WO2019097969A1 - 成形装置 - Google Patents

成形装置 Download PDFInfo

- Publication number

- WO2019097969A1 WO2019097969A1 PCT/JP2018/039511 JP2018039511W WO2019097969A1 WO 2019097969 A1 WO2019097969 A1 WO 2019097969A1 JP 2018039511 W JP2018039511 W JP 2018039511W WO 2019097969 A1 WO2019097969 A1 WO 2019097969A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- mold

- composite material

- molding

- composite

- type

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/40—Shaping or impregnating by compression not applied

- B29C70/42—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles

- B29C70/46—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles using matched moulds, e.g. for deforming sheet moulding compounds [SMC] or prepregs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/38—Moulds or cores; Details thereof or accessories therefor characterised by the material or the manufacturing process

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/32—Component parts, details or accessories; Auxiliary operations

- B29C43/36—Moulds for making articles of definite length, i.e. discrete articles

Definitions

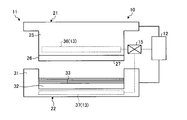

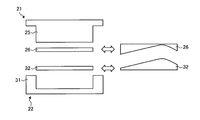

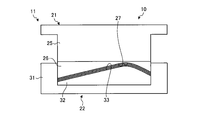

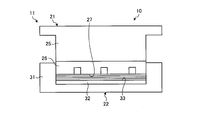

- the molding apparatus is a molding apparatus for forming a molded product by molding a molded material using a mold, wherein the mold sandwiches the lower mold on which the molded material is placed, and the molded material.

- an upper mold provided opposite to the lower mold, at least one of the lower mold and the upper mold includes a mold body and a composite material, and the mold body and the molding material And a composite material type removably provided on the mold body.

- the mold 11 is prepared for each molded product. Since it is not necessary to do so, the manufacturing cost of the mold 11 can be suppressed. In addition, since it is sufficient to replace only the respective composite material types 26 and 32, there is no need to replace the wiring such as the heating mechanism 13 provided in the mold main body 25 or 31 or the cooling device (not shown). The time to replace the Furthermore, in general, in composite molding, the mold can not be removed until the mold is sufficiently cooled, and the next molding can not be performed. However, by removing only the composite molds 26, 32 during cooling, the next molding can be performed using the new composite molds 26, 32.

- the molding apparatus 50 of Embodiment 2 has a heat-resistant coating layer 51 provided on each of the molding surfaces 27 and 33 of the composite material molds 26 and 32, respectively.

- the heat-resistant coating layer 51 is the same as the resin contained in each composite material type 26, 32, and, for example, BMI (bismaleimide) resin is used.

- BMI bismaleimide

- the heat-resistant coating layer 51 is formed to suppress fuzzing of the molding surfaces 27 and 33 with reinforcing fibers when machining the molding surfaces 27 and 33. For this reason, each molding surface 27 and 33 in which the heat-resistant coating layer 51 was formed turns into a smooth surface.

- a resin (PEEK or the like) having hardness and heat resistance than BMI resin may be applied, metal plating or the like may be used, or an inorganic material may be used.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Composite Materials (AREA)

- Manufacturing & Machinery (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Casting Or Compression Moulding Of Plastics Or The Like (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017-222106 | 2017-11-17 | ||

| JP2017222106A JP6975618B2 (ja) | 2017-11-17 | 2017-11-17 | 成形装置 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2019097969A1 true WO2019097969A1 (ja) | 2019-05-23 |

Family

ID=66540161

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2018/039511 Ceased WO2019097969A1 (ja) | 2017-11-17 | 2018-10-24 | 成形装置 |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP6975618B2 (enExample) |

| WO (1) | WO2019097969A1 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20220266546A1 (en) * | 2020-03-26 | 2022-08-25 | Fukui Prefectural Government | Method and apparatus for manufacturing a formed article of a composite material |

| WO2022210719A1 (ja) * | 2021-03-31 | 2022-10-06 | 株式会社チャレンヂ | 成形システム及び圧縮成形品の製造方法 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH04140127A (ja) * | 1990-10-02 | 1992-05-14 | Mitsubishi Heavy Ind Ltd | 複合材の製造方法 |

| US20070012858A1 (en) * | 2005-07-13 | 2007-01-18 | Callis Richard A | Machinable composite mold |

| JP2009113369A (ja) * | 2007-11-07 | 2009-05-28 | Fukui Prefecture | 熱可塑性樹脂複合材料成形品の成形方法 |

| WO2011129385A1 (ja) * | 2010-04-16 | 2011-10-20 | 株式会社棚澤八光社 | 樹脂成形用型部品及びその製造方法 |

| JP2011230328A (ja) * | 2010-04-26 | 2011-11-17 | Kasai Kogyo Co Ltd | 複合繊維体の成形方法および成形型 |

| JP2012011695A (ja) * | 2010-07-01 | 2012-01-19 | Mitsubishi Heavy Ind Ltd | 複合材成形型及びその製造方法 |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6415299A (en) * | 1987-07-08 | 1989-01-19 | Masaaki Uchida | Side pressure type forming method and its device |

| JPS6475210A (en) * | 1987-09-17 | 1989-03-20 | Honsyu Yuka Kk | Mold for molding cushioning material |

-

2017

- 2017-11-17 JP JP2017222106A patent/JP6975618B2/ja active Active

-

2018

- 2018-10-24 WO PCT/JP2018/039511 patent/WO2019097969A1/ja not_active Ceased

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH04140127A (ja) * | 1990-10-02 | 1992-05-14 | Mitsubishi Heavy Ind Ltd | 複合材の製造方法 |

| US20070012858A1 (en) * | 2005-07-13 | 2007-01-18 | Callis Richard A | Machinable composite mold |

| JP2009113369A (ja) * | 2007-11-07 | 2009-05-28 | Fukui Prefecture | 熱可塑性樹脂複合材料成形品の成形方法 |

| WO2011129385A1 (ja) * | 2010-04-16 | 2011-10-20 | 株式会社棚澤八光社 | 樹脂成形用型部品及びその製造方法 |

| JP2011230328A (ja) * | 2010-04-26 | 2011-11-17 | Kasai Kogyo Co Ltd | 複合繊維体の成形方法および成形型 |

| JP2012011695A (ja) * | 2010-07-01 | 2012-01-19 | Mitsubishi Heavy Ind Ltd | 複合材成形型及びその製造方法 |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20220266546A1 (en) * | 2020-03-26 | 2022-08-25 | Fukui Prefectural Government | Method and apparatus for manufacturing a formed article of a composite material |

| US12220883B2 (en) * | 2020-03-26 | 2025-02-11 | Fukui Prefectural Government | Method and apparatus for manufacturing a formed article of a composite material |

| WO2022210719A1 (ja) * | 2021-03-31 | 2022-10-06 | 株式会社チャレンヂ | 成形システム及び圧縮成形品の製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP6975618B2 (ja) | 2021-12-01 |

| JP2019093562A (ja) | 2019-06-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR101932783B1 (ko) | 프리폼의 제조 장치 및 제조 방법, 및 이 방법에 의해 제조된 프리폼 | |

| JP5968566B1 (ja) | 繊維強化複合材料成形品の製造方法及びそれに用いるプレス用金型 | |

| JP6231015B2 (ja) | 繊維強化された成形部材の製造中に繊維スクリムから三次元のプリフォームを製造する方法並びに装置 | |

| JP2015509868A (ja) | 繊維強化された成形部材の製造中に繊維スクリムから三次元のプリフォームを製造する方法並びに装置 | |

| CA3119802C (en) | Frp molding system and method | |

| WO2019097969A1 (ja) | 成形装置 | |

| EP2889126B1 (en) | Method for producing composite material mold for composite material long member | |

| JP5143694B2 (ja) | 金型装置及びこれを用いた成形体の製造方法 | |

| KR102286766B1 (ko) | 복합소재 성형장치 | |

| JP6432750B2 (ja) | 繊維強化複合部材の成形装置 | |

| JP6052526B1 (ja) | 繊維強化複合部材の成形装置 | |

| EP4371726A1 (en) | Molding device and molding method | |

| JP2007090809A (ja) | Frpのプリフォームの製造方法および装置 | |

| KR102529929B1 (ko) | 복합 소재 제조 시스템 및 방법 | |

| TWI605931B (zh) | 模具與使用其之熱壓成形方法 | |

| US20080169583A1 (en) | Processing Method of Fine Structure and Processing Equipment for Fine Structure | |

| JP7312609B2 (ja) | 圧縮式マッチドダイ装置 | |

| WO2022024359A1 (ja) | 賦形装置および賦形方法 | |

| EP4137287B1 (en) | Composite material processing apparatus and composite material processing method | |

| JP2023012200A5 (enExample) | ||

| KR20160046961A (ko) | 복합재 성형방법 | |

| RU164755U1 (ru) | Композитная оснастка | |

| JP2720192B2 (ja) | 繊維強化プラスチック成形用型及び繊維強化プラスチック成形体の製造方法 | |

| KR20250127521A (ko) | 열가소성 복합재를 이용한 항공기 좌석부품 제조용 프레스 금형 장치 | |

| JP2023097476A (ja) | 金型及び成形品の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 18877756 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 18877756 Country of ref document: EP Kind code of ref document: A1 |