WO2017014213A1 - 立体シート及びそれを用いた吸収性物品 - Google Patents

立体シート及びそれを用いた吸収性物品 Download PDFInfo

- Publication number

- WO2017014213A1 WO2017014213A1 PCT/JP2016/071106 JP2016071106W WO2017014213A1 WO 2017014213 A1 WO2017014213 A1 WO 2017014213A1 JP 2016071106 W JP2016071106 W JP 2016071106W WO 2017014213 A1 WO2017014213 A1 WO 2017014213A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- fiber

- layer

- fiber layer

- fibers

- heat

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers of the pads

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

- A61F13/51104—Topsheet, i.e. the permeable cover or layer facing the skin the top sheet having a three-dimensional cross-section, e.g. corrugations, embossments, recesses or projections

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers of the pads

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers of the pads

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

- A61F13/5116—Topsheet, i.e. the permeable cover or layer facing the skin being formed of multiple layers

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers of the pads

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

- A61F13/513—Topsheet, i.e. the permeable cover or layer facing the skin characterised by its function or properties, e.g. stretchability, breathability, rewet, visual effect; having areas of different permeability

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers of the pads

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

- A61F2013/51186—Topsheet, i.e. the permeable cover or layer facing the skin specially shaped topsheets

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers of the pads

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

- A61F13/513—Topsheet, i.e. the permeable cover or layer facing the skin characterised by its function or properties, e.g. stretchability, breathability, rewet, visual effect; having areas of different permeability

- A61F2013/51338—Topsheet, i.e. the permeable cover or layer facing the skin characterised by its function or properties, e.g. stretchability, breathability, rewet, visual effect; having areas of different permeability having improved touch or feeling, e.g. smooth film

Definitions

- the present invention relates to a three-dimensional sheet.

- the present invention also relates to an absorbent article using the three-dimensional sheet.

- the present applicant firstly, as a three-dimensional sheet that can be used as a surface sheet of an absorbent article such as a disposable diaper, the first nonwoven fabric and the second nonwoven fabric are partially heat-sealed to form a joint, and the first nonwoven fabric is formed.

- separates from a 2nd nonwoven fabric in the non-joining part enclosed by this joining part, and has formed many hollow convex parts inside is proposed (refer patent document 1).

- the convex portion in the three-dimensional sheet has a hollow structure, and a solid sheet having a solid structure is also known (see Patent Document 2).

- Patent Document 3 A non-woven fabric that has been strongly fused and the intersections exist throughout is proposed (see Patent Document 3).

- This non-woven fabric has a good texture, is excellent in peeling strength when the convex member of the hook-and-loop fastener is engaged, and has little fuzz even when peeled after the convex member is engaged. It is useful as a concave material for a hook-and-loop fastener, etc.

- the three-dimensional sheet described in Patent Documents 1 and 2 has a high cushion feeling due to the uneven structure, and exhibits a good texture.

- the three-dimensional sheet is used as, for example, a surface sheet of an absorbent article, there is room for improvement with respect to the smoothness of the convex portions and the low irritation to the skin resulting therefrom.

- the nonwoven fabric described in Patent Document 3 is mainly assumed to be used as a concave material of a hook-and-loop fastener, and it is not assumed that the nonwoven fabric is three-dimensionally shaped to enhance its cushion feeling.

- the present invention has a first fiber layer having a first surface and a second surface opposite thereto, and a second fiber layer having a first surface and a second surface opposite thereto, The second surface of the first fiber layer and the first surface of the second fiber layer are laminated so as to face each other, A joint part in which the first fiber layer and the second fiber layer are partially heat-sealed is formed, and the first fiber layer protrudes in a direction away from the second fiber layer between the joint parts, and the convex part is formed.

- Both the first fiber layer and the second fiber layer are made of nonwoven fabric,

- the first fiber layer includes a plurality of types of fibers,

- the plurality of types of fibers include at least two types of fibers composed of first fibers and second fibers,

- Each of the first fiber and the second fiber includes a high melting point component and a low melting point component,

- a three-dimensional sheet in which the diameter ratio between the high melting point component and the low melting point component of the first fiber and the diameter ratio between the high melting point component and the low melting point component of the second fiber are calculated from the following formulas Is.

- the present invention provides an absorbent article using the above three-dimensional sheet.

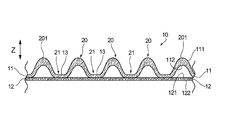

- FIG. 1 is a perspective view showing an embodiment of the three-dimensional sheet of the present invention.

- 2 is a cross-sectional view taken along line II-II in FIG.

- FIG. 3 is a schematic diagram showing an example of a cross-sectional structure of the first fiber or the second fiber used in the present invention.

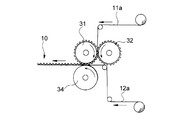

- FIG. 4 is a schematic view showing an apparatus suitably used for manufacturing the three-dimensional sheet shown in FIG.

- FIG. 5 is a schematic diagram illustrating a state in which the sheet is unevenly shaped using the apparatus illustrated in FIG. 4.

- 6 (a) and 6 (b) are diagrams sequentially showing steps for manufacturing the three-dimensional sheet shown in FIG. 1 using the apparatus shown in FIG.

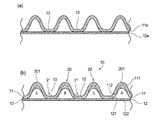

- FIG. 7 (a) shows the method of determining a boundary when it has a visually clear difference in the 1st surface side and the 2nd surface side in the 1st fiber layer of the three-dimensional sheet

- FIG. 7B is a schematic diagram, and FIG. 7B shows a boundary when the first fiber layer of the three-dimensional sheet having a solid convex portion has a visually distinct difference between the first surface side and the second surface side. It is a schematic diagram which shows the method of determining.

- FIG. 8A is a method of determining a boundary when there is no visually distinct difference between the first surface side and the second surface side in the first fiber layer of the three-dimensional sheet having hollow protrusions.

- FIG. 8A is a method of determining a boundary when there is no visually distinct difference between the first surface side and the second surface side in the first fiber layer of the three-dimensional sheet having hollow protrusions.

- FIG. 8B shows a visually distinct difference between the first surface side and the second surface side in the first fiber layer of the three-dimensional sheet having a solid convex portion. It is a schematic diagram which shows the method of determining the boundary when not.

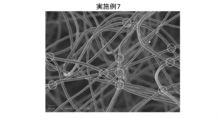

- FIG. 9 is a scanning electron microscope image of the three-dimensional sheet obtained in Example 7.

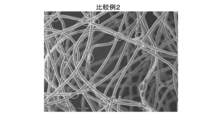

- FIG. 10 is a scanning electron microscope image of the three-dimensional sheet obtained in Comparative Example 2.

- An object of the present invention is to improve a three-dimensionally shaped sheet. More specifically, the present invention provides a three-dimensional sheet in which the smoothness of convex portions is improved while maintaining a cushion feeling by three-dimensional shaping. . Moreover, this invention provides the solid sheet which raised the standing property of a convex part, and the difficulty of crushing a convex part when a load is added.

- FIG. 1 shows a perspective view of an embodiment of the three-dimensional sheet of the present invention.

- 2 is a cross-sectional view taken along line II-II in FIG.

- the three-dimensional sheet 10 shown in these drawings has an XY plane including one direction X and a direction Y orthogonal thereto.

- the three-dimensional sheet 10 includes a first fiber layer 11 and a second fiber layer 12 that are laminated with each other.

- the first fiber layer 11 and the second fiber layer 12 are in direct contact with each other, and no other layers are interposed between the fiber layers 11 and 12.

- the first fiber layer 11 has a first surface 111 and a second surface 112 opposite to the first surface 111.

- the second fiber layer 12 has a first surface 121 and a second surface 122 opposite thereto.

- the first fiber layer 11 and the second fiber layer 12 are laminated so that the first fiber layer second surface 112 and the second fiber layer first surface 121 face each other.

- the first fiber layer first surface 111 forms one surface of the three-dimensional sheet 10.

