WO2018135102A1 - 流路切換弁及びその組立方法 - Google Patents

流路切換弁及びその組立方法 Download PDFInfo

- Publication number

- WO2018135102A1 WO2018135102A1 PCT/JP2017/040417 JP2017040417W WO2018135102A1 WO 2018135102 A1 WO2018135102 A1 WO 2018135102A1 JP 2017040417 W JP2017040417 W JP 2017040417W WO 2018135102 A1 WO2018135102 A1 WO 2018135102A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- valve

- valve body

- flow path

- hole

- path switching

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K11/00—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves

- F16K11/02—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit

- F16K11/08—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit comprising only taps or cocks

- F16K11/087—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit comprising only taps or cocks with spherical plug

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K5/00—Plug valves; Taps or cocks comprising only cut-off apparatus having at least one of the sealing faces shaped as a more or less complete surface of a solid of revolution, the opening and closing movement being predominantly rotary

- F16K5/06—Plug valves; Taps or cocks comprising only cut-off apparatus having at least one of the sealing faces shaped as a more or less complete surface of a solid of revolution, the opening and closing movement being predominantly rotary with plugs having spherical surfaces; Packings therefor

Definitions

- the present invention relates to a flow path switching valve and a method for assembling the same, and for example, relates to a rotary flow path switching valve that switches a flow path by rotating and sliding a ball-shaped valve body (ball valve body) in a valve chamber.

- valve body As a conventional flow path switching valve of this type, a valve body (ball valve body) having an inflow path and an outflow path and made of an elastic body, a valve chamber in which the valve body is rotatably accommodated, and the valve chamber

- a valve main body having an inlet flow path and a plurality of outlet flow paths, the inflow path is always in communication with the inlet flow path, and the outflow path is rotated by the rotation of the valve body.

- a valve (ball valve) that selectively communicates with any of the plurality of outlet channels is known (for example, see Patent Document 1 below).

- the valve body made of an elastic body is rotatably accommodated in the valve chamber while being pressed against the valve body.

- the inflow path always communicates with an inlet channel provided in the lower part of the valve body, and the outlet of the valve body is connected to any of a plurality of outlet channels provided on the side of the valve body by the rotational operation of the valve body. It is designed to communicate alternatively.

- the valve main body has a two-part configuration (divided configuration) of a base member and a holder member that are open on one side, and a valve body or the like is provided inside the base member.

- the valve body and the like are assembled to the valve body (valve chamber) by joining the holder member to the side opening of the base member by ultrasonic welding or the like.

- the dispersion of melting due to ultrasonic welding becomes large, the amount of penetration of the welded portion is largely caused by the crushing rate (crushing allowance) of the O-ring, and the design variation of the crushing rate (crushing allowance) of the O-ring is increased. May grow. Further, the tilting of the holder member with respect to the base member is likely to occur due to the repulsive force of the O-ring made of an elastic body, making it difficult to manage the dimensions. Further, for example, liquid leakage may occur due to poor bonding such as poor welding of ultrasonic welding.

- the present invention has been made in view of the above circumstances, and the object of the present invention is to easily perform dimensional management such as a crushing rate (crushing allowance) of the O-ring, and to minimize defective bonding. It is an object of the present invention to provide a flow path switching valve that can be suppressed and an assembly method thereof.

- a flow path switching valve includes a valve body in which a valve chamber is formed and a plurality of inlets / outlets opened in the valve chamber, A valve body that is rotatably arranged in the valve chamber and has a flow path formed therein, and is disposed between the valve body and the inlet / outlet to seal between the valve body and the inlet / outlet.

- a seat member formed, an elastic member disposed between the seat member and the valve main body to press the seat member against the valve body, a rotation drive unit that rotates the valve body around a rotation axis,

- a flow path switching valve configured to selectively switch the communication state of the plurality of inlets / outlets through the channel of the valve body by rotating the valve body, the plurality of inlet / outlet ports Is at least two sides opened on the side of the valve chamber

- an outlet, rotational axis direction height of the valve body is characterized in that it is less distance between the sheet members together, which are arranged in the two side inlet and outlet.

- the height of the valve body in the rotation axis direction is set to be equal to or less than the interval between the sheet members in a state where the elastic member is compressed with a predetermined pressure.

- valve body is provided with a base member in which the two side inlets / outlets are provided and an opening larger than the outer shape of the valve body is provided at one end in the rotation axis direction, and the base member It is divided into a holder member connected and fixed to the opening.

