WO2019026594A1 - 可撓性マンドレル、複合材部品の製造方法 - Google Patents

可撓性マンドレル、複合材部品の製造方法 Download PDFInfo

- Publication number

- WO2019026594A1 WO2019026594A1 PCT/JP2018/026574 JP2018026574W WO2019026594A1 WO 2019026594 A1 WO2019026594 A1 WO 2019026594A1 JP 2018026574 W JP2018026574 W JP 2018026574W WO 2019026594 A1 WO2019026594 A1 WO 2019026594A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- flexible mandrel

- composite

- contact surface

- main body

- flexible

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/40—Shaping or impregnating by compression not applied

- B29C70/42—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles

- B29C70/44—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles using isostatic pressure, e.g. pressure difference-moulding, vacuum bag-moulding, autoclave-moulding or expanding rubber-moulding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/38—Moulds or cores; Details thereof or accessories therefor characterised by the material or the manufacturing process

- B29C33/3828—Moulds made of at least two different materials having different thermal conductivities

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/38—Moulds or cores; Details thereof or accessories therefor characterised by the material or the manufacturing process

- B29C33/3842—Manufacturing moulds, e.g. shaping the mould surface by machining

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/76—Cores

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/02—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles

- B29C43/10—Isostatic pressing, i.e. using non-rigid pressure-exerting members against rigid parts or dies

- B29C43/12—Isostatic pressing, i.e. using non-rigid pressure-exerting members against rigid parts or dies using bags surrounding the moulding material or using membranes contacting the moulding material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/32—Component parts, details or accessories; Auxiliary operations

- B29C43/36—Moulds for making articles of definite length, i.e. discrete articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D99/00—Subject matter not provided for in other groups of this subclass

- B29D99/0003—Producing profiled members, e.g. beams

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2663/00—Use of EP, i.e. epoxy resins or derivatives thereof for preformed parts, e.g. for inserts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2705/00—Use of metals, their alloys or their compounds, for preformed parts, e.g. for inserts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/757—Moulds, cores, dies

Definitions

- the present disclosure relates to a flexible mandrel used to form a composite part and a method of manufacturing a composite part using the flexible mandrel.

- CFRP carbon fiber reinforced plastic

- An example of such a composite part is a stringer for reinforcing a plate used in an aircraft.

- the stringer has a complex shape including contour and twist depending on the airframe design, and has, for example, an I-shaped cross-sectional shape.

- a soft CFRP sheet composite material

- the entire inside is surrounded by a vacuum bag to eliminate internal air, and the composite material and the mandrel It is molded by heat-hardening treatment in close contact with each other.

- Patent Document 1 in a metal mandrel used to form such a stringer, good flexibility is realized by forming a groove in the depth direction, and a complex shape (contour or twist) is obtained. It is disclosed that it is possible to cope.

- Patent No. 4896035 gazette

- the mandrel used for molding a composite material containing a thermosetting resin as in Patent Document 1 has a larger heat capacity as compared with the composite material to be molded. Therefore, when heat curing is performed on the composite material to be molded, it takes a lot of time to sufficiently raise the temperature, and it is consumed by a decrease in the part production rate or heat curing. The increase in power is a factor causing cost increase.

- a mandrel used to form a composite part having a complicated shape such as a stringer may be formed of CFRP which is also light in weight and flexible. In this case, it is necessary to solve the above problems while securing the flexibility of the mandrel itself.

- At least one embodiment of the present invention is made in view of the above-mentioned circumstances, and promotes temperature rise at the time of thermosetting treatment of a composite material containing a thermosetting resin while securing good flexibility. Accordingly, it is an object of the present invention to provide a flexible mandrel and a method of producing a composite part capable of improving the part production rate and achieving cost reduction.

- a flexible mandrel is a flexible mandrel for molding a composite material containing a thermosetting resin in order to solve the above-mentioned problems, which is a first material And a thermally conductive layer formed to cover at least a portion of the body, the thermally conductive layer comprising a body including: and a second material having a thermal conductivity higher than that of the first material.

- the flexible mandrel extends from a contact surface contacting the composite during molding to a non-contact surface not contacting the composite.