- the second surface 122 of the second fiber layer is the other surface of the three-dimensional sheet 10.

- one layer or two or more other layers may be laminated on the outer surface of the first fiber layer first surface 111.

- one layer or two or more other layers can be laminated on the outer surface of the second fiber layer second surface 122.

- the first fiber layer 11 and the second fiber layer 12 are partially bonded by thermal fusion, thereby forming a large number of bonding portions 13.

- the 1st fiber layer 11 protrudes in the direction which leaves

- a concave portion 21 is formed between the adjacent convex portions 20.

- the bottom of the recess 21 includes the joint 13.

- a concavo-convex structure including the convex portions 20 and the concave portions 21 is formed on the first fiber layer first surface 111 side forming one surface of the three-dimensional sheet 10.

- the second fiber layer second surface 122 side forming the other surface of the three-dimensional sheet 10 is in a flat state.

- the convex part 20 of this embodiment has a hollow structure. Specifically, the convex portion 20 has a hollow space defined by the second surface 112 of the first fiber layer 11 and the first surface 121 of the second fiber layer 12 formed therein. On the other hand, in the recessed part 21, the 1st fiber layer 11 and the 2nd fiber layer 12 are closely_contact

- the convex part 20 in the three-dimensional sheet 10 of this embodiment is not limited to the thing of a hollow structure, The thing of the solid structure where this convex part 20 was satisfy

- the convex portion 20 has a hollow structure or a solid structure, for example, increases the basis weight of the nonwoven fabric on the first fiber layer 11 side and the nonwoven fabric on the second fiber layer 12 side, and is sufficient for the three-dimensional sheet 10. It is determined by processing after the thickness is increased, or by changing the uneven shape of the gear portion in the first roll 31 provided in the manufacturing apparatus shown in FIG. From the standpoint of the standing property of the convex portion 20 and the difficulty of crushing the convex portion 20 when a load is applied, it is advantageous that the convex portion 20 has a hollow structure.

- the protrusions 20 are arranged in a staggered pattern.

- the recesses 21 are also arranged in a staggered pattern.

- the shape and dimension of each convex part 20 are substantially the same. The same applies to each recess 21.

- the convex portion 20 In the plan view from the first fiber layer 11 side of the three-dimensional sheet 10, the convex portion 20 has a substantially circular shape.

- the convex portion 20 has one top portion 201 at a substantially central portion of the convex portion 20 that is substantially circular in plan view.

- the convex part 20 has a substantially hemispherical shell shape.

- the three-dimensional sheet 10 of this embodiment it is advantageous to control the bonding state of the constituent fibers included in the three-dimensional sheet 10.

- the three-dimensional sheet 10 is easily deformed in the XY plane in addition to the cushion feeling due to the convex portion 20 by controlling the fiber bonding state. It has been found. It has also been found that the standing property of the convex portion 20 and the difficulty of crushing the convex portion 20 when a load is applied are improved. Due to these reasons, the convex portion 20 has good followability to the movement of the object with which the convex portion 20 is in contact, and the friction coefficient is lowered.

- the decrease in the coefficient of friction is advantageous in that, when the three-dimensional sheet 10 is used as, for example, a surface sheet of an absorbent article, the skin irritation is reduced.

- the number S1 of fiber fusion points per fiber density on the first fiber layer first surface 111 side and the fibers per fiber density on the first fiber layer second surface 112 side are provided.

- the average value with the number S2 of fusion points is P1 (pieces / mm 3 )

- the number of fiber fusion points per fiber density on the second fiber layer first surface 121 side is P2 (pieces / mm 3 ). It has been found that it is advantageous to manufacture the three-dimensional sheet 10 so that P1 is smaller than P2.

- P1 is preferably 55% or more, particularly 65% or more of P2, more preferably 95% or less, and particularly preferably 85% or less.

- P1 is preferably 55% to 95%, particularly 65% to 85% of P2.

- the value of P1 itself is preferably 150 pieces / mm 3 or more, particularly preferably 175 pieces / mm 3 or more, more preferably 240 pieces / mm 3 or less, particularly preferably 215 pieces / mm 3 or less.

- P1 is preferably 150 pieces / mm 3 or more and 240 pieces / mm 3 or less, particularly preferably 175 pieces / mm 3 or more and 215 pieces / mm 3 or less.

- the value of P2 itself is preferably 220 / mm 3 or more, particularly 240 / mm 3 or more, provided that it is larger than P1, 300 / mm 3 or less, particularly 280 / mm 3 or less. It is preferable that Specifically, P2 is preferably 220 / mm 3 or more and 300 / mm 3 or less, particularly 240 / mm 3 or more and 280 / mm 3 or less.

- P1 and P2 are defined by the number of fiber fusion points per fiber density.

- this type of conventional three-dimensional sheet for example, the three-dimensional sheet described in Patent Document 1, when the fiber density increases, the proportion increases. The number of fiber fusion points has also increased.

- the number of fiber fusion points when compared at the same fiber density, the number of fiber fusion points is smaller than that of the conventional three-dimensional sheet.

- the number of fiber fusion points on the first fiber layer second surface 112 is smaller than that of the conventional three-dimensional sheet.

- P1 is smaller than P2, which is synonymous with the number of fusion points of the first fiber layer 11 being smaller than the number of fusion points of the second fiber layer 12. .

- a small number of fusion points means that there are few bonding points between fibers. If the number of bonding points between the fibers is small, the degree of freedom of the fibers increases, so that the fibers easily move in the XY plane of the three-dimensional sheet 10. In other words, the three-dimensional sheet 10 of the present embodiment in which P1 is smaller than P2 is more easily deformed in the XY plane direction than the conventional three-dimensional sheet, and the movement of the object with which the convex part 20 abuts is reduced. Good trackability. As a result, the effect of reducing the friction coefficient is efficiently exhibited. Thus, in the three-dimensional sheet 10 of the present embodiment, the number of fiber fusion points is controlled so that desired characteristics are expressed. A specific method for controlling the number of fiber fusion points will be described later.

- the fiber density from which P1 and P2 are calculated is the mass of the nonwoven fabric per unit volume.

- ⁇ g / mm 3 is adopted as a unit of fiber density.

- the fiber density on the first fiber layer first surface 111 side is the fiber density of the layer located on the top 201 side when the first fiber layer 11 has a two-layer structure. In the case of a single-layer structure, this is the fiber density of the portion located on the top 201 side when the thickness of the first fiber layer 11 is divided into two equal parts.

- the fiber density on the first fiber layer second surface 112 side is the fiber density of the layer located on the second fiber layer 12 side when the first fiber layer 11 has a two-layer structure.

- the 1 fiber layer 11 has a single-layer structure, it means the fiber density of the portion located on the second fiber layer 12 side when the thickness of the first fiber layer 11 is divided into two equal parts.

- the fiber density on the first surface 121 side of the second fiber layer is the first fiber layer 11 when the thickness of the second fiber layer 12 is divided into two equal parts. It is the fiber density at the site on the side.

- the 2nd fiber layer 12 is a 2 layer structure, it is the fiber density in the layer located in the 1st fiber layer 11 side.

- the boundary between the layers of the nonwoven fabric for example, the boundary between the first fiber layer 11 and the second fiber layer 12 or the boundary between the first fiber layer first surface 111 and the first fiber layer second surface 112 is the fiber amount, fiber

- the fiber layer has a distinctly different diameter, core-sheath ratio, appearance (whiteness), etc., it is identified by visually observing the cross section of the nonwoven fabric with a microscope or an electron microscope (SEM).

- the three-dimensional sheet 10 to be used for the measurement visually includes a fiber containing titanium oxide and having a whitened fiber as viewed from the outside, and a fiber not containing titanium oxide or having a low content and not white.

- a surface where each fiber layer having a visually difference is defined as a boundary, and is identified by the boundary.

- the fibers having the respective fiber diameters and shapes by SEM.

- a surface where the layers touch is observed the surface is defined as a boundary, and is identified by the boundary (see FIGS. 7A and 7B). If there is no clear difference visually, measure the thickness of the nonwoven fabric using a microscope (manufactured by Keyence Corporation, VHX-1000) and divide the thickness into two equal parts. Is the first layer and the other is the second layer.

- the thickness of the first fiber layer 11 is divided into two equal parts.

- the thickness between the top portion 201 and the bottom portion of the concave portion 21 is divided into two equal parts as shown in FIG.

- Measurement pieces for measurement of fiber density and the number of fiber fusion points are prepared by the following procedure. That is, from the first fiber layer first surface 111, the first fiber layer second surface 112, and the second fiber layer first surface 121 of the three-dimensional sheet 10 to be measured with a sharp razor in an environment of 22 ° C. and 65% RH. Then, a measurement piece having a size of 1 mm in the direction of the machine direction of the three-dimensional sheet 10 and 1 mm in the direction of crossing the machine of the three-dimensional sheet 10 is cut out. Then, measurement pieces are cut out from two places per one three-dimensional sheet 10 and measured, and this operation is performed on five three-dimensional sheets 10. The above ten measurement results are averaged to determine the fiber density, the number of fiber fusion points, and the like.

- Fiber density is measured by the following method. First, a cross section of the three-dimensional sheet 10 is cut out, and the thickness of the first surface of the first fiber layer is measured using a “microscope” (manufactured by Keyence Corporation, VHX-1000). Similarly, the thickness of the second surface of the first fiber layer and the thickness of the second fiber layer are measured. The basis weight of each layer is measured, and the basis weight / thickness is measured as the fiber density. When the first fiber layer first surface and the first fiber layer second surface are clearly identifiable, the first fiber layer first surface and the first fiber layer first surface using a cold spray or the like at the layer boundary.

- the first fiber layer first separated after carefully separating the fiber layer second surface or cutting the boundary with a blade and measuring the mass of the first fiber layer first surface and the first fiber layer second surface.

- the area of the surface and the second surface of the first fiber layer is measured and calculated from the quotient thereof. If the boundary between each layer cannot be found visually distinct, measure the mass of the nonwoven fabric without separating the layers, measure the area, calculate the basis weight of the whole nonwoven fabric from their quotients, 2

- the basis weight of each layer is obtained by dividing into equal parts.

- the above-mentioned number of fiber fusion points is the number of fusion points existing in a fiber when attention is paid to one fiber, and is defined by points / book.

- the number of fiber fusion points is measured by the following method. First, the cut-out measurement piece is placed and fixed on an aluminum sample stage for a scanning electron microscope (SEM) on which a carbon tape is placed. Next, for example, as shown in FIGS. 9 and 10 to be described later, an SEM image magnified approximately 140 to 150 times is obtained. From the obtained SEM image, the total number of portions where the intersections of the fibers are heat-sealed (portions surrounded by circles in FIGS. 9 and 10) is counted.

- SEM scanning electron microscope

- the length of the displayed fiber is measured from all the displayed fibers. This operation is performed from five SEM images. Also, an SEM image magnified approximately 35 times is obtained, 50 fibers are extracted from the end of the fiber, and the average fiber length is defined as the fiber length of one fiber.

- the mass per fiber is the mass of one fiber when attention is paid to one fiber, and is defined as ⁇ g / fiber.

- the mass per fiber is measured by the following method. First, from the first fiber layer first surface 111, the first fiber layer second surface 112, and the second fiber layer first surface 121 of the three-dimensional sheet 10 to be measured with a sharp razor in an environment of 22 ° C. and 65% RH. Cut out a measurement piece of 1 mm in the X direction and 1 mm in the Y direction, and measure the length from the end face to the end face of the fiber using a “microscope” (manufactured by Keyence Corporation, VHX-1000). To do.

- each nonwoven fabric is placed and fixing on a scanning electron microscope (SEM) aluminum sample stage on which a carbon tape is placed, the length from the end face to the end face of the fiber is measured using a scanning electron microscope. Measure the length per fiber.

- the fineness of the fiber is measured by an electron microscope or the like to measure the cross-sectional shape of the fiber, and the cross-sectional area of the fiber (the cross-sectional area of each resin component in a fiber formed from a plurality of resins) is measured.

- To identify the type of resin determine the specific gravity, and calculate the fineness. Using the fineness and fiber length obtained as described above, the mass per fiber of the three-dimensional sheet 10 is obtained.

- the above measurement of the number of fiber fusion points is performed at each part on the first fiber layer first surface 111 side, the first fiber layer second surface 112 side, and the second fiber layer first surface 121 side. Then, after dividing the number F (points / fiber) of fiber fusion points by the mass ( ⁇ g / fiber) per fiber, the fiber density ⁇ ( ⁇ g / mm 3 ) measured by the above method is multiplied. Thus, the number of fiber fusion points per fiber density (pieces / mm 3 ) is calculated. In the first fiber layer 11, the number S1 of fiber fusion points per fiber density on the first fiber layer first surface 111 side and the fiber fusion points per fiber density on the first fiber layer second surface 112 side. (S1 + S2) / 2, which is an arithmetic average value with the number S2, is calculated as P1.

- the first fiber layer 11 has a multilayer structure including an upper layer on the first surface side and a lower layer on the second surface side, and one or both of the upper layer and the lower layer are plural. It is preferred to include a type of fiber.

- the plurality of types of fibers preferably include at least two types of fibers including the first fibers and the second fibers. And it is preferable that a 1st fiber and a 2nd fiber respectively contain a high melting-point component and a low melting-point component whose melting

- the high melting point component of the first fiber and the high melting point component of the second fiber may be the same or different.

- the low melting point component of the first fiber and the low melting point component of the second fiber may be the same or different.

- the first fiber and the second fiber are distinguished by different diameter ratios. In this specification, the diameter ratio is the ratio of the diameter ( ⁇ m) of the high melting point component and the low melting point component of each of the first and second fibers.

- the diameter of the high melting point component and the diameter of the low melting point component are, for example, when the first and second fibers are core-sheath type composite fibers, the sheath resin is composed of the low melting point component, and the core resin is composed of the high melting point component.

- D1 is the diameter of the low melting point component C1

- D2 is the diameter of the high melting point component C2.

- the diameter ratio A X of the high melting point component C2 and the low melting point component C1 of the X fiber is calculated from the following equation.

- “the same kind of heat-fusible fiber” refers to a fiber having the same resin and the same structure.

- the high melting point component and the low melting point component of these two are the same resin, and the diameter ratio of the core sheath is When the same, these two are the same kind of heat-fusible fibers.

- the high melting point component and the low melting point component are the same resin, if the diameter ratio is different, they are different types of heat-fusible fibers.

- “including a plurality of types of fibers” means that different types of heat-fusible fibers are included.

- the value of A 2 / A 1 is the ratio of A 2 for A 1 is less than 1, still more preferably 0.99 or less, and still more preferably 0.91 or less.

- the value of A 2 / A 1 is preferably 0.5 or more, more preferably 0.6 or more, and even more preferably 0.7 or more.

- the ratio between A 1 and A 2 By setting in this manner, it is possible to easily control the number P1 and P2 of fibers stick point described above.

- the value of A 2 / A 1 is preferably 0.5 or more and less than 1, more preferably 0.6 or more and 0.99 or less, and even more preferably 0.7 or more and 0.91 or less. preferable.

- the value of the diameter ratio A 1 itself of the first fiber is preferably 1.1 or more 1.2 or more is more preferable, and 1.3 or more is more preferable. Also, it is preferably 2.0 or less, more preferably 1.9 or less, and even more preferably 1.8 or less. Specifically, the value of the diameter ratio A 1 of the first fibers is preferably 1.1 or more and 2.0 or less, more preferably 1.2 or more and 1.9 or less, and 1.3 More preferably, it is 1.8 or less.

- the value of the diameter ratio A 2 itself of the second fiber is a condition that less than A 1, preferably 1.1 or more, still more preferably 1.2 or more, 1.3 or more It is more preferable that Also, it is preferably 2.0 or less, more preferably 1.9 or less, and even more preferably 1.8 or less. Specifically, the value of the diameter ratio A 2 itself of the second fiber is preferably 1.1 to 2.0, further preferably 1.2 to 1.9, 1.3 More preferably, it is 1.8 or less.

- the diameter ratio A 2 of diameter ratio A 1 and the second fibers of the first fiber can be easily control the number P1 and P2 of the fiber splice point.

- the sheath resin is composed of a low melting point component

- the core resin is composed of a high melting point component

- the diameter ratio AX is small

- the volume of the sheath resin is larger than the volume of the core resin. Therefore, the sheath resin is easily stretched during melt spinning, the orientation of the polymer chain is increased, and crystallization proceeds.

- the softening point of the sheath resin is increased on the fiber surface, that is, the surface of the sheath resin and the region in the vicinity thereof.

- the diameter ratio AX when the diameter ratio AX is large, the volume of the sheath resin approaches the volume of the core resin, so that the degree of stretching of the sheath resin during melt spinning is lower than when the diameter ratio AX is small.

- the diameter ratio A X when the diameter ratio A X is large, the orientation of the polymer chains is relatively low and the degree of crystallization is relatively low compared to when the diameter ratio A X is small.

- the diameter ratio A X is large, the softening point of the sheath resin on the fiber surface, that is, the surface of the sheath resin and the region in the vicinity thereof is relatively larger than when the diameter ratio A X is small. It becomes low.

- the softening point of the surface of the X fiber As diameter ratio A X is small, the fiber fused point P1 of the first fibrous layer than the second fibrous layer having a lot of smaller second X fiber diameter ratio A X is, P2 Smaller than.

- the softening point of the surface of the X fiber varies according to the magnitude of the diameter ratio A X, since the degree of fusion between fibers due to its It differs, the number of fibers stick point P1 And P2 can be controlled.

- the reason why the softening point of the sheath resin increases when the diameter ratio AX is small is as follows in detail.

- the fiber is a core-sheath type composite fiber composed of a sheath resin composed of a low melting point component and a core resin composed of a high melting point component

- the diameter ratio when the core-sheath type composite fiber is produced by a melt spinning method.

- the sheath component solidifies faster than the core component.

- the spinning tension during melt spinning tends to concentrate on the sheath resin, and this causes the sheath resin to be more easily stretched. By this stretching, the orientation of the polymer chain is enhanced and crystallization proceeds.

- the increase in the softening point and the increase in the heat of fusion are more noticeable by cutting the core-sheath type composite fiber obtained by melt spinning into short fibers and adjusting the conditions for storing the short fibers appropriately. It became clear as a result of examination of this inventor that it became a thing. Specifically, it is advantageous to set the temperature during storage to 105 ° C. or higher and 120 ° C. or lower, which is a higher temperature than usual. Further, on the condition that the storage temperature is within this range, it is advantageous to set the storage time to 1 hour or more and 3 hours or less, which is longer than usual. That is, it is advantageous to store at a higher temperature and longer time than usual. By such storage at a high temperature and for a long time, the annealing effect of the crystallized sheath resin is expected. Annealing further promotes crystallization of the sheath resin.

- the results shown in Table 1 below were obtained.

- Each of the core-sheath type composite fibers A and B has a core of polyethylene terephthalate, a sheath of polyethylene, and a fineness of 2.3 dtex.

- the core-sheath type composite fiber A was made into a short fiber and then stored at 100 ° C. for 30 minutes.

- the core-sheath type composite fiber B was made into a short fiber and stored at 120 ° C. for 2 hours.

- the following diameter ratio A X is small core-sheath composite yarn B, it can be seen that high softening point endothermic peak of the sheath component is increased.

- the direction of diameter ratio A X is small core-sheath composite yarn B is, it is found that the crystallization heat of fusion is large polyethylene has progressed.

- the softening point of the resin on the surface of the first fiber and the second fiber can be measured by nanothermal analysis (nanoTA).

- nanoTA an atomic force microscope (AFM) image of a sample is obtained with a cantilever having a heating mechanism, and then a target portion is heated. When the sample softens with heating, the cantilever enters the sample. By detecting the displacement of the cantilever, the softening point of the micro area of the sample is measured. The first fiber and the second fiber are measured so that the difference between the softening point S1 of the resin on the surface of the first fiber and the softening point S2 of the resin on the surface of the second fiber is in a specific range. When fibers are selected, the number of fiber fusion points P1 and P2 can be easily controlled.

- the first fiber layer 11 has a multilayer structure including an upper layer on the first surface side and a lower layer on the second surface side, and one or both of the upper layer and the lower layer include at least the first fiber and the second fiber. It is preferable that, as described above, the first fiber layer 11 contains the first heat-fusible fiber as the first fiber and contains the second heat-fusible fiber as the second fiber. More preferably, two types of fibers different from each other are contained. As the first heat-fusible fiber and the second heat-fusible fiber, it is preferable to use a core-sheath type heat-fusible fiber. The first heat-fusible fiber and the second heat-fusible fiber are preferably different from each other in that the sheath component resin is different.

- the first heat-fusible fiber and the second heat-fusible fiber have the same core component and sheath component resin, and the volume ratio of the core component and sheath component resin is different. It is preferable that both types are different.

- the volume ratio can be restated as the area ratio of the core component and the sheath component in the cross section of the fiber.

- V2 / V1 which is the ratio

- V2 / V1 is preferably 0.35 or more, more preferably 0.6 or more, and even more preferably 0.8 or more.

- V2 / V1 is preferably 0.35 or more and 6.0 or less, more preferably 0.6 or more and 4.0 or less, and 0.8 or more and 2.5 or less. Is more preferable.

- the volume ratio of the resin of the core component and the sheath component of the Xth fiber can be restated as the area ratio of the core component and the sheath component in the cross section of the fiber.

- the volume ratio V2 / V1 between the core component of the Xth fiber and the sheath component resin is proportional to the diameter ratio D2 / D1 of the diameter D2 of the core component consisting of the high melting point component and the diameter D1 of the sheath component consisting of the low melting point component. To do. That is, inversely proportional to the diameter ratio A X of the X fiber. That V2 / V1 is large, is synonymous with the diameter ratio A X is small.

- the softening point of the surface of Xth fiber becomes high, so that diameter ratio AX is small.

- the first fibers having a fiber fusion point layer P1 containing many small first X fiber diameter ratio A X than the second fiber layer is less than P2.

- This heat-fusible fiber can be a concentric core-sheath composite fiber, an eccentric core-sheath composite fiber, a side-by-side composite fiber, or the like.

- the second heat-fusible fiber is included as the second fiber, the second heat-fusible fiber is a core-sheath type heat-fusible fiber, and the second heat-fusible fiber.

- the sheath resin can be made of a low melting point component, and the core resin can be made of a high melting point component.

- the second heat-fusible fiber is preferably included at least on the first fiber layer second surface 112 side.

- the second heat-fusible fiber is included as the second fiber, the second heat-fusible fiber is a core-sheath type heat-fusible fiber, and the sheath resin of the second heat-fusible fiber.

- the second heat-fusible fiber is preferably included at least on the first fiber layer second surface 112 side.

- the second heat-fusible fiber is included as the second fiber, the second heat-fusible fiber is a core-sheath type heat-fusible fiber, and the sheath resin in the second heat-fusible fiber is It can be made of a polyethylene resin and the core resin is made of a resin having a melting point higher than that of polyethylene. Also in this case, it is preferable that the second heat-fusible fiber is included at least on the first fiber layer second surface 112 side.

- a fiber having a core-sheath structure having a low melting point polypropylene as a sheath component a fiber having a core-sheath structure having polyethylene as a sheath component

- the fiber selected from the group which consists of a fiber which has a core sheath structure which uses low melting point polyester as a sheath component is used preferably.

- These fibers are preferably included at least on the first fiber layer second surface 112 side.

- the first heat-fusible fiber and the second heat-fusible fiber may be a concentric core-sheath composite fiber, an eccentric core-sheath composite fiber, a side-by-side composite fiber, or the like.

- a fiber having a core-sheath structure with a low melting point polypropylene as a sheath component is used as the first heat-fusible fiber

- a fiber having a core-sheath structure with polyethylene as a sheath component is used as the second heat-fusible fiber

- any one of fibers having a core-sheath structure having a low melting point polyester is used as the sheath component.

- a fiber having a core-sheath structure having a low melting point polypropylene as a sheath component is used to give the non-woven fabric obtained with a sealing property and strength.

- fibers having a core-sheath structure having polyethylene as a sheath component. It is preferable that the first heat-fusible fiber and the second heat-fusible fiber are included at least on the first fiber layer second surface 112 side.

- the low melting point polypropylene used as a sheath component in the fiber having a core-sheath structure having the low melting point polypropylene as a sheath component a known low melting point polypropylene is used without particular limitation, and the melting point thereof is 130 ° C. or higher and 150 ° C. or lower.

- the core component include polyethylene terephthalate (melting point: 250 ° C. or more and 270 ° C. or less), polypropylene (melting point: 150 ° C. or more and 170 ° C. or less), and the like.

- the ratio of the sheath component to the core component is preferably 20% by volume or more, and more preferably 30% by volume or more.

- the sheath component is preferably 80% by volume or less, and more preferably 70% by volume or less. Specifically, the sheath component is preferably 20% by volume to 80% by volume, and more preferably 30% by volume to 70% by volume.

- the core component is preferably 50% by volume or more, and more preferably 60% by volume or more. Moreover, it is preferable to set it as 80 volume% or less, and it is still more preferable to set it as 70 volume% or less. Specifically, it is preferably 50% by volume to 80% by volume, and more preferably 60% by volume to 70% by volume.

- the polyethylene used as the sheath component in the fiber having a core-sheath structure in which the polyethylene is a sheath component it is preferable to use a polyethylene having a melting point of 120 ° C. or higher and 140 ° C. or lower.

- the core component include polyethylene terephthalate (melting point: 250 ° C. or more and 270 ° C. or less), polypropylene (melting point: 150 ° C. or more and 170 ° C. or less), and the like.

- the ratio of the sheath component to the core component is preferably 15% by volume or more, and more preferably 23% by volume or more.

- the sheath component is preferably 75% by volume or less, and more preferably 61% by volume or less.

- the sheath component is preferably 15% by volume to 75% by volume, and more preferably 23% by volume to 75% by volume.

- the core component is preferably 49% by volume or more, and more preferably 59% by volume or more.

- the core component is preferably 85% by volume or less, and more preferably 77% by volume or less.

- the core component is preferably 49% by volume to 85% by volume, and more preferably 59% by volume to 77% by volume.

- the low-melting polyester used as a sheath component in the fiber having a core-sheath structure having the low-melting polyester as a sheath component can be used without particular limitation as long as it is a low-melting polyester, but the melting point is 100 ° C. or higher. It is preferable that it is 150 degrees C or less.

- the core component include polyethylene terephthalate (melting point: 250 ° C. or more and 270 ° C. or less), polypropylene (melting point: 150 ° C. or more and 170 ° C. or less), and the like.

- the ratio of the sheath component to the core component is preferably 20% by volume or more, and more preferably 30% by volume or more.

- the sheath component is preferably 80% by volume or less, and more preferably 70% by volume or less. Specifically, the sheath component is preferably 20% by volume to 80% by volume, and more preferably 30% by volume to 70% by volume.

- the core component is preferably 50% by volume or more, and more preferably 60% by volume or more.

- the core component is preferably 80% by volume or less, and more preferably 70% by volume or less. Specifically, the core component is preferably 50% to 80% by volume, and more preferably 60% to 70% by volume.

- the thickness (fineness) of the first heat-fusible fiber and the second heat-fusible fiber may be the same or different, and is preferably 1 dtex or more, more preferably 2 dtex or more, and 3 dtex.

- the above is particularly preferable. Further, it is preferably 15 dtex or less, more preferably 10 dtex or less, and even more preferably 6 dtex or less. Specifically, it is preferably 1 dtex or more and 15 dtex or less, more preferably 2 dtex or more and 10 dtex or less, and particularly preferably 3 dtex or more and 6 dtex or less.

- first heat-fusible fiber and the second heat-fusible fiber used as the first fiber and the second fiber may be continuous fibers made of long fiber filaments or short fibers such as staple fibers.

- the lengths of the first fibers and the second fibers may be the same or different.

- the fiber lengths of the first fiber and the second fiber are independently 35 mm or more and 70 mm or less. It is preferable to use short fibers as the first fibers and / or the second fibers because the three-dimensional sheet 10 can be easily manufactured according to the manufacturing method described later.

- the blending ratio of the first heat-fusible fiber and the second heat-fusible fiber is arbitrary depending on the fiber used for each, but the total of the first heat-fusible fiber and the second heat-fusible fiber.

- the first heat-fusible fiber is preferably 10 parts by mass or more and 70 parts by mass or less.

- a fiber having a core-sheath structure having the low melting point polypropylene as a sheath component is used as the first heat-fusible fiber

- a core-sheath structure having polyethylene as a sheath component is used as the second heat-fusible fiber.

- the first heat-fusible fiber is 10 parts by mass or more and 70 parts by mass. The following is preferable.

- the first heat-fusible fiber and the second heat-fusible fiber may be included in the first fiber layer 11 having a single-layer structure or included in the first fiber layer 11 having a multilayer structure such as a two-layer structure. It may be. In the latter case, among the upper layer located on the first fiber layer first surface 111 side and the lower layer located on the first fiber layer second surface 112 side, the first heat-fusible fiber and the second heat fusion are formed in the lower layer. When the conductive fiber is contained, the magnitude relationship between P1 and P2 is more easily satisfied.

- the first fiber layer 11 has a two-layer structure of an upper layer located on the first fiber layer first surface 111 side and a lower layer located on the first fiber layer second surface 112 side

- the first fiber layer 11 the number S2 of fiber fusion points per fiber density on the second surface 112 side is preferably smaller than the number S1 of fiber fusion points per fiber density on the first surface 111 side. Even if S1 and S2 are in such a relationship, the magnitude relationship between P1 and P2 can be more easily satisfied.

- S1 is preferably more than 100% of S2, particularly preferably 105% or more, and is preferably 300% or less, particularly preferably 125% or less.

- S1 is preferably more than 100% of S2 and 300% or less, particularly 105% or more and 125% or less.

- two or more kinds of the above-described core-sheath type heat-fusible fibers are used as the heat-fusible fibers contained in the lower layer located on the first fiber layer second surface 112 side. It is preferable to use the above.

- the 1st fiber layer 11 is a 2 layer structure of the upper layer located in the 1st fiber layer 1st surface 111 side and the lower layer located in the 1st fiber layer 2nd surface 112 side, it is the same kind to an upper layer and a lower layer It is preferable that the heat-fusible fiber is contained. Thereby, the meltability of the upper layer and the lower layer is improved, and the mechanical strength of the three-dimensional sheet 10 is increased.

- the 1st fiber layer 11 is a 2 layer structure of the upper layer located in the 1st fiber layer 1st surface 111 side and the lower layer located in the 1st fiber layer 2nd surface 112 side

- an upper layer is 1st heat

- the lower layer preferably includes a plurality of types of fibers, and more preferably includes a plurality of types of heat-fusible fibers.

- the plurality of types of heat-fusible fibers may include the first heat-fusible fiber as one type, or may not include the first heat-fusible fiber.

- the upper layer comprises only the first heat-fusible fiber and the lower layer contains the first heat-fusible fiber and the second heat-fusible fiber. This is preferable because the upper layer and the lower layer are difficult to peel off when rubbed or an external force is applied during use, and the appearance after use is improved.

- the second fiber layer 12 and the first fiber layer 11 contain the same kind of heat-fusible fiber.

- the joint strength of the 1st fiber layer 11 and the 2nd fiber layer 12 in the crevice 21 of nonwoven fabric 10 can be raised further.

- the improvement in the bonding strength in the concave portion 21 contributes to the suppression of fuzz on the first fiber layer first surface 111 side.

- the heat-fusible fiber contained in the lower layer located on the second surface 112 side of the first fiber layer 11 and the heat-fusible fiber contained in the second fiber layer 12 Are preferably of the same type.

- the second fiber layer 12 includes the first heat-fusible fiber.

- the second fiber layer 12 includes the first heat-fusible fiber, and the lower layer located on the second surface 112 side of the first fiber layer 11 also preferably includes the first heat-fusible fiber.

- the first fiber layer 11 and the second fiber layer 12 in the three-dimensional sheet 10 can be made of, for example, a nonwoven fabric.

- the first fiber layer 11 may have a single layer structure or a multilayer structure. From the viewpoint of the degree of freedom in selecting fibers to be blended in the first fiber layer 11, the first fiber layer preferably has a multilayer structure.

- the second fiber layer 12 may also have a single layer structure or a multilayer structure. Examples of the nonwoven fabric include spunbond nonwoven fabric, air-through nonwoven fabric, spunlace nonwoven fabric, meltblown nonwoven fabric, resin bond nonwoven fabric, and needle punched nonwoven fabric.

- the first fiber layer 11 and the second fiber layer 12 may use the same type of non-woven fabric or different types of non-woven fabric.

- the basis weight of the first fiber layer 11 and the second fiber layer 12 can be appropriately set according to the specific application of the three-dimensional sheet 10.

- the basis weights of the first fiber layer 11 and the second fiber layer 12 are each independently 3 g / m 2 or more, particularly 5 g / m 2 or more.

- it is 30 g / m 2 or less, particularly 15 g / m 2 or less.

- it is preferably 3 g / m 2 or more and 30 g / m 2 or less, and particularly preferably 5 g / m 2 or more and 15 g / m 2 or less.

- the basis weight of the three-dimensional sheet 10 including the first fiber layer 11 and the second fiber layer 12 can be appropriately set according to the specific application.

- the basis weight of the three-dimensional sheet 10 is preferably 6 g / m 2 or more, particularly preferably 10 g / m 2 or more, and 60 g / m 2 or less.

- it is preferably 30 g / m 2 or less.

- it is preferably 6 g / m 2 or more and 60 g / m 2 or less, particularly preferably 10 g / m 2 or more and 30 g / m 2 or less.

- the thickness of the three-dimensional sheet 10 can also be set appropriately according to its specific application.

- the thickness of the three-dimensional sheet 10 is preferably 0.1 mm or more, particularly 0.2 mm or more, 5.0 mm or less, particularly 3.0 mm.

- the following is preferable.

- the thickness is preferably 0.1 mm to 5.0 mm, particularly preferably 0.2 mm to 3.0 mm.

- the thickness of the three-dimensional sheet 10 is the thickness at the thickest portion of the three-dimensional sheet 10. The portion having the largest thickness is generally located at the top of the convex portion 20. The thickness is measured as follows.

- the three-dimensional sheet 10 to be measured is cut into 50 mm in the longitudinal direction and 50 mm in the width direction to produce a cut piece of the three-dimensional sheet 10.

- the thickness of this cut piece is measured under a pressure of 49 Pa.

- the measurement environment is a temperature of 20 ⁇ 2 ° C. and a relative humidity of 65 ⁇ 5%.

- a microscope (VHX-1000, manufactured by Keyence Corporation) is used as a measuring instrument.

- an enlarged photograph of the cut piece is obtained. In the magnified picture, a photograph of a known size is taken at the same time.

- a scale is matched with the enlarged photograph of the cut piece, and the thickness of the three-dimensional sheet 10 is measured.

- the above operation is performed three times, and the average value of the three times is defined as the thickness [mm] of the three-dimensional sheet 10 in the dry state.

- the manufacturing method of the three-dimensional sheet 10 according to the present embodiment includes a first roll 31 having a concavo-convex shape on the peripheral surface, and a concavo-convex shape that meshes with the concavo-convex shape of the first roll.

- the second fiber sheet 12a is formed with the convex part 31a in the first roll 31.

- the first fiber sheet 11a positioned above and a step of joining by the heat roll 34 are provided.

- the 1st fiber sheet 11a is a sheet

- the 2nd fiber sheet 12a is a sheet

- the first fiber sheet 11a may have a single layer structure or a multilayer structure.

- the second fiber sheet 12a may have a single layer structure or a multilayer structure.

- it is carried out in the same manner as the method described in JP-A-2004-174234 (particularly the method described in paragraphs [0021] to [0025]). Can do.

- FIG. 5 shows a state in which the first fiber sheet 11a is bitten into the meshing portion between the first roll 31 and the second roll 32, and the sheet 11a is shaped unevenly. .

- the first fiber sheet 11a introduced between the meshed rolls 31, 32 is pulled between the convex portion 31a of the first roll 31 and the convex portion 32a of the second roll 32.

- the first fiber sheet 11a is thereby unevenly shaped.

- the 1st fiber sheet 11a it is suitable to use a nonwoven fabric, for example. Examples of such a nonwoven fabric are as described above. It is preferable that the first heat-fusible fiber and the second heat-fusible fiber described above are included in the first fiber sheet 11a.

- the first fiber sheet 11a has a two-layer structure, and among the two-layer structure, the first heat-fusible fiber and the second layer described above are formed on the lower layer corresponding to the second surface side of the first fiber layer 11. It is preferable that a heat-fusible fiber is included.

- the first fiber sheet 11a has a two-layer structure, and of the two-layer structure, the upper layer corresponding to the first surface side of the first fiber layer 11 and the second surface side of the first fiber layer 11 are supported. It is also preferable that the same kind of heat-fusible fiber is contained in each of the lower layers.

- each surface of the first fiber sheet 11a is substantially parallel.

- the irregularly shaped first fiber sheet 11a is then joined to the second fiber sheet. By this joining, a joining portion 13 is formed.

- the cross-sectional shape of the sheet immediately after joining is as shown in FIG. As shown in the figure, each surface of the first fiber sheet 11a in the sheet immediately after joining is substantially parallel.

- the target three-dimensional sheet 10 is obtained.

- the obtained three-dimensional sheet 10 is a top sheet positioned on the side close to the wearer's skin when worn, a back sheet positioned on the side far from the wearer's skin when worn, and a liquid retaining property disposed between both sheets. It is used suitably as this surface sheet in the absorbent article which comprises this absorber.

- the three-dimensional sheet 10 can also be used as a sheet disposed between the top sheet and the absorber, a sheet for forming a leak-proof cuff, particularly a sheet for forming an inner wall of the leak-proof cuff.

- the nonwoven fabric 10 When using the nonwoven fabric 10 as a surface sheet of an absorbent article, it is preferable to arrange the first fiber layer 11 in the nonwoven fabric 10 so as to face the wearer's skin.

- the absorbent article in which the nonwoven fabric 10 is used include disposable diapers, sanitary napkins, incontinence pads, panty liners, and the like.

- the convex portion of the three-dimensional sheet 10 has a substantially hemispherical shape, but instead, it may have a substantially rectangular parallelepiped shape as described in Patent Document 1, for example. .

- This invention discloses the following three-dimensional sheet

- a first fiber layer having a first surface and a second surface facing it; and a second fiber layer having a first surface and a second surface facing it;

- the second surface of the first fiber layer and the first surface of the second fiber layer are laminated so as to face each other,

- the first fiber layer and the second fiber layer are partially heat-sealed to form a joint portion, and the first fiber layer protrudes in a direction away from the second fiber layer between the joint portions, and the convex portion is formed.

- Both the first fiber layer and the second fiber layer are made of nonwoven fabric,

- the first fiber layer includes a plurality of types of fibers,

- the plurality of types of fibers include at least two types of fibers composed of first fibers and second fibers,

- Each of the first fiber and the second fiber includes a high melting point component and a low melting point component,

- the first fiber layer has a multilayer structure including an upper layer on the first surface side and a lower layer on the second surface side, and one or both of the upper layer and the lower layer include a plurality of types of fibers.

- the value of A 2 / A 1 is the ratio of A 2 for A 1 is less than 1, still more preferably 0.99 or less, the more preferably at 0.91 ⁇ 1> Or the solid sheet as described in ⁇ 2>.

- the three-dimensional sheet according to 1. ⁇ 5> The value of the diameter ratio A 1 of the first fibers, preferably at least 1.1, to further preferably 1.2 or more, even more preferably above ⁇ 1> to be 1.3 or more ⁇ 4 > The three-dimensional sheet

- the value of the diameter ratio A 1 of the first fibers is preferably 2.0 or less, further preferably 1.9 or less, to a more preferred wherein ⁇ 1> not 1.8 or less ⁇ 5 > The solid sheet according to any one of the above.

- the value of the diameter ratio A 2 of the second fiber is a condition that less than A 1, preferably 1.1 or more, further preferably 1.2 or more, 1.3 or more ⁇ 3>

- the value of the diameter ratio A 2 of the second fiber is a condition that less than A 1, preferably 2.0 or less, still more preferably 1.9 or less, 1.8 or less ⁇ 3>

- ⁇ 9> The three-dimensional sheet according to any one of ⁇ 1> to ⁇ 8>, wherein the same kind of heat-fusible fiber is contained in the first fiber layer and the second fiber layer.

- ⁇ 10> The three-dimensional sheet according to any one of ⁇ 1> to ⁇ 9>, wherein the second surface side of the first fiber layer includes the first fiber and the second fiber.

- the first fiber layer includes a plurality of types of fibers having a first fiber and a second fiber, and the first heat-fusible fiber is included as the first fiber,

- the first fiber layer includes a plurality of types of fibers having a first fiber and a second fiber, and the first heat-fusible fiber is included as the first fiber, ⁇ 1> to ⁇ 12>, wherein the first fiber layer has a two-layer structure, and the upper layer on the first surface side of the first fiber layer is composed only of the first heat-fusible fiber.

- ⁇ 14> The three-dimensional sheet according to ⁇ 11> or ⁇ 13>, wherein the second fibers are short fibers.

- ⁇ 15> Containing a second heat-fusible fiber as the second fiber, The solid sheet according to any one of ⁇ 1> to ⁇ 14>, wherein the second heat-fusible fiber is included at least on the second surface side of the first fiber layer.

- the plurality of types of fibers include a first fiber and a second fiber, and the second fiber includes a second heat-fusible fiber.

- the second heat-fusible fiber is a core-sheath type heat-fusible fiber in which the sheath resin is composed of a low melting point component and the core resin is composed of a high melting point component.

- the blending ratio of the first heat-fusible fiber and the second heat-fusible fiber is first when the total amount of the first heat-fusible fiber and the second heat-fusible fiber is 100 parts by mass.

- ⁇ 20> The average value of the number S1 of fiber fusion points per fiber density on the first surface side of the first fiber layer and the number S2 of fiber fusion points per fiber density on the second surface side of the first fiber layer is P1,

- P1 The solid sheet according to any one of ⁇ 1> to ⁇ 19>, wherein P1 is smaller than P2 when the number of fiber fusion points per fiber density on the first surface side of the second fiber layer is P2.

- ⁇ 21> The solid sheet according to ⁇ 20>, wherein P1 is preferably 55% or more of P2, particularly preferably 65% or more.

- P1 is preferably 95% or less of P2, and particularly preferably 85% or less.

- the value of P1 is preferably 150 pieces / mm 3 or more, particularly preferably 175 pieces / mm 3 or more, more preferably 240 pieces / mm 3 or less, particularly preferably 215 pieces / mm 3 or less ⁇ 20> to ⁇

- the value of P2 is preferably 220 pieces / mm 3 or more, particularly 240 pieces / mm 3 or more, preferably 300 pieces / mm 3 or less, particularly 280 pieces / mm 3 or less, provided that it is larger than P1. It is preferable that the three-dimensional sheet according to any one of ⁇ 20> to ⁇ 23>.

- the fiber density from which P1 and P2 are calculated is the mass of the nonwoven fabric per unit volume, and any one of the above ⁇ 20> to ⁇ 24> that employs ⁇ g / mm 3 as the unit of fiber density.

- the solid sheet as described in 1.

- the fiber density on the first fiber layer first surface side is the fiber density in the layer located on the top side

- the fiber density on the second surface side of the first fiber layer refers to the fiber density in the layer located on the second fiber layer side ⁇ 20> to ⁇ The solid sheet according to any one of 25>.

- the fiber density on the first surface side of the second fiber layer is a portion on the first fiber layer side when the thickness of the first fiber layer is divided into two equal parts.

- the solid sheet according to any one of ⁇ 20> to ⁇ 26> which is a fiber density in a layer located on the first fiber layer side in the case of a two-layer structure. . ⁇ 28>

- the number of fiber fusion points refers to the number of fusion points present in the fiber when attention is paid to one fiber, and the ⁇ 20> to ⁇ 27> defined by dots / book.

- the number S2 of fiber fusion points per fiber density on the second surface side is smaller than the number S1 of fiber fusion points per fiber density on the first surface side ⁇ 20.

- ⁇ 30> The solid sheet according to any one of the above ⁇ 20> to ⁇ 29>, wherein S1 is preferably more than 100% of S2, particularly preferably 105% or more.

- S1 is preferably 300% or less of S2, particularly preferably 125% or less.

- ⁇ 33> An absorbent article using the three-dimensional sheet according to any one of ⁇ 1> to ⁇ 31> so that the first fiber layer faces the wearer's skin.

- Example 1 The three-dimensional sheet 10 shown in FIGS. 1 and 2 was manufactured using an apparatus similar to the apparatus shown in FIGS. 2 to 6 of JP-A-2004-174234.

- the fiber (1) and the fiber (2) are used for the 1st surface side, and the fiber (3) and the fiber ( 4) was used.

- Fiber (1) was a core-sheath fiber having a core of polyethylene terephthalate (PET) and a sheath of polyethylene (PE), a fineness of 2.3 dtex, a core diameter D2 of 10.30 ⁇ m, and a sheath diameter of 16.18 ⁇ m.

- PET polyethylene terephthalate

- PE polyethylene

- the core-sheath diameter ratio (sheath / core) A1 was 1.57. Details of the fibers (2), (3) and (4) were as shown in Table 2 below.

- the first fiber sheet 11a was an air-through nonwoven fabric having a two-layer structure (basis weight 18 g / m 2 ).

- Example 2 In this example, as shown in Table 2, the fiber composition on the second surface 112 side of the first fiber sheet 11a having the two-layer structure used in Example 1 is different from that in Example 1. Other than that was carried out similarly to Example 1, and obtained the target solid sheet.

- Example 3 In this example, as shown in Table 2, as the first fiber sheet 11a having a two-layer structure, two types of heat-fusible fibers are blended on the first surface 111 side, and one type of heat is formed on the second surface 112 side. This is an example using an air-through nonwoven fabric blended with fusible fibers. Other than that was carried out similarly to Example 1, and obtained the target solid sheet.

- Example 4 In this example, as shown in Table 2, an air-through nonwoven fabric having a single layer structure was used as the first fiber sheet 11a, and two types of heat-fusible fibers were blended as constituent fibers of the air-through nonwoven fabric. is there. Other than that was carried out similarly to Example 1, and obtained the target solid sheet.

- Examples 5 and 6 In this example, as shown in Table 2, the type of fibers on the second surface 112 side of the first fiber sheet 11a having the two-layer structure used in Example 1 is different from that in Example 1. Other than that was carried out similarly to Example 1, and obtained the target solid sheet.

- Examples 7 and 8 In this example, as shown in Table 2, the use ratio of the fibers on the second surface 112 side in the first fiber sheet 11a having the two-layer structure used in Example 6 is different from that in Example 6. Other than that was carried out similarly to Example 6, and obtained the target solid sheet.

- Example 9 In this example, as shown in Table 2, the ratio of the core-sheath component of the fiber (4) that is the fiber on the second surface 112 side in the first fiber sheet 11a having the two-layer structure used in Example 6 was used in Example 6. It is something different. Other than that was carried out similarly to Example 6, and obtained the target solid sheet.

- Example 11 In this example, as shown in Table 2, an air-through nonwoven fabric having a single layer structure was used as the first fiber sheet 11a, and two types of heat-fusible fibers were blended as constituent fibers of the air-through nonwoven fabric. is there. Other than that was carried out similarly to Example 1, and obtained the target solid sheet.

- Comparative Example 2 In this comparative example, as shown in Table 3, an air-through nonwoven fabric having a single-layer structure is used as the first fiber sheet 11a, and one type of heat-fusible fiber is used as a constituent fiber of the air-through nonwoven fabric. is there. Otherwise, the same procedure as in Example 1 was performed.

- the sheet obtained in this comparative example corresponds to the sheet described in Patent Document 1.

- Example 3 As shown in Table 3, this example is an example in which only one type of fiber is used as the fiber on the second surface 112 side of the first fiber sheet 11a having the two-layer structure used in Example 1. Otherwise, the same procedure as in Example 1 was performed.

- the sheet obtained in this comparative example corresponds to the sheet described in Patent Document 2, and the convex portion has a solid structure.

- the three-dimensional sheet obtained in each example is smoother with a lower coefficient of friction on the uneven surface than the sheet obtained in Comparative Example 2. I understand. Moreover, it turns out that the solid sheet

- the three-dimensional sheet of the present invention has a cushion feeling due to the convex portion, and the smoothness of the convex portion is improved. Furthermore, the solid sheet of the present invention is improved in the standing property of the convex part and the difficulty of crushing the convex part when a load is applied.

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Biomedical Technology (AREA)

- Heart & Thoracic Surgery (AREA)

- Vascular Medicine (AREA)

- Epidemiology (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Nonwoven Fabrics (AREA)

- Absorbent Articles And Supports Therefor (AREA)

- Laminated Bodies (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| BR112018001319A BR112018001319A2 (pt) | 2015-07-21 | 2016-07-19 | folha sólida e artigo absorvente em que a mesma é usada |

| CN201680036047.0A CN107708635B (zh) | 2015-07-21 | 2016-07-19 | 立体片材及使用该立体片材的吸收性物品 |

| RU2018105876A RU2690149C1 (ru) | 2015-07-21 | 2016-07-19 | Трехмерный лист и использующее его абсорбирующее изделие |

| KR1020177036901A KR101862531B1 (ko) | 2015-07-21 | 2016-07-19 | 입체 시트 및 그것을 사용한 흡수성 물품 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015144126 | 2015-07-21 | ||

| JP2015-144126 | 2015-07-21 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2017014213A1 true WO2017014213A1 (ja) | 2017-01-26 |

Family

ID=57834414

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2016/071106 Ceased WO2017014213A1 (ja) | 2015-07-21 | 2016-07-19 | 立体シート及びそれを用いた吸収性物品 |

Country Status (7)

| Country | Link |

|---|---|

| JP (1) | JP6211147B2 (enExample) |

| KR (1) | KR101862531B1 (enExample) |

| CN (1) | CN107708635B (enExample) |

| BR (1) | BR112018001319A2 (enExample) |

| RU (1) | RU2690149C1 (enExample) |

| TW (1) | TWI625117B (enExample) |

| WO (1) | WO2017014213A1 (enExample) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2019205685A (ja) * | 2018-05-29 | 2019-12-05 | 花王株式会社 | 吸収性物品 |

| JP2020049086A (ja) * | 2018-09-28 | 2020-04-02 | 花王株式会社 | 吸収性物品 |

| JP2020121202A (ja) * | 2020-05-18 | 2020-08-13 | 花王株式会社 | 吸収性物品 |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7245963B2 (ja) * | 2017-10-04 | 2023-03-27 | 大和紡績株式会社 | 吸収性物品用不織布、吸収性物品用表面シート、及びそれを含む吸収性物品 |

| JP2022186109A (ja) * | 2021-06-04 | 2022-12-15 | 日本バイリーン株式会社 | 不織布及び電気化学素子用セパレータ |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH05285172A (ja) * | 1992-02-14 | 1993-11-02 | Kao Corp | 吸収性物品 |

| JP2009030218A (ja) * | 2007-06-22 | 2009-02-12 | Uni Charm Corp | 不織布およびその製造方法 |

| JP2009050538A (ja) * | 2007-08-28 | 2009-03-12 | Kao Corp | 吸収性物品用シート |

| JP2015066290A (ja) * | 2013-09-30 | 2015-04-13 | 大王製紙株式会社 | 吸収性物品 |

| JP2015112116A (ja) * | 2013-12-06 | 2015-06-22 | 花王株式会社 | 立体シート |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3467432B2 (ja) * | 1999-06-24 | 2003-11-17 | ユニ・チャーム株式会社 | 使い捨て着用物品の可撓性シート |

| JP3611838B2 (ja) * | 2001-12-28 | 2005-01-19 | 花王株式会社 | 吸収性物品用の表面シート |

| JP4990003B2 (ja) | 2007-03-30 | 2012-08-01 | 花王株式会社 | 吸収性物品 |

| EP2189562B1 (en) * | 2007-08-28 | 2014-11-12 | Kao Corporation | Shaped sheet and absorbent article using the same |

| JP5507193B2 (ja) | 2008-10-15 | 2014-05-28 | 花王株式会社 | 吸収性物品の表面シート |

| JP5572043B2 (ja) | 2010-09-06 | 2014-08-13 | 花王株式会社 | 吸収性物品の表面シート |

| JP6099030B2 (ja) * | 2011-06-23 | 2017-03-22 | 花王株式会社 | 吸収性物品 |

| JP5713951B2 (ja) * | 2012-04-02 | 2015-05-07 | ユニ・チャーム株式会社 | 吸収性物品 |

| JP6105897B2 (ja) | 2012-10-24 | 2017-03-29 | 花王株式会社 | 吸収性物品 |

-

2016

- 2016-07-19 RU RU2018105876A patent/RU2690149C1/ru active

- 2016-07-19 CN CN201680036047.0A patent/CN107708635B/zh active Active

- 2016-07-19 KR KR1020177036901A patent/KR101862531B1/ko not_active Expired - Fee Related

- 2016-07-19 BR BR112018001319A patent/BR112018001319A2/pt not_active Application Discontinuation

- 2016-07-19 TW TW105122780A patent/TWI625117B/zh not_active IP Right Cessation

- 2016-07-19 WO PCT/JP2016/071106 patent/WO2017014213A1/ja not_active Ceased

- 2016-07-19 JP JP2016141039A patent/JP6211147B2/ja active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH05285172A (ja) * | 1992-02-14 | 1993-11-02 | Kao Corp | 吸収性物品 |

| JP2009030218A (ja) * | 2007-06-22 | 2009-02-12 | Uni Charm Corp | 不織布およびその製造方法 |

| JP2009050538A (ja) * | 2007-08-28 | 2009-03-12 | Kao Corp | 吸収性物品用シート |

| JP2015066290A (ja) * | 2013-09-30 | 2015-04-13 | 大王製紙株式会社 | 吸収性物品 |

| JP2015112116A (ja) * | 2013-12-06 | 2015-06-22 | 花王株式会社 | 立体シート |

Cited By (9)