- At least two positions on the outer periphery of the valve body are provided with a rotation engaging portion for rotating and installing the valve body in a predetermined direction in the valve chamber.

- valve body penetrates the valve body in the direction of the rotation axis, and the valve shaft that transmits the rotational force of the rotation drive unit to the valve body is engaged with the valve body in a relatively non-rotatable manner.

- a hole is provided.

- the vertical through hole can be inserted through the valve shaft in the rotation axis direction.

- a lateral hole is formed that joins from the outer periphery of the valve body to the vertical through hole.

- valve shaft is inserted through the vertical through hole and the fitting insertion hole provided in the valve main body, and the drive gear constituting the rotation driving unit at a portion protruding from the fitting insertion hole. Is fixed.

- a stepped portion that is contacted and locked around the fitting insertion hole is provided on the outer periphery of the valve shaft.

- an inner hook-shaped hooking portion is provided in the fitting insertion hole, and a step is provided on the outer periphery of the valve shaft so as to contact and lock the inner hook-shaped hooking portion.

- the flow path switching valve assembly method includes a valve body in which a valve chamber is formed and a plurality of inlets and outlets opened in the valve chamber, and a rotation within the valve chamber.

- a valve member disposed freely and having a flow path formed therein, and a seat member disposed between the valve body and the inlet / outlet to seal between the valve body and the inlet / outlet And an elastic member disposed between the seat member and the valve body to press the seat member against the valve body, and a rotation drive unit that rotates the valve body around a rotation axis,

- a method for assembling a flow path switching valve in which the communication state of the plurality of inlets / outlets is selectively switched through the flow path of the valve body by rotating a valve body, at least on the valve chamber side

- the valve shaft in the step of connecting the valve shaft to the valve body, is passed through a vertical through hole penetrating the valve body in the rotation axis direction, and the valve shaft is not relatively rotatable in the vertical through hole.

- the valve shaft is inserted into a fitting insertion hole provided in the valve main body, and a driving gear constituting the rotation driving unit is fixed to a portion protruding from the fitting insertion hole in the valve shaft.

- valve shaft is inserted into the vertical through hole and the insertion hole until a stepped portion provided on the outer periphery of the valve shaft is abutted and locked around the insertion hole.

- the valve shaft in the step of connecting the valve shaft to the valve body, the valve shaft is inserted into a fitting insertion hole provided in the valve body, and the valve body is vertically penetrated in the rotation axis direction.

- the valve shaft is passed through the hole, the valve shaft is engaged with the vertical through hole so as not to be relatively rotatable, and a drive gear constituting the rotation drive unit is fixed to a portion protruding from the insertion hole in the valve shaft.

- valve shaft is inserted into the fitting insertion hole until a step provided on the outer periphery of the valve shaft comes into contact with and engages with an inner hook-shaped latching portion provided in the fitting insertion hole.

- the valve body has a two-part configuration (divided configuration) of a base member and a holder member, when the base member and the holder member constituting the valve main body are joined (at the time of ultrasonic welding) Etc.), it is not necessary to compress the elastic member, so that dimensional management such as the crushing rate (crushing allowance) of the elastic member is facilitated, and bonding failure (for example, welding fusion failure) is suppressed, resulting in bonding failure. It is possible to effectively prevent liquid leakage and cracking of the joint (welded part).

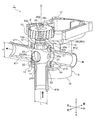

- FIG. 1 The perspective view which shows the whole structure of one Embodiment of the flow-path switching valve (three-way valve) which concerns on this invention.

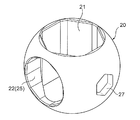

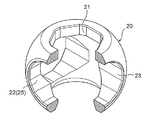

- the fragmentary longitudinal cross-section perspective view of the flow-path switching valve shown by FIG. The perspective view which shows the valve body of FIG.

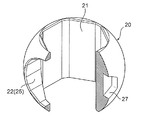

- the partial notch which shows the valve body of FIG. 2 (The central angle 90 degree part is notched by planar view) perspective view.

- 3A and 6B are six-side views of the valve body in FIGS.

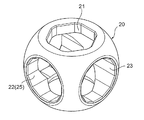

- FIG. 7 is a partially cutaway perspective view showing another example of the valve body of the flow path switching valve shown in FIG. 1 (the central angle 90 ° portion is cut away in plan view).

- FIG. 7B is a six-sided view of the valve body of FIGS.

- FIG. 1 is a perspective view showing the overall configuration of an embodiment of a flow path switching valve according to the present invention

- FIG. 2 is a partial longitudinal sectional perspective view of the flow path switching valve shown in FIG. 3A and 3B are views showing the valve body of FIG. 2

- FIG. 3A is a perspective view

- FIG. 3B is a partially cutaway (a central angle 90 ° portion is cutout in plan view) perspective view

- FIG. It is a 6th page figure of the valve body of 3A and B.

- FIG. 1 is a perspective view showing the overall configuration of an embodiment of a flow path switching valve according to the present invention

- FIG. 2 is a partial longitudinal sectional perspective view of the flow path switching valve shown in FIG. 3A and 3B are views showing the valve body of FIG. 2

- FIG. 3A is a perspective view

- FIG. 3B is a partially cutaway (a central angle 90 ° portion is cutout in plan view) perspective view

- FIG. It is a 6th page figure of the valve body of 3

- the flow path switching valve 1 of the illustrated embodiment is used as, for example, a rotary three-way valve that switches a flow path of a fluid flowing in an engine room of an automobile in multiple directions, and basically includes a valve chamber 11.

- a valve body 10, a ball-shaped valve body (also referred to as a ball valve body) 20 rotatably disposed in the valve chamber 11, and a valve body 20 are rotated to rotate around a rotation axis (center line) O.

- the motor 8 is arranged from the rear part to the upper part of the main body 10, and the rotation drive part 5 is composed of a drive gear 9 and the like.

- the valve body 10 and the rotation drive unit 5 are formed integrally.

- a rotation axis (axis extending in the vertical direction) O of the valve body 20 accommodated in the valve chamber 11 is coaxial with a center line of an inlet p10 and a valve shaft 28 described later.

- the valve body 10 is composed of a square tubular base member 12 with a ceiling portion 12a made of, for example, a synthetic resin or metal, and a holder member 15, and the base member 12 is laid down in a cylindrical shape.

- a valve chamber 11 is formed, and a lateral outlet (entrance / exit) p11 and an outlet (entrance / exit) p12 that open to the valve chamber 11 are provided on the left and right sides, respectively.

- Ports # 11 and # 12 made of pipe joints are integrally connected to the outer periphery of the base member 12 so as to communicate with the outlets p11 and p12.

- the ceiling portion 12 a of the base member 12 is provided with a fitting insertion hole 13 through which a valve shaft 28 (an intermediate body portion 28 b) connected to the valve body 20 is inserted, and left and right of the fitting insertion hole 13.

- a valve shaft 28 an intermediate body portion 28 b

- the fitting insertion hole 13 slightly to the left and right of the portion where the step portion 28s between the lower engagement portion 28a and the intermediate body portion 28b of the valve shaft 28, which will be described later, is contacted and locked.

- Protrusions 14a and 14b for positioning of the annular sheet members 31 and 32 are provided so as to project substantially downward (downward) (see also FIG. 5).

- a holder member 15 having a port # 10 made of a pipe joint provided with a vertical inlet (inlet / outlet) p10 that opens into the valve chamber 11 is ultrasonically welded and screwed.

- the inner fitting is fixed by press fitting, caulking, etc. (ultrasonic welding in the illustrated example).

- valve body 10 is provided with an inlet p10 opened at the bottom of the valve chamber 11, and outlets (side inlet / outlet) p11, p12 opened at the side of the valve chamber 11 are 180. They are provided at an angle interval of ° (in other words, so as to face the opposite side with respect to the rotation axis O of the valve body 20).

- a motor case portion 16 that houses a motor 8 that constitutes the rotation drive portion 5 for rotating the valve body 20 (the valve shaft 28 connected to the valve body 20) is integrally formed at the rear portion of the base member 12 of the valve body 10.

- a gear case portion 17 that accommodates a drive gear 9 that is connected to the motor 8 and transmits the rotational force of the motor 8 to the valve shaft 28 is integrally formed on the upper portion (the upper surface side of the ceiling portion 12a). Is formed.

- the valve body 20 is made of, for example, synthetic resin, metal, or the like, and in order to selectively communicate the inlet p10 and the two outlets p11 and p12 provided in the valve body 10, in other words, the inlet p10 and In order to selectively switch the communication state of the two outlets p11 and p12, a flow path (internal flow path) 25 is provided inside.

- the internal flow path 25 is configured by a through hole that penetrates the valve body 20 from the lower part to the side part, and the lower opening always communicates with the inlet p10, and the side opening has two outlets. It is made to communicate with either p11 or p12 alternatively.

- the valve body 20 has a substantially hexagonal cross section that penetrates the valve body 20 in the vertical direction (the direction of the rotation axis O of the valve body 20).

- the vertical through-hole 21 upper and lower end openings are substantially hexagonal

- the horizontal hole 22 having a substantially hexagonal cross section that joins from the outer periphery (side part) of the valve body 20 to the center of the vertical through-hole 21. (In a direction orthogonal to the rotation axis O of the valve body 20).

- the vertical through hole 21 (the lower opening thereof) is always in communication with the inlet p10, and the lateral hole 22 (the side opening) is selectively in communication with one of the two outlets p11 and p12.

- the lower half of the vertical through hole 21 and the horizontal hole 22 form the internal flow path 25 (inside the valve body 20) having a reverse L-shape when viewed from the side.

- valve body 20 on the outer periphery (outer peripheral seal surface) of the valve body 20, specifically, on the back side of the side opening of the lateral hole 22 and the lateral side of the side opening of the lateral hole 22 on the outer periphery of the valve body 20, 11 are provided with hexagonal holes (hexagonal concave holes in side view) 26 and 27 as rotation engaging portions for rotating and installing the valve body 20 (detailed later).

- hexagonal holes hexagonal concave holes in side view

- a stepped valve shaft 28 (a lower part of the lower engaging portion 28a) for transmitting the rotational force of the motor 8 to the valve body 20 is connected to the valve body 20 (upper part of the vertical through hole 21).

- the valve shaft 28 has a shape complementary to the vertical through hole 21 of the valve body 20 from the lower side (that is, a substantially hexagonal cross section). Or a lower engaging portion 28a that is slightly smaller than the vertical through hole 21, an intermediate body portion 28b that is slightly smaller and circular in cross section than the lower engaging portion 28a, and an outer diameter that is substantially the same as that of the intermediate body portion 28b and a substantially hexagonal cross section.

- the upper connecting portion 28c and a circumferential positioning D-cut convex portion 28d projecting on the upper connecting portion 28c are configured so that the lower engaging portion 28a (the lower portion) of the vertical through hole 21 is formed.

- the intermediate body portion 28b is inserted into (inserted into) the insertion hole 13 of the valve body 10, and the upper connection portion 28c is located above the insertion hole 13 (on the upper surface side of the ceiling portion 12a). ) To protrude.

- An O-ring 29 as a sealing member is interposed in two stages in the intermediate body portion 28b (annular groove formed on the outer periphery thereof) that is rotatably inserted into the fitting insertion hole 13.

- valve body 20 By fitting the lower engagement portion 28 a into the vertical through hole 21, the valve body 20 is engaged with the valve shaft 28 so as not to rotate relative to the rotation axis O, and the valve shaft 28 and the valve body 20 are engaged with each other. It is designed to rotate as a unit.

- a step portion 28s formed between the lower engaging portion 28a and the intermediate body portion 28b in the valve shaft 28 is in contact with the periphery of the fitting hole 13 in the ceiling portion 12a of the valve body 10 (base member 12 thereof).

- the drive gear 9 of the rotation drive unit 5 is externally fitted and fixed to the upper connecting portion 28c protruding from the insertion hole 13 by press fitting, caulking, etc. ) And the drive gear 9 (the lower surface thereof) sandwich the ceiling portion 12a of the valve body 10 so that the valve shaft 28 is rotatably supported with respect to the valve body 10 (without moving up and down). .

- valve shaft 28 can be inserted through the vertical through hole 21 in the vertical direction (rotation axis O direction). (Details later).

- Annular sheet members 31 and 32 are arranged.

- a pair of seat members is disposed so as to be opposed to the rotation axis O of the valve body 20 so as to correspond to the pair of left and right outlets p ⁇ b> 11 and p ⁇ b> 12.

- 31 and 32 are disposed, and the valve body 20 is disposed between the pair of sheet members 31 and 32 (inside) so as to be freely slidable.

- the portion around the opening on the inner periphery (surface) is configured by a curved surface (a part of a concave spherical surface) and is in contact with the outer peripheral seal surface (curved surface) of the valve body 20 when the flow path is formed.

- the inner peripheral sealing surface is squeezed.

- the height H in the vertical direction (rotation axis O direction) of the valve body 20 disposed between the pair of sheet members 31 and 32 is equal to or less than the distance L between the sheet members 31 and 32. Or it is made slightly smaller (detailed later).

- O-rings (elastic members) 33 and 34 as sealing members made of an elastic material such as rubber are interposed (in a compressed state) in the annular groove formed on the (outlet p12 side surface). ing. Due to the elastic force (repulsive force) of the O-rings 33 and 34, the seat members 31 and 32 (the inner peripheral seal surface thereof) are pressed against the valve body 20 (the outer peripheral seal surface) side. The body 20 and each of the outlets p11 and p12 are hermetically sealed (sealed).

- the flow path switching valve (three-way valve) 1 having such a configuration, when the valve body 20 is rotated in the valve chamber 11 by the rotary drive unit 5 including the motor 8, the drive gear 9, and the like, the interior provided in the valve body 20 is provided. Through the flow path 25, the communication state of the inlet p10 and the two outlets p11 and p12 provided in the valve body 10 is selectively switched.

- the inlet p10 provided at the bottom of the valve body 10 and the outlet p11 provided at the left are (the lower half of the vertical through hole 21 and the horizontal hole).

- a communication mode via a first communication state

- Two modes of a mode (second communication state) communicating with each other are selectively taken.

- the opening of the seat member 32 corresponding to the right outlet p12 is closed by the valve body 20 (the outer peripheral seal surface thereof) (here, the portion where the hexagonal hole 26 is formed), and the outlet p12

- the fluid that has flowed upward from the inlet p10 flows through the internal channel 25 of the valve body 20 and flows out only from the left outlet p11.

- the opening of the seat member 31 corresponding to the left outlet p11 is closed by the valve body 20 (the outer peripheral seal surface thereof) (here, the portion where the hexagonal hole 26 is formed)

- the flow path connected to the outlet p11 is blocked, and the fluid that flows upward from the inlet p10 flows out of only the right outlet p12 through the internal flow path 25 of the valve body 20.

- FIG. 5 and 6 are diagrams for explaining the assembly procedure of the flow path switching valve shown in FIG. 1.

- FIG. 5 shows the procedure for installing the valve body in the valve chamber.

- FIG. 6 shows the valve shaft in the valve body. It is a figure explaining the procedure to support and fix.

- O-rings 33 and 34 are attached to the respective seat members 31 and 32 (annular concave grooves thereof) (procedure 1), and the valve body 10 is Before assembling the holder member 15 to the base member 12 (the lower end opening thereof), the seat members 31 and 32 with the O-rings 33 and 34 are inserted into the inside (that is, inside the valve chamber 11) through the lower end opening of the base member 12. ) (Around the left and right outlets p11, p12) (procedure 2).

- the projections 14a and 14b provided on the ceiling portion 12a of the base member 12 are used to align the seat members 31 and 32 in the valve chamber 11, and the interval between the seat members 31 and 32 is determined by the valve

- the height of the body 20 is set to be equal to or higher than the height in the vertical direction (direction of the rotation axis O).

- valve body 20 in which the internal flow path 25 composed of the vertical through hole 21 and the horizontal hole 22 is formed is laid down (that is, the posture in which the rotation axis direction of the valve body 20 is turned sideways or the valve body 20 is rotated).

- the axis line is oriented in the left-right direction

- the upper and lower end faces of the valve body 20 are oriented toward the left and right seat members 31, 32

- the hexagonal hole 26 is oriented downward

- the lower opening of the base member 12 (valve It is arranged in the inside (specifically, between the sheet members 31 and 32 arranged in the respective outlets p11 and p12 in the valve chamber 11) via the opening of the outer shape (outer diameter) of the body 20).

- a rotating jig G such as a hexagonal wrench having a hexagonal cross section at the tip is inserted from the lower opening of the base member 12, and the head is inserted into the hexagonal hole (rotating engagement portion) of the valve body 20.

- the rotation jig G is rotated by being fitted (engaged) with 26, thereby rotating the valve body 20 by about 90 ° between the sheet members 31 and 32 in the valve chamber 11 (extending in the vertical direction). (Rotate approximately 90 ° counterclockwise around the axis as viewed from below) (Procedure 4).

- the outer periphery (outer peripheral seal surface) of the valve body 20 slides on the left and right seat members 31 and 32 (inner peripheral seal surfaces thereof) and is disposed outside the seat members 31 and 32.

- the O-rings 33 and 34 are slightly compressed, and the outer periphery (outer peripheral seal surface) of the valve body 20 is pressed against the seat members 31 and 32 (inner peripheral seal surface thereof).

- the same rotating jig G as described above is inserted through the right port # 12 of the base member 12, and the head thereof is fitted into the hexagonal hole (rotating engagement portion) 27 of the valve body 20 ( The rotating jig G is rotated so that the valve body 20 is rotated about 90 ° between the sheet members 31 and 32 in the valve chamber 11 (viewed from the right around the axis extending in the left-right direction). (Rotate approximately 90 ° counterclockwise) (procedure 5).

- valve body 20 By rotating the valve body 20 around the two axes orthogonal to the rotation axis O between the seat members 31 and 32 in the valve chamber 11, the valve body 20 is in use in the valve chamber 11. (The posture in which the rotation axis O direction of the valve body 20 is vertical), and the vertical through hole 21 is directed in the vertical direction).

- an O-ring 29 is attached to the intermediate body portion 28 b of the valve shaft 28 (procedure 6), and rotation between the lower engagement portion 28 a of the valve shaft 28 and the vertical through hole 21 of the valve body 20.

- the stepped portion 28s between the lower engaging portion 28a of the valve shaft 28 and the intermediate body portion 28b is a ceiling portion 12a of the base member 12 of the valve body 10.

- the valve shaft 28 is inserted into the vertical through-hole 21 of the valve body 20 through the lower opening of the base member 12 until it contacts with (around the fitting insertion hole 13).

- the lower engaging portion 28a (lower portion) of the valve shaft 28 is inserted into the upper opening of the vertical through hole 21 (in a state in which the lower engaging portion 28a is engaged relatively non-rotatably around the rotation axis O),

- the trunk portion 28b is inserted into the insertion hole 13 of the valve body 10, and the upper coupling portion 28c protrudes upward from the insertion hole 13 (procedure 7).

- the holder member 15 is attached to the lower opening of the base member 12 by ultrasonic welding, screwing or the like, and the drive gear 9 of the rotary drive unit 5 is press-fitted into the upper coupling portion 28c of the valve shaft 28 protruding from the fitting insertion hole 13. It is attached by caulking or the like, and the valve shaft 28 is supported and fixed to the valve body 10 in a state where it can be rotated and kept from coming off (procedure 8). Furthermore, the flow path switching valve 1 is assembled by assembling the motor 8 and the like constituting the rotation drive unit 5 to the valve body 10.

- the interval between the sheet members 31 and 32 disposed in the valve chamber 11 is the vertical direction of the valve body 20.

- the height is greater than or slightly larger than the height of the rotation axis O direction, the insertion of the valve body 20 is performed even when the distance between the seat members 31 and 32 is slightly smaller than the vertical height of the valve body 20.

- the left and right O-rings 33 and 34 are compressed via the sheet members 31 and 32 (compressed with a force larger than the compression force applied to the O-rings 33 and 34 during normal use) so that the interval between the sheet members 31 and 32 is increased. You may arrange

- the valve main body 10 is Since it is not necessary to compress the O-rings 33 and 34 at the time of joining the base member 12 and the holder member 15 (such as ultrasonic welding), the crushing rate (crushing allowance) of the O-rings 33 and 34, etc. It becomes easy to manage the dimensions, suppresses bonding defects (for example, welding melt defects), and can effectively prevent liquid leakage, bonding (welding) cracks, and the like due to bonding defects.

- the configuration, shape, and the like of the internal flow path 25 formed in the valve body 20 may be changed as appropriate according to the intended use of the flow path switching valve 1 and the like.

- the valve body 20 in addition to the vertical through hole 21 and the horizontal hole 22 described above, the valve body 20 is vertically penetrated with respect to the rotation axis O and the vertical through path 21 and the horizontal hole 22 are provided.

- the aforementioned hexagonal hole (rotational engagement part) 27 is eliminated, but the lateral through hole 23 (end opening thereof) may be used as the same rotational engagement part as the aforementioned hexagonal hole 27.

- the aforementioned hexagonal hole 27 may be used as the same rotational engagement part as the aforementioned hexagonal hole 27.

- the lower opening of the vertical through hole 21 is a circular shape that is slightly larger than the hexagonal upper opening in plan view.

- the valve body 20 shown in FIGS. 7A, 7B and 8 is used, the valve body 20 is rotated about 180 ° to the inlet p10 provided at the bottom of the valve body 10 and the left part of the valve body 10.

- a mode (first communication state) in which only the provided outlet p11 communicates (via an internal flow path 25 including the lower half of the vertical through hole 21 and the horizontal hole 22) and the bottom of the valve body 10 are provided.

- 3 modes in the mode of communication (through the path 25) (third communication state) There has been adapted to be taken selectively.

- the cross-sectional shapes of the vertical through hole 21, the horizontal hole 22, the horizontal through hole 23, and the hexagonal holes 26 and 27 as the rotation engaging portions formed in the valve body 20 can be selected as appropriate.

- the cross-sectional shape of the vertical through hole 21 and the horizontal through hole 23 may be a polygon or an ellipse other than a hexagon

- the side opening of the horizontal hole 22 is a polygon, an ellipse, or a circle other than a hexagon.

- the hexagonal holes 26 and 27 may be polygonal or elliptical holes other than hexagonal holes.

- the number and arrangement of the inlets and outlets (inlet and outlet) formed in the valve body 10 can be changed as appropriate according to the application location of the flow path switching valve 1 and the like.

- the inlet p10 is opened at the bottom of the valve chamber 11, and the two outlets p11, p12 are opened at an angular interval of 180 ° on the side of the valve chamber 11.

- the three-way valve has been described as an example.For example, a two-way valve in which the bottom side inlet is omitted and one of the side outlets is used as an inlet, or an inlet opened in the valve chamber, Needless to say, four or more switching valves may be used in which the number of outlets and the arrangement configuration are changed.

- valve shaft 28 is attached to the valve body 10 by being inserted into the valve body 20 (the longitudinal through hole 21 thereof) from the lower side (the lower end opening side of the base member 12).

- the configuration of the flow path switching valve 2 as shown in FIG. 9 may be adopted, and the valve shaft 28 may be assembled to the valve body 10 from the upper side.

- the lower engaging portion 28a of the valve shaft 28 has a smaller diameter than the intermediate body portion 28b and the upper connecting portion 28c, and a step 28t between the lower engaging portion 28a and the intermediate body portion 28b is formed.

- the valve shaft 28 is inserted from the upper side (the ceiling portion 12a side of the base member 12 of the valve body 10) until it is contacted and locked to the inner hook-shaped hooking portion 13a provided in the lower inner periphery of the insertion hole 13.

- the lower engagement portion 28a (lower portion) of the valve shaft 28 is engaged with the upper opening of the vertical through hole 21 of the valve body 20 (non-rotatably around the rotation axis O). May be fitted).

- valve body having the configuration shown in FIGS. 7A, 7B and 8 (the configuration having the lateral through hole 23) is employed, but shown in FIGS. 3A, 3B and 4.

- a valve body having a configuration may be used.

- the flow path switching valve of the above embodiment is used for switching the flow path in an engine room or the like (such as an engine cooling circuit or an electronic device cooling circuit) in a vehicle.

- an engine room or the like such as an engine cooling circuit or an electronic device cooling circuit

- it may be used for path switching.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Multiple-Way Valves (AREA)

- Taps Or Cocks (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017-006005 | 2017-01-17 | ||

| JP2017006005A JP6719775B2 (ja) | 2017-01-17 | 2017-01-17 | 流路切換弁及びその組立方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2018135102A1 true WO2018135102A1 (ja) | 2018-07-26 |

Family

ID=62908501

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2017/040417 Ceased WO2018135102A1 (ja) | 2017-01-17 | 2017-11-09 | 流路切換弁及びその組立方法 |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP6719775B2 (enExample) |

| WO (1) | WO2018135102A1 (enExample) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109248464A (zh) * | 2018-11-08 | 2019-01-22 | 乐山师范学院 | 一种全自动蒸馏头 |

| US11054044B2 (en) * | 2018-02-14 | 2021-07-06 | Fisher Controls International Llc | Ball valve having a ball valve element with rotation control |

| CN115681561A (zh) * | 2022-10-17 | 2023-02-03 | 扬中市阀门厂有限公司 | 一种便于快速对接的沥青专用三通切换阀 |

| WO2024057647A1 (ja) * | 2022-09-14 | 2024-03-21 | 株式会社不二工機 | 流路切換弁 |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6951706B2 (ja) * | 2018-07-17 | 2021-10-20 | 株式会社不二工機 | 流路切換弁およびその組立方法 |

| WO2020017170A1 (ja) * | 2018-07-17 | 2020-01-23 | 株式会社不二工機 | 流路切換弁およびその組立方法 |

| JP6999177B2 (ja) | 2018-11-08 | 2022-01-18 | 株式会社不二工機 | 弁装置およびその組立方法 |

| JP7058418B2 (ja) * | 2019-02-05 | 2022-04-22 | 株式会社不二工機 | 流路切換弁 |

| JP7424851B2 (ja) * | 2020-02-05 | 2024-01-30 | 極東開発工業株式会社 | タンク車 |

| JP2024120760A (ja) * | 2023-02-24 | 2024-09-05 | 株式会社不二工機 | 流路切換弁 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS57137866U (enExample) * | 1981-02-23 | 1982-08-28 | ||

| JP2006090408A (ja) * | 2004-09-22 | 2006-04-06 | Nichiden Kogyo Kk | 弁装置 |

| JP2016138626A (ja) * | 2015-01-29 | 2016-08-04 | 三菱電機株式会社 | 切替弁 |

-

2017

- 2017-01-17 JP JP2017006005A patent/JP6719775B2/ja active Active

- 2017-11-09 WO PCT/JP2017/040417 patent/WO2018135102A1/ja not_active Ceased

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS57137866U (enExample) * | 1981-02-23 | 1982-08-28 | ||

| JP2006090408A (ja) * | 2004-09-22 | 2006-04-06 | Nichiden Kogyo Kk | 弁装置 |

| JP2016138626A (ja) * | 2015-01-29 | 2016-08-04 | 三菱電機株式会社 | 切替弁 |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11054044B2 (en) * | 2018-02-14 | 2021-07-06 | Fisher Controls International Llc | Ball valve having a ball valve element with rotation control |

| CN109248464A (zh) * | 2018-11-08 | 2019-01-22 | 乐山师范学院 | 一种全自动蒸馏头 |

| CN109248464B (zh) * | 2018-11-08 | 2023-12-12 | 乐山师范学院 | 一种全自动蒸馏头 |

| WO2024057647A1 (ja) * | 2022-09-14 | 2024-03-21 | 株式会社不二工機 | 流路切換弁 |

| CN115681561A (zh) * | 2022-10-17 | 2023-02-03 | 扬中市阀门厂有限公司 | 一种便于快速对接的沥青专用三通切换阀 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP6719775B2 (ja) | 2020-07-08 |

| JP2018115690A (ja) | 2018-07-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR102362453B1 (ko) | 유로 전환 밸브 및 그 조립 방법 | |

| WO2018135102A1 (ja) | 流路切換弁及びその組立方法 | |

| JP6511427B2 (ja) | 流路切換弁 | |

| JP4192193B2 (ja) | ボールバルブ | |

| JP7403182B2 (ja) | 流路切換弁 | |

| JP7026962B2 (ja) | 流路切換弁及びその組立方法 | |

| JP2025157479A (ja) | 流路切換弁 | |

| KR101585562B1 (ko) | 공기조화기용 서비스 밸브 어셈블리 | |

| CN101680580B (zh) | 用于流体压力装置的连接器 | |

| JP2021127782A (ja) | バルブ装置及びバルブ装置の組み立て方法 | |

| EP1411282B1 (en) | Ball valve with a rotable seal | |

| JP3122808B2 (ja) | 水栓におけるディスク弁体のシール構造 | |

| CN215806552U (zh) | 控制阀 | |

| CN113294545B (zh) | 管接塞门、管接塞门的组装方法及轨道车辆 | |

| CN222255138U (zh) | 一种汽车热管理系统用五通阀、热管理总成 | |

| JP2015224709A (ja) | バタフライバルブ | |

| WO2024024399A1 (ja) | 流路切換弁 | |

| WO2025120900A1 (ja) | 流路切換弁 | |

| WO2023139882A1 (ja) | 流路切換弁、及び流路切換弁の組立方法 | |

| WO2024176558A1 (ja) | 流路切換弁 | |

| JP2949323B2 (ja) | 水栓におけるディスク弁体のシール構造 | |

| JP2025118392A (ja) | 流路切換弁 | |

| CN114909494A (zh) | 温控阀 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 17893216 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 17893216 Country of ref document: EP Kind code of ref document: A1 |