WO2019163416A1 - 防眩性ハードコート積層フィルム - Google Patents

防眩性ハードコート積層フィルム Download PDFInfo

- Publication number

- WO2019163416A1 WO2019163416A1 PCT/JP2019/002639 JP2019002639W WO2019163416A1 WO 2019163416 A1 WO2019163416 A1 WO 2019163416A1 JP 2019002639 W JP2019002639 W JP 2019002639W WO 2019163416 A1 WO2019163416 A1 WO 2019163416A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- hard coat

- mass

- parts

- meth

- laminated film

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/046—Forming abrasion-resistant coatings; Forming surface-hardening coatings

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/043—Improving the adhesiveness of the coatings per se, e.g. forming primers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/042—Coating with two or more layers, where at least one layer of a composition contains a polymer binder

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B27/08—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/18—Layered products comprising a layer of synthetic resin characterised by the use of special additives

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/304—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising vinyl halide (co)polymers, e.g. PVC, PVDC, PVF, PVDF

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/308—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising acrylic (co)polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B33/00—Layered products characterised by particular properties or particular surface features, e.g. particular surface coatings; Layered products designed for particular purposes not covered by another single class

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G75/00—Macromolecular compounds obtained by reactions forming a linkage containing sulfur with or without nitrogen, oxygen, or carbon in the main chain of the macromolecule

- C08G75/02—Polythioethers

- C08G75/04—Polythioethers from mercapto compounds or metallic derivatives thereof

- C08G75/045—Polythioethers from mercapto compounds or metallic derivatives thereof from mercapto compounds and unsaturated compounds

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/18—Manufacture of films or sheets

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/042—Coating with two or more layers, where at least one layer of a composition contains a polymer binder

- C08J7/0423—Coating with two or more layers, where at least one layer of a composition contains a polymer binder with at least one layer of inorganic material and at least one layer of a composition containing a polymer binder

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/0427—Coating with only one layer of a composition containing a polymer binder

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D133/00—Coating compositions based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Coating compositions based on derivatives of such polymers

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D135/00—Coating compositions based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a carboxyl radical, and containing at least another carboxyl radical in the molecule, or of salts, anhydrides, esters, amides, imides or nitriles thereof; Coating compositions based on derivatives of such polymers

- C09D135/02—Homopolymers or copolymers of esters

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D147/00—Coating compositions based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, at least one having two or more carbon-to-carbon double bonds; Coating compositions based on derivatives of such polymers

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D181/00—Coating compositions based on macromolecular compounds obtained by reactions forming in the main chain of the macromolecule a linkage containing sulfur, with or without nitrogen, oxygen, or carbon only; Coating compositions based on polysulfones; Coating compositions based on derivatives of such polymers

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D5/00—Coating compositions, e.g. paints, varnishes or lacquers, characterised by their physical nature or the effects produced; Filling pastes

- C09D5/006—Anti-reflective coatings

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D7/00—Features of coating compositions, not provided for in group C09D5/00; Processes for incorporating ingredients in coating compositions

- C09D7/40—Additives

- C09D7/60—Additives non-macromolecular

- C09D7/63—Additives non-macromolecular organic

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D7/00—Features of coating compositions, not provided for in group C09D5/00; Processes for incorporating ingredients in coating compositions

- C09D7/40—Additives

- C09D7/65—Additives macromolecular

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D7/00—Features of coating compositions, not provided for in group C09D5/00; Processes for incorporating ingredients in coating compositions

- C09D7/40—Additives

- C09D7/66—Additives characterised by particle size

- C09D7/69—Particle size larger than 1000 nm

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K3/00—Materials not provided for elsewhere

- C09K3/18—Materials not provided for elsewhere for application to surfaces to minimize adherence of ice, mist or water thereto; Thawing or antifreeze materials for application to surfaces

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B1/00—Optical elements characterised by the material of which they are made; Optical coatings for optical elements

- G02B1/10—Optical coatings produced by application to, or surface treatment of, optical elements

- G02B1/11—Anti-reflection coatings

- G02B1/111—Anti-reflection coatings using layers comprising organic materials

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B1/00—Optical elements characterised by the material of which they are made; Optical coatings for optical elements

- G02B1/10—Optical coatings produced by application to, or surface treatment of, optical elements

- G02B1/14—Protective coatings, e.g. hard coatings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/02—2 layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/03—3 layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/05—5 or more layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2255/00—Coating on the layer surface

- B32B2255/10—Coating on the layer surface on synthetic resin layer or on natural or synthetic rubber layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2255/00—Coating on the layer surface

- B32B2255/26—Polymeric coating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2255/00—Coating on the layer surface

- B32B2255/28—Multiple coating on one surface

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2264/00—Composition or properties of particles which form a particulate layer or are present as additives

- B32B2264/02—Synthetic macromolecular particles

- B32B2264/0214—Particles made of materials belonging to B32B27/00

- B32B2264/0228—Vinyl resin particles, e.g. polyvinyl acetate, polyvinyl alcohol polymers or ethylene-vinyl acetate copolymers

- B32B2264/0242—Vinyl halide, e.g. PVC, PVDC, PVF or PVDF (co)polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2264/00—Composition or properties of particles which form a particulate layer or are present as additives

- B32B2264/02—Synthetic macromolecular particles

- B32B2264/0214—Particles made of materials belonging to B32B27/00

- B32B2264/025—Acrylic resin particles, e.g. polymethyl methacrylate or ethylene-acrylate copolymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2264/00—Composition or properties of particles which form a particulate layer or are present as additives

- B32B2264/10—Inorganic particles

- B32B2264/102—Oxide or hydroxide

- B32B2264/1021—Silica

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2264/00—Composition or properties of particles which form a particulate layer or are present as additives

- B32B2264/10—Inorganic particles

- B32B2264/102—Oxide or hydroxide

- B32B2264/1023—Alumina

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2264/00—Composition or properties of particles which form a particulate layer or are present as additives

- B32B2264/30—Particles characterised by physical dimension

- B32B2264/302—Average diameter in the range from 100 nm to 1000 nm

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2264/00—Composition or properties of particles which form a particulate layer or are present as additives

- B32B2264/30—Particles characterised by physical dimension

- B32B2264/303—Average diameter greater than 1µm

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/40—Properties of the layers or laminate having particular optical properties

- B32B2307/412—Transparent

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/50—Properties of the layers or laminate having particular mechanical properties

- B32B2307/536—Hardness

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/50—Properties of the layers or laminate having particular mechanical properties

- B32B2307/554—Wear resistance

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2327/00—Polyvinylhalogenides

- B32B2327/12—Polyvinylhalogenides containing fluorine

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2333/00—Polymers of unsaturated acids or derivatives thereof

- B32B2333/04—Polymers of esters

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2383/00—Polysiloxanes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2457/00—Electrical equipment

- B32B2457/20—Displays, e.g. liquid crystal displays, plasma displays

- B32B2457/202—LCD, i.e. liquid crystal displays

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2457/00—Electrical equipment

- B32B2457/20—Displays, e.g. liquid crystal displays, plasma displays

- B32B2457/204—Plasma displays

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2435/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a carboxyl radical, and containing at least one other carboxyl radical in the molecule, or of salts, anhydrides, esters, amides, imides or nitriles thereof; Derivatives of such polymers

- C08J2435/02—Characterised by the use of homopolymers or copolymers of esters

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K5/00—Use of organic ingredients

- C08K5/36—Sulfur-, selenium-, or tellurium-containing compounds

- C08K5/37—Thiols

Definitions

- the present invention relates to an antiglare hard coat laminated film. More specifically, the present invention relates to an antiglare hard coat laminated film having good scratch resistance.

- a car navigation device equipped with a touch panel that is installed on an image display device such as a liquid crystal display, a plasma display, and an electroluminescence display and can be input by touching with a finger or a pen while watching the display. It is popular.

- a plastic display face plate or the surface of a glass display face plate is used. Bonding an anti-scattering film is widely performed. Further, the image display device of the car navigation device is provided with anti-glare properties in order to cope with the problem that light from the outside is incident on the screen and this light is reflected to make it difficult to see the display image.

- the antiglare property is imparted by bonding an antiglare hard coat laminated film to the surface of a plastic display face plate, or forming an antiglare hard coat on the surface of the anti-scattering film.

- a first object of the present invention is to provide a novel antiglare hard coat laminated film having excellent antiglare properties.

- the further subject of this invention is providing the anti-glare hard-coat laminated film which is excellent in anti-glare property and has favorable abrasion resistance.

- Still another subject of the present invention is preferably excellent in antiglare property and scratch resistance, and has at least one characteristic of crack resistance, surface appearance, transparency, color tone, surface hardness, and bending resistance. It is excellent, and more preferably, to provide an antiglare hard coat laminated film excellent in substantially all of these.

- the first hard coat is (A) 100 parts by mass of a copolymer of (a1) polyfunctional (meth) acrylate and (a2) polyfunctional thiol; (B) 0.01 to 7 parts by mass of a water repellent agent; and (C) A hard coat laminated film formed from a paint containing 0.1 to 10 parts by mass of resin fine particles having an average particle size of 0.5 to 10 ⁇ m and no inorganic particles. [2].

- the first hard coat is (A) a copolymer of (a1) polyfunctional (meth) acrylate and (a2) polyfunctional thiol; (B) a water repellent; (C) formed of a paint containing resin fine particles having an average particle size of 0.5 to 10 ⁇ m and no inorganic particles; Hard coat laminated film satisfying the following characteristics (i) to (iii): (I) Place the hard coat laminated film on the Gakushin type testing machine of JIS L0849: 2013 with the first hard coat on the surface, and attach # 0000 steel wool to the friction terminal of the Gakushoku type testing machine Then, after applying a load of 500 g, rubbing the surface of the first hard coat 100 times in a reciprocating manner under the conditions of a moving speed of the friction terminal of 300 mm / min and a moving distance of 30 mm, unacceptable; (Ii) the total light transmittance is

- the third hard coat is formed from a paint containing inorganic particles.

- the hard coat laminated film as described in the above item [1] or [2]. [4].

- the antiglare hard coat laminated film of the present invention is excellent in antiglare property and has good scratch resistance.

- the preferred antiglare hard coat laminated film of the present invention is substantially excellent in all of antiglare properties, scratch resistance, crack resistance, surface appearance, transparency, color tone, surface hardness, and bending resistance. Therefore, this antiglare hard coat laminated film does not have an image display device (an image display device having a touch panel function and a touch panel function) such as an article or an article member, for example, a liquid crystal display, a plasma display, and an electroluminescence display.

- image display devices these display faceplates and members such as housings; devices that are often used in an environment where light from the outside is incident on the screen of a car navigation device or the like, and has a touch panel function It can be suitably used as a member of the apparatus.

- the term “resin” is used as a term including a resin mixture containing two or more resins and a resin composition containing components other than the resin.

- the term “film” is used interchangeably or interchangeably with “sheet”.

- laminating a certain layer and another layer in order means laminating those layers directly and interposing one or more other layers such as anchor coats between these layers. Including both lamination.

- the terms “film” and “sheet” are used for what can be rolled up in a roll form industrially.

- the term “plate” is used for those that cannot be rolled up industrially in roll form.

- ⁇ The term “more” related to a numerical range is used to mean a certain numerical value or a certain numerical value. For example, 20% or more means 20% or more than 20%.

- the term “below” relating to a numerical range is used to mean a certain numerical value or less than a certain numerical value. For example, 20% or less means 20% or less than 20%.

- the symbol “ ⁇ ” in a numerical range is used to mean a certain numerical value, a certain numerical value and less than a certain other numerical value, or another certain numerical value.

- 10-90% means 10%, more than 10% and less than 90%, or 90%.

- the hard coat laminated film of this invention has a 1st hard coat and the layer of a transparent resin film in order from the surface layer side.

- the “surface layer side” refers to the outer surface (display surface when used in an image display device) when an article formed from a hard coat laminated film having a multilayer structure is used in the field. It means close.

- the first hard coat usually forms the surface of the antiglare hard coat laminated film of the present invention.

- the first hard coat generally forms a touch surface when the antiglare hard coat laminated film of the present invention is used as a display face plate of an image display device having a touch panel function.

- the first hard coat exhibits good antiglare properties and good scratch resistance, and functions to prevent scratches even when repeatedly rubbed with steel wool or the like.

- the first hard coat is a copolymer of (A) (a1) polyfunctional (meth) acrylate and (a2) polyfunctional thiol (compound having two or more thiol groups in one molecule), (B) It is formed from a paint containing a water repellent and (C) resin fine particles having an average particle size of 0.5 to 10 ⁇ m and no inorganic particles.

- the first hard coat is preferably 100 parts by mass of (A) (a1) polyfunctional (meth) acrylate and (a2) polyfunctional thiol copolymer, and (B) 0.01 to 7 mass of water repellent. And (C) a coating material containing 0.1 to 10 parts by mass of resin fine particles having an average particle diameter of 0.5 to 10 ⁇ m and not containing inorganic particles.

- Inorganic particles for example, silica (silicon dioxide); metal oxide particles such as aluminum oxide, zirconia, titania, zinc oxide, germanium oxide, indium oxide, tin oxide, indium tin oxide, antimony oxide, and cerium oxide; fluorination Metal fluoride particles such as magnesium and sodium fluoride; metal sulfide particles; metal nitride particles; and metal particles

- silica silicon dioxide

- metal oxide particles such as aluminum oxide, zirconia, titania, zinc oxide, germanium oxide, indium oxide, tin oxide, indium tin oxide, antimony oxide, and cerium oxide

- fluorination Metal fluoride particles such as magnesium and sodium fluoride

- metal sulfide particles metal nitride particles

- metal particles are highly effective in increasing the hardness of the hard coat.

- inorganic particles having an appropriate average particle size are also useful in terms of imparting antiglare properties.

- the inorganic particles have a weak interaction with the resin component such as the

- “does not contain” inorganic particles means that it does not contain a significant amount of inorganic particles from the viewpoint of increasing the hardness of the hard coat.

- the significant amount of the inorganic particles in the above viewpoint is usually about 1 part by mass or more with respect to 100 parts by mass of the copolymer of the component (A). Therefore, “does not contain” inorganic particles means that the amount of inorganic particles is usually 0 parts by mass or more and less than 1 part by mass, preferably 0.5 parts by mass with respect to 100 parts by mass of the copolymer of component (A).

- it can be paraphrased more preferably as 0.1 parts by mass or less, and still more preferably as 0.01 parts by mass or less.

- (A) (a1) Copolymer of polyfunctional (meth) acrylate and (a2) polyfunctional thiol

- the copolymer of component (A) is composed of (a1) polyfunctional (meth) acrylate and (a2) polyfunctional. It is composed of thiol. Since both the component (a1) and the component (a2) are polyfunctional monomers, the component (A) is usually a copolymer having a highly branched structure, a so-called dendrimer structure.

- (meth) acrylate means acrylate or methacrylate.

- the copolymer of the component (A) functions to form a hard coat by being polymerized and cured by an active energy ray such as an ultraviolet ray or an electron beam.

- the component (a1) polyfunctional (meth) acrylate is a (meth) acrylate having two or more (meth) acryloyl groups in one molecule.

- the number of (meth) acryloyl groups in one molecule of the component (a1) is preferably 3 or more, more preferably from the viewpoint of making the copolymer of the component (A) have a so-called dendrimer structure. May be 4 or more, more preferably 5 or more.

- the number of (meth) acryloyl groups in one molecule is usually 20 or less, preferably 12 or less, from the viewpoint of crack resistance.

- polyfunctional (meth) acrylate for example, diethylene glycol di (meth) acrylate, neopentyl glycol di (meth) acrylate, 1,6-hexanediol di (meth) acrylate, polyethylene Glycol di (meth) acrylate, 2,2′-bis (4- (meth) acryloyloxypolyethyleneoxyphenyl) propane, 2,2′-bis (4- (meth) acryloyloxypolypropyleneoxyphenyl) propane, etc.

- diethylene glycol di (meth) acrylate for example, diethylene glycol di (meth) acrylate, neopentyl glycol di (meth) acrylate, 1,6-hexanediol di (meth) acrylate, polyethylene Glycol di (meth) acrylate, 2,2′-bis (4- (meth) acryloyloxypolyethyleneoxyphenyl) propane, 2,2′-bis (4- (meth

- (Meth) acryloyl group-containing bifunctional reactive monomers (meth) acryloyl such as trimethylolpropane tri (meth) acrylate, trimethylolethane tri (meth) acrylate, and ethoxylated trimethylolpropane tri (meth) acrylate -Containing trifunctional reactive monomer; (meth) acryloyl group-containing tetrafunctional reactive monomer such as ditrimethylolpropane tetra (meth) acrylate and pentaerythritol tetramethacrylate; (meth) acryloyl group-containing hexafunctional such as dipentaerythritol hexaacrylate Examples include reactive monomers; (meth) acryloyl group-containing octafunctional reactive monomers such as tripentaerythritol octaacrylate; and polymers (oligomers and prepolymers) containing one or more of these

- the component (a1) polyfunctional (meth) acrylate for example, polyurethane (meth) acrylate, polyester (meth) acrylate, polyacryl (meth) acrylate, polyepoxy (meth) acrylate, polyalkylene glycol Examples thereof include prepolymers or oligomers such as poly (meth) acrylate and polyether (meth) acrylate having two or more (meth) acryloyl groups in one molecule.

- these 1 type, or 2 or more types of mixtures can be used.

- the component (a2) polyfunctional thiol is a compound having two or more thiol groups in one molecule.

- the number of thiol groups in one molecule of the component (a2) is preferably 3 or more, more preferably 4 from the viewpoint of making the copolymer of the component (A) have a so-called dendrimer structure. It may be above.

- the number of thiol groups in one molecule may be usually 20 or less, preferably 12 or less, from the viewpoint of crack resistance of the hard coat laminated film.

- the thiol group of the component (a2) polyfunctional thiol is preferably a secondary thiol group from the viewpoint of the balance between reactivity and handleability.

- the component (a2) polyfunctional thiol has one or more polymerizable functional groups other than thiol groups such as (meth) acryloyl group, vinyl group, epoxy group, and isocyanate group in one molecule. There may be.

- a compound having two or more thiol groups in one molecule and having two or more (meth) acryloyl groups is the component (a2) and not the component (a1).

- Examples of the component (a2) polyfunctional thiol include 1,2-ethanedithiol, ethylene glycol bis (3-mercaptopropionate), diethylene glycol bis (3-mercaptopropionate), 1,4-bis (3 -Compounds having two thiol groups in one molecule such as mercaptobutyryloxy) butane and tetraethylene glycol bis (3-mercaptopropionate); 1,3,5-tris (3-mercaptobutyryloxy) Ethyl) -1,3,5-triazine-2,4,6 (1H, 3H, 5H) -trione, trimethylolpropane tris (3-mercaptobutyrate), trimethylolethane tris (3-mercaptobutyrate), And tris [(3-mercaptopropionyloxy) ethyl] isocyanurate Compounds having three thiol groups in the molecule; compounds having four thiol groups in one molecule such as pentaerythritol

- the copolymer of the component (A) contains a constituent unit derived from a monomer copolymerizable with the component (a1) and the component (a2) in addition to the component (a1) and the component (a2) as long as the object of the present invention is not adversely affected. It may be.

- the copolymerizable monomer is usually a compound having a carbon / carbon double bond, and typically a compound having an ethylenic double bond.

- the content of the structural unit derived from the component (a1) polyfunctional (meth) acrylate in the copolymer of the component (A) (hereinafter sometimes abbreviated as (a1) content) is the polymerizable monomer.

- (a1) content is the polymerizable monomer.

- it may be 50 mol% or more, preferably 60 mol% or more, more preferably 70 mol% or more, still more preferably 80 mol% or more.

- the content of (a1) is from the viewpoint of making the copolymer structure of the component (A) have a so-called dendrimer structure, and from the viewpoint of crack resistance and handling properties of the hard coat laminated film to be formed.

- it may be 99 mol% or less, preferably 97 mol% or less, more preferably 95 mol% or less, and still more preferably 93 mol% or less.

- the content of (a1) is usually 50 mol% or more and 99 mol% or less, preferably 50 mol% or more and 97 mol% or less, with the total of structural units derived from the polymerizable monomer being 100 mol%, 50 mol% to 95 mol%, 50 mol% to 93 mol%, 60 mol% to 99 mol%, 60 mol% to 97 mol%, 60 mol% to 95 mol%, 60 mol% to 93 mol Mol% or less, 70 mol% or more and 99 mol% or less, 70 mol% or more and 97 mol% or less, 70 mol% or more and 95 mol% or less, 70 mol% or more and 93 mol% or less, 80 mol% or more and 99 mol% or less, 80 It may be from mol% to 97 mol%, from 80 mol% to 95 mol%, or from 80 mol% to 93 mol%.

- the content of the structural unit derived from the component (a2) polyfunctional thiol in the copolymer of the component (A) (hereinafter sometimes abbreviated as (a2) content) is derived from the polymerizable monomer. From the viewpoint of making the structure of the component (A) have a so-called dendrimer structure, with the total unit being 100 mol%, and from the viewpoint of crack resistance and handling properties of the hard coat laminated film to be formed, it is usually 1 mol%.

- the content may be 3 mol% or more, more preferably 5 mol% or more, and even more preferably 7 mol% or more.

- the content of (a2) is usually 50 mol from the viewpoint of making the copolymer of the component (A) have a so-called dendrimer structure and from the viewpoint of scratch resistance of the hard coat laminated film to be formed. % Or less, preferably 40 mol% or less, more preferably 30 mol% or less, still more preferably 20 mol% or less.

- the content of (a2) is usually 1 mol% or more and 50 mol% or less, preferably 1 mol% or more and 40 mol% or less, with the total of structural units derived from the polymerizable monomer being 100 mol%, 1 mol% to 30 mol%, 1 mol% to 20 mol%, 3 mol% to 50 mol%, 3 mol% to 40 mol%, 3 mol% to 30 mol%, 3 mol% to 20 Mol% or less, 5 mol% or more and 50 mol% or less, 5 mol% or more and 40 mol% or less, 5 mol% or more and 30 mol% or less, 5 mol% or more and 20 mol% or less, 7 mol% or more and 50 mol% or less, 7 It may be from mol% to 40 mol%, from 7 mol% to 30 mol%, or from 7 mol% to 20 mol%.

- the sum of the content (a1) and the content (a2) is usually 80 mol% or more, preferably 90 mol% or more, with the total of structural units derived from the polymerizable monomer being 100 mol%. Preferably it is 95 mol% or more, More preferably, it may be 99 mol% or more and 100 mol% or less.

- the “polymerizable monomer” means the component (a1) polyfunctional (meth) acrylate, the component (a2) polyfunctional thiol, and a monomer copolymerizable therewith.

- the copolymerizable monomer is usually a compound having a carbon / carbon double bond, and typically a compound having an ethylenic double bond.

- the sulfur content in the copolymer of the component (A) is usually 0.1 to 12% by mass, preferably 0.5 to 10% by mass, from the viewpoint of setting the content (a2) to the above-mentioned preferable range. More preferably, it may be 1 to 7% by mass, and still more preferably 1.5 to 5% by mass. In one embodiment, the sulfur content is 0.1-10 wt%, 0.1-7 wt%, 0.1-5 wt%, 0.5-12 wt%, 0.5-7 wt%, 0.5-5% by mass, 1-12% by mass, 1-10% by mass, 1-5% by mass, 1.5-12% by mass, 1.5-10% by mass, or 1.5-7% by mass It may be.

- the sulfur content is a value measured by atomic absorption spectrometry. Specifically, using a microwave device, using a mixed acid of nitric acid and hydrochloric acid (volume ratio 8: 2), ashing (wet decomposition) of the sample, adding an aqueous hydrochloric acid solution and filtering, It is the value which measured the measurement sample obtained by carrying out the constant volume of a filtrate with purified water by the atomic absorption spectrometry. At this time, yttrium was used as an internal standard. It should be noted that sulfur should be prevented because it binds to iron and the like and precipitates easily. The measurement of the sulfur content by atomic absorption spectrometry was specifically performed according to the following procedure.

- the polytetrafluoroethylene ashing container was allowed to stand until the temperature inside the ashing container reached room temperature, and then degassed for the second time.

- the pressure was increased to 400 PSI at a power of 40 PSI and a temperature of 130 ° C. over 10 minutes, held for 3 minutes, and then increased to a pressure of 60 PSI at a power of 400 P and a temperature of 150 ° C. over 10 minutes.

- the temperature is raised and held for 5 minutes, then the pressure is raised to 400 PSI at a pressure of 100 PSI and a temperature of 160 ° C. over 10 minutes.

- the pressure is raised to a pressure of 250 PSI and a temperature of 180 ° C. over 10 minutes.

- the temperature was raised and held for 3 minutes, and then the temperature was raised to a pressure of 550 PSI at a power of 400 W and a temperature of 200 ° C. over 10 minutes, and maintained for 7 minutes.

- the second heat treatment was performed under the condition that the pressure was raised to a pressure of 600 PSI at a power of 400 W and a temperature of 230 ° C. over 20 minutes and held for 10 minutes.

- 10 mL of a 1: 1 hydrochloric acid aqueous solution of hydrochloric acid for atomic absorption analysis and purified water from Kanto Chemical Co., Inc. was added, mixed, and allowed to stand at room temperature for 6 hours. Filtration was performed using “filter paper No.

- a differential molecular weight distribution curve (hereinafter abbreviated as “GPC curve”) measured by gel permeation chromatography (hereinafter abbreviated as “GPC”) of the copolymer of component (A) using tetrahydrofuran as the mobile phase.

- the weight average molecular weight (Mw) calculated in terms of polystyrene is preferably 5,000 or more, more preferably 8,000, from the viewpoint of the balance between scratch resistance and crack resistance of the hard coat laminated film to be formed. More preferably, it may be 10,000 or more.

- this mass average molecular weight (Mw) is preferably 200,000 or less, more preferably 100,000 or less, and still more preferably 50,000 or less, from the viewpoint of the coating property of the coating material containing the copolymer of the component (A). It may be.

- the mass average molecular weight (Mw) of the copolymer of the component (A) is preferably 5,000 to 200,000, more preferably 5,000 to 100,000, 5,000 to 50,000, It may be 8,000 to 200,000, 8,000 to 100,000, 8,000 to 50,000, 10,000 to 200,000, 10,000 to 100,000, or 10,000 to 50,000.

- the polystyrene-equivalent Z-average molecular weight (Mz) determined from the GPC curve of the copolymer of component (A) is the scratch resistance and crack resistance of the hard coat laminated film to be formed. From the viewpoint of balance, it may be preferably 5,000 or more, more preferably 10,000 or more, and still more preferably 30,000 or more. On the other hand, the Z average molecular weight (Mz) is preferably 200,000 or less, more preferably 150,000 or less, and further preferably 120,000 or less, from the viewpoint of the coating property of the coating material containing the copolymer of the component (A). It may be.

- the Z average molecular weight (Mz) of the copolymer of the component (A) is preferably 5,000 to 200,000, more preferably 5,000 to 150,000, 5,000 to 120,000, It may be 10,000 or more and 200,000 or less, 10,000 or more and 150,000 or less, 10,000 or more and 120,000 or less, 30,000 or more and 200,000 or less, 30,000 or more and 150,000 or less, or 30,000 or more and 120,000 or less.

- GPC measurement uses Tosoh Corporation's high-performance liquid chromatography system “HLC-8320” (trade name) (a system that includes a degasser, liquid feed pump, autosampler, column oven, and RI (differential refractive index) detector).

- HLC-8320 high-performance liquid chromatography system

- GPC column Shodex's GPC columns “KF-806L” (trade name), 2 pieces, “KF-802” (trade name) and “KF-801” (trade name), one each Four tubes are connected in the order of KF-806L, KF-806L, KF-802, and KF-801 from the upstream side; tetrahydrofuran for high-performance liquid chromatograph manufactured by Wako Pure Chemical Industries, Ltd.

- flow rate 1.0 ml / min, column temperature 40 ° C., sample concentration 1 mg / ml, and sample injection volume 00 can be carried out under the conditions of a micro liter.

- the elution amount in each holding volume can be determined from the detection amount of the RI detector, assuming that the refractive index of the measurement sample does not depend on the molecular weight.

- the calibration curve from the retention capacity to the polystyrene-converted molecular weight is the standard polystyrene “EasiCal PS-1” (trade name) (Plain A molecular weight 6335000, 573000, 117000, 31500, 3480; Agilent Technology, Inc .; The molecular weight of Plain B 2517000, 270600, 71800, 10750, 705) can be used.

- the analysis program can use “TOSOH HLC-8320GPC EcoSEC” (trade name) manufactured by Tosoh Corporation.

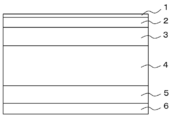

- FIG. 1 shows a differential molecular weight distribution curve of a copolymer of the following component (A-1) used in the examples.

- A-1 the following component used in the examples.

- Three distinct peaks are observed in a relatively low molecular weight region, and the polystyrene equivalent molecular weights at the peak top positions are 340, 570, and 970 in order from the low molecular weight side.

- a plurality of overlapping and broad peaks are observed on the high molecular weight side from these three peaks, and the polystyrene equivalent molecular weight of the highest molecular weight component is recognized to be about 200,000.

- the overall mass average molecular weight is 12,000, the number average molecular weight is 940, and the Z average molecular weight is 73,000.

- the component (B) water-repellent agent functions to improve the scratch resistance, slipping property, dirt adhesion prevention property, and dirt wiping property of the hard coat laminated film to be formed.

- water repellent examples include wax-based water repellents such as paraffin wax, polyethylene wax, and acrylic / ethylene copolymer wax; silicon-based water repellents such as silicon oil, silicon resin, polydimethylsiloxane, and alkylalkoxysilane. Agents; fluorine-containing water repellents such as fluoropolyether water repellents and fluoropolyalkyl water repellents.

- the component (B) water repellent is preferably a fluorine-containing water repellent from the viewpoint of the scratch resistance and water repellent performance of the hard coat laminated film to be formed.

- the component (B) water-repellent agent the hard coat laminated film formed has scratch resistance, water-repellent performance, and the above-mentioned component (B) is chemically bonded to or strongly interacted with the copolymer of component (A).

- the water-repellent agent containing a (meth) acryloyl group and containing a (meth) acryloyl group (hereinafter referred to as “(meth) acryloyl group-containing)” It may be abbreviated as “fluorinated water repellent”).

- the (meth) acryloyl group-containing fluorine-based water repellent has one or more (meth) acryloyl groups in the molecule and one or more, preferably three or more, more preferably five in the molecule.

- a compound having the above fluorine-carbon bond (typically, a structure in which one or two or more hydrogen atoms of an organic functional group such as a hydrocarbon group are substituted with fluorine atoms).

- Examples of the (meth) acryloyl group-containing fluorine-based water repellent include (meth) acryloyl group-containing fluoroether-based water repellent, (meth) acryloyl group-containing fluoroalkyl-based water repellent, and (meth) acryloyl group-containing fluorophore.

- Oroalkenyl water repellent (meth) acryloyl group-containing fluoropolyether water repellent, (meth) acryloyl group-containing fluoropolyalkyl water repellent, and (meth) acryloyl group-containing fluoropolyalkenyl water repellent And so on.

- the component (B) water repellent includes a water repellent (hereinafter referred to as a (meth) acryloyl group-containing fluoropolyether water repellent) containing a compound containing a (meth) acryloyl group and a fluoropolyether group in the molecule. Is abbreviated).

- a water repellent hereinafter referred to as a (meth) acryloyl group-containing fluoropolyether water repellent

- the chemical bond or interaction of the said component (B) and the copolymer of the said component (A) is adjusted suitably, and transparency of the hard coat laminated

- the most suitable mixture is an acryloyl group-containing fluoropolyether water repellent and a methacryloyl group-containing fluoropolyether water repellent. preferable.

- component (B) water repellent one or a mixture of two or more thereof can be used.

- the (meth) acryloyl group-containing fluorine-based water repellent is clearly distinguished from the component (a1) polyfunctional (meth) acrylate in that it has one or more fluorine / carbon bonds in the molecule.

- a compound containing two or more (meth) acryloyl groups in one molecule and having one or more fluorine / carbon bonds in the molecule is the component (B).

- the (meth) acryloyl group-containing fluoropolyether water repellent is clearly distinguished from the component (a1) polyfunctional (meth) acrylate in that it contains a fluoropolyether group in the molecule.

- the compound containing two or more (meth) acryloyl groups in one molecule and containing a fluoropolyether group is the component (B).

- the blending amount of the component (B) water repellent is appropriately determined from the viewpoint of improving the sufficient scratch resistance of the hard coat laminated film to be formed, particularly the property (i) (steel wool resistance). be able to.

- the blending amount of the component (B) water repellent in the first hard coat forming coating material In general, 0.01 parts by mass or more, preferably 0.02 parts by mass or more, more preferably 0.03 parts by mass or more, still more preferably 0.05 parts by mass or more, still more preferably 0.1 parts by mass or more, Even more preferably, it may be 0.3 parts by mass or more.

- this blending amount is usually 7 parts by mass or less, preferably 4 parts by mass or less, more preferably 2 parts by mass or less from the viewpoint of preventing troubles such as bleeding out of the component (B).

- the amount of the component (B) water repellent is usually 0.01 to 7 parts by mass, preferably 0.01 to 4 parts by mass, 0.01 to 2 parts by mass. 0.02 parts by mass to 7 parts by mass, 0.02 parts by mass to 4 parts by mass, 0.02 parts by mass to 2 parts by mass, 0.03 parts by mass to 7 parts by mass, 0.03 parts by mass Parts by mass to 4 parts by mass, 0.03 parts by mass to 2 parts by mass, 0.05 parts by mass to 7 parts by mass, 0.05 parts by mass to 4 parts by mass, 0.05 parts by mass to 2 parts by mass 0.1 to 7 parts by mass, 0.1 to 4 parts by mass, 0.1 to 2 parts by mass, 0.3 to 7 parts by mass, 0.3 parts by mass It may be 4 parts by mass or less, or 0.3 parts by mass or more and 2 parts by mass or less.

- (C) Resin fine particles having an average particle size of 0.5 to 10 ⁇ m

- the resin fine particles of the above component (C) impart antiglare properties to the antiglare hard coat laminated film of the present invention, and are externally displayed on the screen of the image display device. Even if the light from the light enters and reflects, the display image can be visually recognized.

- the resin fine particles include resin fine particles such as silicon resin, styrene resin, acrylic resin, fluorine resin, polycarbonate resin, ethylene resin, and a cured resin of an amino compound and formaldehyde. .

- resin fine particles such as silicon resin, styrene resin, acrylic resin, fluorine resin, polycarbonate resin, ethylene resin, and a cured resin of an amino compound and formaldehyde.

- fine particles of silicon resin, acrylic resin, and fluorine resin are preferable.

- a spherical shape is preferable.

- the resin fine particles one or a mixture of two or more of these can be used.

- the average particle diameter of the resin fine particles of the component (C) is usually 0.5 ⁇ m or more, preferably 1 ⁇ m or more from the viewpoint of reliably obtaining the antiglare property of the hard coat laminated film. On the other hand, this average particle diameter is usually 10 ⁇ m or less, preferably 6 ⁇ m or less, from the viewpoint of maintaining the transparency of the hard coat laminated film. In one embodiment, the average particle size of the resin fine particles of the component (C) is usually 0.5 ⁇ m to 10 ⁇ m, preferably 0.5 ⁇ m to 6 ⁇ m, 1 ⁇ m to 10 ⁇ m, 1 ⁇ m to 6 ⁇ m. .

- the average particle diameter of the resin fine particles is a particle diameter at which the accumulation from the smaller particles becomes 50 mass% in the particle diameter distribution curve measured by the laser diffraction / scattering method.

- the average particle size of the resin fine particles is 50% by mass from the smaller particle size in a particle size distribution curve measured using a laser diffraction / scattering particle size analyzer “MT3200II” (trade name) manufactured by Nikkiso Co., Ltd.

- the particle diameter can be calculated as follows.

- the blending amount of the resin fine particles of the component (C) depends on the antiglare level to be imparted, but the characteristic (iii) is a viewpoint for setting the Y value of the XYZ display system based on the 2-degree visual field to a suitable range. Can be determined as appropriate.

- the blending amount of the resin fine particles of the component (C) is usually 0.1 to 10 mass, although it depends on the antiglare level to be imparted to 100 parts by mass of the copolymer of the component (A). Parts, preferably 0.2 to 5 parts by weight, more preferably 0.3 to 3 parts by weight. Further, from the viewpoint of scratch resistance and transparency of the hard coat laminated film, it may be preferably 0.5 to 3 parts by mass. In one embodiment, the amount of the resin fine particles of the component (C) is 0.1 to 5 parts by weight, 0.1 to 3 parts by weight, 0 parts by weight with respect to 100 parts by weight of the copolymer of the component (A). 2-10 parts by weight, 0.2-3 parts by weight, 0.3-10 parts by weight, 0.3-5 parts by weight, 0.5-10 parts by weight, or 0.5-5 parts by weight Good.

- the first hard coat forming coating composition includes a compound having two or more isocyanate groups (—N ⁇ C ⁇ O) in one molecule and / or photopolymerization from the viewpoint of improving curability by active energy rays. It is preferable to further include an initiator.

- Examples of the compound having two or more isocyanate groups in one molecule include methylene bis-4-cyclohexyl isocyanate; a trimethylolpropane adduct of tolylene diisocyanate, a trimethylolpropane adduct of hexamethylene diisocyanate, and a trimethylolpropane adduct of isophorone diisocyanate.

- Polyisocyanates such as methylolpropane adduct, isocyanurate of tolylene diisocyanate, isocyanurate of hexamethylene diisocyanate, isocyanurate of isophorone diisocyanate, biuret of hexamethylene diisocyanate; and block isocyanates of the above polyisocyanates, etc.

- examples thereof include a urethane cross-linking agent.

- the compound having two or more isocyanate groups in one molecule one or a mixture of two or more thereof can be used.

- a catalyst such as dibutyltin dilaurate or dibutyltin diethylhexoate may be added as necessary.

- photopolymerization initiator examples include benzophenone, methyl-o-benzoylbenzoate, 4-methylbenzophenone, 4,4′-bis (diethylamino) benzophenone, methyl o-benzoylbenzoate, 4-phenylbenzophenone, 4-benzoyl.

- Benzophenone compounds such as -4'-methyldiphenyl sulfide, 3,3 ', 4,4'-tetra (tert-butylperoxycarbonyl) benzophenone, 2,4,6-trimethylbenzophenone; benzoin, benzoin methyl ether, benzoin Benzoin compounds such as ethyl ether, benzoin isopropyl ether, benzyl methyl ketal; acetophenone, 2,2-dimethoxy-2-phenylacetophenone, 1-hydroxycyclohexyl phenyl ketone Acetophenone compounds; anthraquinone compounds such as methylanthraquinone, 2-ethylanthraquinone, 2-amylanthraquinone; thioxanthone compounds such as thioxanthone, 2,4-diethylthioxanthone, 2,4-diisopropylthioxanthone; alkyls such

- acetophenone photopolymerization initiators such as 1-hydroxy-cyclohexyl-phenylketone and 2-hydroxy-1- ⁇ 4- [4- (2-hydroxy-2-methyl-) are used. It is preferred to use in combination with propionyl) -benzyl] phenyl ⁇ -2-methyl-propan-1-one. Thereby, it can fully harden, suppressing coloring of a hard coat lamination film.

- the first hard coat-forming coating material includes, as desired, an antistatic agent, a surfactant, a leveling agent, a thixotropic agent, a stain-preventing agent, a printability improving agent, an antioxidant, a weathering stabilizer, One or more additives such as a light resistance stabilizer, an ultraviolet absorber, a heat stabilizer, and an organic colorant can be included.

- the first hard coat-forming coating material may contain a solvent as desired in order to dilute to a concentration that facilitates coating.

- the solvent is not particularly limited as long as it does not react with the above components (A) to (C) and other optional components, nor does it catalyze (promote) the self-reaction (including deterioration reaction) of these components.

- the solvent include 1-methoxy-2-propanol, ethyl acetate, n-butyl acetate, toluene, methyl ethyl ketone, methyl isobutyl ketone, diacetone alcohol, and acetone.

- these 1 type, or 2 or more types of mixtures can be used.

- the first hard coat forming paint can be obtained by mixing and stirring these components.

- the method for forming the first hard coat using the first hard coat forming paint is not particularly limited, and a known web coating method can be used. Examples of the method include methods such as roll coating, gravure coating, reverse coating, roll brushing, dip coating, spray coating, spin coating, air knife coating, and die coating.

- the thickness of the first hard coat is usually 0.5 ⁇ m or more, preferably 1 ⁇ m or more, from the viewpoint of scratch resistance of the hard coat laminated film to be formed, in particular, from the viewpoint of satisfying the above characteristic (i) and the surface hardness. More preferably, it may be 1.5 ⁇ m or more, more preferably 1.8 ⁇ m or more.

- the thickness of the first hard coat is preferably 3 times the average particle diameter of the resin fine particles of the component (C) used in the first hard coat forming coating material from the viewpoint of antiglare property of the hard coat laminated film. Hereinafter, it may be more preferably 2 times or less, and still more preferably 1x or less.

- the thickness of the first hard coat is preferably 6 ⁇ m or less, more preferably 4 ⁇ m.

- the thickness of the first hard coat is preferably 9 ⁇ m or less, more preferably 6 ⁇ m or less, More preferably, it may be 3 ⁇ m or less.

- the thickness of the first hard coat is preferably 0.5 ⁇ m or more and not more than 3 times the average particle diameter of the resin fine particles of the component (C), 0.5 ⁇ m or more and the thickness of the component (C). 2 times or less the average particle diameter of the resin fine particles, 0.5 ⁇ m or more and 3 times the average particle diameter of the resin fine particles of the above component (C) and 1 ⁇ m or more and 1 ⁇ m or more.

- the average particle diameter of the resin fine particles of the component (C) is 3 times or less, 1.8 ⁇ m or more, and the average particle diameter of the resin fine particles of the above component (C) is 2 times or less, or 1.8 ⁇ m or more and of the above component (C). It may be less than or equal to the average particle diameter of the resin fine particles.

- the hard coat laminated film of the present invention preferably has a first hard coat, a transparent resin film layer, and a second hard coat in order from the surface layer side.

- a first hard coat a transparent resin film layer

- a second hard coat in order from the surface layer side.

- the second hard coat is not particularly limited, and can be formed by any method using any paint.

- the second hard coat is preferably (A) (a1) polyfunctional (meth) acrylate and (a2) two or more thiol groups in one molecule from the viewpoint of curl resistance of the resulting hard coat laminated film. It is formed from the coating material containing the copolymer with the compound which has this.

- the second hard coat is more preferably (A) (a1) a polyfunctional (meth) acrylate and (a2) a copolymer of a compound having two or more thiol groups in one molecule, and (D) leveling. It is formed from a paint containing an agent.

- the second hard coat is more preferably 100 parts by mass of a copolymer of (A) (a1) polyfunctional (meth) acrylate and (a2) a compound having two or more thiol groups in one molecule, and ( D) It is formed from a paint containing 0.01 to 10 parts by weight of a leveling agent.

- copolymer of the above component (A) those described above in the description of the first hard coat forming paint can be used.

- these 1 type, or 2 or more types of mixtures can be used.

- the copolymer of the component (A) from the viewpoint of curling resistance of the hard coat laminated film to be obtained, the same one as that used for the first hard coat forming paint is more preferable.

- Leveling agent is preferably included in the second hard coat forming coating material from the viewpoint of smoothening the surface of the second hard coat.

- the leveling agent examples include acrylic leveling agents, silicon leveling agents, fluorine leveling agents, silicon / acrylic copolymer leveling agents, fluorine-modified acrylic leveling agents, fluorine-modified silicon leveling agents, and functionalities thereof.

- a leveling agent having a group introduced therein for example, alkoxy group such as methoxy group, ethoxy group, acyloxy group, halogen group, amino group, vinyl group, epoxy group, methacryloxy group, acryloxy group, and isocyanate group.

- an acrylic leveling agent and a silicon / acrylic copolymer leveling agent are preferable from the viewpoint of printability.

- these 1 type, or 2 or more types of mixtures can be used.

- the amount of the component (D) leveling agent is usually 0.01 parts by mass from the viewpoint of smoothening the surface of the second hard coat with respect to 100 parts by mass of the copolymer of the component (A). As mentioned above, Preferably it may be 0.1 mass part or more, More preferably, it may be 0.2 mass part or more. On the other hand, the blending amount is usually 10 parts by mass or less, preferably 7 parts by mass or less, more preferably 4 parts by mass or less, and still more preferably, from the viewpoint of preventing troubles such as bleeding out of the component (D) leveling agent. It may be 2 parts by mass or less.

- the compounding quantity of the said component (D) leveling agent is 0.01 mass part or more normally 10 mass parts or less with respect to 100 mass parts of copolymers of the said component (A), Preferably, it is 0.00. 01 parts by mass to 7 parts by mass, 0.01 parts by mass to 4 parts by mass, 0.01 parts by mass to 2 parts by mass, 0.1 parts by mass to 10 parts by mass, 0.1 parts by mass to 7 parts by mass Parts by weight, 0.1 parts by weight or more and 4 parts by weight or less, 0.1 parts by weight or more and 2 parts by weight or less, 0.2 parts by weight or more and 10 parts by weight or less, 0.2 parts by weight or more and 7 parts by weight or less, 0.2 It may be no less than 4 parts by mass and no greater than 0.2 parts by mass and no greater than 2 parts by mass.

- the second hard coat-forming coating material has a compound having two or more isocyanate groups (—N ⁇ C ⁇ O) in one molecule and / or photopolymerization. It is preferable to further include an initiator.

- the compound having two or more isocyanate groups in one molecule those described above in the description of the first hard coat forming paint can be used.

- the compound having two or more isocyanate groups in one molecule one or a mixture of two or more thereof can be used.

- photopolymerization initiator those described above in the description of the first hard coat forming paint can be used.

- photopolymerization initiator one or a mixture of two or more of these can be used.

- an antistatic agent for the second hard coat forming coating, an antistatic agent, a surfactant, a thixotropic agent, a stain inhibitor, a printability improver, an antioxidant, a weather resistance stabilizer, and a light resistance stability are optionally added.

- One or more additives such as an agent, an ultraviolet absorber, a heat stabilizer, a colorant, inorganic particles, and organic particles can be included.

- the second hard coat-forming coating material may contain a solvent as desired in order to dilute to a concentration that is easy to apply. If the said solvent does not react with the said component (A), the said component (D), and other arbitrary components, or does not catalyze (promote) the self-reaction (including deterioration reaction) of these components, There is no particular limitation.

- the solvent include 1-methoxy-2-propanol, ethyl acetate, n-butyl acetate, toluene, methyl ethyl ketone, methyl isobutyl ketone, diacetone alcohol, and acetone. As said solvent, these 1 type, or 2 or more types of mixtures can be used.

- the second hard coat forming paint can be obtained by mixing and stirring these components.

- the method for forming the second hard coat using the second hard coat forming paint is not particularly limited, and a known web coating method can be used. Examples of the method include methods such as roll coating, gravure coating, reverse coating, roll brushing, dip coating, spray coating, spin coating, air knife coating, and die coating.

- the thickness of the second hard coat is not particularly limited, but is usually 60 ⁇ m or less, preferably 30 ⁇ m or less, more preferably 25 ⁇ m or less, and even more preferably 20 ⁇ m or less from the viewpoint of bending resistance of the obtained hard coat laminated film. It's okay.

- the thickness of the second hard coat is usually 0.5 ⁇ m or more, preferably 1 ⁇ m or more, more preferably 1.5 ⁇ m or more, and further preferably 1.8 ⁇ m or more, from the viewpoint of suppressing the curling force of the hard coat laminated film. It may be.

- the thickness of the second hard coat is usually 0.5 ⁇ m to 60 ⁇ m, preferably 0.5 ⁇ m to 30 ⁇ m, 0.5 ⁇ m to 25 ⁇ m, 0.5 ⁇ m to 20 ⁇ m, 1 ⁇ m to 60 ⁇ m. 1 ⁇ m to 30 ⁇ m, 1 ⁇ m to 25 ⁇ m, 1 ⁇ m to 20 ⁇ m, 1.5 ⁇ m to 60 ⁇ m, 1.5 ⁇ m to 30 ⁇ m, 1.5 ⁇ m to 25 ⁇ m, 1.5 ⁇ m to 20 ⁇ m, 1.8 ⁇ m to 60 ⁇ m 1.8 ⁇ m to 30 ⁇ m, 1.8 ⁇ m to 25 ⁇ m, or 1.8 ⁇ m to 20 ⁇ m.

- the thickness of the second hard coat may be the same as that of the first hard coat from the viewpoint of curl resistance of the hard coat laminated film.

- the“ same thickness ” should not be interpreted as completely the same thickness in a physicochemically strict sense.

- the thickness should be construed as the same thickness within the range of process / quality control that is usually performed in industry. This is because the curl resistance of the hard coat laminated film can be kept good if the thickness is the same within the range of the amplitude of the process and quality control that are usually performed industrially. Since the thickness of the hard coat (after curing) is usually controlled in process and quality with a width of about ⁇ 0.5 to +0.5 ⁇ m, for example, when the set thickness is 10 ⁇ m, the thickness is 9.5 ⁇ m and the thickness 10 .5 ⁇ m should be interpreted as the same.

- the “same thickness” here is also referred to as “substantially the same thickness”.

- the hard coat laminated film of the present invention may preferably have a first hard coat, a third hard coat, and a transparent resin film layer in order from the surface layer side.

- the hard coat laminated film of the present invention may more preferably have a first hard coat, a third hard coat, a transparent resin film layer, and a second hard coat in order from the surface layer side.

- the third hard coat By forming the third hard coat, the surface hardness of the first hard coat can be increased.

- the third hard coat is not particularly limited, and can be formed by any method using any paint.

- As the third hard coat forming coating material (E) a coating material containing inorganic particles is preferable from the viewpoint of increasing the surface hardness of the first hard coat.

- the paint for forming the third hard coat is more preferably a paint containing (F) an active energy ray-curable resin and (E) inorganic particles.

- containing inorganic particles means that the particles contain a significant amount of inorganic particles to increase the hardness of the hard coat.

- the amount of inorganic particles significant for increasing the hardness of the hard coat is usually about 5 parts by mass or more with respect to 100 parts by mass of the resin component of the paint. Therefore, “containing” the inorganic particles means that the amount of the inorganic particles is usually 5 parts by mass or more, preferably 30 parts by mass or more, more preferably 50 parts by mass or more, and still more preferably with respect to 100 parts by mass of the resin component of the paint. Can be paraphrased as 80 parts by mass or more, still more preferably 100 parts by mass or more, and most preferably 120 parts by mass or more.

- the upper limit of the amount of the inorganic particles is not particularly limited. For example, it is usually 1000 parts by mass or less, preferably 500 parts by mass or less, and more preferably 300 parts by mass or less with respect to 100 parts by mass of the resin component of the paint. It's okay.

- the amount of the component (E) inorganic particles is usually 5 parts by mass or more and 1000 parts by mass or less, preferably 5 parts by mass or more and 500 parts by mass or less, 5 parts by mass with respect to 100 parts by mass of the resin component of the paint.

- Part by mass to 300 parts by mass, 30 parts by mass to 1000 parts by mass, 30 parts by mass to 500 parts by mass, 30 parts by mass to 300 parts by mass, 50 parts by mass to 1000 parts by mass, 50 parts by mass to 500 parts by mass. 50 to 300 parts by mass, 80 to 1000 parts by mass, 80 to 500 parts by mass, 80 to 300 parts by mass, 100 to 1000 parts by mass, 100 parts by mass 500 parts by weight or less, 100 parts by weight or more and 300 parts by weight or less, 120 parts by weight or more and 1000 parts by weight or less, 120 parts by weight or more and 500 parts by weight or less, or 1 0 may be at mass parts to 300 parts by weight.

- the component (F) active energy ray-curable resin functions to form a hard coat by being polymerized and cured by active energy rays such as ultraviolet rays and electron beams.

- component (F) active energy ray-curable resin examples include polyfunctional (meth) acrylates, polyfunctional thiols, monomers copolymerizable therewith, and polymers containing one or more of these as constituent monomers (pre-polymers). Polymer or oligomer). Examples of the polymer include a copolymer of a polyfunctional (meth) acrylate and a polyfunctional thiol.

- polyfunctional (meth) acrylate those described above as the component (a1) in the description of the first hard coat-forming coating material can be used.

- polyfunctional thiol what was mentioned above as a component (a2) in description of the coating material for 1st hard-coat formation can be used.

- Examples of the monomer copolymerizable with these include, for example, methyl (meth) acrylate, ethyl (meth) acrylate, n-butyl (meth) acrylate, hexyl (meth) acrylate, 2-ethylhexyl (meth) acrylate, lauryl (meth) ) Acrylate, isobornyl (meth) acrylate, dicyclopentenyl (meth) acrylate, dicyclopentenyloxyethyl (meth) acrylate, phenyl (meth) acrylate, phenyl cellosolve (meth) acrylate, 2-methoxyethyl (meth) acrylate, Hydroxyethyl (meth) acrylate, hydroxypropyl (meth) acrylate, 2-acryloyloxyethyl hydrogen phthalate, dimethylaminoethyl (meth) acrylate, trifluoroethy

- component (F) active energy ray-curable resin one or a mixture of two or more of these can be used.

- (meth) acrylate means acrylate or methacrylate.

- the component (E) inorganic particles function to dramatically increase the hardness of the hard coat laminated film of the present invention.

- the inorganic particles include silica (silicon dioxide); metal oxide particles such as aluminum oxide, zirconia, titania, zinc oxide, germanium oxide, indium oxide, tin oxide, indium tin oxide, antimony oxide, and cerium oxide.

- Metal fluoride particles such as magnesium fluoride and sodium fluoride; metal sulfide particles; metal nitride particles; and metal particles.

- silica or aluminum oxide particles are preferable, and silica particles are more preferable.

- examples of commercially available silica particles include Snowtex (trade name) manufactured by Nissan Chemical Industries, Ltd., Quartron (trade name) manufactured by Fuso Chemical Industries, Ltd., and the like.

- the surface of the inorganic particles is treated with a silane coupling agent such as vinylsilane or aminosilane; a titanate cup. Ringing agent; aluminate coupling agent; organic compound having reactive functional group such as ethylenically unsaturated bond group such as (meth) acryloyl group, vinyl group and allyl group and epoxy group; and fatty acid, fatty acid metal salt It is preferable to use those treated with a surface treating agent such as

- component (E) inorganic particles one kind or a mixture of two or more kinds thereof can be used.

- the average particle size of the above component (E) inorganic particles is usually 300 nm or less, preferably 200 nm or less, more preferably 120 nm or less, from the viewpoint of maintaining the transparency of the hard coat and ensuring the effect of improving the hardness. It's okay. On the other hand, there is no particular lower limit on the average particle diameter, but usually available inorganic particles are at most about 1 nm even if they are fine.

- the average particle diameter of the inorganic particles is a particle diameter at which the accumulation from the smaller particles becomes 50% by mass in the particle diameter distribution curve measured by the laser diffraction / scattering method.

- the average particle size of the inorganic particles is 50% by mass from the smaller particle size in a particle size distribution curve measured using a laser diffraction / scattering particle size analyzer “MT3200II” (trade name) manufactured by Nikkiso Co., Ltd.

- the particle diameter can be calculated as follows.

- the amount of the component (E) inorganic particles is based on 100 parts by mass of the component (F). From the viewpoint of the surface hardness of the hard coat laminated film, it is usually 30 parts by mass or more, preferably 50 parts by mass or more, more preferably 80 parts by mass or more, still more preferably 100 parts by mass or more, and most preferably 120 parts by mass or more. Good. On the other hand, the blending amount is usually 300 parts by mass or less, preferably 250 parts by mass or less, more preferably 200 parts by mass or less, from the viewpoint of the transparency of the hard coat laminated film.

- the compounding amount of the component (E) inorganic particles is usually 30 parts by mass or more and 300 parts by mass with respect to 100 parts by mass of the component (F) active energy ray curable resin (when the resin is used). Parts by mass or less, preferably 30 parts by mass to 250 parts by mass, 30 parts by mass to 200 parts by mass, 50 parts by mass to 300 parts by mass, 50 parts by mass to 250 parts by mass, 50 parts by mass to 200 parts by mass 80 to 300 parts by mass, 80 to 250 parts by mass, 80 to 200 parts by mass, 100 to 300 parts by mass, 100 to 250 parts by mass, 100 parts by mass 200 parts by mass or less, 120 parts by mass or more and 300 parts by mass or less, 120 parts by mass or more and 250 parts by mass or less, or 120 parts by mass or more and 200 parts by mass or less. .

- the third hard coat forming coating composition further includes (D) a leveling agent from the viewpoint of making the surface of the third hard coat smooth and facilitating the formation of the first hard coat. Preferably.