WO2017150105A1 - ニッケル粉の製造方法 - Google Patents

ニッケル粉の製造方法 Download PDFInfo

- Publication number

- WO2017150105A1 WO2017150105A1 PCT/JP2017/004499 JP2017004499W WO2017150105A1 WO 2017150105 A1 WO2017150105 A1 WO 2017150105A1 JP 2017004499 W JP2017004499 W JP 2017004499W WO 2017150105 A1 WO2017150105 A1 WO 2017150105A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- nickel

- mixed slurry

- nickel powder

- added

- powder

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F9/00—Making metallic powder or suspensions thereof

- B22F9/16—Making metallic powder or suspensions thereof using chemical processes

- B22F9/18—Making metallic powder or suspensions thereof using chemical processes with reduction of metal compounds

- B22F9/24—Making metallic powder or suspensions thereof using chemical processes with reduction of metal compounds starting from liquid metal compounds, e.g. solutions

- B22F9/26—Making metallic powder or suspensions thereof using chemical processes with reduction of metal compounds starting from liquid metal compounds, e.g. solutions using gaseous reductors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F1/00—Metallic powder; Treatment of metallic powder, e.g. to facilitate working or to improve properties

- B22F1/05—Metallic powder characterised by the size or surface area of the particles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F9/00—Making metallic powder or suspensions thereof

- B22F9/16—Making metallic powder or suspensions thereof using chemical processes

- B22F9/18—Making metallic powder or suspensions thereof using chemical processes with reduction of metal compounds

- B22F9/24—Making metallic powder or suspensions thereof using chemical processes with reduction of metal compounds starting from liquid metal compounds, e.g. solutions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F2201/00—Treatment under specific atmosphere

- B22F2201/01—Reducing atmosphere

- B22F2201/013—Hydrogen

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F2301/00—Metallic composition of the powder or its coating

- B22F2301/15—Nickel or cobalt

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F2304/00—Physical aspects of the powder

- B22F2304/10—Micron size particles, i.e. above 1 micrometer up to 500 micrometer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F2999/00—Aspects linked to processes or compositions used in powder metallurgy

Definitions

- the present invention relates to a method for suppressing scaling in a reaction tank in a method for producing nickel powder from a solution containing a nickel sulfate ammine complex.

- it can be applied to the treatment of an intermediate product solution in a process generated from a wet nickel smelting process.

- Patent Document 1 As a method for producing a fine nickel powder, an atomizing method in which molten nickel is dispersed in gas or water to obtain a fine powder, or nickel is volatilized and reduced in the gas phase as disclosed in Patent Document 1. A dry method such as a CVD method for obtaining nickel powder is known.

- Non-Patent Document 1 a method for obtaining nickel powder by supplying hydrogen gas to a nickel sulfate ammine complex solution and reducing nickel ions in the complex solution as shown in Non-Patent Document 1 is industrially inexpensive and useful.

- a method is used in which a small amount of fine particles called seed crystals coexist, a reducing agent is supplied thereto, and seed crystals are grown to obtain a powder having a predetermined particle size.

- a so-called scaling is formed in which a part of nickel is deposited not on the seed crystal but on the reaction vessel wall in the apparatus in the reaction tank, which may cause problems such as blockage of piping.

- the present invention provides a method for suppressing the generation of scaling in the reaction tank and reducing the labor and cost required for removal in the process of producing nickel powder from a solution containing a nickel sulfate ammine complex. It is to provide.

- the first invention of the present invention for solving the above-mentioned problem is that a seed crystal of 0.3 to 3 times the weight of nickel in the solution is added to a solution containing a nickel sulfate ammine complex.

- the formed mixed slurry is charged into a reaction tank, and the reaction tank is maintained in a liquid phase part occupied by the mixed slurry and a gas phase part other than the liquid phase part, and then hydrogen gas is added to the mixed slurry.

- nickel complex ions are reduced to form nickel precipitates, thereby producing a nickel powder.

- a polyacrylate dispersion agent is added to the mixed slurry in the first invention, and 0.5 to 5% is added to the seed crystal weight of the seed crystal added to the mixed slurry. This is a method for producing nickel powder.

- a solution containing a nickel sulfate ammine complex is added to the nickel deposits in the first and second inventions, hydrogen gas is blown, and nickel is deposited and grown on the nickel deposits. This is a method for producing nickel powder.

- a method for producing nickel powder characterized in that the temperature of the mixed slurry when hydrogen gas is blown into the mixed slurry according to the first to third aspects is 150 to 200 ° C. It is.

- the pressure in the gas phase portion in the reaction vessel when hydrogen gas is blown into the mixed slurry in the first to fourth aspects is in the range of 1.0 to 4.0 MPa. This is a method for producing nickel powder.

- the occurrence of scaling can be suppressed. Therefore, the frequency of descaling is reduced, and labor and cost can be saved.

- the present invention is a method for producing nickel powder characterized by producing nickel powder by adding seed crystals to a nickel sulfate ammine complex solution and blowing hydrogen gas.

- the manufacturing method of the nickel powder of this invention is demonstrated.

- the nickel sulfate ammine complex solution used in the present invention is not particularly limited, but one or a mixture selected from nickel and cobalt mixed sulfide, crude nickel sulfate, nickel oxide, nickel hydroxide, nickel carbonate, nickel powder and the like.

- nickel-containing materials such as industrial intermediates

- nickel leaching solution solution containing nickel

- a solution obtained by adding ammonia to a solution obtained by removing impurity elements from the solution to form a nickel sulfate ammine complex solution is suitable.

- seed crystals are added to the nickel sulfate ammine complex solution to form a mixed slurry.

- the seed crystal added here is preferably a powder having a particle size of 20 ⁇ m or less, and nickel powder is suitable as a substance that does not contaminate the final nickel deposit.

- the nickel powder used as the seed crystal can be produced, for example, by adding a reducing agent such as hydrazine to the nickel sulfate ammine complex solution.

- the weight of the seed crystal added here is preferably 0.3 to 3 times the weight of nickel in the solution. If the amount is less than 0.3 times, the effect of suppressing the scaling cannot be sufficiently obtained, and even if an amount exceeding 3 times is added, the effect is not affected, and the addition is excessive.

- a dispersant can be added in order to disperse the seed crystals in the mixed slurry.

- the dispersant used here is not particularly limited as long as it is a polyacrylate, but sodium polyacrylate is preferred as an industrially available product.

- the amount of the dispersant added is preferably 0.5 to 5% based on the seed crystal weight. If it is less than 0.5%, the dispersion effect cannot be obtained, and even if added over 5%, the dispersion effect is not affected, and the addition is excessive.

- the slurry formed by adding seed crystals or seed crystals and a dispersing agent is charged into a reaction tank of a high pressure resistant high temperature vessel, and a liquid phase part and a gas phase part occupied by the slurry are formed in the reaction tank. To do. Thereafter, hydrogen gas is blown into the slurry in the reaction tank to reduce nickel complex ions in the solution and deposit nickel on the added seed crystals.

- the reaction temperature at this time is preferably in the range of 150 to 200 ° C. If it is less than 150 degreeC, reduction efficiency will fall, and even if it is 200 degreeC or more, there is no influence on reaction, rather, since loss, such as a heat energy, increases, it is not suitable.

- the pressure in the gas phase part of the reaction tank during the reaction is preferably 1.0 to 4.0 MPa. If it is less than 1.0 MPa, the reaction efficiency decreases, and even if it exceeds 4.0 MPa, there is no influence on the reaction, and the loss of hydrogen gas increases.

- nickel precipitates are formed on the seed crystals, and nickel can be extracted and recovered from the solution as fine powdery precipitates by the effect of the dispersant.

- the nickel powder produced as described above can be used, for example, as a nickel paste, which is an internal constituent material of a multilayer ceramic capacitor.

- the above-mentioned hydrogen reduction is repeated to grow particles to produce high-purity nickel metal. can do.

- the reducing slurry in the inner cylinder can was filtered to recover nickel powder.

- a nickel sulfate solution containing 75 g of nickel, a solution containing 330 g of ammonium sulfate, and 191 ml of 25% aqueous ammonia were added to the collected nickel deposits to prepare a mixed slurry adjusted to a total liquid volume of 1000 ml.

- the adjusted mixed slurry was reacted in an autoclave in the same manner as described above, and the operation of reacting the recovered nickel precipitates again in the above manner was repeated to grow nickel powder.

- the reduced slurry in the inner cylinder can was taken out and dried, and the weight of the inner cylinder can was measured to measure the change in weight before and after the reaction.

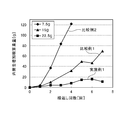

- the results are shown in FIG. 1 (see legend 22.5g).

- the “number of repetitions” when the seed crystal nickel powder is 22.5 g (addition ratio 30%), it is understood that the change in weight is small and the occurrence of scaling can be suppressed.

- Nickel powder was grown under the same conditions as in Example 1 except that 225 g of nickel powder as a seed crystal was added, which was 3.0 times the weight of nickel in the mixed solution. The result was similar to that of Example 1, and the weight of the generated scaling was 20 g or less each time even when the number of repetitions was increased.

- Example 2 The growth was repeated in the same manner as in Example 1 except that 7.5 g of 1 ⁇ m nickel powder (addition ratio 10%) and 0.1 g of sodium polyacrylate (42% solution) were added initially. As a result, as shown in FIG. 1 (refer to legend 7.5g), it can be seen that a large increase in the amount of scaling was observed in the second repeated reaction, and the trend continued thereafter.

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Manufacture Of Metal Powder And Suspensions Thereof (AREA)

- Powder Metallurgy (AREA)

- Manufacture And Refinement Of Metals (AREA)

Abstract

Description

しかし、これらの方法は高価な試薬類や多量のエネルギーを必要とするため、経済的とは言えない。

この方法では、種結晶と呼ばれる微細な粒子を少量共存させ、そこに還元剤を供給し、種結晶を成長させて所定の粒径の粉末を得る方法が用いられる。しかしながら、この方法では反応槽内に一部のニッケルが種結晶上でなく装置内の反応容器壁などに析出するいわゆるスケーリングを形成し、配管の閉塞などの不具合を引き起こす虞がある。

以下、本発明のニッケル粉の製造方法を説明する。

本発明に用いる硫酸ニッケルアンミン錯体溶液は、特に限定はされないが、ニッケルおよびコバルト混合硫化物、粗硫酸ニッケル、酸化ニッケル、水酸化ニッケル、炭酸ニッケル、ニッケル粉などから選ばれる一種、または複数の混合物から成る工業中間物などのニッケル含有物を、硫酸あるいはアンモニアにより溶解して得られるニッケル浸出液(ニッケルを含む溶液)を、溶媒抽出法、イオン交換法、中和などの浄液工程を施すことにより溶液中の不純物元素を除去して得られる溶液に、アンモニアを添加し、硫酸ニッケルアンミン錯体溶液としたもの等が適している。

この工程では、上記の硫酸ニッケルアンミン錯体溶液に、種結晶を添加して混合スラリーとするものである。

ここで添加する種結晶は、粒径が20μm以下の粉末が好ましく、最終のニッケル析出物を汚染しない物質として、ニッケル粉が好適である。この種結晶として使用するニッケル粉は、例えば上記硫酸ニッケルアンミン錯体溶液にヒドラジンなどの還元剤を添加することにより作製することができる。

このような条件による還元・析出処理によって、種結晶上にニッケルの析出物が形成され、分散剤の効果により微細な粉状の析出物としてニッケルを溶液から抽出、回収できる。

次いで、作製した混合スラリーを反応槽として用いたオートクレーブの内筒缶に装入し、液相部と気相部を設けた後、撹拌しながら185℃に昇温、保持した状態で、水素ガスを吹き込み、オートクレーブの内筒缶内気相部の圧力が3.5MPaになるように水素ガスを供給して還元処理を行い、還元スラリーを生成した。水素ガスの供給から60分が経過した後に、水素ガスの供給を停止し、内筒缶を冷却した。

その調整した混合スラリーを上記と同じ方法でオートクレーブにて反応させ、回収したニッケル析出物を再び上記の方法で反応させる操作を繰返し、ニッケル粉を成長させた。

その結果を図1(凡例22.5g参照)示す。

図1から判るように、「繰返し回数」にしたがい、種結晶ニッケル粉が22.5g(添加比率30%)のときは、重量変化が小さく、スケーリングの発生が抑制できていることがわかる。

その結果は、実施例1と同程度であり、繰返し回数が増えても、発生したスケーリングの重量は、毎回20g以下であった。

初期に1μmのニッケル粉15.0g(添加比率20%)、ポリアクリル酸ナトリウム(42%溶液)0.3gを添加した以外は実施例1と同様の方法にて繰返し成長を行なった。

その結果、図1(凡例15g参照)に示すように繰返し反応が増えるに従い、緩やかではあるが、繰返し反応の回数につれてスケーリングの量が増加しているのが判る。

初期に1μmのニッケル粉7.5g(添加比率10%)、ポリアクリル酸ナトリウム(42%溶液)0.1gを添加した以外は実施例1と同様の方法にて繰返し成長を行なった。

その結果、図1(凡例7.5g参照)に示すように、繰返し反応が2回目には、スケーリングの量の大幅な増加が見られ、それ以降もその傾向が続きているのが判る。

Claims (5)

- 硫酸ニッケルアンミン錯体を含有する溶液に、溶液中のニッケル重量に対して0.3倍以上、3倍以下の種結晶を加えて形成した混合スラリーを、反応槽内に装入して前記反応槽内を、前記混合スラリーが占有する液相部と前記液相部以外の気相部に維持した後、前記混合スラリーに水素ガスを吹き込み、ニッケル錯イオンを還元してニッケル析出物を形成することを特徴とするニッケル粉の製造方法。

- 前記混合スラリーにポリアクリル酸塩の分散剤を、前記混合スラリーに添加された種結晶の種結晶重量に対し、0.5~5%を添加することを特徴とする請求項1に記載のニッケル粉の製造方法。

- 前記ニッケル析出物に、硫酸ニッケルアンミン錯体を含有する溶液を加え、水素ガスを吹き込み、前記ニッケル析出物上にニッケルを析出させ成長させることを特徴とする請求項1又は2に記載のニッケル粉の製造方法。

- 前記混合スラリーに、水素ガスを吹き込む際の混合スラリーの温度が、150~200℃であることを特徴とする請求項1~3のいずれか1項に記載のニッケル粉の製造方法。

- 前記混合スラリーに、水素ガスを吹き込む際の前記反応槽内気相部の圧力が、1.0~4.0MPaの範囲であることを特徴とする請求項1~4のいずれか1項に記載のニッケル粉の製造方法。

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP17759576.6A EP3424625A4 (en) | 2016-02-29 | 2017-02-08 | NICKEL POWDER PROCESS |

| AU2017227099A AU2017227099A1 (en) | 2016-02-29 | 2017-02-08 | Nickel powder production method |

| US16/080,363 US20210197266A1 (en) | 2016-02-29 | 2017-02-08 | Method for producing nickel powder |

| CA3016924A CA3016924A1 (en) | 2016-02-29 | 2017-02-08 | Method for producing nickel powder |

| CN201780013765.0A CN108698131A (zh) | 2016-02-29 | 2017-02-08 | 镍粉的制造方法 |

| PH12018501840A PH12018501840A1 (en) | 2016-02-29 | 2018-08-29 | Method for producing nickel powder |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016038185A JP2017155265A (ja) | 2016-02-29 | 2016-02-29 | ニッケル粉の製造方法 |

| JP2016-038185 | 2016-02-29 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2017150105A1 true WO2017150105A1 (ja) | 2017-09-08 |

Family

ID=59743801

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2017/004499 WO2017150105A1 (ja) | 2016-02-29 | 2017-02-08 | ニッケル粉の製造方法 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US20210197266A1 (ja) |

| EP (1) | EP3424625A4 (ja) |

| JP (1) | JP2017155265A (ja) |

| CN (1) | CN108698131A (ja) |

| AU (1) | AU2017227099A1 (ja) |

| CA (1) | CA3016924A1 (ja) |

| PH (1) | PH12018501840A1 (ja) |

| WO (1) | WO2017150105A1 (ja) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7007650B2 (ja) * | 2018-07-31 | 2022-01-24 | 住友金属鉱山株式会社 | ニッケル粉の製造方法 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005505695A (ja) | 2001-10-18 | 2005-02-24 | カナディアン・エレクトロニック・パウダーズ・コーポレーション・(シーイーピーシー) | 積層セラミックコンデンサ電極内部用粉末 |

| JP4286220B2 (ja) | 2002-08-28 | 2009-06-24 | 東邦チタニウム株式会社 | 金属ニッケル粉末及びその製造方法 |

| JP2010242143A (ja) | 2009-04-02 | 2010-10-28 | Sumitomo Electric Ind Ltd | 金属粉末および金属粉末製造方法、導電性ペースト、並びに積層セラミックコンデンサ |

| JP2015166489A (ja) * | 2014-02-17 | 2015-09-24 | 国立大学法人高知大学 | ニッケル粉の製造方法 |

| JP5796696B1 (ja) * | 2015-01-22 | 2015-10-21 | 住友金属鉱山株式会社 | ニッケル粉の製造方法 |

| JP2016033255A (ja) * | 2014-03-26 | 2016-03-10 | 国立大学法人高知大学 | ニッケル粉の製造方法 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009079239A (ja) * | 2007-09-25 | 2009-04-16 | Sumitomo Electric Ind Ltd | ニッケル粉末、またはニッケルを主成分とする合金粉末およびその製造方法、導電性ペースト、並びに積層セラミックコンデンサ |

| CN101428349B (zh) * | 2008-07-29 | 2011-06-22 | 张建玲 | 一种镍钴金属粉末的制备方法 |

| JP5828923B2 (ja) * | 2014-01-30 | 2015-12-09 | 国立大学法人高知大学 | ニッケル粉の製造方法 |

| CA2939809C (en) * | 2014-02-21 | 2017-08-22 | Kochi University, National University Corporation | Method for producing nickel powder |

| JP6610425B2 (ja) * | 2015-08-31 | 2019-11-27 | 住友金属鉱山株式会社 | ニッケル粉の製造方法 |

-

2016

- 2016-02-29 JP JP2016038185A patent/JP2017155265A/ja active Pending

-

2017

- 2017-02-08 AU AU2017227099A patent/AU2017227099A1/en not_active Abandoned

- 2017-02-08 WO PCT/JP2017/004499 patent/WO2017150105A1/ja active Application Filing

- 2017-02-08 EP EP17759576.6A patent/EP3424625A4/en not_active Withdrawn

- 2017-02-08 CN CN201780013765.0A patent/CN108698131A/zh active Pending

- 2017-02-08 CA CA3016924A patent/CA3016924A1/en not_active Abandoned

- 2017-02-08 US US16/080,363 patent/US20210197266A1/en not_active Abandoned

-

2018

- 2018-08-29 PH PH12018501840A patent/PH12018501840A1/en unknown

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005505695A (ja) | 2001-10-18 | 2005-02-24 | カナディアン・エレクトロニック・パウダーズ・コーポレーション・(シーイーピーシー) | 積層セラミックコンデンサ電極内部用粉末 |

| JP4286220B2 (ja) | 2002-08-28 | 2009-06-24 | 東邦チタニウム株式会社 | 金属ニッケル粉末及びその製造方法 |

| JP2010242143A (ja) | 2009-04-02 | 2010-10-28 | Sumitomo Electric Ind Ltd | 金属粉末および金属粉末製造方法、導電性ペースト、並びに積層セラミックコンデンサ |

| JP2015166489A (ja) * | 2014-02-17 | 2015-09-24 | 国立大学法人高知大学 | ニッケル粉の製造方法 |

| JP2016033255A (ja) * | 2014-03-26 | 2016-03-10 | 国立大学法人高知大学 | ニッケル粉の製造方法 |

| JP5796696B1 (ja) * | 2015-01-22 | 2015-10-21 | 住友金属鉱山株式会社 | ニッケル粉の製造方法 |

Non-Patent Citations (2)

| Title |

|---|

| "The Manufacture and properties of Metal powder produced by the gaseous reduction of aqueous solutions", POWDER METALLURGY, 1958, pages 40 - 52 |

| See also references of EP3424625A4 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN108698131A (zh) | 2018-10-23 |

| PH12018501840A1 (en) | 2019-05-15 |

| JP2017155265A (ja) | 2017-09-07 |

| EP3424625A4 (en) | 2019-11-20 |

| EP3424625A1 (en) | 2019-01-09 |

| CA3016924A1 (en) | 2017-09-08 |

| AU2017227099A1 (en) | 2018-09-13 |

| US20210197266A1 (en) | 2021-07-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2015122535A1 (ja) | ニッケル粉の製造方法 | |

| WO2017006795A1 (ja) | コバルト粉の製造方法 | |

| JP2015166488A5 (ja) | ||

| WO2016117138A1 (ja) | ニッケル粉の製造方法 | |

| AU2017226381B2 (en) | Nickel powder production method | |

| JP5796696B1 (ja) | ニッケル粉の製造方法 | |

| JP6241617B2 (ja) | コバルト粉の製造方法 | |

| WO2017073392A1 (ja) | コバルト粉の種結晶の製造方法 | |

| WO2017150105A1 (ja) | ニッケル粉の製造方法 | |

| JP2017155265A5 (ja) | ||

| JP5881091B2 (ja) | ニッケル粉の製造方法 | |

| JP7272761B2 (ja) | ニッケル粉の製造方法 | |

| JP2020012138A (ja) | ニッケル粉の製造方法 | |

| JP2018154883A (ja) | ニッケル粉の製造方法 | |

| JP2018141203A (ja) | 種晶用ニッケル粉末の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| DPE1 | Request for preliminary examination filed after expiration of 19th month from priority date (pct application filed from 20040101) | ||

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 2017227099 Country of ref document: AU Date of ref document: 20170208 Kind code of ref document: A |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2017759576 Country of ref document: EP |

|

| ENP | Entry into the national phase |

Ref document number: 2017759576 Country of ref document: EP Effective date: 20181001 |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 17759576 Country of ref document: EP Kind code of ref document: A1 |