WO2016152895A1 - 攪拌機 - Google Patents

攪拌機 Download PDFInfo

- Publication number

- WO2016152895A1 WO2016152895A1 PCT/JP2016/059122 JP2016059122W WO2016152895A1 WO 2016152895 A1 WO2016152895 A1 WO 2016152895A1 JP 2016059122 W JP2016059122 W JP 2016059122W WO 2016152895 A1 WO2016152895 A1 WO 2016152895A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- screen

- rotor

- slit

- width

- stirrer

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/80—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis

- B01F27/81—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis the stirrers having central axial inflow and substantially radial outflow

- B01F27/812—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis the stirrers having central axial inflow and substantially radial outflow the stirrers co-operating with surrounding stators, or with intermeshing stators, e.g. comprising slits, orifices or screens

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F23/00—Mixing according to the phases to be mixed, e.g. dispersing or emulsifying

- B01F23/40—Mixing liquids with liquids; Emulsifying

- B01F23/41—Emulsifying

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/80—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis

- B01F27/81—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis the stirrers having central axial inflow and substantially radial outflow

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F23/00—Mixing according to the phases to be mixed, e.g. dispersing or emulsifying

- B01F23/40—Mixing liquids with liquids; Emulsifying

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/40—Static mixers

- B01F25/44—Mixers in which the components are pressed through slits

- B01F25/441—Mixers in which the components are pressed through slits characterised by the configuration of the surfaces forming the slits

- B01F25/4412—Mixers in which the components are pressed through slits characterised by the configuration of the surfaces forming the slits the slits being formed between opposed planar surfaces, e.g. pushed again each other by springs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/05—Stirrers

- B01F27/11—Stirrers characterised by the configuration of the stirrers

- B01F27/114—Helically shaped stirrers, i.e. stirrers comprising a helically shaped band or helically shaped band sections

- B01F27/1145—Helically shaped stirrers, i.e. stirrers comprising a helically shaped band or helically shaped band sections ribbon shaped with an open space between the helical ribbon flight and the rotating axis

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/05—Stirrers

- B01F27/11—Stirrers characterised by the configuration of the stirrers

- B01F27/19—Stirrers with two or more mixing elements mounted in sequence on the same axis

- B01F27/192—Stirrers with two or more mixing elements mounted in sequence on the same axis with dissimilar elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/40—Mixers with rotor-rotor system, e.g. with intermeshing teeth

- B01F27/41—Mixers with rotor-rotor system, e.g. with intermeshing teeth with the mutually rotating surfaces facing each other

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/80—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/80—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis

- B01F27/81—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis the stirrers having central axial inflow and substantially radial outflow

- B01F27/811—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis the stirrers having central axial inflow and substantially radial outflow with the inflow from one side only, e.g. stirrers placed on the bottom of the receptacle, or used as a bottom discharge pump

- B01F27/8111—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis the stirrers having central axial inflow and substantially radial outflow with the inflow from one side only, e.g. stirrers placed on the bottom of the receptacle, or used as a bottom discharge pump the stirrers co-operating with stationary guiding elements, e.g. surrounding stators or intermeshing stators

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/80—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis

- B01F27/84—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis with two or more stirrers rotating at different speeds or in opposite directions about the same axis

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/80—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis

- B01F27/90—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis with paddles or arms

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/80—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis

- B01F27/92—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis with helices or screws

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/80—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis

- B01F27/92—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis with helices or screws

- B01F27/922—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis with helices or screws with two or more helices, e.g. with intermeshing helices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F2215/00—Auxiliary or complementary information in relation with mixing

- B01F2215/04—Technical information in relation with mixing

- B01F2215/0409—Relationships between different variables defining features or parameters of the apparatus or process

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F2215/00—Auxiliary or complementary information in relation with mixing

- B01F2215/04—Technical information in relation with mixing

- B01F2215/0413—Numerical information

- B01F2215/0418—Geometrical information

- B01F2215/0431—Numerical size values, e.g. diameter of a hole or conduit, area, volume, length, width, or ratios thereof

Definitions

- the present invention relates to an improvement of a stirrer, particularly a stirrer used for emulsification, dispersion or mixing treatment of a fluid to be treated.

- stirrers have been proposed as devices for emulsifying, dispersing or mixing fluids.

- a fluid to be treated containing a substance having a small particle diameter, such as nanoparticles is processed well. It is demanded.

- a bead mill and a homogenizer are known as a kind of a well-known stirrer.

- the bead mill has a problem that the crystal state on the surface of the particles is destroyed and deteriorated due to damage. There is also a large problem of foreign matter generation.

- the high-pressure homogenizer has not solved the problem of stable machine operation and the problem of large required power.

- the rotary homogenizer has been conventionally used as a premixer.

- a finishing machine is required for further nano-finishing.

- This stirrer is provided with a rotor having a plurality of blades and a screen laid around the rotor and having a plurality of slits.

- the rotor and the screen rotate relatively to cause shearing of the fluid to be processed in a minute gap between the inner wall of the screen including the slit and the blades, and the inside of the screen as an intermittent jet flow through the slit.

- the fluid to be processed is discharged from the outside to the outside.

- the width in the circumferential direction of the blade tip of the rotor and the width in the circumferential direction of the slit provided in the screen are both under certain conditions (specifically, the widths of both are substantially equal,

- the thickness of the blades 12 allows the mechanical strength and the like from the viewpoint of increasing the space between the blades 12.

- the width of the distal end portion 21 is also set small. For this reason, the period of change between discharge and suction is shortened and frequently performed, but it has been found that the fluid to be treated may not sufficiently follow the state change between discharge and suction.

- An object of this invention is to provide the stirrer which can make more efficiently the shear added to a to-be-processed fluid by the effect

- Another object of the present invention is to provide a stirrer that can realize extremely fine dispersion and emulsification such as nano-dispersion and nano-emulsification as a result of the efficient shearing.

- the present invention was born as a result of an attempt to improve the stirrer from the new viewpoint of increasing the relative speed difference at the interface between the forward and backward flow (discharge and suction from the slit) of the fluid to be treated caused by the intermittent jet flow.

- Invention Specifically, the relationship between the screen that can increase the relative speed difference between the forward and reverse flow of the fluid to be treated, the slits provided in the screen, the blades of the rotor, and the tips of the blades is found. The invention has been completed.

- the present invention includes a rotor having a plurality of blades and rotating, and a screen laid around the rotor, and the screen is positioned between the plurality of slits and adjacent slits in the circumferential direction.

- the blade tip and the slit have a matching region at the same position overlapping each other in the length direction of the slit, and at least the rotor of the rotor and the screen rotates to rotate the rotor.

- a stirrer in which the fluid to be treated is discharged from the inside to the outside of the screen as an intermittent jet flow through the slit by rotating relative to the screen is improved.

- the present invention provides a stirrer that satisfies the following conditions 1 and 2 at the same time.

- Condition 1 In the matching region, The width (b) in the rotational direction of the tip of the blade; The circumferential width (s) of the slit; The circumferential width (t) of the screen member; Relationship b ⁇ 2s + t It is.

- Condition 2 In the matching region, The relationship between the rotational width (b) of the blade tip and the maximum inner diameter (c) of the screen is as follows: b ⁇ 0.1c It is.

- the present inventor specifies the relationship between the blade (particularly its tip), the screen, and the slit so as to satisfy the above conditions 1 and 2, and thereby discharge and suction.

- the present invention has been completed by knowing that it can be made larger than before.

- the circumferential width of the slit can be changed on the condition that an intermittent jet flow is generated, but the circumferential width (s) of the slit is preferably 0.2 to 4.0 mm, More preferably, it is 0.5 to 2.0 mm.

- the screen is implemented so that the diameters of the blades and the screen decrease as the distance from the introduction port for introducing the fluid to be processed into the screen increases in the axial direction.

- the discharge amount in the axial direction of the screen can be made uniform by configuring so that the diameters of the blades and the screen become smaller from the introduction port in the axial direction. Thereby, generation

- the plurality of slits have the same width in the circumferential direction and are formed at equal intervals in the circumferential direction, so that the fluid to be treated can be processed under more uniform conditions in the circumferential direction. it can. However, this does not prevent the use of a plurality of slits having different widths, and does not prevent the embodiment from being performed with non-uniform intervals between the plurality of slits.

- the size of the blades can be variously changed as long as the conditions 1 and 2 are satisfied. However, if the volume of the space between the blades is too small, the processing amount may be reduced. It is preferable that the sum total of the cross-sectional areas of the blades in a plane orthogonal to the rotation axis of the rotor is smaller than the cross-sectional area of the space in the screen.

- the sum of the cross-sectional areas of the blades in the plane orthogonal to the rotation axis is set to Y in the following specific expressions 1 and 2

- the cross-sectional area of the space in the screen in the plane orthogonal to the rotation axis is specified in the following specific expression 1. 2 and Z, it is preferable that Y and Z satisfy the following specific formula 2.

- X in the specific formula 1 refers to an area of a cross section orthogonal to the rotation axis in a region defined by the outer peripheral surface of the rotation shaft and the inner peripheral surface of the screen.

- X, Y, and Z are all in the coincidence area.

- XY Z (Specific Formula 1)

- Y ⁇ Z specific formula 2) It is preferable that the specific formula 2 is satisfied in at least one of the plurality of cross sections in the coincidence region, and it is more preferable that the specific formula 2 is satisfied in all cross sections.

- the present invention includes a rotor having a plurality of blades and rotating, and a screen laid around the rotor, and the screen is a screen member positioned between a plurality of slits and adjacent slits in the circumferential direction.

- the blade tip and the slit have a matching region that is located at the same position in the axial position of the rotation axis of the rotor, and at least the rotor of the rotor and the screen is rotated so that the rotor and the screen

- the stirrer satisfying the following conditions 1 and 2 is provided.

- (Condition 1) In the matching region, The width (b) in the rotational direction of the tip of the blade; The circumferential width (s) of the slit; The circumferential width (t) of the screen member; Relationship b ⁇ 2s + t It is.

- Condition 2 In the matching region, The relationship between the rotational width (b) of the blade tip and the maximum inner diameter (c) of the screen is as follows: b ⁇ 0.1c It is.

- the present invention has been able to provide further a stirrer that can further improve the shear applied to the fluid to be treated by the action of the intermittent jet flow by further research on the intermittent jet flow.

- a stirrer capable of realizing extremely fine dispersion and emulsification such as nano-dispersion and nano-emulsification can be provided.

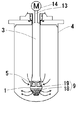

- This stirrer includes a processing unit 1 disposed in a fluid to be processed that is scheduled for processing such as emulsification, dispersion, or mixing, and a rotor 2 disposed in the processing unit 1.

- the processing unit 1 is a hollow housing, and is supported by the support tube 3 so as to be disposed in the storage container 4 for storing the fluid to be processed or the flow path of the fluid to be processed.

- the processing unit 1 is provided at the tip of the support tube 3 and is inserted from the upper part of the storage container 4 to the inside downward.

- the present invention is not limited to this example.

- FIG. As shown, even if the processing unit 1 is supported by the support tube 3 so as to protrude upward from the bottom surface of the storage container 4, it can be implemented.

- the processing unit 1 includes a suction chamber 6 having a suction port 5 for sucking a fluid to be processed from the outside to the inside, and a stirring chamber 7 connected to the suction chamber 6.

- the outer periphery of the stirring chamber 7 is defined by a screen 9 having a plurality of slits 18.

- the screen 9 is described as being composed of a slit 18 that is a space and a screen member 19 that is an actual member positioned between the slits 18. Therefore, the screen 9 means the whole including the slits 18 formed in the plurality of screen members 19, and the screen member 19 is a single member that exists between the adjacent slits 18. means.

- the suction chamber 6 and the stirring chamber 7 are partitioned by a partition wall 10 and are conducted through an introduction opening 11 provided in the partition wall 10.

- the suction chamber 6 and the partition wall 10 are not essential.

- the entire upper end of the stirring chamber 7 becomes an opening for introduction without providing the suction chamber 6, and the fluid to be processed in the container 4 May be introduced directly into the stirring chamber 7, or may constitute one space in which the suction chamber 6 and the stirring chamber 7 are not partitioned without providing the partition wall 10.

- the rotor 2 is a rotating body including a plurality of blades 12 in the circumferential direction, and rotates while maintaining a minute clearance between the blades 12 and the screen 9.

- Various rotation drive structures can be adopted as the structure for rotating the rotor 2.

- the rotor 2 is provided at the tip of the rotating shaft 13 and is rotatably accommodated in the stirring chamber 7. More specifically, the rotary shaft 13 is inserted into the support tube 3 and further disposed so as to reach the stirring chamber 7 through the suction chamber 6 and the opening 11 of the partition wall 10, and its tip (lower end in the figure).

- a rotor 2 is attached to the main body.

- the rear end of the rotary shaft 13 is connected to a rotary drive device such as a motor 14. It is preferable to use a motor 14 having a control system such as numerical control or one that is placed under the control of a computer.

- This stirrer is emulsified, dispersed or mixed by the shearing force applied to the fluid to be treated existing between the rotating blades 12 passing through the inner wall surface of the screen member 19 as the rotor 2 rotates. Is made.

- the kinetic energy is given to the fluid to be treated by the rotation of the rotor 2, and the fluid to be treated passes through the slit 18 to be further accelerated to form an intermittent jet flow. It flows out to the outside. Due to this intermittent jet flow, a liquid-liquid shearing force is generated at the velocity interface, and emulsification, dispersion, or mixing is performed.