- the thermally conductive layer including the second material having the thermal conductivity higher than that of the first material is covered by the thermally conductive layer including the second material having the thermal conductivity higher than that of the first material. Since such a heat conductive layer extends from the contact surface to the non-contact surface, the amount of heat supplied from the outside during the heat curing process is effectively applied to the composite material to be formed through the heat conductive layer. It is transmitted. Therefore, it is possible to shorten the time required to raise the temperature for the thermal curing process, to improve the part production rate, and to achieve cost reduction.

- the heat conduction layer surrounds the entire circumferential direction of the main body.

- the second material is PITCH-based CFRP.

- group CFRP is used as a 2nd material which forms a heat conductive layer.

- PITCH CFRP is a relatively expensive material, but because the heat conduction layer is thinner than the main body, efficient heat conduction can be realized while suppressing costs.

- the PITCH CFRP has a fiber direction from the contact surface toward the non-contact surface.

- the thermal conductivity of PITCH CFRP has anisotropy, and the thermal conductivity in the fiber direction is excellent. According to the configuration of the above (4), since the fiber direction of the PITCH CFRP contained in the heat conduction layer is directed from the contact surface to the non-contact surface, the amount of heat supplied from the outside at the time of heat curing treatment is an object to be molded It is well transmitted to the composite material.

- the second material is a metal.

- the metal which has a favorable heat conductivity as a 2nd material contained in a heat conductive layer.

- the thickness of the metal contained in the heat conduction layer may be set to such a thickness as not to impair the flexibility required at the time of molding.

- the first material is PAN-based CFRP.

- PAN-based CFRP that is relatively inexpensive and has good flexibility is used as the first material that constitutes the main body that occupies most of the volume of the flexible mandrel.

- the heat conductive layer has a thickness of less than 2 mm.

- the thickness of the heat conduction layer in the above range, shortening of the temperature rising time by the heat conduction layer can be achieved while sufficiently securing the flexibility required for the mandrel. Can be achieved.

- the main body is provided with at least one hole directed inward.

- the heat capacity of the flexible mandrel can be reduced by forming the hole in the main body of the flexible mandrel. Thereby, the time required for temperature rising of a thermosetting process can further be shortened.

- the hole is provided on the non-contact surface side of the main body.

- the contact surface is ensured the contact state with the composite material and secures good heat conduction.

- the heat capacity of the flexible mandrel it is possible to more effectively reduce the temperature rise time during the heat curing process.

- the configuration of the above (8) or (9) further comprises a filler for filling the hole, wherein the filler has higher thermal conductivity than the first material.

- the heat conductivity of the flexible mandrel can be further improved by filling the hole with a filler having a high thermal conductivity as the filler as compared to the main body. Thereby, temperature rise at the time of heat hardening processing can be performed more quickly.

- the manufacturing method of the composite material part forms a composite material containing a thermosetting resin using a pair of flexible mandrels

- a method for manufacturing a composite part comprising using a first material to form the body of the flexible mandrel, and a second material having a higher thermal conductivity than the first material.

- the method of the above (11) further includes the step of forming a hole toward the inside of the main body before forming the heat conduction layer on the main body.

- the heat curing process is performed on the composite material containing the thermosetting resin. It is possible to manufacture a flexible mandrel that can effectively conduct heat.

- the heat conductive layer is formed by thermal spraying a metal material.

- the heat conduction layer is formed of a metal material, by using thermal spraying, a heat conduction layer having flexibility required as specifications of a mandrel can be suitably formed.

- the component production rate is improved by accelerating the temperature rise when thermosetting the composite material containing the thermosetting resin while securing good flexibility. It is possible to provide a flexible mandrel and a method of manufacturing a composite part capable of achieving cost reduction.

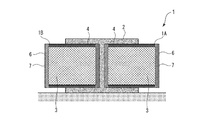

- FIG. 5 is a perspective view of a flexible mandrel according to at least one embodiment of the present invention. It is sectional drawing of FIG. It is a 1st modification of FIG. It is a 2nd modification of FIG. It is a flowchart which shows the manufacturing method of the composite material component 2 concerning at least one Embodiment of this invention for every process. It is a schematic diagram which shows the combination pattern of the CFRP sheet for shape

- the expression expressing a shape such as a quadrilateral shape or a cylindrical shape not only represents a shape such as a rectangular shape or a cylindrical shape in a geometrically strict sense, but also an uneven portion The shape including a chamfer etc. shall also be expressed.

