WO2018230666A1 - 吸収性物品 - Google Patents

吸収性物品 Download PDFInfo

- Publication number

- WO2018230666A1 WO2018230666A1 PCT/JP2018/022798 JP2018022798W WO2018230666A1 WO 2018230666 A1 WO2018230666 A1 WO 2018230666A1 JP 2018022798 W JP2018022798 W JP 2018022798W WO 2018230666 A1 WO2018230666 A1 WO 2018230666A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- compound

- less

- liquid film

- sheet

- liquid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers of the pads

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

- A61F13/513—Topsheet, i.e. the permeable cover or layer facing the skin characterised by its function or properties, e.g. stretchability, breathability, rewet, visual effect; having areas of different permeability

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers of the pads

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

- A61F13/51104—Topsheet, i.e. the permeable cover or layer facing the skin the top sheet having a three-dimensional cross-section, e.g. corrugations, embossments, recesses or projections

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15577—Apparatus or processes for manufacturing

- A61F13/15699—Forming webs by bringing together several webs, e.g. by laminating or folding several webs, with or without additional treatment of the webs

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15577—Apparatus or processes for manufacturing

- A61F13/15707—Mechanical treatment, e.g. notching, twisting, compressing, shaping

- A61F13/15731—Treating webs, e.g. for giving them a fibrelike appearance, e.g. by embossing

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15577—Apparatus or processes for manufacturing

- A61F13/15804—Plant, e.g. involving several steps

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/47—Sanitary towels, incontinence pads or napkins

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers of the pads

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers of the pads

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

- A61F13/51113—Topsheet, i.e. the permeable cover or layer facing the skin comprising an additive, e.g. lotion or odour control

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers of the pads

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

- A61F13/5116—Topsheet, i.e. the permeable cover or layer facing the skin being formed of multiple layers

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers of the pads

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

- A61F13/513—Topsheet, i.e. the permeable cover or layer facing the skin characterised by its function or properties, e.g. stretchability, breathability, rewet, visual effect; having areas of different permeability

- A61F13/51305—Topsheet, i.e. the permeable cover or layer facing the skin characterised by its function or properties, e.g. stretchability, breathability, rewet, visual effect; having areas of different permeability having areas of different permeability

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4282—Addition polymers

- D04H1/4291—Olefin series

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H3/00—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length

- D04H3/08—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length characterised by the method of strengthening or consolidating

- D04H3/16—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length characterised by the method of strengthening or consolidating with bonds between thermoplastic filaments produced in association with filament formation, e.g. immediately following extrusion

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H5/00—Non woven fabrics formed of mixtures of relatively short fibres and yarns or like filamentary material of substantial length

- D04H5/06—Non woven fabrics formed of mixtures of relatively short fibres and yarns or like filamentary material of substantial length strengthened or consolidated by welding-together thermoplastic fibres, filaments, or yarns

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M15/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment

- D06M15/19—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment with synthetic macromolecular compounds

- D06M15/37—Macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds

- D06M15/643—Macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds containing silicon in the main chain

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15577—Apparatus or processes for manufacturing

- A61F2013/15821—Apparatus or processes for manufacturing characterized by the apparatus for manufacturing

- A61F2013/15861—Apparatus or processes for manufacturing characterized by the apparatus for manufacturing for bonding

- A61F2013/15878—Apparatus or processes for manufacturing characterized by the apparatus for manufacturing for bonding by thermal bonding

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15577—Apparatus or processes for manufacturing

- A61F2013/15821—Apparatus or processes for manufacturing characterized by the apparatus for manufacturing

- A61F2013/15934—Apparatus or processes for manufacturing characterized by the apparatus for manufacturing for making non-woven

Definitions

- the present invention relates to an absorbent article such as a sanitary napkin.

- Patent Document 1 describes that a liquid film generated in a narrow space between fibers of a nonwoven fabric can be cleaved with a liquid film cleaving agent to reduce liquid residue in the nonwoven fabric. Thereby, the dryness of a nonwoven fabric can be improved significantly.

- the present invention is an absorbent article having a top sheet, a back sheet, and an absorbent body sandwiched between the top sheet and the back sheet, wherein the liquid film cleaving agent is disposed at an intermediate position in the thickness of the top sheet.

- An absorbent article is provided.

- the present invention is an absorbent article having a top sheet, a back sheet, and an absorbent body sandwiched between the top sheet and the back sheet, wherein the following compound C1 and Provided is an absorbent article having an arrangement part of one or more compounds selected from compound C2.

- [Compound C1] A compound having an expansion coefficient of 15 mN / m or more and a water solubility of 0 g or more and 0.025 g or less for a liquid having a surface tension of 50 mN / m.

- [Compound C2] A compound having an expansion coefficient greater than 0 mN / m for a liquid having a surface tension of 50 mN / m, a water solubility of 0 g or more and 0.025 g or less, and an interfacial tension for a liquid having a surface tension of 50 mN / m or less of 20 mN / m or less. .

- the present invention is an absorbent article having a top sheet, a back sheet, and an absorbent body sandwiched between the top sheet and the back sheet, the liquid film cleaving agent on the absorbent side of the top sheet.

- An absorbent article having a placement portion is provided.

- the present invention is an absorbent article having a top sheet, a back sheet, and an absorbent body sandwiched between the top sheet and the back sheet, and the following compound C1 and the following compound on the absorber side of the top sheet

- An absorbent article having an arrangement part of one or a plurality of compounds selected from the compound C2 is provided.

- [Compound C1] A compound having an expansion coefficient of 15 mN / m or more and a water solubility of 0 g or more and 0.025 g or less for a liquid having a surface tension of 50 mN / m.

- [Compound C2] A compound having an expansion coefficient greater than 0 mN / m for a liquid having a surface tension of 50 mN / m, a water solubility of 0 g or more and 0.025 g or less, and an interfacial tension for a liquid having a surface tension of 50 mN / m or less of 20 mN / m or less. .

- the present invention provides a step of applying a liquid film cleaving agent to one side of the first fiber layer having a heat-fusible fiber and a surface of the first fiber layer to which the liquid film cleaving agent has been applied.

- the manufacturing method of the nonwoven fabric which has these.

- the present invention provides a step of applying one or more compounds selected from the following compound C1 and the following compound C2 to one side of the first fiber layer having a heat-fusible fiber, and the first fiber layer, A step of laminating a second fiber layer having a heat-fusible fiber on a surface provided with one or more compounds selected from the compound C1 and the compound C2, and at a temperature equal to or higher than the melting point of the heat-fusible fiber.

- a method for producing a nonwoven fabric comprising a step of joining the first fiber layer and the second fiber layer by heat fusion by heat treatment.

- [Compound C1] A compound having an expansion coefficient of 15 mN / m or more and a water solubility of 0 g or more and 0.025 g or less for a liquid having a surface tension of 50 mN / m.

- [Compound C2] A compound having an expansion coefficient greater than 0 mN / m for a liquid having a surface tension of 50 mN / m, a water solubility of 0 g or more and 0.025 g or less, and an interfacial tension for a liquid having a surface tension of 50 mN / m or less of 20 mN / m or less. .

- FIG. 1 It is a partially cutaway perspective view showing a preferred embodiment of an absorbent article according to the present invention. It is a partial cross section perspective view which expands the preferred mode of the surface sheet in the absorptive article of this embodiment partially, and shows typically. It is explanatory drawing which shows the aspect which provided the arrangement

- FIG. 2 is a drawing-substituting photograph showing a result of a cleaving action on a liquid membrane of simulated menstrual blood when the liquid film cleaving agent macroscopically expands in the plane direction of the nonwoven fabric, and (A) is a state of the nonwoven fabric in which no liquid film cleaving agent is arranged.

- (B) shows the arrangement part of the liquid film cleaving agent in the form of dots with a diameter of 0.8 mm at an arrangement ratio of the coating liquid to the fiber mass of the arrangement part (arrangement part OPU: Oil Per Unit)

- the state of the formed nonwoven fabric is shown

- (C) shows the state of the nonwoven fabric in which the arrangement ratio of the coating liquid (arrangement part OPU) to the fiber mass of the arrangement part shown in (B) is increased to 8.0% by mass. ing.

- (A) is explanatory drawing which shows the content of the test for confirming that the liquid film cleaving agent carries out the cleaving action with respect to the liquid film of pseudo menstrual blood by the macro expansion to the thickness direction of a surface sheet

- (B ) Is an explanatory view showing a state in which an arrangement portion of a liquid film cleaving agent is formed on the surface facing the absorber side of the top sheet in (A).

- 6 is a drawing representative photograph showing the results of the test shown in FIG. 6, (A) shows the state of the surface 1A of the topsheet 1 immediately after the injection of pseudomenstrual blood, (B) after 20 seconds, (C) is It shows after 30 seconds. It is a partial cross section perspective view which expands partially and shows typically another desirable aspect of the surface sheet in the absorbent article of this embodiment partially.

- the present invention relates to an absorptive article that can simultaneously realize a reduction in liquid residue and a reduction in skin stickiness by using the liquid film cleaving agent.

- the inventors of the present invention have been able to achieve an improvement in liquid residue reduction of the nonwoven fabric that becomes the top sheet using the liquid film cleaving agent described in Patent Document 1.

- the surface sheet of the absorbent article if the amount of the liquid film cleaving agent that contacts the skin of the wearer is too large, a sticky feeling of the skin is likely to occur, and there is room for improvement from the viewpoint of good touch. It was.

- the absorbent article of the present invention can simultaneously reduce the liquid residue and the skin stickiness.

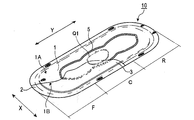

- the sanitary napkin 10 as the preferable embodiment is shown, and it demonstrates below, referring drawings.

- the side in contact with the human body is referred to as the skin side, the skin contact surface side or the surface side, and the opposite side is referred to as the non-skin side, the non-skin contact surface. It is called side or back side.

- the direction positioned on the front side of the human body when worn is referred to as the front, and its end is referred to as the front end, and the direction positioned on the rear is referred to as the rear, and the end is referred to as the rear end.

- the normal line direction of the surface or back surface of an absorbent article is called thickness direction, and the quantity is called thickness.

- a sanitary napkin 10 (hereinafter, also simply referred to as a napkin 10) of the present embodiment is disposed on a surface sheet 1 disposed on the skin contact surface side and on the non-skin contact surface side.

- the liquid-retaining absorbent 3 is sandwiched between the back sheet 2 and the top sheet 1 and the back sheet 2.

- a leak-proof groove 5 squeezed from the top sheet 1 to the absorber 3 is disposed, and the leak-proof groove 5 has an annular shape in plan view.

- channel 5 can be arrange

- the napkin 10 may include other components.

- a liquid diffusible intermediate sheet may be included between the top sheet 1 and the absorbent body 3, and a pair of wing parts for fixing to the clothes may be provided on both sides in the longitudinal direction of the napkin 10.

- the napkin 10 has a vertically long shape having a vertical direction (Y direction) and a horizontal direction (X direction) orthogonal to the vertical direction.

- the napkin 10 is arranged so that the topsheet 1 side faces the wearer's skin contact surface side, and the longitudinal direction is arranged from the lower abdomen side to the buttocks side, and the width direction is along the line connecting the left and right feet. Arranged and worn.

- the napkin 10 has a crotch part C covering the excretion part of the wearer in the vertical direction (Y direction), a front part F corresponding to the lower abdominal part side of the crotch part C, and a rear buttock part. It has a rear portion R corresponding to the side.

- the liquid receiving region Q1 that directly receives excretion liquid at the center in the width direction.

- the liquid receiving region Q1 that is, “the center in the width direction” of the crotch C is a line that bisects the length in the width direction in the width direction of the sanitary napkin when the absorbent article is a sanitary napkin. Therefore, it is an area of 2.5 cm or less in the left-right width direction, and is an area arranged in the entire longitudinal direction of the crotch C in the longitudinal direction.

- the crotch C is the second area from the front when the napkin is divided into four in the longitudinal direction in the case of a night napkin, and the central area where the napkin is divided into three in the longitudinal direction in the case of a daytime napkin It is.

- the liquid receiving region Q1 has a width of 3.5 cm or less in the width direction from the line that bisects the length in the width direction in the width direction of the diaper. It is an area, and in the longitudinal direction, it is an area of 8.0 cm or less in the front F direction from a line that bisects the longitudinal direction of the diaper.

- the absorbent article is a urine absorption pad or an incontinence pad, it is the same as the daytime napkin.

- the liquid receiving region Q1 is a region surrounded by the leak-proof groove 5 in the crotch part.

- the division position of the crotch part C, the front part F, and the rear part R can be appropriately set according to the length of the absorbent article set according to the purpose of use and the like.

- the sanitary napkin 10 of the present embodiment shows an example of a shape set for daytime or the like, and the front part F, the crotch part C, and the rear part R are divided into about three equal lengths in the vertical direction. Is set.

- the crotch part C is closer to the front of the napkin, and for example, the second region from the front part F obtained by dividing the napkin into four equal parts in the longitudinal direction may correspond to the crotch part C.

- the crotch part C can be set as a part at a certain distance from the front part F regardless of the shape of the napkin 10.

- the top sheet 1 is made of a fiber sheet that is closer to the skin than the absorbent body 3 and contacts the wearer's skin.

- the fiber sheet has sheet integrity (for example, non-woven fabric) by joining the fibers by heat fusion.

- heat-fusible fibers are used as constituent fibers. Specifically, the heat-fusible fiber is melted by heat treatment, and the fibers are fused to each other by the melted component. In this case, the melting may occur in both fibers to be fused, or may occur only in one of the fibers.

- the heat treatment include hot air treatment (air-through treatment) and emboss pressure bonding treatment.

- the fiber sheet is a laminated sheet composed of a plurality of fiber layers

- the fiber layers are bonded to each other by the heat fusion or an adhesive. That is, at the interface between the fiber layers, the fibers of both fiber layers are joined together by heat fusion or by an adhesive.

- the fiber layers may be bonded to each other or may be partially bonded.

- there is no bonding with an adhesive from the viewpoint of quickly passing excretion liquid from the top sheet to the absorbent body, and from the viewpoint of maintaining the soft touch of the top sheet.

- it is.

- N1 A laminated nonwoven fabric formed by hot air treatment at a temperature at which two fiber webs (fiber layers in a state in which fiber fusion does not occur) are laminated and the fibers can be melted.

- N2 A fiber web is laminated on a non-woven fabric (fiber layer in a state where fibers are fusion-bonded), the non-woven fabric and the fiber web are fusion-bonded by an embossing pressure-bonding process, and the temperature is higher than the melting point of the fibers.

- Laminated nonwoven fabric in which fiber layers are joined by hot air treatment is exemplified.

- N3 A laminated nonwoven fabric in which a fiber web is laminated on a nonwoven fabric, the nonwoven fabric and the fiber web are fusion-bonded by an embossing pressure-bonding treatment, and a hot air treatment at a temperature lower than the melting point of the fibers is applied.

- N4 A laminated nonwoven fabric in which another long fiber is spun and laminated on a long fiber layer formed by spinning a molten resin, and bonded by an emboss pressure bonding process.

- the fiber layers are bonded to each other by hot air treatment.

- the fiber layers are joined to each other mainly at the embossed pressure-bonded portion.

- the top sheet 1 has hydrophilicity as a whole, and has liquid permeability that allows the fluid to be rapidly drawn into the internal absorbent body 3 upon receiving excretion of the body fluid.

- various forms usually used for absorbent articles can be employed without particular limitation. Examples thereof include the nonwoven fabrics described in paragraphs [0100] to [0110] of the specification of International Publication No. 2016/098796 and FIGS.

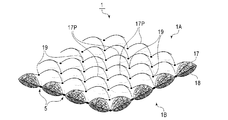

- the 1B side has an uneven shape. More specifically, it has a structure in which a skin-side fiber layer (hereinafter also referred to as skin-side layer) 17 and a non-skin-side fiber layer (hereinafter also referred to as non-skin-side layer) 18 are laminated. Both layers are partly joined by a concave joint 19.

- the concave joint portion 19 is formed by heat fusion of fibers by an emboss pressure bonding process.

- the surface 1A has an uneven shape, so that the contact area between the skin and the surface sheet 1 is reduced, and the feeling of stickiness and stuffiness of the skin is suppressed, resulting in an excellent dry feeling. It becomes.

- corrugated shape is a dome shape filled with the fiber, cushioning properties when touching the skin are increased, which is preferable.

- the surface sheet 1 as shown in FIG. 2 preferably has a fiber structure described in paragraphs [0010] to [0055] of JP-A-2015-11084.

- the non-skin side layer 18 includes a spiral crimped fiber, and the fiber density of the non-skin side layer 18 is higher than the fiber density of the skin side layer 17.

- the topsheet 1 has quick liquid permeability due to capillary pressure difference and bulky and high cushioning properties. Thereby, the liquid residual reduction effect

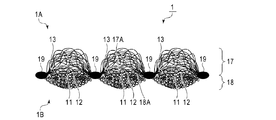

- the topsheet 1 has a liquid film cleaving agent arrangement part 11.

- the arrangement unit 11 is arranged as shown in FIG. 3 or as shown in FIG.

- the surface sheet 1 may have the arrangement part 11 in the whole in the plane direction, or may have it in part.

- positioning part 11 exists in the liquid receiving area

- the arrangement part 11 of the liquid film cleaving agent takes into account the possibility that the excretion liquid diffuses out from the liquid reception region Q1 due to the displacement of the mounting position of the napkin 10 or the increase in the amount of excretion liquid due to physical condition.

- positioning part 11 may be pattern-arranged in the whole plane direction or the whole liquid receiving area

- FIG. The pattern arrangement is to regularly arrange a plurality of arrangement portions 11 apart from each other. In this case, it is preferable that the arrangement portions 11 and non-arrangement portions 12 described later are alternately arranged in the planar direction of the topsheet 1.

- the liquid film cleaving agent placement portion 11 is located at the intermediate thickness position 13 of the topsheet 1. There are a plurality of arrangement portions 11 in the plane direction of the topsheet 1 at the intermediate thickness position 13. In FIG. 4, there is a liquid film cleaving agent placement portion 11 on the back surface 1 ⁇ / b> B side (absorber side) of the topsheet 1. There are a plurality of arrangement portions 11 in the plane direction of the topsheet 1 on the back surface 1B side.

- positioning part 11 are parts in which the liquid film cleaving agent is not arrange

- the topsheet 1 When the topsheet 1 is divided into approximately three equal parts in the thickness direction, when the placement portion 11 is in the layer on the skin side layer surface side that is the section closest to the skin side, from the surface 1A side, the most skin side layer When it is in the surface side of the non-skin side layer, which is a distant segment, the rear surface 1B surface side (absorber side), and when it is in the middle segment layer, there is a liquid film cleaving agent arrangement portion 11 at the intermediate thickness position 13 to decide.

- the arrangement portion 11 is shown with a pattern in order to understand the arrangement position of the arrangement portion 11, but in actuality, the arrangement portion 11 cannot always be visually determined. 3 and 4, the arrangement portion 11 is shown in a circular shape and separated from each other. However, specific aspects such as the arrangement interval and the number of the arrangement portions 11 are not limited to this, and can be set as appropriate from the viewpoint of the effect of reducing the remaining liquid.

- the liquid film cleaving agent in the arrangement part 11 exists in the middle of the path

- positioning part 11 exists in the exit vicinity where a bodily fluid transfers to the absorber 3 side from the surface sheet 1.

- the liquid film cleaving agent expands (transfers) from the position of the placement portion 11 and performs a liquid film cleaving action described later on the body fluid. This expansion action will be described later.

- the “thickness intermediate position 13 of the top sheet 1” refers to a portion inside the front surface 1A and the back surface 1B.

- the intermediate thickness position 13 is preferably a central area obtained by dividing the thickness of the topsheet into three equal parts, and more preferably near the center of the thickness width.

- the intermediate thickness position 13 is an inner position than the surface of the front surface 1A and the back surface 1B along the uneven shape.

- the intermediate thickness position 13 can be a boundary surface between the fiber layers.

- positioning part 11 may exist in the surface of either side among the opposing surfaces of both adjacent fiber layers.

- positioning part 11 is in any surface of the opposing surface 17A with the non-skin side layer 18 of the skin side layer 17, and the opposing surface 18A with the skin side layer 17 of the non skin side layer 18.

- the arrangement part 11 may be present on both opposing surfaces.

- a surface sheet consists of a some fiber layer, not only two layers like FIG. 3 but three layers or more may be sufficient.

- positioning part 11 should just exist in an at least one boundary surface, may exist in one interface, and may exist in a some interface.

- the formation of the arrangement portion 11 at the “thickness intermediate position 13 of the topsheet 1” can be performed by various methods that are usually used in the manufacturing process of the fiber sheet to be the topsheet 1.

- the topsheet 1 is composed of a single-layer fiber layer (nonwoven fabric)

- there is a method of applying (disposing) a liquid film cleaving agent during the fiber-filling process for forming a fiber web containing heat-fusible fibers. is there.

- the liquid film cleaving agent after the liquid film cleaving agent is applied, the remaining necessary fiber bundle treatment is performed, the fibers are fused together by heat treatment at a temperature equal to or higher than the melting point of the heat-fusible fiber, and the fiber web is made into a nonwoven fabric.

- the nonwoven fabric can be produced by performing the following processing steps (P1) to (P3).

- P1 A step of applying (disposing) a liquid film cleaving agent to one surface of the first fiber layer having the heat-fusible fiber.

- P2 The process of laminating

- (P3) A step of joining the first fiber layer and the second fiber layer by heat fusion by heat treatment at a temperature equal to or higher than the melting point of the heat-fusible fiber.

- the “first fiber layer” and the “second fiber layer” mean various fiber assemblies such as a nonwoven fabric, a fiber web, and a long fiber layer.

- the “first fiber layer” and the “second fiber layer” may be laminated in the same form or in different forms.

- the “heat treatment at a temperature equal to or higher than the melting point of the heat-fusible fiber” in (P3) may be either one of the embossing pressure-bonding process and the hot air process, or both.

- a hot air process may be performed at a temperature not higher than the “melting point of the heat-fusible fiber” but not lower than the “melting point of the heat-fusible fiber”.

- the compound having a liquid film cleavage effect one or a plurality of compounds selected from the compound C1 and the compound C2 described later may be used (hereinafter referred to as “liquid film for convenience in this specification”). Collectively referred to as "cleaving agents").

- the liquid film cleaving agent and a hydrophilizing agent described later may be mixed and applied.

- the non-woven fabric produced as described above is cut into an appropriate size as a surface sheet and molded.

- the surface sheet becomes an absorbent article through a process of laminating and bonding with other constituent members of the absorbent article by a normal method.

- an absorbent body and a back sheet are laminated in this order on one surface side (back surface side) of the top sheet and joined to form an absorbent article.

- side sheets for preventing side leakage are laminated on both sides in the longitudinal direction of the top sheet, an adhesive part for fixing the absorbent article to the clothes on the non-skin side of the back sheet, or wrapped around the clothes.

- the liquid film cleaving agent contained in the surface sheet 1 is an agent having the following properties (characteristics that cause the liquid film to disappear). Specifically, liquids such as highly viscous liquids such as menstrual blood and excretion liquids (body fluids) such as urine touch the nonwoven fabric to cleave the liquid film formed between the fibers of the nonwoven fabric or on the fiber surface. An agent that inhibits the formation of a liquid film.

- the liquid film cleaving agent has an action of cleaving the formed liquid film and an action of inhibiting the formation of the liquid film. The former can be called the main action, and the latter can be called the subordinate action.

- the liquid film cleaving agent acts as described in paragraphs [0024] and [0025] and FIGS.

- the liquid film cleaving agent does not perform liquid modification such as lowering the surface tension of the liquid film, but cleaves and pushes away the liquid film itself generated between the fibers or on the fiber surface, thereby inhibiting it from the nonwoven fabric. Encourage drainage of liquid.

- the liquid film cleaving agent used in the present invention has the property of eliminating the liquid film, and due to this property, the liquid film cleaving agent is applied to a test liquid or artificial urine mainly composed of plasma components. Moreover, the liquid film disappearance effect can be expressed. Artificial urine is 1.940% by mass of urea, 0.795% by mass of sodium chloride, 0.111% by mass of magnesium sulfate, 0.062% by mass of calcium chloride, 0.198% by mass of potassium sulfate, red No.

- test solution is a liquid component extracted from equine defibrinated blood (manufactured by Nippon Biotest Co., Ltd.). Specifically, when 100 mL of equine defibrinated blood is allowed to stand at a temperature of 22 ° C. and a humidity of 65% for 1 hour, the equine defibrinated blood is separated into an upper layer and a lower layer. It is.

- the upper layer mainly contains plasma components

- the lower layer mainly contains blood cell components.

- a transfer pipette manufactured by Nippon Micro Corporation

- the liquid film disappearance effect here refers to the effect of inhibiting the liquid film formation of the structure and the formed structure of the structure in which air is held by the liquid film formed from the test liquid or artificial urine. It can be said that an agent that exhibits both of the effects of disappearing the body and that exhibits at least one of the effects has the property of exhibiting the effect of disappearing the liquid film.

- the degree of the “property of disappearing the liquid film” of a certain agent is determined when the structure formed from the test solution or artificial urine to which the agent is applied is easily generated. It is judged by the amount of the structure, that is, the liquid film. That is, the test solution or artificial urine is adjusted to a temperature of 25 ° C., and then 10 g is put into a screw tube (manufactured by Maruemu Co., Ltd., No. 5, body diameter 27 mm, total length 55 mm) to obtain a standard sample. In addition, a measurement sample obtained by adding 0.01 g of an agent to be measured, which is adjusted in advance to 25 ° C., to the same sample as the standard sample is obtained.

- the standard sample and the measurement sample are vigorously shaken twice in the vertical direction of the screw tube, and then quickly placed on a horizontal plane.

- the structure of the liquid layer (lower layer) without the structure and a large number of structures formed on the liquid layer (the lower layer) is formed inside the screw tube after shaking.

- Upper layer After the elapse of 10 seconds immediately after shaking, the height of the structure layers of both samples (the height from the liquid surface of the liquid layer to the upper surface of the structure layer) is measured.

- the height of the structure layer of the measurement sample is 90% or less with respect to the height of the structure layer of the standard sample, it is assumed that the agent to be measured has a liquid film cleavage effect.

- the liquid film cleaving agent used in the present invention satisfies the above properties by a single compound that meets the above properties, a mixture of a plurality of single compounds that meet the above properties, or a combination of a plurality of compounds (liquid Agent capable of developing membrane cleavage). That is, the liquid film cleaving agent is an agent limited to those having a liquid film cleaving effect as defined above. Therefore, when the compound applied in the absorbent article contains a third component that does not meet the above definition, it is distinguished from a liquid film cleaving agent.

- the “single compound” is a concept including compounds having the same composition formula but having different molecular weights due to different numbers of repeating units.

- the liquid film cleaving agent it can be appropriately selected from those described in paragraphs [0007] to [0186] of the specification of WO2016 / 098796.

- That the surface sheet 1 has a liquid film cleaving agent mainly means that it adheres to the surface of the fiber.

- the liquid film cleaving agent may be a liquid film cleaving agent that is encapsulated in the fiber or that is present inside the fiber by internal addition.

- a method for attaching (applying) the liquid film cleaving agent to the surface of the fiber various commonly used methods can be employed without particular limitation. For example, application processes such as flexographic printing, ink jet printing, gravure printing, screen printing, spraying, and brush application can be used.

- These treatments may be carried out after the fibers are made into a web by various methods, and then after the web is made into a nonwoven fabric or incorporated into an absorbent article.

- the fiber having the liquid film cleaving agent attached to the surface is dried at a temperature sufficiently lower than the melting point of the fiber resin (for example, 120 ° C. or less) by, for example, a hot air blowing type dryer.

- the liquid film cleaving agent In order for the liquid film cleaving agent to have a liquid film cleaving effect to be described later in the nonwoven fabric, the liquid film cleaving agent needs to exist as a liquid when it comes into contact with body fluid. From this point, the melting point of the compound contained in the liquid film cleaving agent is preferably 40 ° C. or less, and more preferably 35 ° C. or less. Furthermore, the melting point of the compound contained in the liquid film cleaving agent according to the present invention is preferably ⁇ 220 ° C. or higher, more preferably ⁇ 180 ° C. or higher.

- the liquid film cleaving agent exhibits an expansibility to the liquid film between and on the fibers in the placement portion 11 to cause cleavage. Furthermore, the liquid film cleaving agent moves from the position of the arrangement part 11 to another area of the surface sheet 1 (an area other than the arrangement part, that is, the non-arrangement part 12) due to its expansibility, and exhibits a liquid film cleaving action.

- the former is called micro expansion

- the latter is called macro expansion. Macro expansion of the liquid film cleaving agent is manifested in both the planar direction and the thickness direction of the topsheet 1.

- the area ratio of the arrangement part 11 of the liquid film cleaving agent can be kept low. That is, in the area

- positioning part 11 refers to the area

- an arrangement part (basis weight 1.3 g / m 2 , OPU 0.4 mass%) of a liquid film cleaving agent is formed in a dot shape with a diameter of 0.8 mm on the surface of the nonwoven fabric having the same structure as that of the top sheet 1.

- Menstrual blood (6.0 g) was added dropwise.

- the liquid film cleaving agent was colored with a red paint so that the range of the arrangement portion could be confirmed.

- the color to be colored may be colored with an arbitrary color such as blue as long as the arrangement portion can be visually recognized.

- the simulated menstrual blood is prepared by adjusting equine defibrinated blood manufactured by Japan Biotest Laboratory Co., Ltd. to a viscosity of 8.0 cP. Specifically, it was adjusted under the condition of 30 rpm with a TVB10 type viscometer manufactured by Toki Sangyo Co., Ltd. When the equine defibrinated blood is allowed to stand, a highly viscous portion (such as red blood cells) precipitates, and a low viscosity portion (plasma) remains as a supernatant. The mixing ratio of the portion was adjusted to 8.0 cP (hereinafter, pseudo menstrual blood described in this specification is prepared by the same method unless otherwise specified).

- an absorbent article from a sanitary napkin (trade name: Laurie F, happy bare skin 22.5 cm, made in 2016) from a sanitary napkin, after cold spray is applied and the adhesive is solidified, it is carefully treated

- the top sheet was removed (in this specification, this method is used for removing the constituent members from the absorbent article).

- the above-mentioned nonwoven fabric is laminated so that the surface of the concavo-convex structure is on the skin contact surface side, and an acrylic plate having a perforation hole with an inner diameter of 1 cm is overlapped with the center of the permeation hole and the arrangement portion. Put it on.

- the liquid film cleaving action can be expressed by expanding to a wider range.

- the basis weight is 25.9 g / m 2 (OPU 8.0% by mass) in the arrangement part 11 having the same diameter

- the liquid film reaches a range of 12 mm in diameter (K2) that is about 15 times the diameter of the arrangement part 11. It was confirmed that the cleaving agent expanded concentrically and exhibited a liquid film cleaving action, and the redness M1 of simulated menstrual blood was eliminated (see FIGS. 5A and 5C).

- the liquid film cleaving agent is the liquid receiving surface from the thickness intermediate position 13 or the back surface 1B side of the top sheet 1 when the flow of the liquid is settled as compared with that during and immediately after the liquid injection. Expands to the surface 1A side.

- the surface 1A which is the liquid receiving surface, may exhibit a phenomenon of developing a liquid film cleaving action with a time difference with respect to the intermediate thickness position 13 or the back surface 1B side.

- the arrangement part 11 of the liquid film cleaving agent is not on the front surface 1A and is on the thickness intermediate position 13 or the back surface 1B side, the liquid residue of the entire topsheet 1 is suppressed low, and a high level of dryness is realized. be able to. Moreover, since the elimination of redness can be confirmed on the surface 1A side, the wearer can realize with the skin and eyes that the remaining liquid is kept low. Furthermore, when the arrangement

- the placement portion 11 is more effective in reducing the liquid residue when it is at the intermediate thickness position 13 than when it is on the back surface 1B side.

- the arrangement part 11 of the liquid film cleaving agent is located at the intermediate thickness position 13 or the back surface 1B side of the topsheet 1, so that the non-arrangement part on the surface 1A side between the skin and the arrangement part 11 of the liquid film cleaving agent Therefore, the contact opportunity between the liquid film cleaving agent and the skin of the wearer is suppressed, and the skin stickiness is highly prevented.

- the liquid film cleaving agent arrangement portion OPU in the thickness intermediate position 13 or the arrangement portion 11 on the back surface 1B side, excessive expansion of the liquid film cleaving agent to the surface 1A is controlled, and the liquid film cleaving agent and skin It is possible to suitably suppress contact with.

- the surface sheet 1 can suppress the feeling of sticking to or clinging to the skin, and can keep the dry feeling of the skin high.

- the preferable range of the arrangement ratio (arrangement part OPU) of the liquid film cleaving agent in the arrangement part 11 and the measuring method are the arrangement ratio of the liquid film cleaving agent with respect to the total fiber mass of the surface sheet (hereinafter referred to as “ It will be described later together with a preferable range and measurement method of “average OPU”.

- each fiber layer can be changed, which is preferable.

- the capillary pressure on the back surface 1B side can be made higher than the front surface 1A side, and the capillary pressure difference between both surfaces can be increased, and the liquid after cleaving with the liquid film cleaving agent can be transferred to the absorber 3 rather than the single layer. And can be easily pulled in.

- the specific form of each fiber layer that increases the capillary pressure difference is to increase the fiber weight by increasing the basis weight of the non-skin side layer or reducing the fiber diameter than the skin side layer, or increasing the hydrophilicity. A raised form can be mentioned.

- the arrangement pattern of the arrangement part 11 of a liquid film cleaving agent and the arrangement ratio of a liquid film cleaving agent can be set with high precision. Therefore, when the topsheet 1 is a laminated sheet, the liquid film cleaving action of the liquid film cleaving agent arranged with high accuracy at the intermediate thickness position 13 is coupled with the pulling force of the liquid due to the above-described capillary pressure difference, etc. A higher liquid residue reducing effect is achieved, which is preferable.

- the liquid film cleaving agent arrangement part 11 (arrangement part OPU 0.4 mass%) is formed on the convex top of the back surface 1B as shown in FIG. 6B. It formed in the shape of a 0.8mm diameter dot.

- the liquid film cleaving agent was colored with a red paint so that the range of the arrangement portion could be confirmed.

- FIG. 6 (A) the top sheet 1 was placed on the absorber 3 with the top surface 1A facing up, and the acrylic plate 100 having the inlet of the cylinder 101 was placed on the sample. .

- the degree of macro expansion of the liquid film cleaving agent depends on various factors. For example, the larger the expansion coefficient described later, the longer the expansion distance in the droplet, and the higher the expandability. In addition, the larger the arrangement ratio of the liquid film cleaving agent in the arrangement portion 11, the longer the expansion distance in the droplet and the higher extensibility. In addition, the liquid film cleaving agent exhibits a suitable high expandability with respect to droplets by appropriately suppressing the viscosity.

- the liquid film cleaving agent When the arrangement part 11 of the liquid film cleaving agent is located at the thickness intermediate position 13 or the back surface 1B side, in consideration of extending in the thickness direction from the arrangement part 11 to the surface 1A that is the liquid receiving surface, In comparison, it is preferable that the liquid film cleaving agent moderately suppresses the viscosity.

- the viscosity of the liquid film cleaving agent when the liquid film cleaving agent arrangement portion 11 is at the middle thickness position 13 or the back surface 1B side is 0 cps or more, preferably 6000 cps or less, more preferably 600 cps or less. 200 cps or less is more preferable.

- the viscosity of the liquid film cleaving agent can be measured by the following method. First, 40 g of a liquid film cleaving agent is prepared. Next, the viscosity of the liquid film cleaving agent is measured using a tuning fork type vibration viscometer SV-10 (manufactured by A & D Co., Ltd.) in an environmental region of a temperature of 25 ° C. and a relative humidity (RH) of 65%. This is repeated three times, and the average value is adopted as the viscosity.

- SV-10 tuning fork type vibration viscometer

- the liquid film cleaving agent When the liquid film cleaving agent is solid, the liquid film cleaving agent is heated to the melting point of the liquid film cleaving agent + 5 ° C. to cause a phase transition to the liquid, and the measurement is carried out while maintaining the temperature condition.

- a liquid film cleaving agent is taken out from a fiber by the method used in measurement of the expansion coefficient etc. which are mentioned later. In this case, when only a small amount can be taken out for the above measurement, the viscosity is measured in the same manner as in the case of measuring the expansion coefficient described later.

- the liquid (body fluid) that touched the surface sheet 1 can easily pass through without remaining in a very small space between the fibers. 1 can be achieved at a higher level. Furthermore, even if the arrangement of the liquid film cleaving agent on the surface 1A of the surface sheet 1 is reduced or eliminated, the liquid film cleaving agent at the thickness intermediate position 13 or the back surface 1B side of the surface sheet 1 expands the macro. It is expressed and the liquid remaining reduction effect of the entire surface sheet 1 can be obtained as in the case of the surface 1A. In addition, as described above, contact between the liquid film cleaving agent and the skin on the surface 1A of the topsheet 1 is suppressed. Thereby, in this embodiment, reduction of a liquid residue and reduction of the stickiness of skin can be implement

- the surface flow of the liquid on the surface 1A of the topsheet 1 can be suitably suppressed. That is, since the liquid film cleaving agent has high expandability with respect to the liquid film, the surface tension is smaller than that of a conventional hydrophilizing agent used for nonwoven fabric fibers. Therefore, when the liquid film cleaving agent is arranged, the wettability of the fibers in the initial contact stage with the liquid is slightly reduced as compared with the case where no liquid film cleaving agent is arranged. On the surface 1A of the topsheet 1, a surface flow of body fluid (for example, excretion fluid such as menstrual blood or urine) is more likely to occur than when no liquid film cleaving agent is disposed.

- body fluid for example, excretion fluid such as menstrual blood or urine

- positioning part 11 of the liquid film cleaving agent is arrange

- the liquid film cleaving agent can exhibit a liquid film cleaving action not only in the arrangement portion 11 but also in a wide range in the thickness direction and the planar direction of the topsheet 1 due to its expandability. Thereby, even when the liquid film cleaving agent is at the intermediate thickness position 13 or the back surface 1B side, the effect of reducing the remaining liquid of the entire top sheet 1 can be obtained as in the case of the front surface 1A.

- the liquid film cleaving agent can hold a passage space for transferring body fluid from the topsheet 1 to the absorber 3 on the back surface 1B side of the topsheet 1. In addition, the liquid drawing force of the absorber 3 is easily transmitted to the surface 1A side through the passage space.

- the placement of the placement portion 11 on the topsheet 1A side of the topsheet 1 is preferably reduced.

- the area ratio of the arrangement portion 11 occupying the area of the topsheet 1 is the surface 1A (wearer) of the topsheet 1 rather than the middle thickness position 13 or the backside 1B (surface facing the absorber) of the topsheet 1. It is preferable that it is made small in the surface facing the skin side. Furthermore, it is more preferable that the arrangement

- the surface 1 ⁇ / b> A is shown as an aspect in which the liquid film cleaving agent arrangement portion 11 is not provided.

- the area ratio of the placement part 11 is calculated by (total area of placement part / total area of placement part and non-placement part) ⁇ 100. “The total area of the arrangement part and the non-arrangement part” is the area of the topsheet 1.

- the area of the topsheet 1 relating to the calculation of the area ratio is an area defined by the outer shape of the topsheet 1 in any case of the thickness intermediate position 13 of the topsheet 1, the top surface 1A, and the back surface 1B.

- the surface sheet 1 is carefully peeled off from the absorbent article to be measured, taken out, a sample cut into a 3.0 cm square is created, and placed in the liquid receiving region of the absorbent article.

- a surface sheet is taken out from a sanitary napkin (manufactured by Kao Corporation, trade name: Why F happy bare skin, 22.5 cm, manufactured in 2016), and the sample is prepared. Then, the sample is stacked on the liquid receiving area of the napkin.

- the liquid-receiving area in the sanitary napkin is between 7.5 cm and 15.0 cm from the front part F, and is an area that is 2.5 cm or less in the width direction from a line that bisects the short direction. .

- an acrylic plate having a transmission hole with an inner diameter of 1 cm is placed so that the transmission hole and the center of the sample overlap each other, and a constant load of 100 Pa is applied to the napkin.

- Inject 6.0 g of menstrual blood Immediately after the injection, the acrylic plate is removed, the sample is immersed in liquid nitrogen, and is cut along the width direction of the topsheet 1 passing through the center of the sample using a cutter.

- the cut section is observed with an optical microscope, and at the intermediate thickness position of the sample, the portion where the redness of pseudo menstrual blood is eliminated more than the front side and the back side is the placement portion 11, and the other portion is the non-placement portion 12. It is. And when the surface sheet 1 is divided into about three equal parts in the thickness direction, when the part where redness is eliminated is in the layer on the skin side layer surface side which is the section closest to the skin side, When it is in the layer on the surface side of the non-skin side layer, which is the section farthest from the skin side layer, the arrangement part 11 of the liquid film cleaving agent is located at the middle position of the thickness in the case of the back side (absorber side) and in the middle section. Judge that there is.

- the presence or absence of the liquid film cleaving agent when the liquid film cleaving agent placement portion 11 of the top sheet 1 is on the front surface 1A side or the back surface 1B side can be confirmed by the following method. That is, after blotting paper is applied to each surface of the top sheet 1, an acrylic plate having a thickness of 4 mm is placed, and a weight is applied for 30 seconds so as to be 600 g / cm 2 from the top. Immediately after the loading, the oil-blotting paper is peeled off, and the oil-blotting paper is placed on a black mount and the color change is visually confirmed.

- the portion of the surface sheet 1 corresponding to the discolored portion of the blotting paper is the placement portion 11 of the liquid film cleaving agent, and the other portion is the non-placement portion 12.

- Various materials can be used as the above-mentioned oil blotting paper, and examples thereof include gold leaf punching paper manufacturing oil blotting paper manufactured by Katani Sangyo Co., Ltd.

- the presence or absence of the liquid film cleaving agent when the arrangement portion 11 of the surface sheet 1 is in the middle position as shown in FIG. 3 is the same as the above (Method for confirming the presence or absence of the liquid film cleaving agent in the thickness direction).

- the arrangement portion 11 of the topsheet 1 is on the front surface 1A side or the back surface 1B side

- the previous stage of the above-described method for confirming the presence or absence of the liquid film cleaving agent in the planar direction with respect to the entire surface of the topsheet 1 Measure according to the procedure described in. That is, the area of the placement part 11 is defined as the area of the part that is loaded and the discolored part of the blotting paper is copied to the OHP sheet, and the value obtained by subtracting the area of the placement part 11 from the area of the top sheet 1 The area.

- positioning part 11 of the surface sheet 1 exists in the thickness intermediate position 13 like FIG.

- the capillary pressure on the back surface 1B side it is preferable to increase the capillary pressure difference between the two surfaces.

- the liquid film cleaving agent slightly reduces the wettability of the fiber. That is, there is a possibility that the contact angle of the fibers is slightly increased and the capillary pressure difference is affected.

- the capillary pressure difference between both surfaces can be controlled to an appropriate state by taking the following mode.

- the liquid film cleaving agent can sufficiently exhibit the liquid film cleaving action even in the non-arranged portion 12 by macro expansion as described above.

- the mixture it is possible to suitably suppress the reduction of the hydrophilicity of the fiber by the liquid film cleaving agent as the entire surface region on the thickness intermediate position 13 or the back surface 1B side.

- the hydrophilicity on the absorber 3 side can be made higher than the top surface 1 ⁇ / b> A side, and the capillary pressure difference between both surfaces can be controlled to be large.

- the area ratio of the placement portion 11 is preferably 75% or less, more preferably 60% or less, and even more preferably 50% or less from the viewpoint of appropriately maintaining the capillary pressure difference at each of the intermediate thickness position 13 and the back surface 1B.

- the area ratio of the placement portion 11 is preferably 5% or more, more preferably 10% or more, and still more preferably 20% or more, from the viewpoint of effectively expressing the liquid film cleaving action.

- both the placement portion 11 and the non-placement portion 12 extend in a strip shape in the vertical direction (Y direction), and the strip-like placement portion 11 and the non-placement portion 12 are alternately arranged in the width direction (X direction).

- One vertical stripe pattern

- a plurality of arrangement parts 11 arranged in a circle (dot shape) in the non-arrangement part 12 are arranged apart from each other.

- a hydrophilizing agent on the top sheet 1 as follows. That is, it is preferable to increase the amount of the hydrophilizing agent disposed on the surface (back surface) 1B facing the absorber 3 side, rather than the surface (front surface) 1A facing the wearer skin side of the top sheet 1.

- positioning part 11 of a liquid film cleaving agent it is preferable to apply

- the mass ratio of the total amount of the hydrophilic agent arranged on the back surface 1B of the top sheet 1 to the total amount of the hydrophilic agent arranged on the surface 1A of the top sheet 1 is preferably 1.2 or more from the viewpoint of increasing the capillary pressure difference. 1.7 or more is more preferable, and 2.7 or more is still more preferable. In addition, the mass ratio is preferably 17.3 or less, more preferably 9.1 or less, and even more preferably 5.9 or less, from the viewpoint of successfully draining the surface sheet 1 from the top sheet 1 to the absorber. This mass ratio is calculated based on a “method for measuring the arrangement ratio” of the hydrophilizing agent described later.

- the mass ratio of the total amount of the hydrophilizing agent in the coating solution to the total amount of the coating solution (hydrophilizing agent / coating solution) is preferably 0.3 or more from the viewpoint of clarifying the capillary pressure difference in the thickness direction of the surface sheet, 0.5 or more is more preferable, and 0.75 or more is still more preferable.

- the mass ratio (hydrophilizing agent / coating solution in the coating solution) is preferably 0.9 or less, more preferably 0.85 or less, and 0.8 or less from the viewpoint of successfully obtaining the effect of the liquid film cleaving agent. Is more preferable. This mass ratio is calculated on the basis of the “measurement method of the arrangement ratio” of the liquid film cleaving agent and the hydrophilizing agent in the coating solution described later.

- the mass ratio can be measured by applying the method described in paragraph [0018] of the specification of International Publication No. 2016/098796.

- the total amount of the hydrophilizing agent (“the hydrophilizing agent pre-applied to the fiber web as the nonwoven fabric sample” and “the hydrophilizing agent in the coating solution”) is an arrangement ratio (average OPU) with respect to the total fiber mass of the topsheet 1. From the viewpoint of increasing the capillary pressure difference in the thickness direction of the surface sheet while giving moderate hydrophilicity that allows the liquid to easily enter between the fibers on the surface of the nonwoven fabric forming the surface sheet, it is preferably 0.3% by mass or more. .6% by mass or more is more preferable, and 0.9% by mass or more is still more preferable.

- the average OPU of the total amount of the hydrophilizing agent (“the hydrophilizing agent previously applied to the fiber web as the nonwoven fabric sample” and “the hydrophilizing agent in the coating liquid”) is promptly transmitted to the absorbent body. Is preferably 6% by mass or less, more preferably 3% by mass or less, and still more preferably 2% by mass or less.

- the total amount of the liquid film cleaving agent is preferably 0.1% by mass or more from the viewpoint of effectively expressing the liquid film cleaving action as an arrangement ratio (average OPU) with respect to the total fiber mass of the top sheet 1. More preferably 2% by mass or more, and still more preferably 0.3% by mass or more.

- the average OPU of the liquid film cleaving agent is preferably 10% by mass or less, more preferably 7.5% by mass or less, and still more preferably 5% by mass or less from the viewpoint of effectively suppressing the surface flow of the liquid.

- average OPU shows the arrangement

- average OPU shows the arrangement

- the total amount of the liquid film cleaving agent is sufficient as the arrangement ratio (arrangement part OPU) with respect to the fiber mass in the arrangement part 11 of the topsheet 1 to the non-arrangement part 12 in the planar direction and the thickness direction of the topsheet 1.

- the content is preferably 0.1% by mass or more, more preferably 0.4% by mass or more, and still more preferably 0.8% by mass or more.

- the liquid film cleaving agent arrangement portion OPU is 8 mass% or less, preferably 4 mass% or less, more preferably 1.5 mass% or less.

- positioning part OPU shows the arrangement

- the disposing portion OPU indicates the disposition ratio of the total amount of the liquid film cleaving agent to the fiber mass in the disposing portion 11 of the topsheet 1, and the disposed component is a hydrophilizing agent and When it is / or a coating liquid, the arrangement ratio of the total amount of the hydrophilizing agent and / or the coating liquid to the fiber mass in the arrangement portion 11 of the topsheet 1 is shown.

- the total mass of the liquid film cleaving agent, the hydrophilizing agent and other components is clarified from the mass of the residue. Then, after setting the measurement conditions such as column and solvent appropriately, the extract is separated and isolated using liquid chromatography. From the mass ratio of the separated substance, the liquid membrane cleaving agent, hydrophilizing agent and other components The mass ratio of is clarified. Moreover, the above-mentioned average OPU (mass%) regarding each component is calculated using the mass ratio, the mass of the residue, and the mass of the top sheet.

- the molecular structure of the substance is identified by the following measurement method, and the corresponding structural unit is obtained to determine the physical properties.

- the molecular weight of the separated product is measured using either mass spectrometry (MS) or gel permeation chromatograph (GPC).

- MS mass spectrometry

- GPC gel permeation chromatograph

- the molecular skeleton is identified using 1 H-NMR, 13 C-NMR, 29 Si-NMR, the functional group owned is identified using IR, and the ratio of elements using elemental analysis.

- the molecular structure is identified by combining all the above information.

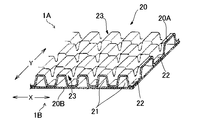

- topsheet 1 used in the absorbent article of the present invention is a topsheet 20 made of laminated fiber sheets as shown in FIG.

- the top sheet 20 has a two-layer structure having a hollow portion 21. Both layers contain thermoplastic fibers.

- the upper layer sheet 20A that is a skin side layer and the lower layer sheet 20B that is a non-skin side layer have a joint portion 22 that is partially heat-sealed.

- the upper layer sheet 20A protrudes in a direction away from the lower layer sheet 20B, and has a large number of convex parts 23 each having a hollow part 21 therein.

- the joint portion 22 is a concave portion located between the adjacent convex portions 23, 23, and constitutes an uneven surface 1 ⁇ / b> A together with the convex portion 23.

- the topsheet 20 can be formed by a commonly used method. For example, after the upper layer sheet 20A is unevenly shaped by meshing two uneven rolls, the lower sheet 20B is bonded to obtain the top sheet 20. From the viewpoint of shaping the nonwoven fabric by meshing the concavo-convex rolls, it is preferable that both the upper layer sheet 20A and the lower layer sheet 20B include non-heat-extensible and non-heat-shrinkable heat-fusible fibers.

- the topsheet 20 is excellent in liquid permeability from the top surface 1A side to the back surface 1B side when used by laminating the top surface 1A on the absorbent body with the front surface 1A facing the skin contact surface side. Specifically, liquid permeation through the hollow portion 21 is performed. Moreover, a wearer's body pressure is added to the convex part 23, and the liquid in the convex part 23 transfers to the lower layer sheet 20B directly. Thereby, there is little liquid residue on the surface 1A side. Such an action can be continuously exerted at a higher level by the action of the liquid film cleaving agent described above or the cooperative action of the liquid film cleaving agent and the phosphate ester type anionic surfactant.

- the arrangement part 11 of the liquid film cleaving agent is in “the intermediate thickness position of the surface sheet 20” means that the arrangement part 11 faces the lower sheet 20B of the upper layer sheet 20A or the lower layer sheet 20B. It says that it exists in the opposing surface with 20 A of upper layer sheets.

- positioning part 11 of a liquid film cleaving agent exists in the "absorber side of the surface sheet 20” means that this arrangement

- the liquid film cleaving action accompanied by the macro and micro expansion of the liquid film cleaving agent described above simultaneously achieves a reduction in liquid residue and a reduction in skin stickiness in absorbent articles. can do.

- the hydrophilizing agent in the present invention is preferably an agent that hardly reduces the liquid film cleaving action.

- the agent is difficult to reduce the surface tension of the body fluid to be subjected to liquid film cleavage. That is, the agent is preferably an agent having a low dissolution rate or low solubility in the body fluid.

- the expandability on the liquid film of the liquid film cleaving agent is maintained, and the liquid film cleaving action can be sufficiently exhibited. .

- the hydrophilizing agent includes one or more selected from (D1) a nonionic surfactant and (D2) a compound having a surface tension of 42 mN / m or more as specific examples of those having a slow dissolution rate or low solubility in body fluids. It is preferable to include.

- the hydrophilizing agent (D1) and the hydrophilizing agent (D2) respectively.

- the hydrophilizing agent (D1) is a hydrocarbon-based nonionic surfactant having a hydrophobic group having a hydrophobicity lower than that of a fluorocarbon group, as a component for enhancing hydrophilicity on the fiber surface of the nonwoven fabric in which the liquid film cleaving agent is disposed. It is preferable to include one or more selected from silicone-based nonionic surfactants. More specifically, it is preferable to include a nonionic surfactant having “an alkyl chain or a silicone chain excluding a polyhydric alcohol fatty acid skeleton” as a hydrophobic group.

- the hydrophilic group structure of the nonionic surfactant that forms the hydrophilizing agent (D1) preferably includes a polyethylene oxide type, a polyol (polyhydric alcohol) type, a block polymer type, a nitrogen-containing type, and the like.

- the polyethylene oxide type nonionic surfactant preferably contains polyoxyethylene alkyl ether, polyoxyethylene fatty acid ester and the like.

- Examples of the polyol (polyhydric alcohol) type nonionic surfactant include sorbitan monoalkylate, polyoxyethylene sorbitan monoalkylate, glycerol monoalkylate, polyglyceryl monoalkylate, alkyl glucoside, pentaerythritol monoalkylate, etc. preferable.

- the block polymer type nonionic surfactant preferably contains an alkyl ether of polyoxyethylene polyoxypropylene glycol, polyoxyethylene polyoxypropylene alkyl ether, or the like.

- the nitrogen-containing nonionic surfactant preferably includes polyoxyethylene alkylamine, alkyl polyoxyethylene fatty acid amide, and the like. Among these, it is preferable to have at least a “polyoxyethylene (hereinafter also referred to as“ POE ”)” group as a hydrophilic group.