WO2017065064A1 - 自動車用複合ケーブル - Google Patents

自動車用複合ケーブル Download PDFInfo

- Publication number

- WO2017065064A1 WO2017065064A1 PCT/JP2016/079566 JP2016079566W WO2017065064A1 WO 2017065064 A1 WO2017065064 A1 WO 2017065064A1 JP 2016079566 W JP2016079566 W JP 2016079566W WO 2017065064 A1 WO2017065064 A1 WO 2017065064A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- electric wire

- twisted pair

- wire

- pair electric

- automobile

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B11/00—Communication cables or conductors

- H01B11/02—Cables with twisted pairs or quads

- H01B11/04—Cables with twisted pairs or quads with pairs or quads mutually positioned to reduce cross-talk

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R16/00—Electric or fluid circuits specially adapted for vehicles and not otherwise provided for; Arrangement of elements of electric or fluid circuits specially adapted for vehicles and not otherwise provided for

- B60R16/02—Electric or fluid circuits specially adapted for vehicles and not otherwise provided for; Arrangement of elements of electric or fluid circuits specially adapted for vehicles and not otherwise provided for electric constitutive elements

- B60R16/0207—Wire harnesses

- B60R16/0215—Protecting, fastening and routing means therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R16/00—Electric or fluid circuits specially adapted for vehicles and not otherwise provided for; Arrangement of elements of electric or fluid circuits specially adapted for vehicles and not otherwise provided for

- B60R16/02—Electric or fluid circuits specially adapted for vehicles and not otherwise provided for; Arrangement of elements of electric or fluid circuits specially adapted for vehicles and not otherwise provided for electric constitutive elements

- B60R16/03—Electric or fluid circuits specially adapted for vehicles and not otherwise provided for; Arrangement of elements of electric or fluid circuits specially adapted for vehicles and not otherwise provided for electric constitutive elements for supply of electrical power to vehicle subsystems or for

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B7/00—Insulated conductors or cables characterised by their form

- H01B7/0009—Details relating to the conductive cores

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B7/00—Insulated conductors or cables characterised by their form

- H01B7/17—Protection against damage caused by external factors, e.g. sheaths or armouring

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B9/00—Power cables

- H01B9/02—Power cables with screens or conductive layers, e.g. for avoiding large potential gradients

Definitions

- the present invention relates to an automotive composite cable.

- a multi-core composite cable in which a wire bundle formed by bundling a plurality of wires is covered with a sheath.

- Many wire bundles have a structure in which the wires are twisted together.

- the electric wires constituting the electric wire bundle there are a one-core electric wire whose outer periphery is covered with an insulator, a two-core twisted pair electric wire in which a pair of electric wires are twisted together, and the like.

- Prior Patent Document 1 discloses an automotive parking brake cable that is connected to an electric parking brake mechanism and an ABS sensor cable that is connected to an ABS sensor by covering them with a common outer sheath.

- a composite cable is disclosed.

- the present invention has been made in view of the above-described background, and an object of the present invention is to provide an automotive composite cable that can reduce noise interference and crosstalk between twisted-pair electric wires.

- One aspect of the present invention is a wire bundle including a two-core first twisted-pair electric wire, a two-core second twisted-pair electric wire, a one-core first electric wire, and a one-core second electric wire, A sheath for covering the wire bundle,

- the wire bundle has a first twisted-pair electric wire disposed on one side of a center line connecting the center of the first electric wire and the center of the second electric wire when viewed in a cable cross section,

- the second twisted-pair electric wire is arranged on the other side, and the first twisted-pair electric wire and the second twisted-pair electric wire are in a composite cable for automobiles that are separated from each other.

- the wire bundle includes a first twisted pair electric wire disposed on one side of a center line connecting the center of the first electric wire and the center of the second electric wire as viewed in the cable cross section, A second twisted pair electric wire is arranged on the other side of the wire, and the first twisted pair electric wire and the second twisted pair electric wire are separated from each other. Therefore, according to the said composite cable for motor vehicles, the physical distance of a 1st twisted pair electric wire and a 2nd twisted pair electric wire is ensured reliably by the 1st electric wire and the 2nd electric wire, and electromagnetic noise is reduced. Therefore, the composite cable for automobiles can reduce noise interference and crosstalk between the first twisted pair electric wire and the second twisted pair electric wire.

- the first twisted pair electric wire and the second twisted pair electric wire are both used while the automobile is running, and the first electric wire and the second electric cable are both used after the automobile is stopped. be able to.

- the physical distance between the first twisted pair electric wire and the second twisted pair electric wire used during the traveling of the automobile is reliably ensured by the first electric wire and the second electric wire that are not used during the traveling of the automobile. Electromagnetic noise during driving of the automobile is reduced.

- the use while the automobile is running includes not only the use when the automobile is running, but also the use when the automobile is stopped. Further, in this case, the first electric wire and the second electric wire that are used only after the automobile is stopped are grounded to the chassis or the like while the automobile is running, thereby reducing radiation noise during the running of the automobile. Therefore, in this case, it is possible to reduce noise interference and crosstalk between the first twisted-pair electric wire and the second twisted-pair electric wire while the automobile is running.

- the first twisted-pair electric wire is used for transmitting a signal for detecting the rotational speed of the wheel in the automobile (hereinafter also referred to as “for ABS”), and the second twisted-pair cable.

- the electric wire is used to supply electric power for driving to a driving source that opens and closes a valve of a damper in the suspension of the automobile (hereinafter sometimes referred to as “for ADS”), and the first electric wire and the second electric wire are used.

- Any of the electric wires may be used for supplying electric power for driving to a brake caliper in an electric parking brake device of an automobile (hereinafter sometimes referred to as “for EPB”).

- the first twisted pair electric wire is used when the vehicle is running and when it is stopped.

- the second twisted pair electric wire is used when the automobile is running. Further, both the first electric wire and the second electric wire are used after the automobile is stopped. Therefore, in this case, for the same reason as described above, it is possible to reliably reduce noise interference and crosstalk between the first twisted pair electric wire and the second twisted pair electric wire while the automobile is running.

- the wire bundle can be specifically configured such that each wire is twisted in a bundled state.

- the cable cross section in the wire bundle is easily maintained in the cable axial direction. Therefore, in this case, the above-described operational effects can be ensured. Moreover, it becomes easy to make a cable cross section circular.

- the shape of the cable cross section may be, for example, a circular shape or an elliptical shape.

- the first twisted pair electric wire and / or the second twisted pair electric wire may be covered with a shield conductor.

- a shield conductor In this case, combined with the above-described effects, an automotive composite cable that is advantageous for improving noise resistance can be obtained.

- the first twisted pair electric wire is for ABS and the second twisted pair electric wire is for ADS

- the first twisted pair electric wire that often flows a lower current than the second twisted pair electric wire is covered with at least a shield conductor. Good. In this case, it becomes easy to improve the noise resistance characteristics of the composite cable for automobiles.

- the shield conductor include metal foil and braided wire.

- the metal foil can be wound around the outer periphery of the twisted pair electric wire, or can be arranged vertically along the outer periphery of the twisted pair electric wire.

- the twist pitch of the first twisted pair electric wire and the twist pitch of the second twisted pair electric wire may be the same or different from each other. In the latter case, a physical distance between the first twisted pair electric wire and the second twisted pair electric wire having different twist pitches is secured by the first electric wire and the second electric wire. Therefore, it is easy to reduce crosstalk between the first twisted pair electric wire and the second twisted pair electric wire.

- the twisting pitch of one twisted pair electric wire can be set to a pitch length that is more than 1 to 5 times the twisting pitch of the other twisted pair electric wire. More specifically, for example, when the first twisted pair electric wire is for ABS and the second twisted pair electric wire is for ADS, the twist pitch of the second twisted pair electric wire is more than twice the twist pitch of the first twisted pair electric wire. It can be the pitch length. In this case, it becomes easy to improve the noise resistance characteristics of the composite cable for automobiles by reducing the twist pitch of the first twisted pair electric wire in which a lower current often flows than the second twisted pair electric wire.

- the first twisted pair electric wire and the second twisted pair electric wire can be specifically configured by twisting two insulated electric wires whose outer periphery is covered with an insulator.

- the 1st electric wire and the 2nd electric wire can be specifically comprised from the insulated wire by which the outer periphery of the conductor was coat

- each electric wire included in the wire bundle may be made of the same material as the conductor, or may be made of different materials, and the insulator may be made of the same material or different materials. Good.

- the material of the sheath in the above-described composite cable for automobiles include polyurethane resin and vinyl chloride resin.

- a polyurethane resin can be suitably used from the viewpoint of damage resistance, wear resistance, and the like.

- the wire bundle can include one or a plurality of other twisted pair wires and wires in addition to the above-described wires.

- another twisted pair electric wire or electric wire is preferably covered with a shield conductor.

- the above-mentioned composite cable for automobiles can have an inclusion layer between the wire bundle and the sheath.

- the degree of unevenness on the surface of the wire bundle is relaxed by the inclusion layer. Therefore, it is difficult to form irregularities on the outer surface of the sheath due to the irregularities on the surface of the electric wire bundle, and a composite cable for automobiles having a good appearance with less swell and the like is obtained.

- the inclusion layer can be composed of one layer or two or more layers.

- the material for the inclusion layer examples include papers, polyolefin resins such as polyethylene, and talc. More specifically, for example, when the insulator of each electric wire in the electric wire bundle is polyethylene, the inclusion layer is composed of an inner layer made of paper and an outer layer made of polyethylene arranged outside the inner layer. It can be set as the structure which has. In this case, when the outer layer of the inclusion layer and the sheath are formed by two-layer extrusion molding, the insulator of each electric wire in the wire bundle and the outer layer of the inclusion layer are difficult to fuse, and a good sheath A composite cable for automobiles having a peelability can be obtained.

- the first twisted pair electric wire and / or the second twisted pair electric wire may be covered with an inner sheath.

- the material of the inner sheath include polyolefin resin such as polyethylene, vinyl chloride resin, and the like.

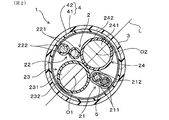

- Example 1 The automotive composite cable of Example 1 will be described with reference to FIG.

- the automotive composite cable 1 of this example includes an electric wire bundle 2 and a sheath 3 that covers the electric wire bundle 2.

- the wire bundle 2 includes a two-core first twisted pair electric wire 21, a two-core second twisted pair electric wire 22, a one-core first electric wire 23, and a one-core second electric wire 24.

- the first twisted-pair electric wire 21 has a configuration in which two insulated wires each having a conductor 211 covered with an insulator 212 are twisted in a spiral shape.

- the conductor 211 of the first twisted pair electric wire 21 is made of a copper alloy, and the conductor cross-sectional area is 0.3 mm 2 .

- the insulator 212 is made of polyethylene.

- the 2nd twisted pair electric wire 22 has the structure by which the insulated wire with which the outer periphery of the conductor 221 was coat

- the conductor 221 of the second twisted pair electric wire 22 is made of a copper alloy, and the conductor cross-sectional area is 0.5 mm 2 .

- the insulator 222 is made of polyethylene.

- the twist pitch of the 1st twisted pair electric wire 21 and the twist pitch of the 2nd twisted pair electric wire 22 are set to the same pitch length.

- the sheath 3 is made of a polyurethane resin and has a thickness of 1.5 mm.

- the first electric wire 23 is configured by an insulated wire in which the outer periphery of the conductor 231 is covered with the insulator 232.

- the conductor 231 of the first electric wire 23 is made of a copper alloy, and the conductor cross-sectional area is 2.5 mm 2 .

- the insulator 232 is made of polyethylene.

- the second electric wire 24 is composed of an insulated wire in which an insulator 242 is coated on the outer periphery of the conductor 241.

- the conductor 241 of the second electric wire 24 is made of a copper alloy, and the conductor cross-sectional area is 2.5 mm 2 .

- the insulator 242 is made of polyethylene. In the electric wire bundle 2, the electric wires 21, 22, 23, and 24 are twisted in a bundled state.

- the first twisted pair electric wire 21 is for ABS.

- the second twisted pair electric wire 22 is for ADS.

- Both the first electric wire 23 and the second electric wire 24 are for EPB.

- the first twisted pair electric wire 21 is arranged on one side of the center line L connecting the center O ⁇ b> 1 of the first electric wire 23 and the center O ⁇ b> 2 of the second electric wire 24 when viewed in the cable cross section.

- the second twisted pair electric wire 22 is arranged on the other side of the center line L.

- the 1st twisted pair electric wire 21 and the 2nd twisted pair electric wire 22 are mutually spaced apart. That is, the first twisted pair electric wire 21 and the second twisted pair electric wire 22 are in a non-contact state.

- the first electric wire 23 and the second electric wire 24 may be in contact with each other. You may be in the state of contact.

- the automotive composite cable 1 further includes an inclusion layer 4 between the wire bundle 2 and the sheath 3.

- the inclusion layer 4 has a two-layer structure including an inner layer 41 that covers the wire bundle and an outer layer 42 that is disposed outside the inner layer 41.

- the inner layer 41 is made of paper

- the outer layer 42 is made of polyethylene.

- the wire bundle 2 is a first twisted pair on one side of the center line L connecting the center O1 of the first wire 23 and the center O2 of the second wire 24 when viewed in the cable cross section.

- the electric wire 21 is arranged, the second twisted pair electric wire 22 is arranged on the other side of the center line L, and the first twisted pair electric wire 21 and the second twisted pair electric wire 22 are separated from each other. Therefore, according to the composite cable 1 for an automobile of this example, the physical distance between the first twisted pair electric wire 21 and the second twisted pair electric wire 22 is reliably ensured by the first electric wire 23 and the second electric wire 24, and the electromagnetic Noise is reduced. Therefore, the automotive composite cable 1 of this example can reduce noise interference and crosstalk between the first twisted pair electric wire 21 and the second twisted pair electric wire 22.

- the composite cable for automobile 1 of the present example is configured such that the first electric wire 23 and the second electric wire 24 that are used only after the automobile is stopped are grounded to a chassis or the like while the automobile is running, thereby radiating noise during running of the automobile. Is reduced. Therefore, the automotive composite cable 1 of this example is useful for reducing noise interference and crosstalk between the first twisted pair electric wire 21 and the second twisted pair electric wire 22 while the automobile is running.

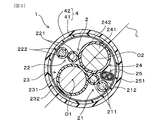

- Example 2 The automotive composite cable of Example 2 will be described with reference to FIG.

- the twist pitch of the second twisted pair electric wire 22 for ADS is set to a pitch length that is twice the twist pitch of the first twisted pair electric wire 21 for ABS.

- Other configurations are the same as those of the first embodiment.

- the twist pitch of the first twisted pair electric wire 21 in which a lower current often flows than the second twisted pair electric wire 22 is set to a pitch length smaller than the twisted pitch of the second twisted pair electric wire 22. ing. Therefore, the composite cable for automobile 1 is advantageous for improving the noise resistance.

- Other functions and effects are the same as those of the first embodiment.

- Example 3 The automotive composite cable of Example 3 will be described with reference to FIG.

- a first twisted pair electric wire 21 for ABS is covered with a shield conductor 5.

- the shield conductor 5 is formed by horizontally winding an aluminum alloy foil that is a metal foil.

- Other configurations are the same as those of the first embodiment.

- the composite cable for automobile 1 of this example the first twisted pair electric wire 21 in which a lower current often flows than the second twisted pair electric wire 22 is covered with the shield conductor 5. Therefore, the composite cable for automobile 1 is advantageous for improving the noise resistance.

- Other functions and effects are the same as those of the first embodiment.

- Example 4 The automobile composite cable of Example 4 will be described with reference to FIG.

- the composite cable for automobile 1 of this example is an example in which the wire bundle includes another two-core twisted pair electric wire 25 in addition to the electric wires 21, 22, 23, and 24 described above.

- the twisted pair electric wire 25 is covered with a shield conductor 251.

- the shield conductor 251 is formed by horizontally winding an aluminum alloy foil that is a metal foil.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Insulated Conductors (AREA)

- Communication Cables (AREA)

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201680056450.XA CN108352220A (zh) | 2015-10-14 | 2016-10-05 | 汽车用复合线缆 |

| DE112016004742.8T DE112016004742T5 (de) | 2015-10-14 | 2016-10-05 | Kombinationskabel für Fahrzeug |

| US15/764,148 US10723289B2 (en) | 2015-10-14 | 2016-10-05 | Combination cable for vehicle |

| CN202210146702.5A CN114582546A (zh) | 2015-10-14 | 2016-10-05 | 汽车用复合线缆 |

| US16/909,474 US11077807B2 (en) | 2015-10-14 | 2020-06-23 | Combination cable for vehicle |

| US17/366,881 US11377050B2 (en) | 2015-10-14 | 2021-07-02 | Combination cable for vehicle |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015203082A JP6667190B2 (ja) | 2015-10-14 | 2015-10-14 | 自動車用複合ケーブル |

| JP2015-203082 | 2015-10-14 |

Related Child Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US15/764,148 A-371-Of-International US10723289B2 (en) | 2015-10-14 | 2016-10-05 | Combination cable for vehicle |

| US16/909,474 Continuation US11077807B2 (en) | 2015-10-14 | 2020-06-23 | Combination cable for vehicle |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2017065064A1 true WO2017065064A1 (ja) | 2017-04-20 |

Family

ID=58518216

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2016/079566 Ceased WO2017065064A1 (ja) | 2015-10-14 | 2016-10-05 | 自動車用複合ケーブル |

Country Status (5)

| Country | Link |

|---|---|

| US (3) | US10723289B2 (enExample) |

| JP (1) | JP6667190B2 (enExample) |

| CN (2) | CN108352220A (enExample) |

| DE (1) | DE112016004742T5 (enExample) |

| WO (1) | WO2017065064A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2020047450A (ja) * | 2018-09-19 | 2020-03-26 | ロベルト・ボッシュ・ゲゼルシャフト・ミト・ベシュレンクテル・ハフツングRobert Bosch Gmbh | 複合ケーブルおよびワイヤハーネス |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6667190B2 (ja) * | 2015-10-14 | 2020-03-18 | 住友電装株式会社 | 自動車用複合ケーブル |

| CN107851487B (zh) * | 2016-06-02 | 2021-01-29 | 住友电气工业株式会社 | 车辆用的多芯线缆 |

| JP2018190523A (ja) | 2017-04-28 | 2018-11-29 | 住友電装株式会社 | 複合ケーブル |

| JP6896500B2 (ja) * | 2017-04-28 | 2021-06-30 | 住友電装株式会社 | 複合ケーブル |

| JP7102185B2 (ja) * | 2018-03-26 | 2022-07-19 | 住友電装株式会社 | 複合ケーブル |

| JP7097205B2 (ja) * | 2018-03-26 | 2022-07-07 | 住友電装株式会社 | 複合ケーブル |

| JP7112921B2 (ja) * | 2018-09-20 | 2022-08-04 | ロベルト・ボッシュ・ゲゼルシャフト・ミト・ベシュレンクテル・ハフツング | 複合ケーブルおよびワイヤハーネス |

| DE102018217580B4 (de) * | 2018-10-15 | 2023-07-06 | Continental Automotive Technologies GmbH | Kabelanordnung zum Anschluss eines Raddrehzahlsensors und einer elektrischen Parkbremse |

| CN209401371U (zh) * | 2018-10-31 | 2019-09-17 | 罗伯特·博世有限公司 | 复合电缆和复合线束 |

| JP6939755B2 (ja) * | 2018-11-22 | 2021-09-22 | 日立金属株式会社 | 複合ケーブル |

| WO2020111162A1 (ja) * | 2018-11-30 | 2020-06-04 | 住友電装株式会社 | 複合ケーブル |

| JP7192455B2 (ja) | 2018-12-07 | 2022-12-20 | 日立金属株式会社 | 複合ケーブル及び複合ハーネス |

| JP7279422B2 (ja) * | 2019-03-07 | 2023-05-23 | 株式会社プロテリアル | 複合ケーブル及び複合ハーネス |

| DE112021002006T5 (de) * | 2020-03-31 | 2023-01-26 | Autonetworks Technologies, Ltd. | Kommunikationskabel und Kabelbaum |

| JP2022007625A (ja) * | 2020-06-26 | 2022-01-13 | モレックス エルエルシー | 電線及び複合ケーブル |

| JP2023048883A (ja) * | 2021-09-28 | 2023-04-07 | 株式会社プロテリアル | 複合ケーブル |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2012105142A1 (ja) * | 2011-01-31 | 2012-08-09 | オリンパスメディカルシステムズ株式会社 | 内視鏡用信号ケーブル |

| JP2014135153A (ja) * | 2013-01-08 | 2014-07-24 | Hitachi Metals Ltd | 車両用複合ケーブル |

| JP2016119245A (ja) * | 2014-12-22 | 2016-06-30 | 日立金属株式会社 | 車両用複合ケーブル及び車両用複合ハーネス |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5866207A (ja) * | 1981-10-16 | 1983-04-20 | モガミ電線株式会社 | 多心シ−ルドワイヤ |

| IES930581A2 (en) * | 1993-07-30 | 1994-03-09 | Ardnaboha Trading Ltd | A cable assembly |

| JPH08138455A (ja) * | 1994-11-14 | 1996-05-31 | Sumitomo Wiring Syst Ltd | 高速伝送用ツイストペアケーブル及びその使用方法 |

| JP4358353B2 (ja) * | 1999-05-13 | 2009-11-04 | 日本圧着端子製造株式会社 | 平衡伝送シールドケーブル |

| JP2002260457A (ja) * | 2001-03-05 | 2002-09-13 | Yazaki Corp | 複合ケーブル |

| AU2003235790A1 (en) * | 2002-01-07 | 2003-07-24 | Conectl Corporation | Improved communications cable and method for making same |

| CA2631883A1 (en) * | 2005-12-09 | 2007-06-14 | Belden Technologies, Inc. | Twisted pair cable having improved crosstalk isolation |

| WO2008092003A2 (en) * | 2007-01-25 | 2008-07-31 | Honda Motor Co., Ltd. | Vehicle systems control for improving stability |

| DE102007015102A1 (de) * | 2007-03-29 | 2008-10-02 | Robert Bosch Gmbh | Motoranordnung |

| JP2010033879A (ja) * | 2008-07-29 | 2010-02-12 | Oki Electric Cable Co Ltd | 低スキュー差動伝送用多心丸型複合ケーブル |

| JP2013099184A (ja) * | 2011-11-04 | 2013-05-20 | Yazaki Corp | ワイヤハーネス |

| JP5594446B2 (ja) | 2012-04-20 | 2014-09-24 | 日立金属株式会社 | 複合ハーネス |

| JP5541331B2 (ja) * | 2012-04-20 | 2014-07-09 | 日立金属株式会社 | 複合ハーネス |

| JP6044498B2 (ja) * | 2013-09-26 | 2016-12-14 | 日立金属株式会社 | 電気ケーブル |

| US9508467B2 (en) * | 2015-01-30 | 2016-11-29 | Yfc-Boneagle Electric Co., Ltd. | Cable for integrated data transmission and power supply |

| JP6424950B2 (ja) * | 2015-03-24 | 2018-11-21 | 日立金属株式会社 | 複合ケーブル、複合ハーネス、及び車両 |

| JP6667190B2 (ja) * | 2015-10-14 | 2020-03-18 | 住友電装株式会社 | 自動車用複合ケーブル |

| JP6822770B2 (ja) * | 2016-03-09 | 2021-01-27 | 日立金属株式会社 | 複合ケーブル及び複合ハーネス |

-

2015

- 2015-10-14 JP JP2015203082A patent/JP6667190B2/ja active Active

-

2016

- 2016-10-05 DE DE112016004742.8T patent/DE112016004742T5/de active Pending

- 2016-10-05 US US15/764,148 patent/US10723289B2/en active Active

- 2016-10-05 WO PCT/JP2016/079566 patent/WO2017065064A1/ja not_active Ceased

- 2016-10-05 CN CN201680056450.XA patent/CN108352220A/zh active Pending

- 2016-10-05 CN CN202210146702.5A patent/CN114582546A/zh active Pending

-

2020

- 2020-06-23 US US16/909,474 patent/US11077807B2/en active Active

-

2021

- 2021-07-02 US US17/366,881 patent/US11377050B2/en active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2012105142A1 (ja) * | 2011-01-31 | 2012-08-09 | オリンパスメディカルシステムズ株式会社 | 内視鏡用信号ケーブル |

| JP2014135153A (ja) * | 2013-01-08 | 2014-07-24 | Hitachi Metals Ltd | 車両用複合ケーブル |

| JP2016119245A (ja) * | 2014-12-22 | 2016-06-30 | 日立金属株式会社 | 車両用複合ケーブル及び車両用複合ハーネス |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2020047450A (ja) * | 2018-09-19 | 2020-03-26 | ロベルト・ボッシュ・ゲゼルシャフト・ミト・ベシュレンクテル・ハフツングRobert Bosch Gmbh | 複合ケーブルおよびワイヤハーネス |

| JP7112920B2 (ja) | 2018-09-19 | 2022-08-04 | ロベルト・ボッシュ・ゲゼルシャフト・ミト・ベシュレンクテル・ハフツング | 複合ケーブルおよびワイヤハーネス |

Also Published As

| Publication number | Publication date |

|---|---|

| US20180281706A1 (en) | 2018-10-04 |

| US11077807B2 (en) | 2021-08-03 |

| CN114582546A (zh) | 2022-06-03 |

| US20200317146A1 (en) | 2020-10-08 |

| US11377050B2 (en) | 2022-07-05 |

| US20210331634A1 (en) | 2021-10-28 |

| JP2017076515A (ja) | 2017-04-20 |

| US10723289B2 (en) | 2020-07-28 |

| CN108352220A (zh) | 2018-07-31 |

| DE112016004742T5 (de) | 2018-07-12 |

| JP6667190B2 (ja) | 2020-03-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6667190B2 (ja) | 自動車用複合ケーブル | |

| US9545888B2 (en) | Vehicle composite cable and vehicle composite harness | |

| US9881716B2 (en) | Composite cable and composite harness | |

| JP2017076515A5 (enExample) | ||

| JP2021036532A (ja) | 車両用複合ハーネス | |

| WO2017209298A1 (ja) | 車両用の多芯フラットケーブル | |

| JPWO2017209299A1 (ja) | 車両用の多芯ケーブル | |

| US11264148B2 (en) | Composite cable and composite harness | |

| US9928940B2 (en) | Cable and harness | |

| JP6688215B2 (ja) | 車両用複合ケーブル及び車両用複合ハーネス | |

| JP6702000B2 (ja) | ケーブル、及びワイヤハーネス | |

| JP7542304B2 (ja) | 複合ケーブル及び複合ハーネス | |

| JP2020009610A (ja) | 複合ケーブル | |

| JP7481825B2 (ja) | 複合ケーブル及び複合ハーネス | |

| JP2018137243A (ja) | 自動車用複合ケーブル | |

| JP7124920B2 (ja) | 複合ケーブル対 | |

| JP2018137243A5 (enExample) | ||

| JP6354675B2 (ja) | 自動車用多芯ケーブル | |

| JP2020080334A (ja) | 自動車用複合ケーブル | |

| JP2017117702A (ja) | ケーブル及びハーネス | |

| JP2017010655A (ja) | 自動車用複合ケーブル | |

| JP2017117701A (ja) | ケーブル及びハーネス | |

| JP2025162726A (ja) | 複合ケーブル | |

| JP2020080334A5 (enExample) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 16855318 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 15764148 Country of ref document: US |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 112016004742 Country of ref document: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 16855318 Country of ref document: EP Kind code of ref document: A1 |