- the expressions “comprising”, “having”, “having”, “including” or “having” one component are not exclusive expressions excluding the presence of other components.

- a carbon fiber reinforced plastic is a carbon fiber reinforced resin as a composite material, which is mainly an epoxy resin, unsaturated polyester, vinyl ester, phenol, and the like.

- a thermosetting resin such as cyanate ester or polyimide

- a material that can be molded by a thermosetting process will be described as an example.

- glass fibers, boron fibers, aramid fibers and the like can be similarly applied to the reinforcing fibers of the composite material.

- a stringer for reinforcing a plate used in an aircraft is exemplified, but various parts may be used within the scope of common technical ideas. Applicable to In particular, it can be used for structures such as aircraft and space equipment that require weight reduction as well as strength and rigidity.

- FIG. 1 is a perspective view showing a flexible mandrel 1 according to at least one embodiment of the present invention

- FIG. 2 is a cross-sectional view of FIG.

- first flexible mandrel 1A and “second flexible mandrel 1 1B ”

- the flexible mandrel 1 is a mold for molding the composite part 2 and has a shape corresponding to the composite part 2 to be molded.

- an aircraft stringer having an I-shaped cross section and having a longitudinally extending shape is shown as an example of the composite part 2.

- the first flexible mandrel 1A and the second flexible mandrel 1B have the same shape, and in FIG. 1, the composite material to be the material of the composite part 2 is placed between them to form It is shown how it will be done.

- the flexible mandrel 1 comprises a main body 3 and a thermally conductive layer 7 formed to cover at least a part of the main body 3.

- the main body 3 is a mold material for molding the composite material part 2 and has a shape corresponding to the composite material part 2 to be molded.

- an aircraft stringer having an I-shaped cross section and having a longitudinally extending shape is shown as an example of the composite part 2.

- the first flexible mandrel 1A and the second flexible mandrel 1B have the same shape, and in FIG. 1, the composite material to be the material of the composite part 2 is placed between them to form It is shown how it will be done.

- the main body 3 of the flexible mandrel 1 is attached to the composite component 2 via the heat conduction layer 7 and the contact surface 4 contacting the composite component 2 via the heat conduction layer 7. It includes a noncontact surface 6 which does not contact.

- the contact surface 4 has a shape corresponding to the composite component 2 for forming the composite component 2 as described above, but the non-contact surface 6 may have any shape.

- the body 3 comprises a first material.

- the first material includes a thermally conductive material in order to transfer the externally supplied heat quantity to the composite component 2 when performing the heat curing process.

- the material of the main body 3 has flexibility which can be deformed according to the specification shape of the composite part 2.

- a composite material CFRP

- PAN-based CFRP that is relatively inexpensive

- the heat conduction layer 7 is formed so as to cover at least a part of the main body 3, and in the present embodiment, in particular, surrounds the entire circumferential direction of the main body 3.

- a heat conductive layer 7 includes a second material having a high thermal conductivity as compared to the first material contained in the main body 3, and as shown in FIG. To the non-contact surface 6. Since a part of the heat conduction layer 7 is exposed to the atmosphere, when the flexible mandrel 1 is heated in the high temperature and high pressure autoclave, the heat from the external atmosphere is transmitted via the heat conduction layer 7. It is transmitted to the composite part 2 in contact with the conductive layer 7. Therefore, compared with the flexible mandrel which does not have the heat conductive layer 7, time required for temperature rising at the time of thermosetting process can be shortened.

- the heat conducting layer 7 is thinner than the main body 3 defining the basic shape of the flexible mandrel 1.

- the thickness of the heat conduction layer 7 is preferably in a range that does not affect the basic shape of the flexible mandrel 1 and is, for example, 2 mm or less.

- PITCH-based CFRP can be used as a second material contained in the heat conduction layer 7, for example.

- PITCH CFRP is more expensive than PAN CFRP

- the heat conduction layer 7 is thinner than the main body 3, so the cost does not increase significantly.

- the thermal conductivity of the PITCH CFRP has anisotropy with respect to the fiber direction, so the fiber direction is from the contact surface 4 to the non-contact surface It is preferable to form in a direction toward 6. Thereby, the heat transfer in the direction from the contact surface 4 toward the non-contact surface 6 is improved, so that the heat transfer from the external atmosphere to the composite component 2 can be more effectively improved.

- PITCH CFRP is excellent in resistance to deformation along the fiber direction. Therefore, by forming the heat conductive layer 7 so that the fiber direction is from the contact surface 4 toward the non-contact surface 6, when the flexible mandrel 1 is deformed, the heat conductive layer 7 is cracked or cracked. It does not occur and can respond flexibly. That is, even when the heat conduction layer 7 is provided on the main body 3, the flexibility of the flexible mandrel 1 can be favorably maintained.

- the heat conduction layer 7 may be formed by thermal spraying a metal material.

- the metal material is higher in rigidity than the above-mentioned PITCH CFRP, but the required flexibility can be secured by forming a sufficiently thin heat conductive layer by thermal spraying.

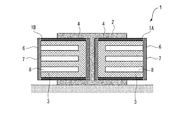

- FIG. 3 is a first modification of FIG.

- the flexible mandrel 1 according to the first modification has at least one hole 8 formed toward the inside of the main body 3.

- a flexible mandrel of this type is typically formed of a solid bulk body, but in this case, the heat capacity of the mandrel body tends to be larger than that of the composite component 2 to be molded, and the thermal It takes time to raise the temperature during the curing process.

- the flexible mandrel 1 according to the first modification since the heat capacity of the flexible mandrel 1 can be reduced by forming the hole 8 in the main body 3, the temperature rise at the time of the thermosetting process is promoted. it can.

- the hole 8 is opened to the non-contact surface 6 of the main body 3. Therefore, the contact state with the composite component 2 is secured on the contact surface 4, and good heat transfer to the composite component 2 becomes possible.

- the hole 8 is formed as a bottomed non-through hole.

- the depth of the hole 8 may be arbitrary, for example, it has a depth of 60% to 90% of the distance L between the contact surface 4 and the non-contact surface 6. By setting the depth of the hole 8 to the above range, the heat capacity of the flexible mandrel 1 can be properly reduced, and good heat conduction to the composite component 2 can be achieved.

- the hole 8 may be formed as a through hole. Although the hole 8 in FIG. 3 has a substantially straight shape, it may have a curved shape, for example, inside the main body 3.

- a plurality of holes 8 are provided.

- the heat capacity is effectively achieved while appropriately securing the flexibility and rigidity of the flexible mandrel 1 as compared with the case where only a single hole 8 is provided. Can be reduced.

- the plurality of holes 8 have a uniform distribution. As described above, in the region where the holes 8 are uniformly distributed, the heat capacity decreases at a constant rate over the entire region, so that heat can be uniformly supplied to the composite at the time of the heat curing treatment, and good quality can be obtained. It becomes possible to form.

- the plurality of holes 8 may be formed unevenly.

- the distribution of the holes 8 may be random, for example, when the flexible mandrel 1 is deformed according to the shape of the composite part 2, a predetermined temperature distribution, stress distribution, etc. are realized. And may be set in accordance with the shape of the composite part 2. As a result, the amount of heat transferred to the composite component 2 can be controlled at the time of heat curing treatment, and molding of high quality can be performed.

- FIG. 4 is a second modification of FIG.

- the hole 8 in the first modification is filled with the filler 12 containing a material having a thermal conductivity higher than that of the main body 3.

- the thermal conductivity of the main body 3 can be further improved by the filler 12 filled in the holes 8, and the temperature can be raised more quickly.

- a material of the filler 12 for example, a metal foam is useful, and specifically, a material that is lightweight and has excellent thermal conductivity, such as aluminum foam, is preferable.

- FIG. 5 is a flowchart showing the method of manufacturing the composite part 2 according to at least one embodiment of the present invention in each step.

- a predetermined material is used to form the main body 3 of the flexible mandrel 1 (step S1).

- the material of the main body 3 has thermal conductivity capable of transferring the amount of heat supplied from the outside to the composite component 2 at the time of the thermosetting process, and according to the specification shape of the composite component 2 It is a material having deformable flexibility, and for example, a composite material (PAN-based CFRP) is used.

- a main body 3 is formed, for example, as a substantially rectangular solid bulk body.

- the heat conduction layer 7 is formed so as to at least partially surround the main body 3 formed in step S1 (step S2).

- the heat conduction layer 7 is formed of a second material having high thermal conductivity, for example, PITCH-based CFRP, as compared to the first material contained in the main body 3.

- the thickness of the heat conduction layer 7 is such that it does not affect the basic shape of the flexible mandrel 1 and is set to, for example, 2 mm or less.

- a material having anisotropy in thermal conductivity such as PITCH CFRP

- the fiber direction is formed from the contact surface 4 toward the non-contact surface 6.

- the heat conduction layer 7 is formed by thermal spraying, for example.

- the hole portion 8 is provided in the main body 3 as in the above-described modified example (see FIGS. 3 and 4), cutting is performed on the main body 3 before forming the heat conduction layer 7 in step S2. It is good to do such machining.

- the hole 8 may be formed at the same time (for example, the main body 3 and the hole 8 may be integrally formed).

- the filler 12 When the filler 12 is filled in the hole 8 formed in the main body 3 as in the second modification described above, the filling operation of the filler 12 is also performed before the heat conductive layer 7 is formed in step S2. Good to be done.

- the filler 12 may comprise a material having a high thermal conductivity as compared to the body 3, for example a metal foam such as aluminum foam can be used.

- step S3 A pair of the above-mentioned flexible mandrels 1 is prepared (step S3), and a composite material to be a material of the composite component 2 is placed between them (step S4).

- the composite used here is, for example, a soft CFRP sheet in a semi-cured state, and is combined according to the shape of the composite part 2.

- FIG. 6 is a schematic view showing a combination pattern of CFRP sheets for forming a composite part 2 having an I-shaped cross section.

- a first sheet 2A covering the contact surface 4 of the first flexible mandrel 1A

- a second flexible Sheet 2B covering the contact surface 4 of the flexible mandrel 1B

- a third sheet 2C covering the first sheet 2A and the second sheet 2B from above

- a fourth sheet covering the first sheet 2A and the second sheet 2B from above

- the sheet 2D of and are combined.

- step S5 the whole is covered with a bag material, and the vacuum bag processing is performed by discharging the air inside.

- a thermosetting process is performed on the pair of flexible mandrels 1 in which the composite material is disposed (step S6).

- the heat curing process is carried out in a high temperature high pressure autoclave. As the ambient temperature within the autoclave increases, the amount of heat transferred through the flexible mandrel 1 heats the composite.

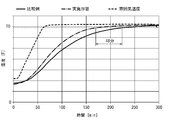

- FIG. 7 is a measurement result which shows time progress of the internal temperature of the flexible mandrel 1 of FIG.1 and FIG.2 at the time of a thermosetting process, and the atmospheric temperature in an autoclave.

- the broken line indicates the ambient temperature in the autoclave, and it is shown that it gradually increases to the target temperature T0 with the passage of time. As the ambient temperature changes in this manner, the internal temperature of the flexible mandrel 1 also increases to follow.

- the measurement result (solid line) is the measurement result according to the comparative example without the heat conductive layer 7 (the same as the flexible mandrel 1 of FIGS.

- the measurement result (dashed-dotted line) is a measurement result according to the flexible mandrel 1 of the present embodiment in which the hole 8 is formed.

- the time to reach the target temperature T0 was about 48 minutes earlier than in the comparative example. This indicates that the flexible mandrel 1 according to this embodiment can be rapidly heated by having the heat conduction layer 7.

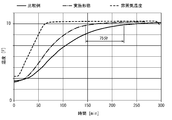

- FIG. 8 is a measurement result showing the time course of the internal temperature of the flexible mandrel 1 of FIG. 3 and the ambient temperature in the autoclave during heat curing.

- the broken line indicates the ambient temperature in the autoclave, and it is shown that it gradually increases to the target temperature T0 with the passage of time. As the ambient temperature changes in this manner, the internal temperature of the flexible mandrel 1 also increases to follow.

- the measurement result (solid line) relates to the measurement according to the comparative example without the heat conduction layer 7 (the same as the flexible mandrel 1 of FIG. 3 except that the heat conduction layer 7 and the hole 8 are not provided).

- a measurement result (dashed dotted line) is a measurement result concerning flexible mandrel 1 of this embodiment in which hole 8 was formed.

- the time to reach the target temperature T0 was about 75 minutes earlier than in the comparative example. This indicates that the flexible mandrel 1 according to the present embodiment can raise its temperature more quickly by having the heat conduction layer 7.

- step S6 the temperature rising to the target temperature is maintained for a predetermined time, whereby the heat curing of the composite material proceeds, and the composite component 2 is molded.

- the thermosetting process is completed, the bag material is released, and the completed composite part 2 is taken out from the inside (step S7).

- the heat capacity of the flexible mandrel is reduced by forming non-through holes in the non-contact surface of the main body of the flexible mandrel, and the thermosetting treatment is performed.

- the time required for temperature rise can be shortened, and good parts production rate and cost reduction can be achieved.

- At least one embodiment of the present invention is applicable to a flexible mandrel used to form a composite part including a composite material such as CFRP, and a method of manufacturing a composite part using the flexible mandrel. is there.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Composite Materials (AREA)

- Manufacturing & Machinery (AREA)

- Moulding By Coating Moulds (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Casting Or Compression Moulding Of Plastics Or The Like (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US16/624,409 US11584095B2 (en) | 2017-08-03 | 2018-07-13 | Flexible mandrel, and method for producing composite component |

| EP18841011.2A EP3620295B1 (en) | 2017-08-03 | 2018-07-13 | Flexible mandrel, and method for producing composite material component |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017150650A JP6836474B2 (ja) | 2017-08-03 | 2017-08-03 | 可撓性マンドレル、複合材部品の製造方法 |

| JP2017-150650 | 2017-08-03 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2019026594A1 true WO2019026594A1 (ja) | 2019-02-07 |

Family

ID=65233660

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2018/026574 Ceased WO2019026594A1 (ja) | 2017-08-03 | 2018-07-13 | 可撓性マンドレル、複合材部品の製造方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US11584095B2 (enExample) |

| EP (1) | EP3620295B1 (enExample) |

| JP (1) | JP6836474B2 (enExample) |

| WO (1) | WO2019026594A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111823449A (zh) * | 2020-05-29 | 2020-10-27 | 成都飞机工业(集团)有限责任公司 | 一种用于“λ”型复合材料零件精确制造的软模 |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102020134901A1 (de) | 2020-12-23 | 2022-06-23 | Airbus Operations Gmbh | Formkern zur Herstellung eines Bauteils aus Faserverbundmaterial |

| JP7358425B2 (ja) * | 2021-08-18 | 2023-10-10 | 三菱重工業株式会社 | 複合材の加工装置及び複合材の加工方法 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008521645A (ja) * | 2004-11-24 | 2008-06-26 | ザ・ボーイング・カンパニー | 高度に成形された複合材ストリンガ用の可撓性マンドレル及び前記ストリンガの製造方法 |

| JP2012131080A (ja) * | 2010-12-20 | 2012-07-12 | Mitsubishi Heavy Ind Ltd | 複合材成形治具 |

| JP2014532000A (ja) * | 2011-10-12 | 2014-12-04 | ザ・ボーイング・カンパニーTheBoeing Company | 軽量可撓性マンドレルおよび軽量可撓性マンドレルを作る方法 |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2658753A1 (fr) * | 1990-02-23 | 1991-08-30 | Snecma | Dispositif de moulage en materiau composite pour le pressage a chaud de pieces en materiau refractaire. |

| US5502886A (en) | 1994-09-02 | 1996-04-02 | The Boeing Company | Composite stringer disassembly machine |

| EP0861145B1 (en) * | 1995-11-13 | 2003-06-04 | GMIC, Corp. | Fabrication of tooling by thermal spraying |

| JP3384264B2 (ja) | 1996-11-28 | 2003-03-10 | 松下電器産業株式会社 | 熱伝導制御装置及び樹脂成形金型装置 |

| US6447704B1 (en) | 2000-05-23 | 2002-09-10 | Gmic, Corp. | Thermal-sprayed tooling |

| US6743384B2 (en) * | 2001-03-19 | 2004-06-01 | Honeywell International Inc. | Anisotropic heat diffuser plate |

| US8336596B2 (en) * | 2002-11-22 | 2012-12-25 | The Boeing Company | Composite lamination using array of parallel material dispensing heads |

| GB2447964B (en) * | 2007-03-29 | 2012-07-18 | Gurit Uk Ltd | Moulding material |

| JP2008280432A (ja) | 2007-05-10 | 2008-11-20 | Teijin Ltd | 熱伝導性炭素繊維複合シート及びその製造方法 |

| CL2007003772A1 (es) * | 2007-12-21 | 2008-04-25 | Vulco Sa | Procedimiento para la fabricacion de un mandril flexible de poliuretano, que contiene un alma metalica que comprende recubrir con goma un alma metalica, aplicar desmoldante, precalentar el conjunto, curar el poliuretano y enfriar el codo. |

| JP6544993B2 (ja) * | 2014-06-23 | 2019-07-17 | キヤノン株式会社 | 定着用部材の製造装置 |

-

2017

- 2017-08-03 JP JP2017150650A patent/JP6836474B2/ja active Active

-

2018

- 2018-07-13 EP EP18841011.2A patent/EP3620295B1/en active Active

- 2018-07-13 US US16/624,409 patent/US11584095B2/en active Active

- 2018-07-13 WO PCT/JP2018/026574 patent/WO2019026594A1/ja not_active Ceased

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008521645A (ja) * | 2004-11-24 | 2008-06-26 | ザ・ボーイング・カンパニー | 高度に成形された複合材ストリンガ用の可撓性マンドレル及び前記ストリンガの製造方法 |

| JP4896035B2 (ja) | 2004-11-24 | 2012-03-14 | ザ・ボーイング・カンパニー | 高度に成形された複合材ストリンガ用の可撓性マンドレル及び前記ストリンガの製造方法 |

| JP2012131080A (ja) * | 2010-12-20 | 2012-07-12 | Mitsubishi Heavy Ind Ltd | 複合材成形治具 |

| JP2014532000A (ja) * | 2011-10-12 | 2014-12-04 | ザ・ボーイング・カンパニーTheBoeing Company | 軽量可撓性マンドレルおよび軽量可撓性マンドレルを作る方法 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP3620295A4 |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111823449A (zh) * | 2020-05-29 | 2020-10-27 | 成都飞机工业(集团)有限责任公司 | 一种用于“λ”型复合材料零件精确制造的软模 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3620295A1 (en) | 2020-03-11 |

| EP3620295B1 (en) | 2021-02-17 |

| JP2019025870A (ja) | 2019-02-21 |

| US11584095B2 (en) | 2023-02-21 |

| EP3620295A4 (en) | 2020-06-03 |

| US20200180244A1 (en) | 2020-06-11 |

| JP6836474B2 (ja) | 2021-03-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR102197337B1 (ko) | 안정화 부재를 구비한 복합 구조물 | |

| US8961724B2 (en) | Structural composite panel with metallic foam core | |

| JP2019073263A (ja) | 航空機の構造的構成要素の強度及び靭性を高めるための方法及び装置 | |

| WO2019026594A1 (ja) | 可撓性マンドレル、複合材部品の製造方法 | |

| US20170274604A1 (en) | Artificial defect material and manufacturing method of frp structure | |

| CN110104202B (zh) | 使用铰接式芯轴的复合飞机制造工具 | |

| JP6543577B2 (ja) | 複合材の成形方法及び複合材の成形用治具 | |

| TW201919839A (zh) | 纖維強化塑膠及纖維強化塑膠之製造方法 | |

| KR20200133203A (ko) | 섬유 강화 수지의 제조 방법 | |

| KR101498406B1 (ko) | 성형형 | |

| US20180257317A1 (en) | Composite materials molding method, and composite materials | |

| JP5709512B2 (ja) | 複合材成形治具および複合材成形治具の製造方法 | |

| WO2019026418A1 (ja) | 可撓性マンドレル、複合材部品の製造方法 | |

| KR102274173B1 (ko) | 보강재를 통한 복합재료 동시경화 방법 및 그 복합재료 | |

| US10906267B2 (en) | Composite structure | |

| EP3152045B1 (en) | Method for making a composite structure utilizing thermal properties of forming elements | |

| JP7321030B2 (ja) | 補強部材、組立体、及び、補強部材の製造方法 | |

| CN108215440B (zh) | 阶梯状或空心状蜂窝夹层结构的制作方法 | |

| GB2638695A (en) | Composite aircraft components and methods relating thereto |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 18841011 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2018841011 Country of ref document: EP Effective date: 20191203 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |