser.

- the dehumidifying and heating mode is an operation mode in which the blown air cooled and dehumidified by the indoor evaporator is reheated by the indoor condenser.

- a refrigerant circuit that connects the outdoor heat exchanger and the indoor evaporator in series with the refrigerant flow, and an outdoor heat exchanger and the indoor evaporator that are connected in parallel with the refrigerant flow

- the amount of heat exchange between the refrigerant and the outside air in the outdoor heat exchanger is adjusted during dehumidification and heating of the vehicle interior, so that the temperature of the blown air can be widened from a high temperature to a low temperature. It can be adjusted continuously.

- the ability to continuously adjust the temperature of the blown air in a wide range can realize comfortable heating of the passenger compartment when applied to an air conditioner for a vehicle in which a heat source for heating is likely to be insufficient. It is effective in that.

- a vehicle in which the heat source for heating is likely to be insufficient is, for example, a vehicle such as an electric vehicle in which exhaust heat of an engine cannot be used as a heat source for heating.

- the present applicant is studying cooling of a battery, which is an object of heat absorption, by adding a cooling heat exchanger to the refrigeration cycle apparatus of Patent Document 1. Specifically, by arranging the cooling heat exchanger in parallel with the air conditioning heat exchanger (that is, at least one of the indoor condenser and the outdoor heat exchanger) in the refrigerant flow, the temperature adjustment of the blown air and the battery And cooling.

- the air conditioning heat exchanger that is, at least one of the indoor condenser and the outdoor heat exchanger

- the cooling heat exchanger has a higher target temperature and a smaller required cooling amount than the air conditioning heat exchanger. Therefore, the flow rate of the refrigerant flowing through the cooling heat exchanger is low, and the refrigerant on the outlet side of the cooling heat exchanger is likely to be a superheated gas refrigerant. For this reason, oil stagnation may occur in the cooling heat exchanger. Note that oil stagnation refers to a phenomenon in which refrigeration oil accumulates in the cooling heat exchanger and the return of the refrigeration oil from the cooling heat exchanger to the compressor becomes insufficient.

- the present disclosure in a refrigeration cycle apparatus in which a heat exchanger for air conditioning and a heat exchanger for cooling a heat-absorbing object are arranged in parallel to a refrigerant flow, oil stagnation into the cooling heat exchanger is performed.

- the purpose is to control.

- a refrigeration cycle device includes a compressor, a radiator, an air conditioning heat exchanger, a cooling heat exchanger, an air conditioning decompression unit, a cooling decompression unit, and a refrigerant flow detection unit. , And a control unit.

- the compressor sucks and discharges the refrigerant.

- the radiator radiates the refrigerant discharged from the compressor.

- the air-conditioning heat exchanger absorbs heat from air to evaporate the refrigerant.

- the cooling heat exchanger is arranged in parallel with the air conditioning heat exchanger in the flow of the refrigerant radiated by the radiator, and absorbs heat from the heat medium circulating between the heat absorbing target and the heat absorbing target. Evaporate the refrigerant.

- the air-conditioning decompression unit adjusts the pressure reduction amount of the refrigerant flowing into the air-conditioning heat exchanger by adjusting the opening area of the air-conditioning passage that guides the refrigerant flowing out of the radiator to the inlet side of the air-conditioning heat exchanger.

- the cooling decompression unit adjusts the pressure reduction amount of the refrigerant flowing into the cooling heat exchanger by adjusting the opening area of the cooling passage that guides the refrigerant flowing out of the radiator to the inlet side of the cooling heat exchanger. .

- the refrigerant flow detection unit detects the flow rate of the refrigerant flowing into the cooling heat exchanger.

- the control unit controls the operation of the cooling pressure reducing unit such that the flow rate of the refrigerant detected by the refrigerant flow rate detecting unit exceeds a predetermined reference flow rate.

- the operation of the cooling decompression unit is controlled such that the flow rate of the refrigerant flowing into the cooling heat exchanger exceeds the reference flow rate, the flow rate of the refrigerant flowing through the cooling heat exchanger can be ensured. Can be. For this reason, it is possible to suppress accumulation of the refrigerating machine oil of the refrigerating cycle device in the cooling heat exchanger. Therefore, oil stagnation in the cooling heat exchanger that cools the heat absorbing target can be suppressed.

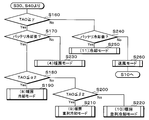

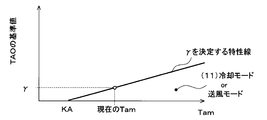

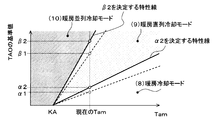

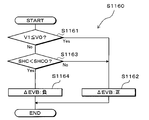

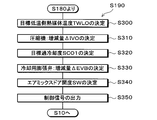

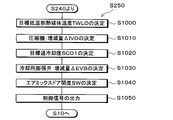

- 1 is an overall configuration diagram of a vehicle air conditioner according to a first embodiment. It is a block diagram which shows the electric control part of the vehicle air conditioner of 1st Embodiment. It is a flowchart which shows a part of control processing of the air conditioning control program of the first embodiment. It is a flowchart which shows another part of control processing of the air-conditioning control program of 1st Embodiment. It is a control characteristic figure for switching the operation mode of the air-conditioning control program of a 1st embodiment. It is another control characteristic figure for switching the operation mode of the air-conditioning control program of 1st Embodiment. It is another control characteristic figure for switching the operation mode of the air-conditioning control program of 1st Embodiment.

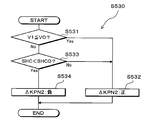

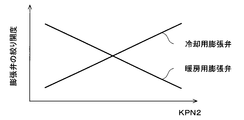

- FIG. 4 is a control characteristic diagram for determining an opening degree pattern of a heating expansion valve and a cooling expansion valve in a heating series cooling mode according to the first embodiment. It is a flowchart which shows the control processing of the heating parallel cooling mode of 1st Embodiment. It is a flowchart which shows the control processing for determining the opening degree pattern variation of the heating expansion valve and the cooling expansion valve in the heating parallel cooling mode of the first embodiment.

- FIG. 4 is a control characteristic diagram for determining an opening pattern of a heating expansion valve and a cooling expansion valve in a heating parallel cooling mode according to the first embodiment.

- the refrigeration cycle device 10 is applied to a vehicle air conditioner 1 mounted on an electric vehicle that obtains a driving force for traveling from an electric motor.

- the vehicle air conditioner 1 has a function of adjusting the temperature of the battery 80 as well as performing air conditioning of the vehicle interior, which is a space to be air-conditioned. For this reason, the vehicle air conditioner 1 can also be called an air conditioner with a battery temperature adjusting function.

- the battery 80 is a secondary battery that stores electric power supplied to in-vehicle devices such as an electric motor.

- the battery 80 of the present embodiment is a lithium ion battery.

- the battery 80 is a so-called assembled battery formed by stacking a plurality of battery cells 81 and electrically connecting these battery cells 81 in series or in parallel.

- the battery 80 can be cooled by the cold generated by the refrigeration cycle device 10. Therefore, the cooling object (in other words, the heat absorbing object) different from the blown air in the refrigeration cycle device 10 of the present embodiment is the battery 80.

- the vehicle air conditioner 1 includes a refrigeration cycle device 10, an indoor air conditioning unit 30, a high-temperature heat medium circuit 40, a low-temperature heat medium circuit 50, and the like, as shown in the overall configuration diagram of FIG.

- the refrigeration cycle apparatus 10 cools the air blown into the vehicle interior and heats the high-temperature side heat medium circulating in the high-temperature side heat medium circuit 40 in order to perform air conditioning in the vehicle interior. Further, the refrigeration cycle apparatus 10 cools the low-temperature side heat medium circulating in the low-temperature side heat medium circuit 50 in order to cool the battery 80.

- the refrigeration cycle device 10 is configured to be able to switch refrigerant circuits for various operation modes in order to perform air conditioning in the passenger compartment. For example, it is configured such that a refrigerant circuit in a cooling mode, a refrigerant circuit in a dehumidifying and heating mode, a refrigerant circuit in a heating mode, and the like can be switched. Further, the refrigeration cycle apparatus 10 can switch between an operation mode for cooling the battery 80 and an operation mode for not cooling the battery 80 in each operation mode for air conditioning.

- an HFO-based refrigerant (specifically, R1234yf) is employed as a refrigerant, and the pressure of the discharged refrigerant discharged from the compressor 11 does not exceed the critical pressure of the refrigerant. Constructs a subcritical refrigeration cycle. Further, a refrigerant oil for lubricating the compressor 11 is mixed in the refrigerant. Part of the refrigerating machine oil circulates through the cycle together with the refrigerant.

- the compressor 11 sucks, compresses, and discharges the refrigerant in the refrigeration cycle device 10.

- the compressor 11 is disposed in front of a vehicle compartment and is disposed in a driving device compartment in which an electric motor and the like are accommodated.

- the compressor 11 is an electric compressor in which a fixed displacement compression mechanism having a fixed discharge capacity is rotationally driven by an electric motor.

- the rotation speed (that is, the refrigerant discharge capacity) of the compressor 11 is controlled by a control signal output from a control device 60 described later.

- the inlet of the refrigerant passage of the water-refrigerant heat exchanger 12 is connected to the outlet of the compressor 11.

- the water-refrigerant heat exchanger 12 has a refrigerant passage through which the high-pressure refrigerant discharged from the compressor 11 flows, and a water passage through which the high-temperature side heat medium circulating through the high-temperature side heat medium circuit 40 flows.

- the water-refrigerant heat exchanger 12 is a heating heat exchanger that exchanges heat between the high-pressure refrigerant flowing through the refrigerant passage and the high-temperature heat medium flowing through the water passage to heat the high-temperature heat medium. is there.

- the water-refrigerant heat exchanger 12 is a radiator that radiates heat of the refrigerant discharged from the compressor 11 to the high-temperature side heat medium.

- the outlet of the coolant passage of the water-refrigerant heat exchanger 12 is connected to the inlet of a first three-way joint 13a having three inflow ports that communicate with each other.

- a three-way joint one formed by joining a plurality of pipes or one formed by providing a plurality of refrigerant passages in a metal block or a resin block can be employed.

- the refrigeration cycle device 10 includes second to sixth three-way joints 13b to 13f as described later.

- the basic configuration of the second to sixth three-way joints 13b to 13f is the same as that of the first three-way joint 13a.

- the inlet of the heating expansion valve 14a is connected to one outlet of the first three-way joint 13a.

- the other outlet of the first three-way joint 13a is connected to one inlet of the second three-way joint 13b via a bypass passage 22a.

- An on-off valve 15a for dehumidification is arranged in the bypass passage 22a.

- the dehumidifying on-off valve 15a is an electromagnetic valve that opens and closes a refrigerant passage connecting the other outflow side of the first three-way joint 13a and one inflow side of the second three-way joint 13b.

- the dehumidifying on-off valve 15a is a bypass opening and closing unit that opens and closes the bypass passage 22a.

- the refrigeration cycle device 10 includes a heating on-off valve 15b as described later.

- the basic configuration of the heating on-off valve 15b is the same as that of the dehumidifying on-off valve 15a.

- the on-off valve 15a for dehumidification and the on-off valve 15b for heating can switch the refrigerant circuit in each operation mode by opening and closing the refrigerant passage. Therefore, the on-off valve 15a for dehumidification and the on-off valve 15b for heating are refrigerant circuit switching devices for switching the refrigerant circuit of the cycle. The operations of the dehumidifying on-off valve 15a and the heating on-off valve 15b are controlled by a control voltage output from the control device 60.

- the heating expansion valve 14a depressurizes the high-pressure refrigerant flowing out of the refrigerant passage of the water-refrigerant heat exchanger 12 at least in the operation mode of heating the vehicle interior, and also causes the flow rate (mass flow rate) of the refrigerant to flow downstream. This is a heating decompression unit that adjusts the pressure.

- the heating expansion valve 14a is an electric variable throttle mechanism that includes a valve body configured to change the throttle opening and an electric actuator that changes the opening of the valve body.

- the refrigeration cycle apparatus 10 includes a cooling expansion valve 14b and a cooling expansion valve 14c, as described later.

- the basic configuration of the cooling expansion valve 14b and the cooling expansion valve 14c is the same as that of the heating expansion valve 14a.

- the heating expansion valve 14a, the cooling expansion valve 14b, and the cooling expansion valve 14c have a fully open function and a fully closed function.

- the full-opening function is a function of simply making the refrigerant passage without exerting the flow rate adjusting function and the refrigerant depressurizing function by fully opening the valve opening.

- the fully closed function is a function of closing the refrigerant passage by fully closing the valve opening.

- the heating expansion valve 14a, the cooling expansion valve 14b, and the cooling expansion valve 14c can switch the refrigerant circuit in each operation mode by the fully open function and the fully closed function.

- the heating expansion valve 14a, the cooling expansion valve 14b, and the cooling expansion valve 14c of the present embodiment also have a function as a refrigerant circuit switching device.

- the operations of the heating expansion valve 14a, the cooling expansion valve 14b, and the cooling expansion valve 14c are controlled by a control signal (control pulse) output from the control device 60.

- the refrigerant inlet side of the outdoor heat exchanger 16 is connected to the outlet of the heating expansion valve 14a.

- the outdoor heat exchanger 16 is a heat exchanger that exchanges heat between the refrigerant flowing out of the heating expansion valve 14a and the outside air blown by a cooling fan (not shown).

- the outdoor heat exchanger 16 functions as a radiator for releasing the refrigerant discharged from the compressor 11 or an air conditioning heat exchanger for absorbing heat from air and evaporating the refrigerant, depending on the operation mode.

- the outdoor heat exchanger 16 is arranged on the front side in the drive device room. Therefore, when the vehicle is traveling, the traveling wind can be applied to the outdoor heat exchanger 16.

- the first refrigerant passage 16a is a refrigerant passage for guiding the refrigerant flowing out of the water-refrigerant heat exchanger 12 to the inlet side of the outdoor heat exchanger 16, and corresponds to an air conditioning passage.

- the heating expansion valve 14a is an air-conditioning decompression unit that adjusts the opening area of the first refrigerant passage 16a to adjust the decompression amount of the refrigerant flowing into the outdoor heat exchanger 16.

- the heating expansion valve 14a corresponds to a first throttle section.

- the refrigerant outlet of the outdoor heat exchanger 16 is connected to the inlet side of the third three-way joint 13c.

- One outlet of the fourth three-way joint 13d is connected to one outlet of the third three-way joint 13c via a heating passage 22b.

- the heating passage 22b is a second refrigerant passage for guiding the refrigerant flowing out of the outdoor heat exchanger 16 to the suction side of the compressor 11.

- a heating on-off valve 15b for opening and closing the refrigerant passage is arranged in the heating passage 22b.

- the heating on-off valve 15b is a second refrigerant passage opening / closing unit that opens and closes the second refrigerant passage.

- the other inlet of the second three-way joint 13b is connected to the other outlet of the third three-way joint 13c.

- a check valve 17 is arranged in the refrigerant passage connecting the other outlet side of the third three-way joint 13c and the other inlet side of the second three-way joint 13b. The check valve 17 allows the refrigerant to flow from the third three-way joint 13c to the second three-way joint 13b, and prohibits the refrigerant from flowing from the second three-way joint 13b to the third three-way joint 13c.

- the outlet of the fifth three-way joint 13e is connected to the outlet of the second three-way joint 13b.

- the inlet side of the cooling expansion valve 14b is connected to one outlet of the fifth three-way joint 13e.

- the inlet side of the cooling expansion valve 14c is connected to the other outlet of the fifth three-way joint 13e.

- the cooling expansion valve 14b is a heating decompression unit that depressurizes the refrigerant that has flowed out of the outdoor heat exchanger 16 and adjusts the flow rate of the refrigerant that flows downstream, at least in an operation mode in which cooling is performed in the vehicle interior.

- the refrigerant inlet side of the indoor evaporator 18 is connected to the outlet of the cooling expansion valve 14b.

- the indoor evaporator 18 is arranged in an air-conditioning case 31 of an indoor air-conditioning unit 30 described later.

- the indoor evaporator 18 blows air by exchanging heat between the low-pressure refrigerant depressurized by the cooling expansion valve 14b and the blast air blown from the blower 32 to evaporate the low-pressure refrigerant and exerting an endothermic effect on the low-pressure refrigerant.

- This is a cooling heat exchanger that cools air.

- the indoor evaporator 18 is an air-conditioning heat exchanger that absorbs heat from air to evaporate the refrigerant.

- One inlet side of the sixth three-way joint 13f is connected to the refrigerant outlet of the indoor evaporator 18.

- the cooling expansion valve 14c is a cooling pressure reducing unit that reduces the pressure of the refrigerant flowing out of the outdoor heat exchanger 16 and adjusts the flow rate of the refrigerant flowing downstream at least in the operation mode in which the battery 80 is cooled.

- the outlet side of the cooling expansion valve 14c is connected to the inlet side of the refrigerant passage of the chiller 19.

- the chiller 19 has a refrigerant passage through which the low-pressure refrigerant depressurized by the cooling expansion valve 14c flows, and a water passage through which the low-temperature heat medium circulating through the low-temperature heat medium circuit 50 flows.

- the chiller 19 is an evaporator that exchanges heat between the low-pressure refrigerant flowing through the refrigerant passage and the low-temperature side heat medium flowing through the water passage, evaporates the low-pressure refrigerant, and exerts an endothermic effect.

- the chiller 19 is a cooling heat exchanger that absorbs heat from the low-temperature side heat medium and evaporates the refrigerant.

- the chiller 19 is arranged in parallel with at least one of the outdoor heat exchanger 16 and the indoor evaporator 18 in the flow of the refrigerant radiated by the water-refrigerant heat exchanger 12.

- the other inlet side of the sixth three-way joint 13f is connected to the outlet of the refrigerant passage of the chiller 19.

- the inlet of the evaporation pressure regulating valve 20 is connected to the outlet of the sixth three-way joint 13f.

- the evaporation pressure regulating valve 20 maintains the refrigerant evaporation pressure in the indoor evaporator 18 at or above a predetermined reference pressure in order to suppress frost formation on the indoor evaporator 18.

- the evaporating pressure adjusting valve 20 is configured by a mechanical variable throttle mechanism that increases the valve opening as the pressure of the refrigerant on the outlet side of the indoor evaporator 18 increases.

- the evaporation pressure regulating valve 20 maintains the refrigerant evaporation temperature in the indoor evaporator 18 at a frost formation suppression temperature (1 ° C. in the present embodiment) capable of suppressing frost formation on the indoor evaporator 18. . Furthermore, the evaporating pressure regulating valve 20 of the present embodiment is disposed downstream of the sixth three-way joint 13f, which is the junction. For this reason, the evaporation pressure regulating valve 20 also maintains the refrigerant evaporation temperature in the chiller 19 at a temperature equal to or higher than the frost formation suppression temperature.

- the other inlet side of the fourth three-way joint 13d is connected to the outlet of the evaporation pressure regulating valve 20.

- the inlet of the accumulator 21 is connected to the outlet of the fourth three-way joint 13d.

- the accumulator 21 is a gas-liquid separator that separates the gas-liquid of the refrigerant flowing into the inside and stores the surplus liquid-phase refrigerant in the cycle.

- the suction port side of the compressor 11 is connected to the gas-phase refrigerant outlet of the accumulator 21.

- the third refrigerant passage 18a is a refrigerant passage for guiding the refrigerant flowing out of the outdoor heat exchanger 16 to the suction side of the compressor 11 via the evaporator 18, and corresponds to an air conditioning passage.

- the cooling expansion valve 14b is an air conditioning decompression unit that adjusts the opening area of the third refrigerant passage 18a to adjust the pressure reduction amount of the refrigerant flowing into the evaporator 18.

- the cooling expansion valve 14b corresponds to a second throttle unit.

- the cooling passage 19a transfers the refrigerant flowing between the outdoor heat exchanger 16 and the cooling expansion valve 14b to the third refrigerant passage 18a between the indoor evaporator 18 and the suction side of the compressor 11 via the chiller 19. It is a refrigerant passage for guiding.

- the cooling expansion valve 14c is a cooling decompression unit that adjusts the opening area of the cooling passage 19a to adjust the amount of decompression of the refrigerant flowing into the chiller 19.

- the fifth three-way joint 13e of the present embodiment functions as a branch part that branches the flow of the refrigerant flowing out of the outdoor heat exchanger 16.

- the sixth three-way joint 13 f is a junction where the flow of the refrigerant flowing out of the indoor evaporator 18 and the flow of the refrigerant flowing out of the chiller 19 are merged and flown out to the suction side of the compressor 11.

- the indoor evaporator 18 and the chiller 19 are connected in parallel with each other with respect to the refrigerant flow. Further, the bypass passage 22a guides the refrigerant flowing out of the refrigerant passage of the water-refrigerant heat exchanger 12 to an upstream side of the branch portion. The heating passage 22 b guides the refrigerant flowing out of the outdoor heat exchanger 16 to the suction port side of the compressor 11.

- the high-temperature side heat medium circuit 40 is a heat medium circulation circuit that circulates the high-temperature side heat medium.

- the high-temperature side heat medium a solution containing ethylene glycol, dimethylpolysiloxane, a nanofluid, or the like, an antifreeze, or the like can be used.

- the high-temperature-side heat medium circuit 40 includes a water passage of the water-refrigerant heat exchanger 12, a high-temperature-side heat medium pump 41, a heater core 42, and the like.

- the high-temperature heat medium pump 41 is a water pump that pumps the high-temperature heat medium to the inlet side of the water passage of the water-refrigerant heat exchanger 12.

- the high-temperature-side heat medium pump 41 is an electric pump whose rotation speed (ie, pumping capacity) is controlled by a control voltage output from the control device 60.

- the outlet of the water passage of the water-refrigerant heat exchanger 12 is connected to the heat medium inlet side of the heater core 42.

- the heater core 42 is a heat exchanger that heats the blown air by exchanging heat between the high-temperature side heat medium heated by the water-refrigerant heat exchanger 12 and the blown air that has passed through the indoor evaporator 18.

- the heater core 42 is arranged inside the air conditioning case 31 of the indoor air conditioning unit 30.

- the heat medium outlet of the heater core 42 is connected to the suction port side of the high-temperature side heat medium pump 41.

- the high-temperature side heat medium pump 41 adjusts the flow rate of the high-temperature side heat medium flowing into the heater core 42, so that the heat radiation amount of the high-temperature side heat medium to the blow air in the heater core 42 is reduced. Can be adjusted. That is, in the high-temperature-side heat medium circuit 40, the high-temperature-side heat medium pump 41 adjusts the flow rate of the high-temperature-side heat medium flowing into the heater core 42, so that the heating amount of the blown air in the heater core 42 can be adjusted.

- each component of the water-refrigerant heat exchanger 12 and the high-temperature side heat medium circuit 40 constitutes a heating unit that heats the blown air using the refrigerant discharged from the compressor 11 as a heat source. I have.

- the low-temperature-side heat medium circuit 50 is a heat medium circulation circuit that circulates the low-temperature-side heat medium.

- the same fluid as the high-temperature side heat medium can be used as the low-temperature side heat medium.

- a water passage of the chiller 19 a low-temperature side heat medium pump 51, a cooling heat exchange section 52, a three-way valve 53, a low-temperature side radiator 54, and the like are arranged.

- the low-temperature heat medium pump 51 is a water pump that pumps the low-temperature heat medium to the inlet side of the water passage of the chiller 19.

- the basic configuration of the low-temperature-side heat medium pump 51 is the same as that of the high-temperature-side heat medium pump 41.

- the inlet side of the cooling heat exchange unit 52 is connected to the outlet of the water passage of the chiller 19.

- the cooling heat exchanging section 52 has a plurality of metal heat medium passages arranged to be in contact with the plurality of battery cells 81 forming the battery 80.

- the heat exchange unit cools the battery 80 by exchanging heat between the battery cell 81 and the low-temperature side heat medium flowing through the heat medium flow path.

- Such a cooling heat exchange section 52 may be formed by disposing a heat medium flow path between the battery cells 81 arranged in a stack. Further, cooling heat exchanging section 52 may be formed integrally with battery 80.

- the battery case may be formed integrally with the battery 80 by providing a heat medium flow path in a dedicated case for accommodating the stacked battery cells 81.

- the outlet of the cooling heat exchange unit 52 is connected to the inflow side of the three-way valve 53.

- the three-way valve 53 is an electric three-way flow control valve having one inflow port and two outflow ports, and capable of continuously adjusting the passage area ratio of the two outflow ports. The operation of the three-way valve 53 is controlled by a control signal output from the control device 60.

- the heat medium inlet side of the low-temperature radiator 54 is connected to one outlet of the three-way valve 53.

- the other outlet of the three-way valve 53 is connected to the suction side of the low-temperature side heat transfer medium pump 51 via a radiator bypass passage 53a.

- the radiator bypass flow path 53 a is a heat medium flow path in which the low-temperature side heat medium flowing out of the cooling heat exchange unit 52 flows by bypassing the low-temperature side radiator 54.

- the three-way valve 53 continuously adjusts the flow rate of the low-temperature side heat medium flowing into the low-temperature side radiator 54 among the low-temperature side heat medium flowing out of the cooling heat exchange section 52 in the low-temperature side heat medium circuit 50. .

- the low-temperature radiator 54 exchanges heat between the low-temperature heat medium flowing out of the cooling heat exchange unit 52 and the outside air blown by an outside air fan (not shown), and radiates heat of the low-temperature heat medium to the outside air. It is a vessel.

- the low-temperature radiator 54 is disposed on the front side in the drive device chamber. Therefore, when the vehicle is traveling, the traveling wind can be applied to the low-temperature radiator 54. Therefore, the low temperature radiator 54 may be formed integrally with the outdoor heat exchanger 16 and the like.

- the heat medium outlet of the low-temperature radiator 54 is connected to the suction port side of the low-temperature heat medium pump 51. Therefore, in the low-temperature heat medium circuit 50, the low-temperature heat medium pump 51

- the cooling unit that cools the battery 80 by evaporating the refrigerant flowing out of the cooling expansion valve 14c is configured by the respective components of the chiller 19 and the low-temperature side heat medium circuit 50.

- the indoor air-conditioning unit 30 is for blowing out the blast air whose temperature has been adjusted by the refrigeration cycle device 10 into the vehicle interior.

- the indoor air-conditioning unit 30 is arranged inside the instrument panel (instrument panel) at the forefront of the passenger compartment.

- the indoor air-conditioning unit 30 accommodates a blower 32, an indoor evaporator 18, a heater core 42, and the like in an air passage formed in an air-conditioning case 31 forming an outer shell.

- the air-conditioning case 31 forms an air passage for blast air blown into the vehicle interior.

- the air-conditioning case 31 has a certain degree of elasticity and is formed of a resin (for example, polypropylene) excellent in strength.

- An inside / outside air switching device 33 is disposed on the most upstream side of the airflow of the air conditioning case 31.

- the inside / outside air switching device 33 switches between the inside air (vehicle interior air) and the outside air (vehicle outside air) into the air conditioning case 31.

- the inside / outside air switching device 33 continuously adjusts the opening area of the inside air introduction port for introducing the inside air into the air conditioning case 31 and the outside air introduction port for introducing the outside air by the inside / outside air switching door, and the inside air introduction air volume and the outside air. Is to change the ratio of the introduced air flow to the introduced air flow.

- the inside / outside air switching door is driven by an electric actuator for the inside / outside air switching door. The operation of the electric actuator is controlled by a control signal output from the control device 60.

- a blower 32 is disposed downstream of the inside / outside air switching device 33 in the flow of the blown air.

- the blower 32 blows the air taken in through the inside / outside air switching device 33 toward the vehicle interior.

- the blower 32 is an electric blower that drives a centrifugal multi-blade fan with an electric motor.

- the rotation speed (that is, the blowing capacity) of the blower 32 is controlled by the control voltage output from the control device 60.

- the indoor evaporator 18 and the heater core 42 are arranged in this order with respect to the blown air flow. That is, the indoor evaporator 18 is arranged on the upstream side of the flow of the blown air with respect to the heater core 42.

- a cool air bypass passage 35 is provided in the air-conditioning case 31 to allow the air blown after passing through the indoor evaporator 18 to bypass the heater core 42.

- An air mix door 34 is arranged on the downstream side of the air flow of the indoor evaporator 18 in the air conditioning case 31 and on the upstream side of the air flow of the heater core 42.

- the air mix door 34 adjusts a flow rate ratio of a flow rate of the blown air passing through the heater core 42 and a flow rate of the blown air passing through the cool air bypass passage 35 among the blown air after passing through the indoor evaporator 18. Department.

- the air mix door 34 is driven by an electric actuator for the air mix door. The operation of the electric actuator is controlled by a control signal output from the control device 60.

- the mixing space is disposed downstream of the air flow of the heater core 42 and the cool air bypass passage 35 in the air conditioning case 31.

- the mixing space is a space that mixes the blast air heated by the heater core 42 with the blast air that has not passed through the cool air bypass passage 35 and is not heated.

- an opening hole for blowing out the blast air mixed in the mixing space (that is, the conditioned air) into the vehicle interior, which is the space to be air-conditioned, is arranged downstream of the airflow of the air-conditioning case 31.

- the face opening hole is an opening hole for blowing out conditioned air toward the upper body of the occupant in the passenger compartment.

- the foot opening hole is an opening hole for blowing out conditioned air toward the feet of the occupant.

- the defroster opening hole is an opening hole for blowing out conditioned air toward the inside surface of the vehicle front window glass.

- the face opening, the foot opening, and the defroster opening are respectively formed by a face opening, a foot opening, and a defroster opening provided in the vehicle cabin through ducts forming air passages. )It is connected to the.

- the temperature of the conditioned air mixed in the mixing space is adjusted by adjusting the air flow ratio of the air flow passing through the heater core 42 and the air flow passing through the cool air bypass passage 35 by the air mixing door 34. Then, the temperature of the blown air (conditioned air) blown out from each outlet into the vehicle interior is adjusted.

- Face doors, foot doors, and defroster doors are disposed on the upstream side of the airflow from the face opening, the foot opening, and the defroster opening.

- the face door adjusts the opening area of the face opening hole.

- the foot door adjusts the opening area of the foot opening hole.

- the defroster door is for adjusting the opening area of the froster opening hole.

- These face doors, foot doors and defroster doors constitute an outlet mode switching device for switching the outlet mode.

- These doors are connected to an electric actuator for driving the outlet mode door via a link mechanism or the like, and are rotated in conjunction therewith.

- the operation of the electric actuator is also controlled by a control signal output from the control device 60.

- Specific examples of the outlet mode switched by the outlet mode switching device include a face mode, a bi-level mode, and a foot mode.

- the face mode is an outlet mode in which the face outlet is fully opened and air is blown from the face outlet toward the upper body of the occupant in the vehicle.

- the bi-level mode is an outlet mode in which both the face outlet and the foot outlet are opened to blow air toward the upper body and feet of the occupant in the vehicle.

- the foot mode is an outlet mode in which the foot outlet is fully opened and the defroster outlet is opened by a small opening, and air is mainly blown out from the foot outlet.

- the defroster mode is an outlet mode in which the defroster outlet is fully opened and air is blown from the defroster outlet to the inner surface of the windshield.

- the control device 60 is a control unit including a well-known microcomputer including a CPU, a ROM, a RAM, and the like, and peripheral circuits thereof. Then, various calculations and processes are performed based on the air-conditioning control program stored in the ROM, and various control target devices 11, 14a to 14c, 15a, 15b, 32, 41, 51, 53 connected to the output side. And the like.

- Temperature sensor 64g On the input side of the control device 60, as shown in the block diagram of FIG. Temperature sensor 64g, first refrigerant pressure sensor 65a, second refrigerant pressure sensor 65b, high-temperature heat medium temperature sensor 66a, first low-temperature heat medium temperature sensor 67a, second low-temperature heat medium temperature sensor 67b, battery temperature sensor 68, an air-conditioning air temperature sensor 69 and the like are connected.

- the control unit 60 receives detection signals from these sensor groups.

- the internal air temperature sensor 61 is an internal air temperature detecting unit that detects the vehicle interior temperature (internal air temperature) Tr.

- the outside air temperature sensor 62 is an outside air temperature detection unit that detects a vehicle outside temperature (outside air temperature) Tam.

- the solar radiation sensor 63 is a solar radiation amount detecting unit that detects a solar radiation amount Ts irradiated to the vehicle interior.

- the first refrigerant temperature sensor 64a is a discharge refrigerant temperature detection unit that detects the temperature T1 of the refrigerant discharged from the compressor 11.

- the second refrigerant temperature sensor 64b is a second refrigerant temperature detector that detects the temperature T2 of the refrigerant flowing out of the refrigerant passage of the water-refrigerant heat exchanger 12.

- the third refrigerant temperature sensor 64c is a third refrigerant temperature detecting unit that detects the temperature T3 of the refrigerant flowing out of the outdoor heat exchanger 16.

- the fourth refrigerant temperature sensor 64d is a fourth refrigerant temperature detector that detects the temperature T4 of the refrigerant flowing out of the indoor evaporator 18.

- the fifth refrigerant temperature sensor 64e is a fifth refrigerant temperature detector that detects the temperature T5 of the refrigerant flowing out of the refrigerant passage of the chiller 19.

- the sixth refrigerant temperature sensor 64f is a suction refrigerant temperature detection unit that detects the temperature T6 of the suction refrigerant drawn into the compressor 11, and constitutes the suction refrigerant detection unit.

- the evaporator temperature sensor 64g is an evaporator temperature detector that detects the refrigerant evaporation temperature (evaporator temperature) Tefin in the indoor evaporator 18. Specifically, the evaporator temperature sensor 64g of this embodiment detects the heat exchange fin temperature of the indoor evaporator 18.

- the first refrigerant pressure sensor 65a is a first refrigerant pressure detector that detects the pressure P1 of the refrigerant flowing out of the refrigerant passage of the water-refrigerant heat exchanger 12.

- the second refrigerant pressure sensor 65b is a second refrigerant pressure detector that detects the pressure P2 of the refrigerant flowing out of the refrigerant passage of the chiller 19.

- the high-temperature heat medium temperature sensor 66a is a high-temperature heat medium temperature detection unit that detects the high-temperature heat medium temperature TWH, which is the temperature of the high-temperature heat medium flowing out of the water passage of the water-refrigerant heat exchanger 12.

- the first low-temperature heat medium temperature sensor 67a is a first low-temperature heat medium temperature detection unit that detects the first low-temperature heat medium temperature TWL1, which is the temperature of the low-temperature heat medium flowing out of the water passage of the chiller 19.

- the second low-temperature-side heat medium temperature sensor 67b is a second low-temperature-side heat medium temperature detection unit that detects the second low-temperature-side heat medium temperature TWL2 that is the temperature of the low-temperature side heat medium flowing out of the cooling heat exchange unit 52. .

- the battery temperature sensor 68 is a battery temperature detector that detects the battery temperature TB (that is, the temperature of the battery 80).

- the battery temperature sensor 68 of the present embodiment has a plurality of temperature sensors and detects temperatures at a plurality of locations of the battery 80. For this reason, the control device 60 can also detect a temperature difference between the components of the battery 80. Further, as the battery temperature TB, an average value of detection values of a plurality of temperature sensors is employed.

- the air-conditioning air temperature sensor 69 is an air-conditioning air temperature detecting unit that detects the temperature of the air blown from the mixing space into the vehicle compartment TAV.

- an operation panel 70 disposed near the instrument panel in the front of the vehicle compartment is connected to the input side of the control device 60, and operation from various operation switches provided on the operation panel 70 is performed. A signal is input.

- Specific examples of various operation switches provided on the operation panel 70 include an auto switch, an air conditioner switch, an air volume setting switch, a temperature setting switch, a blowing mode switching switch, and the like.

- the auto switch is an operation unit for setting or canceling the automatic control operation of the vehicle air conditioner.

- the air conditioner switch is an operation unit that requests that the blown air be cooled by the indoor evaporator 18.

- the air volume setting switch is an operation unit for manually setting the air volume of the blower 32.

- the temperature setting switch is an operation unit that sets a target temperature Tset in the vehicle compartment.

- the blowout mode changeover switch is an operation unit for manually setting the blowout mode.

- the control device 60 of the present embodiment has an integrated control unit for controlling various control target devices connected to the output side.

- the configuration (hardware and software) of the control device 60 that controls the operation of each device to be controlled constitutes a control unit that controls the operation of each device to be controlled.

- the configuration for controlling the refrigerant discharge capacity of the compressor 11 constitutes the compressor control unit 60a.

- the configuration for controlling the operations of the heating expansion valve 14a, the cooling expansion valve 14b, and the cooling expansion valve 14c constitutes an expansion valve control unit 60b.

- the configuration for controlling the operations of the dehumidifying on-off valve 15a and the heating on-off valve 15b constitutes a refrigerant circuit switching control unit 60c.

- the configuration for controlling the pumping capacity of the high-temperature side heat medium pump of the high-temperature side heat medium pump 41 constitutes the high-temperature side heat medium pump control unit 60d.

- the configuration for controlling the low-temperature-side heat medium pumping capability of the low-temperature-side heat medium pump 51 constitutes a low-temperature-side heat medium pump control unit 60e.

- the control device 60 has a refrigerant flow rate calculation unit 60f that calculates the flow rate V1 of the refrigerant flowing into the chiller 19.

- the refrigerant flow rate detecting unit 60f firstly detects the flow rate V2 of the refrigerant discharged from the compressor 11 based on the temperature T6 of the refrigerant suctioned by the compressor 11 detected by the sixth refrigerant temperature sensor 64f and the rotation speed of the compressor 11. Is calculated.

- the refrigerant flow rate detection unit 60f determines the opening area of the cooling passage 19a and the opening area of the refrigerant passage of the first refrigerant passage 16a and the third refrigerant passage 18a in which the refrigerant flow is parallel to the cooling passage 19a. Is calculated.

- the refrigerant flow detecting unit 60f calculates the flow V1 of the refrigerant flowing into the chiller 19 based on the flow V2 of the refrigerant discharged from the compressor 11 and the opening area ratio. Therefore, the refrigerant flow rate calculating section 60f of the present embodiment constitutes a refrigerant flow rate detecting section.

- the control device 60 includes a superheat degree calculating unit 60g that calculates the superheat degree SHC of the refrigerant flowing out of the refrigerant passage of the chiller 19.

- the superheat degree calculation unit 60g calculates the superheat degree SHC of the refrigerant flowing out of the refrigerant passage of the chiller 19 based on the temperature T5 detected by the fifth refrigerant temperature sensor 64e and the pressure P2 detected by the second refrigerant pressure sensor 65b. calculate. Therefore, the superheat degree calculator 60g of the present embodiment constitutes a superheat degree detector.

- the vehicle air conditioner 1 of the present embodiment has a function of adjusting the temperature of the battery 80 as well as performing air conditioning of the vehicle interior. For this reason, in the refrigeration cycle apparatus 10, it is possible to perform operation in the following 11 operation modes by switching the refrigerant circuit.

- Cooling mode is an operation mode in which the inside of the vehicle compartment is cooled by cooling the blown air and blowing it out into the vehicle compartment without cooling the battery 80.

- In-series dehumidification heating mode is an operation in which the cooled and dehumidified blast air is reheated and blown out into the vehicle compartment without cooling the battery 80 to perform dehumidification and heating in the vehicle compartment. Mode.

- Parallel dehumidifying and heating mode In the parallel dehumidifying and heating mode, the cooled and dehumidified blast air is reheated with a higher heating capacity than the serial dehumidifying and heating mode and is blown into the vehicle interior without cooling the battery 80. This is an operation mode for performing dehumidification and heating of the vehicle interior.

- the heating mode is an operation mode in which the inside of the vehicle compartment is heated by heating the blown air and blowing it out into the vehicle compartment without cooling the battery 80.

- Cooling cooling mode is an operation mode in which the battery 80 is cooled, and the inside of the vehicle compartment is cooled by cooling the blown air and blowing it out into the vehicle compartment.

- Series dehumidification heating / cooling mode performs cooling of the battery 80, and also performs dehumidification and heating of the vehicle interior by reheating the cooled and dehumidified blast air and blowing it out into the vehicle interior. Operation mode.

- Parallel dehumidification heating / cooling mode cools the battery 80 and reheats the cooled and dehumidified blast air with a higher heating capacity than the serial dehumidification heating / cooling mode to achieve cabin interior. This is an operation mode in which dehumidification and heating of the vehicle interior is performed by blowing air to the vehicle interior.

- Heating / cooling mode is an operation mode in which the battery 80 is cooled, and the inside of the vehicle is heated by heating the blast air and blowing it out into the vehicle interior.

- Heating series cooling mode In the heating series cooling mode, the operation of cooling the battery 80 and heating the inside of the vehicle by heating the blast air with a higher heating capacity than the heating and cooling mode and blowing the air into the vehicle interior. Mode.

- Heating parallel cooling mode In the heating parallel cooling mode, the battery 80 is cooled, and the blast air is heated with a higher heating capacity than the heating serial cooling mode and is blown into the vehicle cabin, thereby heating the vehicle cabin. Operation mode.

- Cooling mode This is an operation mode in which the battery 80 is cooled without performing air conditioning in the passenger compartment.

- the air-conditioning control program is executed when an automatic switch of the operation panel 70 is turned on (ON) by an occupant's operation and automatic control of the vehicle interior is set.

- the air conditioning control program will be described with reference to FIGS.

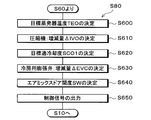

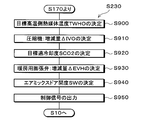

- Each control step shown in the flowchart of FIG. 3 and the like is a function realizing unit of the control device 60.

- step S10 of FIG. 3 the detection signal of the above-described sensor group and the operation signal of the operation panel 70 are read.

- a target outlet temperature TAO which is a target temperature of the air blown into the vehicle interior, is determined based on the detection signal and the operation signal read in step S10. Therefore, step S20 is a target outlet temperature determination unit.

- TAO Kset ⁇ Tset ⁇ Kr ⁇ Tr ⁇ Kam ⁇ Tam ⁇ Ks ⁇ Ts + C (F1)

- Tset is a vehicle interior set temperature set by the temperature setting switch. Tr is a vehicle interior temperature detected by the inside air sensor. Tam is the vehicle outside temperature detected by the outside air sensor. Ts is the amount of solar radiation detected by the solar radiation sensor. Kset, Kr, Kam, and Ks are control gains, and C is a correction constant.

- step S30 it is determined whether or not the air conditioner switch is ON (turned on).

- the fact that the air conditioner switch is turned on means that the occupant is requesting cooling or dehumidification in the vehicle interior.

- the fact that the air conditioner switch is ON means that it is required to cool the blown air in the indoor evaporator 18.

- step S30 If it is determined in step S30 that the air conditioner switch is ON, the process proceeds to step S40. If it is determined in step S30 that the air conditioner switch has not been turned on, the process proceeds to step S160.

- step S40 it is determined whether the outside temperature Tam is equal to or higher than a predetermined reference outside temperature KA (0 ° C. in the present embodiment).

- the reference outside air temperature KA is set so that cooling of the blown air by the indoor evaporator 18 is effective for cooling or dehumidifying the space to be air-conditioned.

- the evaporation pressure regulating valve 20 changes the refrigerant evaporation temperature in the indoor evaporator 18 into a frost formation suppression temperature (1 ° C. in the present embodiment). ) Or more. For this reason, in the indoor evaporator 18, the blown air cannot be cooled to a temperature lower than the frost formation suppression temperature.

- the reference outside air temperature KA is set to a value lower than the frost formation suppression temperature, and when the outside air temperature Tam is lower than the reference outside air temperature KA, the air blown by the indoor evaporator 18 is not cooled. .

- step S40 If it is determined in step S40 that the outside temperature Tam is equal to or higher than the reference outside temperature KA, the process proceeds to step S50. If it is determined in step S40 that the outside temperature Tam is not equal to or higher than the reference outside temperature KA, the process proceeds to step S160.

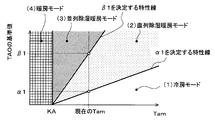

- step S50 it is determined whether the target outlet temperature TAO is equal to or lower than the cooling reference temperature ⁇ 1.

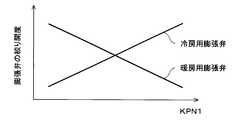

- the cooling reference temperature ⁇ 1 is determined based on the outside air temperature Tam with reference to a control map stored in the control device 60 in advance. In the present embodiment, as shown in FIG. 5, the cooling reference temperature ⁇ 1 is determined to be a low value as the outside temperature Tam decreases.

- step S50 If it is determined in step S50 that the target outlet temperature TAO is equal to or lower than the cooling reference temperature ⁇ 1, the process proceeds to step S60. If it is determined in step S50 that the target outlet temperature TAO is not lower than the cooling reference temperature ⁇ 1, the process proceeds to step S90.