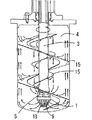

- the screen 9 has a cylindrical shape with a circular cross section. It is desirable that the diameter of the screen 9 gradually decreases as the screen 9 moves away from the introduction opening 11 (in the example of FIG. 2, downward), for example, like a conical surface shape. In the case of a constant diameter in the axial direction, the discharge amount from the slit 18 is large near the introduction opening 11 (upward in FIG. 2), and conversely, the discharge amount decreases farther away (lower in FIG. 2). ). As a result, cavitation that cannot be controlled may occur, which may lead to mechanical failure.

- the slit 18 is linearly extended in the axial direction of the rotating shaft 13 (up and down in the example in the figure), it may be curved and extended.

- the shape of the slit 18 is not necessarily an elongated space, and may be a polygon, a circle, an ellipse, or the like.

- a plurality of slits 18 are formed at equal intervals.

- the slits 18 can be formed at different intervals, and this does not hinder the provision of slits 18 of a plurality of types and sizes.

- the slit 18 can be implemented by appropriately changing the lead angle.

- the lead angle formed by the plane perpendicular to the rotation shaft 13 and the direction in which the slit 18 extends is a linear shape extending in the vertical direction of 90 degrees, and a spiral shape having a predetermined lead angle. A thing etc. which curve and extend in the up-down direction may be used.

- the blades 12 of the rotor 2 can extend linearly from the center of the rotor 2 in a straight line with a certain width in a cross section (a cross section perpendicular to the axial direction of the rotary shaft 13), and as it goes outward.

- the width may be gradually increased, or may be extended outward while being curved.

- the lead angle of the tip portion 21 of these blades 12 can be changed as appropriate.

- the lead angle formed by the plane orthogonal to the rotation shaft 13 and the direction in which the tip end portion 21 extends is linearly extending in the vertical direction of 90 degrees, and the spiral shape having a predetermined lead angle, etc. Further, it may be curved and extended in the vertical direction.

- each of these constituent members is such that the tip end portion of the blade 12 and the slit 18 are provided with a matching region in the same position where they overlap each other in the length direction of the slit 18.

- the fluid to be treated can be sheared between the blades 12 and the screen member 19 in the coincidence region by the rotation of the rotor 2 and passes through the slit 18 as the blades 12 rotate.

- Kinetic energy can be given to the fluid so that an intermittent jet flow is generated.

- the clearance between the screen 9 and the blade 12 can be appropriately changed within the range in which the shearing and the intermittent jet flow are generated, but it is generally preferably about 0.2 to 4.0 mm.

- this clearance can be easily achieved by allowing at least one of the stirring chamber 7 and the rotor 2 to move in the axial direction when a screen 9 having a tapered shape as shown in FIG. 2 is used. Can be adjusted.

- FIG.4 and FIG.5 is also employable.

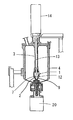

- a separate stirring device is disposed in the storage container 4 in order to make the entire fluid to be processed in the storage container 4 uniform.

- a stirring blade 15 for stirring the entire inside of the container 4 can be provided so as to rotate in the same body as the stirring chamber 7.

- the stirring blade 15 and the stirring chamber 7 including the screen 9 are rotated together.

- the rotation direction of the stirring blade 15 and the stirring chamber 7 may be the same as the rotation direction of the rotor 2 or may be the opposite direction. That is, the rotation of the stirring chamber 7 including the screen 9 is lower than the rotation of the rotor 2 (specifically, the peripheral speed of the screen rotation is about 0.02 to 0.5 m / s).

- the stirring chamber 7 can be rotated with respect to the support tube 3, and the rotation shaft of the second motor 20 is connected to the tip of the stirring chamber 7, so that the screen 9 can be rotated at high speed. It is what.

- the rotation direction of the screen 9 is rotated in the direction opposite to the rotation direction of the rotor 2 disposed inside the stirring chamber 7. As a result, the relative rotational speed between the screen 9 and the rotor 2 increases.

- the present invention is applied as follows.

- a shearing force between a liquid and a liquid is generated at a velocity interface by an intermittent jet flow, whereby emulsification, dispersion or mixing is performed.

- the rotor 2 and the screen 9 shown in FIGS. 6A and 6B and FIG. 7 can be used.

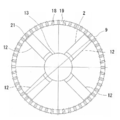

- the matching region where the shearing action is exerted on the screen 9 that is, the tip portion 21 of the blade 12 and the slit 18 of the screen 9 are arranged in the length direction of the slit 18. In the same region overlapping each other), both the following first condition and second condition are satisfied.

- the stirrer according to the present invention satisfies both the first condition and the second condition in the coincidence region.

- the axial position of the rotating shaft of the rotor 2 may be any position as long as it is in the coincidence region, but at least at the position where the axial position of the rotating shaft 13 is the maximum inner diameter of the screen 9, It is preferable to satisfy both conditions of the second condition.

- the shear force between the liquid and the liquid can be increased at the speed interface, and extremely fine such as nano-dispersion or nano-emulsification. It has been found that the invention is extremely effective in achieving dispersion and emulsification, and the invention has been completed.

- the intermittent jet flow is generated by the rotation of the blade 12. More specifically, the pressure of the fluid to be processed increases on the front side in the rotation direction of the blade 12. . As a result, the fluid to be treated is discharged as an intermittent jet flow from the slit 18 located on the front side of the blade 12. On the other hand, on the rear surface side in the rotation direction of the blades 12, the fluid to be treated is sucked from the slit 18 located on the rear surface side due to the pressure of the fluid to be treated being reduced.

- the fluid to be treated since the width of the tip 21 of the blade 12 is wide, the fluid to be treated remains stationary during discharge / suction. A period occurs. As a result, the fluid to be treated follows the change in opening and closing of the slit 18 by the blades 12, and the relative speed difference at the interface of the forward and reverse flow (discharge and suction) of the fluid to be treated increases. The shear force generated between the fluids to be treated can be increased. Conditions for realizing this well are the first condition and the second condition.

- the tip portion 21 of the blade 12 and the slit 18 include at least a coincidence region at the same position where they overlap each other in the length direction of the slit 18.

- the length of the blade 12 is set to be equal to or longer than the length of the slit 18, and the blade 12 is in the same position where it overlaps the slit 18 in the entire length of the slit 18, but the length of the blade 12 is the length of the slit 18. It can also be carried out with a shorter length.

- the relationship in the coincidence region means unless otherwise specified.

- the screen 9 can be implemented even when the diameter of the taper shape is changed.

- the maximum inner diameter means the maximum inner diameter of the screen 9 in the matching region.

- the slit 18 may extend in parallel to the axial direction of the rotation axis of the rotor 2 or may have an angle with respect to the axial direction, such as a spiral extension.

- the circumferential width (s) of the slit 18 is the circumferential direction of the screen 9 in the coincidence region (in other words, the axial direction of the rotating shaft of the rotor 2).

- the axial position of the rotating shaft of the rotor 2 may be any position as long as it is in the coincidence region, but at least the axial position of the rotating shaft 13 is a position where the maximum inner diameter of the screen 9 is obtained.

- the circumferential width (s) of the slit 18 is preferably 0.2 to 4.0 mm, and more preferably 0.5 to 2.0 mm. However, the width (s) is appropriately changed on condition that an intermittent jet flow is generated. Can be implemented.

- the circumferential width (t) of the screen member 19 (in other words, the circumferential distance between adjacent slits 18) can be changed as appropriate, but the circumferential width (s) of the slit 18 (s ) Is preferably 0.1 to 10 times, more preferably about 0.5 to 2 times. If the circumferential width (t) of the screen member 19 is too large, the number of shears decreases and the amount of processing decreases, and if it is too small, the slit 18 is substantially the same. The mechanical strength may be significantly reduced.

- the rotor 2 is a rotating body having a plurality of blades 12 as described above. In the coincidence region, the tip portion 21 of the blade 12 satisfies the conditions 1 and 2, thereby exhibiting the effects of the present invention. If the width of the tip portion 21 of the blade 12 is too large, the volume of the space between the blade 12 and the blade 12 becomes too small, which may cause a problem such as reducing the processing amount. From this point, the rotor 2 changes in accordance with the inner diameter of the screen 9, but the rotor 2 has a blade 12 on a plane orthogonal to the rotary shaft 13 in a region defined by the outer peripheral surface of the rotary shaft 13 and the inner peripheral surface of the screen 9.

- the sum of the cross-sectional areas of the blades 12 in the plane orthogonal to the rotation axis 13 is Y in the following specific formulas 1 and 2, and the screen 9 in the plane perpendicular to the rotation axis 13 in the coincidence area.

- the sectional area of the inner space is Z in the following specific formulas 1 and 2, it is preferable that Y and Z satisfy the following specific formula 2.

- X in the specific formula 1 refers to an area of a cross section orthogonal to the rotation shaft 13 in a region defined by the outer peripheral surface of the rotary shaft 13 and the inner peripheral surface of the screen 9 in the matching region.

- XY Z (Specific Formula 1) Y ⁇ Z (specific formula 2) It is preferable that the specific formula 2 is satisfied in at least one of the plurality of cross sections in the coincidence region, and it is more preferable that the specific formula 2 is satisfied in all cross sections. Then, as shown in FIG. 2, the screen 9 whose diameter gradually decreases with increasing distance from the introduction opening 11 (downward in the example of FIG. 2), and the axial direction of the plane orthogonal to the rotation axis 13. When the position is a position that is the maximum inner diameter of the screen 9 in the coincidence region, Y / Z is preferably 0.2 or more and less than 1, and Y / Z is more preferably 0.34 or more and 0.6 or less.

- Y / Z is more preferably 0.34 or more and 0.5 or less.

- Y / Z can be calculated based on the diameter of the rotating shaft 13, the diameter of the blade 12, the width of the blade 12 in the rotation direction, the inner diameter of the screen 9, and the like.

- the numerical conditions of the screen 9, the slit 18, and the rotor 2 that can be applied to the conditions 1 and 2 of the present invention and are suitable for mass production with the current technical capabilities are as follows.

- Maximum inner diameter of the screen 9 30 to 500 mm (however, the maximum diameter in the matching area)

- Number of rotations of screen 9 15 to 390 times / s

- Number of slits 18 20 to 500

- Maximum outer diameter of rotor 2 30 to 500 mm

- Number of rotations of rotor 2 15 to 390 times / s

- these numerical conditions are merely examples.

- the present invention does not exclude the use of conditions other than the above-mentioned conditions as technology advances in the future such as rotation control.

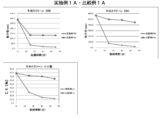

- Example 1 and Comparative Example 1 As Example 1 (ie, Example 1A and Example 1B) and Comparative Example 1 (ie, Comparative Example 1A and Comparative Example 1B), the stirrer according to the first embodiment of the present invention (FIGS. 1 and 2) Were used to conduct treatment tests (Example 1A / Comparative Example 1A and Example 1B / Comparative Example 1B) on two types of fluids to be treated.

- Aqualon KH-10 is a surfactant manufactured by Daiichi Kogyo Seiyaku.

- the pre-mixed product in the external container (1 L tall beaker equipped with a stirrer) is introduced into the processing container (350 cc) having a stirrer by the pump in the test apparatus shown in FIG.

- the processing container 350 cc having a stirrer by the pump in the test apparatus shown in FIG.

- the fluid to be processed is discharged from the discharge port and circulating between the processing container and the external container,

- the rotor of the stirrer was rotated at 20000 rpm and discharged from the screen, and the fine particle treatment was performed under the conditions shown in Table 1. In either example, the screen was not rotated.

- the slit width and the width of the screen member described in Table 1 are the slit width and the width of the screen member at a position where the axial position of the surface orthogonal to the rotation axis 13 is the maximum inner diameter of the screen 9 in the coincidence region. .

- Example 1 both the above-described Condition 1 and Condition 2 were satisfied, whereas in Comparative Example 1, both Condition 1 and Condition 2 were not satisfied.

- the variation coefficient of the particle diameter serves as an index representing the degree of uniformity of the obtained particles, and the coefficient of variation (CV) is calculated from the average particle diameter (D50) and the standard deviation in the particle diameter distribution of the particles.

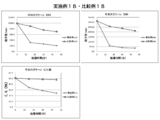

- Example 2 Next, according to Example 2, it was confirmed whether the particle diameter of the rotor and the screen having a larger diameter than that of Example 1 was significantly reduced according to the processing time.

- the processing conditions are shown in Table 1, and the test results are shown in FIG.

- the processing apparatus is substantially the same as in Example 1 except that the entire size is increased according to the processing amount (external container: a 300 L tank equipped with a stirring device, a processing container (8.5 L)). did.

- pulverized component dextrin

- dispersion medium vegetable oil were used.

- Even in the second embodiment as apparent from Table 1, both the above-described condition 1 and condition 2 are satisfied.

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Dispersion Chemistry (AREA)

- Mixers Of The Rotary Stirring Type (AREA)

Abstract

Description

例えば、広く知られた攪拌機の一種としてビーズミルやホモジナイザーが知られている。

高圧ホモジナイザーでは、機械の安定稼働の問題や大きな必要動力の問題等が解決されていない。

また、回転式ホモジナイザーは、従来プレミキサーとして用いられていたが、ナノ分散やナノ乳化を行うには、さらにナノ化の仕上げのために仕上げ機を必要とする。

これに対して、特許文献1乃至3の攪拌機を本発明者は提案した。この攪拌機は、複数の羽根を備えたローターと、ローターの周囲に敷設されると共に複数のスリットを有するスクリーンとを備えるものである。ローターとスクリーンとは、相対的に回転することによって、スリットを含むスクリーンの内壁と羽根との間の微小な間隙において被処理流動体のせん断が行われると共に、スリットを通じて断続ジェット流としてスクリーンの内側から外側に被処理流動体が吐出されるものである。

本発明の発明者は、特許文献1~3に示された装置によって、被処理流動体の微細化を促進し、より微細の分散や乳化を実現することを試みたところ、まず、スリットを含むスクリーンの内壁と羽根との間の微小な間隙において被処理流動体のせん断が行われる点からすると、せん断の効率化を図るためには、単位時間当たりのせん断回数を増やすことが有効であると考えられるため、単位時間当たりのせん断回数を増やす視点から検討を行った。

また、このせん断が効率的になされる結果、ナノ分散やナノ乳化等の極めて微細な分散や乳化を実現することができる攪拌機の提供を目的とする。

(条件1)

一致領域における、

羽根の先端部の回転方向の幅(b)と、

スリットの周方向の幅(s)と、

スクリーン部材の周方向の幅(t)と、

の関係が、

b≧2s+t

である。

(条件2)

一致領域における、

羽根の先端部の回転方向の幅(b)と

スクリーンの最大内径(c)との関係が、

b≧0.1c

である。

X-Y=Z (特定式1)

Y<Z (特定式2)

前記一致領域における複数の断面のうちの少なくとも1箇所の断面において特定式2を満たすことが好ましく、全ての断面において特定式2を満たすことがより好ましい。

本発明は、複数の羽根を備えると共に回転するローターと、ローターの周囲に敷設されたスクリーンとを備え、スクリーンは、その周方向に複数のスリットと、隣り合うスリット同士の間に位置するスクリーン部材とを備え、羽根の先端部とスリットとは、ローターの回転軸の軸方向位置において互いに同一位置にある一致領域を備え、ローターとスクリーンとのうち少なくともローターが回転することによって、ローターとスクリーンとが相対的に回転することにより、被処理流動体がスリットを通じて断続ジェット流としてスクリーンの内側から外側に吐出する攪拌機において、下記の条件1と条件2とを同時に満たす攪拌機を提供する。

(条件1)

一致領域における、

羽根の先端部の回転方向の幅(b)と、

スリットの周方向の幅(s)と、

スクリーン部材の周方向の幅(t)と、

の関係が、

b≧2s+t

である。

(条件2)

一致領域における、

羽根の先端部の回転方向の幅(b)と

スクリーンの最大内径(c)との関係が、

b≧0.1c

である。

また、前記せん断が効率的になされる結果、ナノ分散やナノ乳化等の極めて微細な分散や乳化を実現することができる攪拌機を提供することができたものである。

更に、粒子径の分布が狭く、粒子径の揃った粒子を得ることができる攪拌機を提供することができたものである。

まず、図1、図2を参照して、本発明を適用することができる攪拌機の一例の基本的な構造を説明する。

この攪拌機は、乳化、分散或は混合等の処理を予定する被処理流動体内へ配される処理部1と、処理部1内に配置されたローター2とを備えるものである。

スリット18は、そのリード角を適宜変更して実施することができる。図示したように、回転軸13と直交する平面と、スリット18の伸びる方向とのなすリード角が、90度である上下方向に直線状に伸びるものの他、所定のリード角を備えたスパイラル状のもの等、上下方向に湾曲して伸びるものであってもよい。

また、これらの羽根12は、その先端部21のリード角は適宜変更することができる。例えば、回転軸13と直交する平面と、先端部21の伸びる方向とのなすリード角が、90度である上下方向に直線状に伸びるものの他、所定のリード角を備えたスパイラル状のもの等、上下方向に湾曲して伸びるものであってもよい。

また、攪拌機の他の構造としては、図4及び図5に示すものも採用することができる。

また、図5の例は、攪拌室7を支持管3に対して回動可能とし、攪拌室7の先端に、第2モータ20の回転軸を接続したものであり、スクリーン9を高速回転可能とするものである。このスクリーン9の回転方向は、攪拌室7の内部に配置されたローター2の回転方向とは逆方向に回転させる。これによって、スクリーン9とローター2との相対的回転速度が増加する。

本発明に係る攪拌機については、断続ジェット流により、速度界面で液-液間のせん断力が発生することによって、乳化、分散或は混合の処理が行われる。その際、本発明の実施の形態に係る攪拌機にあっては、例えば、図6(A)(B)及び図7に示すローター2及びスクリーン9を用いることができる。この例のローター2及びスクリーン9にあっては、スクリーン9におけるせん断作用が発揮される一致領域(即ち、羽根12の先端部21とスクリーン9のスリット18とが、スリット18の長さ方向にて、互いに重なり合う同一位置にある領域)において、次の第1条件と第2条件との両条件を満たすものである。

羽根12の先端部21の回転方向の幅(b)と、

スリット18の周方向の幅(s)と、

スクリーン部材19の周方向の幅(t)との関係が、

b≧2s+tの条件を満たすものである。

言い換えれば、ローター2における羽根12の先端部21の回転方向の幅が、隣り合う2つのスリット18の両端縁間の距離よりも大きく設定されているものである。

(第2条件)

羽根12の先端部21の回転方向の幅(b)と、

スクリーン9の最大内径(c)との関係が、

b≧0.1cの条件を満たすものである。

言い換えれば、羽根12の先端部21は、スクリーン9の最大内径に対して、所定の比率以上に設定されているものである。

まず、前述したように、断続ジェット流は、羽根12の回転によって発生するものであるが、これをより詳しく説明すると、羽根12の回転方向の前面側では、被処理流動体の圧力が上昇する。これによって、羽根12の前面側に位置するスリット18から被処理流動体が断続ジェット流となって吐出される。他方、羽根12の回転方向の後面側では、被処理流動体の圧力が低下することにより、後面側に位置するスリット18から被処理流動体が吸い込まれる。その結果、スクリーン9の外側では、被処理流動体に正逆の流れ(吐出と吸込)が生じ、両流れの界面における相対的な速度差によって、被処理流動体同士に液-液間のせん断力が生じるものである。

羽根12の先端部21とスリット18とは、スリット18の長さ方向において互いに重なり合う同一位置にある一致領域を少なくとも備える。通常、羽根12の長さはスリット18の長さ以上に設定されており、スリット18の全長において羽根12はスリット18とは互いに重なり合う同一位置にあるが、羽根12の長さをスリット18の長さよりも短くして実施することもできる。本発明において、羽根12とスリット18との関係を規定する場合、特に説明のない限り、一致領域における関係を意味する。

スクリーン9は、前述の通り、テーパ形等の径が変化するものとしても、実施することができる。本発明において、内径が変化する場合、特に説明のない限り、最大内径とは、一致領域におけるスクリーン9の最大内径を意味する。

スリット18は、ローター2の回転軸の軸方向と平行に伸びるものであってもよく、スパイラル状に伸びるもの等、軸方向に対して角度を有するものであってもよい。何れの場合にあっても、本発明において、特に説明がない限り、スリット18の周方向の幅(s)とは、一致領域におけるスクリーン9の周方向(言い換えればローター2の回転軸の軸方向に対して直交する方向)の長さを言う。ローター2の回転軸の軸方向位置にあっては、一致領域であればどの位置であってもかまわないが、少なくとも回転軸13の軸方向位置がスクリーン9の最大内径となる位置であることが好ましい。このスリット18の周方向の幅(s)は、0.2~4.0mmが好ましく、0.5~2.0mmであることがより好ましいが、断続ジェット流が発生することを条件に適宜変更して実施することができる。

ローター2は、前述のとおり、複数枚の羽根12を有する回転体である。一致領域において、羽根12の先端部21は、条件1と条件2とを充足するものとすることによって、本発明の作用効果を発揮する。なお、羽根12の先端部21の幅を大きくし過ぎると、羽根12と羽根12との間の空間の容積が少なくなり過ぎ、処理量を徒に低下させる等の問題が生じるおそれがある。この点からすると、スクリーン9の内径によっても変化するが、ローター2は、回転軸13の外周面とスクリーン9の内周面とにより規定される領域において、回転軸13と直交する面における羽根12の断面積の総和が、スクリーン9内の空間の断面積よりも小さく設定することが好ましい。上述したように、一致領域において、回転軸13と直交する面における羽根12の断面積の総和を下記特定式1、2におけるYとし、同じく一致領域において、回転軸13と直交する面におけるスクリーン9内の空間の断面積を下記の特定式1、2におけるZとしたとき、YとZとが下記特定式2を満たすことが好ましい。特定式1のXは、一致領域において、回転軸13の外周面とスクリーン9の内周面とにより規定される領域の、回転軸13と直交する断面の面積をいう。

X-Y=Z (特定式1)

Y<Z (特定式2)

一致領域における複数の断面のうちの少なくとも1箇所の断面において特定式2を満たすことが好ましく、全ての断面において特定式2を満たすことがより好ましい。

そして、図2に示すように、導入用の開口11から遠ざかるに従って(図2の例では下方に向かうに従って)、漸次その径が小さくなるスクリーン9を用い、回転軸13と直交する面の軸方向位置が、一致領域におけるスクリーン9の最大内径となる位置であるとき、Y/Zが0.2以上1未満であることが好ましく、Y/Zが0.34以上0.6以下あることがより好ましく、Y/Zが0.34以上0.5以下であることが更に好ましい。Y/Zは、回転軸13の径、羽根12の径、羽根12の回転方向の幅、スクリーン9の内径等に基づいて算出することができる。

本発明の条件1及び条件2を適用できると共に、現在の技術力で量産に適すると考えられるスクリーン9、スリット18、ローター2の数値条件は、下記の通りである。

スクリーン9の最大内径:30~500mm(但し前記の一致領域における最大径)

スクリーン9の回転数:15~390回/s

スリット18の本数:20~500本

ローター2の最大外径:30~500mm

ローター2の回転数:15~390回/s

もちろん、これらの数値条件は一例を示すものであり、例えば、回転制御等の将来における技術進歩に伴い、前記の条件以外の条件を採用することを、本発明は除外するものではない。

実施例1(即ち、実施例1Aと実施例1B)及び比較例1(即ち、比較例1Aと比較例1B)として、本発明における第1の実施の形態(図1、図2)に係る攪拌機を用いて、2種の被処理流動体に対する処理試験(実施例1A・比較例1Aと実施例1B・比較例1B)を行った。

顔料の分散処理を行った実施例1A・比較例1Aにあっては、被処理流動体として、銅フタロシアニン/ドデシル硫酸ナトリウム/純水=2/0.2/97.8(重量比)を用いた。

樹脂類の乳化処理を行った実施例1B・比較例1Bにあっては、被処理流動体として、メタクリル酸メチルモノマー/アクアロンKH-10/純水=10/1/89(重量比)を用いた。但し、アクアロンKH-10は、第一工業製薬製の界面活性剤である。

なお、表1に記載のスリット幅とスクリーン部材の幅は、回転軸13と直交する面の軸方向位置が、一致領域におけるスクリーン9の最大内径となる位置におけるスリット幅とスクリーン部材の幅である。

実施例1にあっては、前述の条件1と条件2とを共に充足するのに対して、比較例1にあっては条件1と条件2とを共に充足しないものであった。

実施例1

(条件1)3.6>2×0.8+1.19=2.79

(条件2)3.6>0.1×30.4=3.04

比較例1

(条件1)2.4<2×0.8+1.19=2.79

(条件2)2.4<0.1×30.4=3.04

実施例1及び比較例1について、最長の処理時間45分後までの複数点で計測した粒子の粒子径(D50、D90)及び粒子径の変動係数(C.V.)を図9及び図10に示す。粒子径の変動係数とは、得られる粒子の均一さの度合いを表す指標となるものであり、粒子の粒子径分布における平均粒子径(D50)と標準偏差とから、変動係数(C.V.)(%)=標準偏差÷平均粒子径(D50)×100の式にて求められる。この変動係数の値が小さいほど得られる粒子の粒子径の分布は狭く、粒子としての均一性が高い。

図9及び図10に見られるように、実施例1にあっては、比較例1に比して、処理時間に応じて粒子径及び粒子径の変動係数が顕著に低下することが明らかになった。

次に、実施例2によって、実施例1よりも大きな径のローター及びスクリーンでも、処理時間に応じて粒子径が顕著に低下するか否かを確認した。処理条件を表1に、試験結果を図11にそれぞれ示す。処理装置は、処理量に応じて全体を大型化した(外部容器:攪拌装置を備えた300Lタンク、処理容器(8.5L)とした)点を除いて、実施例1と実質的に同じものとした。被処理流動体は、粉砕成分:デキストリン、分散媒:植物油を用いた。

この実施例2にあっても、表1から明らかなように、前述の条件1と条件2とを共に充足するものである。

実施例2

(条件1)11.3>2×1.1+1.90=4.10

(条件2)11.3>0.1×95.4=9.54

図11に見られるように、実施例2にあっても、処理時間に応じて粒子径(D50及びD90)が顕著に低下することが明らかになった。

2 ローター

3 支持管

4 収容容器

5 吸入口

6 吸入室

7 攪拌室

9 スクリーン

10 隔壁

11 開口

12 羽根

13 回転軸

14 モータ

15 攪拌翼

18 スリット

19 スクリーン部材

20 第2モータ

21 先端部

Claims (6)

- 複数の羽根を備えると共に回転するローターと、前記ローターの周囲に敷設されたスクリーンとを備え、

前記スクリーンは、その周方向に複数のスリットと、隣り合う前記スリット同士の間に位置するスクリーン部材とを備え、

前記羽根の先端部と前記スリットとは、前記スリットの長さ方向において互いに重なり合う同一位置にある一致領域を備え、

前記ローターと前記スクリーンとのうち少なくともローターが回転することによって、前記ローターと前記スクリーンとが相対的に回転することにより、被処理流動体が前記スリットを通じて断続ジェット流として前記スクリーンの内側から外側に吐出する攪拌機において、下記の条件1と条件2とを充足する攪拌機。

(条件1)

前記一致領域における、

前記羽根の前記先端部の回転方向の幅(b)と、

前記スリットの周方向の幅(s)と、

前記スクリーン部材の周方向の幅(t)と、

の関係が、

b≧2s+t

である。

(条件2)

前記一致領域における、

前記羽根の前記先端部の回転方向の幅(b)と

前記スクリーンの最大内径(c)との関係が、

b≧0.1c

である。 - 前記スリットの周方向の幅(s)が0.2~4.0mmであることを特徴とする請求項1に記載の攪拌機。

- 前記スクリーンの内部に前記被処理流動体を導入する導入口から、軸方向に遠ざかるに従って、前記羽根及び前記スクリーンの径が小さくなることを特徴とする請求項1又は2に記載の攪拌機。

- 前記複数のスリットは、前記周方向に同一の幅であり、且つ、前記周方向に等間隔に形成されたものであり、

前記スクリーンは回転しないものであることを特徴とする請求項1~3の何れかに記載の攪拌機。 - 前記複数のスリットは、前記周方向に同一の幅であり、且つ、前記周方向に等間隔に形成されたものであり、

前記スクリーンは前記ローターと逆方向に回転するものであることを特徴とする請求項1~3の何れかに記載の攪拌機。 - 前記ローターの回転軸と直交する面における前記羽根の断面積の総和が、前記スクリーン内の空間の断面積よりも小さいものであることを特徴とする請求項1~5の何れかに記載の攪拌機。

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020177025071A KR102526910B1 (ko) | 2015-03-24 | 2016-03-23 | 교반기 |

| CN201680014471.5A CN107427794B (zh) | 2015-03-24 | 2016-03-23 | 搅拌机 |

| US15/557,016 US10478790B2 (en) | 2015-03-24 | 2016-03-23 | Stirrer producing intermittent jet flow |

| EP16768798.7A EP3275534B1 (en) | 2015-03-24 | 2016-03-23 | Stirrer |

| JP2017508377A JPWO2016152895A1 (ja) | 2015-03-24 | 2016-03-23 | 攪拌機 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015061360 | 2015-03-24 | ||

| JP2015-061360 | 2015-03-24 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2016152895A1 true WO2016152895A1 (ja) | 2016-09-29 |

Family

ID=56978205

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2016/059122 WO2016152895A1 (ja) | 2015-03-24 | 2016-03-23 | 攪拌機 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US10478790B2 (ja) |

| EP (1) | EP3275534B1 (ja) |

| JP (2) | JPWO2016152895A1 (ja) |

| KR (1) | KR102526910B1 (ja) |

| CN (1) | CN107427794B (ja) |

| WO (1) | WO2016152895A1 (ja) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6598345B1 (ja) * | 2019-04-15 | 2019-10-30 | エム・テクニック株式会社 | 攪拌機 |

| JP6601862B1 (ja) * | 2019-04-15 | 2019-11-06 | エム・テクニック株式会社 | 攪拌機 |

| JP2020006362A (ja) * | 2018-07-02 | 2020-01-16 | 株式会社田定工作所 | 撹拌用回転体及び撹拌装置 |

| JP6650162B1 (ja) * | 2019-04-15 | 2020-02-19 | エム・テクニック株式会社 | 攪拌機 |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107427794B (zh) * | 2015-03-24 | 2021-05-07 | M技术株式会社 | 搅拌机 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2679789A1 (fr) * | 1991-07-31 | 1993-02-05 | Ouest Enrobes Modernes | Melangeur-disperseur a pulsations pour la preparation de produits thermoplastiques, en particulier de produits bitumineux. |

| JPH0796167A (ja) * | 1993-09-27 | 1995-04-11 | Matsumoto Yushi Seiyaku Co Ltd | マイクロカプセルの製法 |

Family Cites Families (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1048465B (de) * | 1959-01-08 | Fritz Eichenauer Bernd Eichenauer und Erika Eichtnauer Kandel (Pfalz) | Vorrichtung zum Femaufspal ten von Glimmer durch Naßzerkleinerung | |

| US1048465A (en) * | 1912-12-24 | Cornelius J Nolan | Glass-blowing machine. | |

| US755913A (en) * | 1901-07-06 | 1904-03-29 | Donald Barns Morison | Mortar-box for stamp-mills. |

| US1140440A (en) * | 1914-02-17 | 1915-05-25 | Romulus C Chevalier | Hoist. |

| US2628081A (en) * | 1948-11-12 | 1953-02-10 | T J Laird Equipment Corp | Mixer |

| GB755913A (en) * | 1950-08-19 | 1956-08-29 | Equipments Ind Et Laitiers S B | Machines for the production of finely divided mixtures |

| DE1140440B (de) * | 1957-11-06 | 1962-11-29 | Forsch Inst Professor Ing Chem | Zerkleinerungs-, Ruehr- und Mischvorrichtung |

| US3195867A (en) * | 1962-01-23 | 1965-07-20 | Liberty Nat Bank And Trust Com | Homogenizing apparatus |

| JPS5147091B2 (ja) | 1971-09-30 | 1976-12-13 | ||

| US4347004A (en) * | 1979-06-13 | 1982-08-31 | Unishear Mixers Limited | Mixing apparatus |

| JPS6061028A (ja) * | 1983-09-14 | 1985-04-08 | Kikuji Okada | 流体混合装置 |

| JP3123556B2 (ja) | 1990-06-30 | 2001-01-15 | エム・テクニック株式会社 | 攪はん機 |

| JP2813673B2 (ja) | 1990-09-01 | 1998-10-22 | エム・テクニック株式会社 | 攪拌機 |

| JP2002091072A (ja) * | 2000-09-13 | 2002-03-27 | Canon Inc | トナーの製造方法 |

| JP4909693B2 (ja) * | 2006-07-24 | 2012-04-04 | 相川鉄工株式会社 | スクリーン装置 |

| CN103180036B (zh) * | 2010-08-19 | 2016-08-03 | 株式会社明治 | 微粒化装置的性能评价方法以及尺度上推方法 |

| SG188232A1 (en) * | 2010-08-19 | 2013-04-30 | Meiji Co Ltd | Particle size breakup device and its performance estimation method and scale up method |

| CN103221120B (zh) * | 2010-08-19 | 2016-08-17 | 株式会社明治 | 微粒化装置 |

| JP6035499B2 (ja) * | 2011-03-23 | 2016-11-30 | エム・テクニック株式会社 | 微粒子の製造方法 |

| TWI604885B (zh) * | 2011-08-19 | 2017-11-11 | 明治股份有限公司 | Microprocessing equipment |

| CN104411392B (zh) * | 2012-07-13 | 2017-06-23 | M技术株式会社 | 搅拌机 |

| JP6207091B2 (ja) * | 2012-12-25 | 2017-10-04 | エム・テクニック株式会社 | 攪拌処理装置及び処理方法 |

| US10137420B2 (en) * | 2014-02-27 | 2018-11-27 | Schlumberger Technology Corporation | Mixing apparatus with stator and method |

| EP3170927B1 (en) * | 2014-07-14 | 2020-09-30 | M Technique Co., Ltd. | Method for preparing single crystal zinc oxide nanoparticles |

| CN107427794B (zh) * | 2015-03-24 | 2021-05-07 | M技术株式会社 | 搅拌机 |

| WO2017002938A1 (ja) * | 2015-06-30 | 2017-01-05 | エム・テクニック株式会社 | 有機化合物の製造方法 |

-

2016

- 2016-03-23 CN CN201680014471.5A patent/CN107427794B/zh active Active

- 2016-03-23 EP EP16768798.7A patent/EP3275534B1/en active Active

- 2016-03-23 US US15/557,016 patent/US10478790B2/en active Active

- 2016-03-23 WO PCT/JP2016/059122 patent/WO2016152895A1/ja active Application Filing

- 2016-03-23 KR KR1020177025071A patent/KR102526910B1/ko active IP Right Grant

- 2016-03-23 JP JP2017508377A patent/JPWO2016152895A1/ja active Pending

-

2021

- 2021-10-05 JP JP2021163810A patent/JP7212965B2/ja active Active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2679789A1 (fr) * | 1991-07-31 | 1993-02-05 | Ouest Enrobes Modernes | Melangeur-disperseur a pulsations pour la preparation de produits thermoplastiques, en particulier de produits bitumineux. |

| JPH0796167A (ja) * | 1993-09-27 | 1995-04-11 | Matsumoto Yushi Seiyaku Co Ltd | マイクロカプセルの製法 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP3275534A4 * |

Cited By (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2020006362A (ja) * | 2018-07-02 | 2020-01-16 | 株式会社田定工作所 | 撹拌用回転体及び撹拌装置 |

| JP7240652B2 (ja) | 2018-07-02 | 2023-03-16 | 株式会社田定工作所 | 撹拌用回転体及び撹拌装置 |

| WO2020213177A1 (ja) | 2019-04-15 | 2020-10-22 | エム・テクニック株式会社 | 攪拌機 |

| KR20210151059A (ko) | 2019-04-15 | 2021-12-13 | 엠. 테크닉 가부시키가이샤 | 교반기 |

| JP6598345B1 (ja) * | 2019-04-15 | 2019-10-30 | エム・テクニック株式会社 | 攪拌機 |

| WO2020213184A1 (ja) | 2019-04-15 | 2020-10-22 | エム・テクニック株式会社 | 攪拌機 |

| WO2020213048A1 (ja) | 2019-04-15 | 2020-10-22 | エム・テクニック株式会社 | 攪拌機 |

| KR20210150950A (ko) | 2019-04-15 | 2021-12-13 | 엠. 테크닉 가부시키가이샤 | 교반기 |

| KR20210150949A (ko) | 2019-04-15 | 2021-12-13 | 엠. 테크닉 가부시키가이샤 | 교반기 |

| JP6650162B1 (ja) * | 2019-04-15 | 2020-02-19 | エム・テクニック株式会社 | 攪拌機 |

| US11241661B2 (en) | 2019-04-15 | 2022-02-08 | M. Technique Co., Ltd. | Stirrer |

| EP3957391A4 (en) * | 2019-04-15 | 2022-12-21 | M. Technique Co., Ltd. | STIRRER |

| JP6601862B1 (ja) * | 2019-04-15 | 2019-11-06 | エム・テクニック株式会社 | 攪拌機 |

| US11628412B2 (en) | 2019-04-15 | 2023-04-18 | M. Technique Co., Ltd. | Stirrer |

| KR102666286B1 (ko) * | 2019-04-15 | 2024-05-16 | 엠. 테크닉 가부시키가이샤 | 교반기 |

| KR102666285B1 (ko) * | 2019-04-15 | 2024-05-16 | 엠. 테크닉 가부시키가이샤 | 교반기 |

| KR102703317B1 (ko) * | 2019-04-15 | 2024-09-05 | 엠. 테크닉 가부시키가이샤 | 교반기 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3275534A4 (en) | 2018-11-14 |

| EP3275534A1 (en) | 2018-01-31 |

| US10478790B2 (en) | 2019-11-19 |

| CN107427794A (zh) | 2017-12-01 |

| KR102526910B1 (ko) | 2023-04-28 |

| US20180056255A1 (en) | 2018-03-01 |

| EP3275534B1 (en) | 2020-04-22 |

| JPWO2016152895A1 (ja) | 2018-01-18 |

| CN107427794B (zh) | 2021-05-07 |

| JP7212965B2 (ja) | 2023-01-26 |

| KR20170129723A (ko) | 2017-11-27 |

| JP2022000306A (ja) | 2022-01-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5147091B1 (ja) | 攪拌機 | |

| JP7212965B2 (ja) | 攪拌機 | |

| JP6601862B1 (ja) | 攪拌機 | |

| JP6069707B2 (ja) | 流体処理装置及び流体処理方法 | |

| JP6598345B1 (ja) | 攪拌機 | |

| JP6650162B1 (ja) | 攪拌機 | |

| JP6685066B1 (ja) | 攪拌機 | |

| KR102649462B1 (ko) | 교반기 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 16768798 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2017508377 Country of ref document: JP Kind code of ref document: A |

|

| ENP | Entry into the national phase |

Ref document number: 20177025071 Country of ref document: KR Kind code of ref document: A |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 15557016 Country of ref document: US |

|

| REEP | Request for entry into the european phase |

Ref document number: 2016768798 Country of ref document: EP |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |