WO2015198619A1 - 冷蔵庫 - Google Patents

冷蔵庫 Download PDFInfo

- Publication number

- WO2015198619A1 WO2015198619A1 PCT/JP2015/053289 JP2015053289W WO2015198619A1 WO 2015198619 A1 WO2015198619 A1 WO 2015198619A1 JP 2015053289 W JP2015053289 W JP 2015053289W WO 2015198619 A1 WO2015198619 A1 WO 2015198619A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- light

- transparent

- laminated sheet

- refrigerator according

- operation display

- Prior art date

Links

- 239000000758 substrate Substances 0.000 claims abstract description 27

- 239000000463 material Substances 0.000 claims abstract description 9

- 238000009792 diffusion process Methods 0.000 claims description 11

- 238000005192 partition Methods 0.000 claims description 5

- 230000001419 dependent effect Effects 0.000 claims 2

- 230000001678 irradiating effect Effects 0.000 claims 1

- WABPQHHGFIMREM-UHFFFAOYSA-N lead(0) Chemical compound [Pb] WABPQHHGFIMREM-UHFFFAOYSA-N 0.000 description 9

- 235000013311 vegetables Nutrition 0.000 description 8

- 230000008014 freezing Effects 0.000 description 5

- 238000007710 freezing Methods 0.000 description 5

- 230000007257 malfunction Effects 0.000 description 5

- 239000002131 composite material Substances 0.000 description 4

- 238000005057 refrigeration Methods 0.000 description 4

- 235000013305 food Nutrition 0.000 description 3

- 230000004048 modification Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000003071 parasitic effect Effects 0.000 description 2

- 230000006641 stabilisation Effects 0.000 description 2

- 238000011105 stabilization Methods 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 239000003292 glue Substances 0.000 description 1

- 230000008520 organization Effects 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 230000035945 sensitivity Effects 0.000 description 1

- 238000000638 solvent extraction Methods 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G09—EDUCATION; CRYPTOGRAPHY; DISPLAY; ADVERTISING; SEALS

- G09F—DISPLAYING; ADVERTISING; SIGNS; LABELS OR NAME-PLATES; SEALS

- G09F13/00—Illuminated signs; Luminous advertising

- G09F13/04—Signs, boards or panels, illuminated from behind the insignia

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D23/00—General constructional features

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H36/00—Switches actuated by change of magnetic field or of electric field, e.g. by change of relative position of magnet and switch, by shielding

Definitions

- the touch operation part of the operation display part is also provided with a power saving function such that it is turned off when not normally operated and turned on only when operated.

- the touch operation portion, the icon, and the character display portion need a light emitting area of a certain size, and many light guide plates are used for surface light emission in many cases. (For example, refer to Patent Document 1).

- the present invention has been made in order to solve the above-described problems. Even when the operation display unit emits light, the number of parts of the operation display unit is reduced, thereby improving productivity and reducing costs. And it aims at providing the refrigerator which enabled stabilization of quality.

- the refrigerator according to the present invention by adopting the above-described configuration for the operation display unit, it is possible to greatly reduce the number of components of the operation display unit, thereby improving productivity, reducing costs, and improving quality. Stabilization is realized.

- FIG. 4 is a detailed view of components of the operation display panel of FIG. 3, (a) showing a transparent electrode sheet and a supporting component, and (b) showing a supporting component and an electronic substrate. It is an external view of the transparent electrode sheet of FIG. It is sectional drawing of the transparent electrode sheet of FIG. It is sectional drawing of the operation display panel of FIG. It is an external view of the transparent electrode sheet which concerns on Embodiment 2 of this invention. It is an external view of the transparent electrode sheet which concerns on the modification of FIG.

- FIG. 13 is a detailed view of a connector connection portion of the operation display panel of FIG. 12. It is a disassembled perspective view of the operation display panel which concerns on Embodiment 5 of this invention. It is a front view of the refrigerator which concerns on Embodiment 5 of this invention.

- FIG. 1 is a front view of a refrigerator according to Embodiment 1 of the present invention.

- the refrigerator 1 includes a refrigerating room 100, a switching room 200, an ice making room 300, a freezing room 400, and a vegetable room 500.

- the refrigerator compartment 100 includes an open / close door and is disposed at the top.

- the switching chamber 200 has a drawer door and is disposed below the refrigeration chamber 100.

- Each of the switching chambers 200 includes a refrigeration temperature range ( ⁇ 18 ° C.), a refrigeration (3 ° C.), a chilled (0 ° C.), a soft freezing ( ⁇ 7 ° C.) It can be switched to a temperature zone.

- the ice making chamber 300 includes a drawer door and is disposed in parallel with the switching chamber 200.

- the freezer compartment 400 includes a drawer door and is disposed below the switching chamber 200 and the ice making chamber 300.

- the vegetable compartment 500 is provided with a drawer door and is arranged at the bottom.

- FIG. 2 is a side sectional view of the refrigerator 1 of FIG.

- the refrigerator 1 includes a compressor 2, a cooler 3, and a blower fan 4.

- the blower fan 4 blows the cool air cooled by the cooler 3 to each room in the refrigerator 1 through the air path 5.

- the air path 5 is an air path for introducing the cold air cooled by the cooler 3 into each room. That is, the cold air cooled by the cooler 3 passes through the air passage 5 and is blown to the freezing room 400, the switching room 200, the ice making room 300, and the refrigerating room 100 to cool each room.

- the return cold air of the refrigerator compartment 100 circulates through a return air passage (not shown) for the refrigerator compartment and is cooled, and then returned to the cooler 3 from the return air passage for the vegetable compartment (not shown). .

- the temperature of each room is detected by a thermistor (not shown) installed in each room, and the opening degree of a damper (not shown) installed in the air passage 5, the capacity of the compressor 2, and the air blow so that the temperature becomes a preset temperature. It is controlled by adjusting the air flow rate of the fan 4.

- a storage case 401 is installed in the freezer compartment 400 and can store food.

- a storage case 201 is also installed in the switching chamber 200 and can store food.

- the vegetable compartment 500 is also provided with a storage case 501 and can store food.

- the number of cases in each room may be one, but there may be two or more cases when the capacity of the entire refrigerator 1 improves the organization.

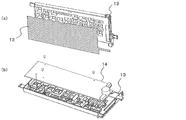

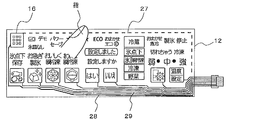

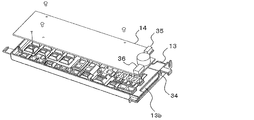

- FIG. 3 is an exploded perspective view of the operation display panel 6.

- FIG. 4 is a detailed view of the operation display panel 6 of FIG. 3, (a) shows the transparent electrode sheet 12 and the support component 13, and (b) shows the support component 13 and the electronic substrate 14.

- the operation display panel 6 is composed of a capacitive touch sensor that operates by detecting the amount of change in capacitance.

- the transparent electrode sheet 12 is composed of a laminated sheet in which layers having various functions are laminated, and corresponds to the “laminated sheet” of the present invention.

- the operation display panel 6 includes a transparent member 11, a transparent electrode sheet 12, a support component 13 that supports the transparent electrode sheet 12, an electronic board 14 that includes a microcomputer and a light source 25, and holds them.

- the holding component 15 is divided into five elements.

- the material of the transparent member 11 is not particularly limited as long as it is transparent and can transmit light, such as glass or resin, and may be decorated by printing or the like as long as the light emitted from the light source 25 is transmitted.

- the support component 13 also has a function as a light shielding wall that shields light of adjacent icons. Further, an inexpensive light emitting diode is often used as the light source 25, but another light source may be used.

- the transparent member 11 constitutes a part of the door of the refrigerator 1 and corresponds to the “transparent plate member” of the present invention.

- the support component 13 supports the transparent electrode sheet 12 and corresponds to a “support member” of the present invention.

- the microcomputer (not shown) takes in a signal detected by the transparent electrode sheet 12 as an operation signal and controls lighting of the plurality of light emitting sources 25, and corresponds to a “control device” of the present invention.

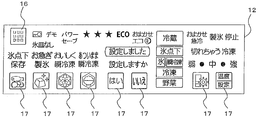

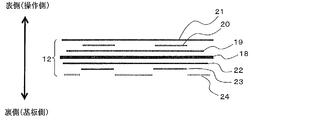

- FIG. 5 is an external view of the transparent electrode sheet 12, and FIG. 6 is a cross-sectional view of the transparent electrode sheet 12.

- FIG. 5 shows a state in which all the display elements of the transparent electrode sheet 12 are displayed, but only the start button 16 is displayed in the initial state. When the start button 16 of the transparent electrode sheet 12 is touched, the operation icon 17 is displayed (lighted). Note that FIG. 5 is shown in a state where black and white are reversed for the sake of drawing. This also applies to FIGS. 8 and 9 described later.

- the configuration cross section of the transparent electrode sheet 12 has a pattern wiring layer 19, a transparent conductive ink layer 20, and an insulating ink layer 21 formed on the front side (operation side) with a transparent substrate 18 as the center, and an icon on the back side (substrate side).

- a printing layer (light-shielding layer) 22, a light diffusion printing layer 23, and a paste printing layer 24 are formed.

- the transparent electrode sheet 12 is supported by sticking the transparent electrode sheet 12 having such a configuration to the support component 13.

- a transparent conductive ink layer 20 is printed on the start button 16 portion, and a transparent conductive ink layer 20, an icon print layer 22 and a light diffusion print layer 23 are printed on the operation icon portion.

- the pattern wiring layer 19 is a colored wiring pattern that connects the transparent conductive ink layer 20 and the electronic substrate 14.

- the pattern wiring layer 19 includes a plurality of conductive wirings arranged in parallel and corresponds to “a plurality of conductive wirings” of the present invention, and the transparent conductive ink layer 20 detects a change in capacitance.

- the icon print layer (light shielding layer) 22 has a pattern for displaying a plurality of shapes such as characters and symbols (see FIG. 5), and corresponds to the “light shielding layer” of the present invention.

- the light diffusion printing layer 23 diffuses the light irradiated from the light source 25 and corresponds to the “light diffusion layer” of the present invention.

- FIG. 7 is a cross-sectional view of the operation display panel 6 and shows the entire components of the operation display panel 6.

- the operation icon 17 When the operation icon 17 is displayed (when lit), the light emission source 25 is lit, and this light passes through the transparent conductive ink layer 20, the icon print layer 22, the light diffusion print layer 23, and the transparent member 11. The icon is displayed and visually recognized.

- the operation icon 17 When the operation icon 17 is touched, the operation is accepted.

- the light emission source 25 is arranged for each of the start button 16, the operation icon 17, and the word (character group) formed on the icon print layer 22, and the light diffusion print layer 23 also emits light for each icon or word. It is configured as follows.

- the reflected light of the light source 25 can be effectively used for the icon part, and the visibility is further enhanced.

- a transparent member such as a white member

- a part of the light from the light emission source 25 may be transmitted through the support component 13 and the adjacent icon may be mistakenly illuminated.

- a double wall 26 is formed on the support part 13. Thereby, transmission of light can be suppressed.

- the double wall 26 corresponds to the “light-shielding wall” of the present invention.

- the transparent conductive ink layer 20 that senses a change in capacitance is transmitted to the electronic substrate 14.

- the pattern wiring layer 19, the icon print layer 22 that changes the light emitted from the light emission source 25 into an icon, and the light diffusion print layer 23 that changes the light into a surface emission are integrated into one transparent base material (film base material) 18.

- the transparent member 11 since the icons and characters (words) are displayed through the transparent member 11 with the light emitting source 25 turned on, the visibility is very excellent, and the operation display panel 6 is easy to use for users of any age. It has become. Furthermore, by devising the shapes of the transparent electrode sheet 12 and the support component 13, it is possible to realize surface emission equal to or higher than that when using the light guide plate, and further increase the visibility without increasing the number of components. It has become. In addition, you may make it the transparent member 11 comprise a part of door of the refrigerator 1 as a decorated design component.

- FIG. FIG. 8 is an external view of the transparent electrode sheet 12 according to Embodiment 2 of the present invention.

- the start button 16 For each wiring pattern of the pattern wiring layer 19, there are many ways to route the wiring pattern. For example, how to wire the start button 16 will be described. If the wiring of the start button 16 is drawn like the single wiring 27, when the finger touches the wiring portion, the start button 16 reacts, which may lead to a malfunction. When this is a single wiring, the parasitic capacitance is reduced, and not only the transparent conductive ink layer 20 but also the wiring portion is in a highly sensitive state, and as a result, the start button 16 reacts.

- the pattern wiring is gathered together on one side together with another pattern wiring group 29 in which a plurality of wirings are gathered in parallel.

- the parasitic capacitance of the wiring of the button 16 is lower than that of the single wiring as a result.

- the sensitivity of the wiring portion becomes dull, and malfunction of the start button 16 can be prevented. Therefore, it is possible to prevent malfunction of each button by collecting the wiring group.

- Such a wiring structure may be applied to operation buttons other than the start button 16.

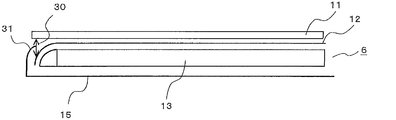

- FIG. 9 is a view showing a modification of the transparent electrode sheet 12 of FIG. 8, and FIG. 10 is a cross-sectional view of the operation display panel 6 including the transparent electrode sheet 12 of FIG.

- the shape of the transparent electrode sheet 12 (and the transparent substrate 18) is partially extended to the left.

- the individual wiring 27 of the start button 16 is placed over the extended part.

- the extended portion of the transparent electrode sheet 12 is curved along the support component 13 and attached to the support component 13, and the air gap 30 is interposed between the transparent member 11 and the transparent electrode sheet 12.

- an inlay structure 31 is formed in the holding component 15, and the transparent electrode sheet 12 in a curved state is accommodated in the inlay structure 31.

- the transparent electrode sheet 12 is curved and attached to the support component 13, and the adhesive force may weaken and peel off. However, even if the transparent electrode sheet 12 is peeled off, the transparent electrode sheet 12 remains curved with the inlay structure 31. As a result, the state in which the air gap 30 is formed can be maintained.

- any location where the air gap 30 is formed is effective for preventing malfunctions as long as it is a wiring portion, and can be arbitrarily set according to the order of the peripheral structure and icon arrangement.

- the air gap 30 may be formed in the portion of the composite wiring 28.

- FIG. 11 is a cross-sectional view of the operation display panel 6 according to Embodiment 3 of the present invention.

- a light shielding wall 13a that shields light from the light source 25 adjacent to the support component 13 is formed, and a tapered surface 32 is provided on the light shielding wall 13a.

- a tapered surface is formed in the light guide portion formed between the adjacent light shielding walls 13a and the light shielding wall 13a, thereby blocking the light emitted from the light emitting source 25.

- the light can be delivered to the icon print layer 22 of the transparent electrode sheet 12.

- the angle of the taper surface 32 is larger than the irradiation range 33 of the light emitting source 25, there is a restriction on the structure. Therefore, the visibility can be improved without necessarily using such an angle.

- the color of the support component 13 (the light shielding wall 13a) is set to white or a color similar thereto, the reflected light of the light source 25 can be effectively used for the icon print layer 22 and visually recognized. Sexuality further increases.

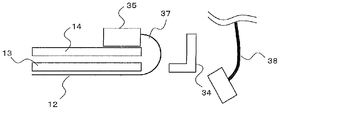

- FIG. 12 is an exploded perspective view of the operation display panel according to Embodiment 4 of the present invention

- FIG. 13 is a detailed view of the connector connecting portion of FIG.

- a partition plate 34 is formed on the support component 13

- a transparent electrode sheet connection connector 35 and a main body lead wire connection connector 36 are provided on the electronic substrate 14, respectively.

- the transparent electrode sheet connecting portion 37 is formed as a part of the transparent electrode sheet 12 so as to be continuous with the composite wiring 28 in FIG.

- the transparent electrode sheet connection part 37 is connected to the transparent electrode sheet connection connector 35 through the opening 13 b formed in the support component 13.

- the main body lead wire 38 drawn from the door of the refrigerator 1 is connected to the main body lead wire connector 36.

- the partition plate 34 is provided so that the transparent electrode sheet connecting portion 37 and the main body lead wire 38 are not in close contact with the support component 13. That is, the partition plate 34 protects the transparent electrode sheet connection part 37 by partitioning the transparent electrode sheet connection part 37 and the main body lead wire 38 so as not to contact each other. As a result, an unintended operation of the operation display panel 6 can be prevented.

- the transparent electrode sheet connecting portion 37 corresponds to the “strip-shaped portion where a plurality of conductive wirings are formed” of the present invention formed on the transparent electrode sheet 12.

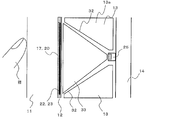

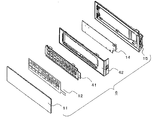

- FIG. 14 is an exploded perspective view of the operation display panel according to Embodiment 5 of the present invention, showing the entire components of the operation display panel, and FIG. 15 is attached with the operation display panel of FIG. It is a front view of a refrigerator. 14 and 15, the same reference numerals as those in FIGS. 3 and 1 denote the same or corresponding parts.

- the operation display panel 6 includes a transparent member 11, a transparent electrode sheet 12, a light guide component 41, an outer component 42, an electronic substrate 14 and a holding component 15, and is roughly divided into six elements.

- the light guide component 41 and the outer component 42 have the function of the support component 13 in FIG.

- the light guide component 41 is for guiding light from the light emitting source 25 to the transparent electrode sheet 12, and the outer component 42 is for supporting the light guide component 41.

- the operation display panel 6 is configured as described above, after the transparent electrode sheet 12 is attached to the outer part 42, the transparent electrode sheet 12 and the electronic substrate 14 are connected by a connector, and then the light guide part 41 Can be incorporated. For this reason, since the transparent electrode sheet 12 is attached to the outer shell part 42 and is connected to the electronic substrate 14 by the connector, workability is improved and productivity is improved.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- Thermal Sciences (AREA)

- General Engineering & Computer Science (AREA)

- General Physics & Mathematics (AREA)

- Theoretical Computer Science (AREA)

- Cold Air Circulating Systems And Constructional Details In Refrigerators (AREA)

- Illuminated Signs And Luminous Advertising (AREA)

- Switches That Are Operated By Magnetic Or Electric Fields (AREA)

Abstract

Description

図1は、本発明の実施の形態1に係る冷蔵庫の正面図である。

図1に示されるように、冷蔵庫1は、冷蔵室100、切替室200、製氷室300、冷凍室400及び野菜室500を備えている。冷蔵室100は、開閉ドアを備え、最上部に配置されている。切替室200は、引き出しドアを備え、冷蔵室100の下方に配置され、冷凍温度帯(-18℃)から冷蔵(3℃)、チルド(0℃)、ソフト冷凍(-7℃)などの各温度帯に切り替えることができる。製氷室300は、引き出しドアを備え、切替室200と並列に配置されている。冷凍室400は、引き出しドアを備え、切替室200と製氷室300の下方に配置されている。野菜室500は、引き出しドアを備え、最下部に配置されている。

図2に示されるように、冷蔵庫1は、圧縮機2、冷却器3及び送風ファン4を備えている。送風ファン4は、冷却器3によって冷却された冷気を冷蔵庫1内の各部屋へ風路5を介して送風する。風路5は、冷却器3によって冷却された冷気を各部屋へ導入するための風路である。つまり、冷却器3で冷却された冷気は、風路5を通り、冷凍室400、切替室200、製氷室300、冷蔵室100へと送風されて各部屋を冷却する。野菜室500は、冷蔵室100の戻り冷気が冷蔵室用帰還風路(図示せず)を循環して冷却され、そして、野菜室用帰還風路(図示せず)から冷却器3に戻される。各部屋の温度は、各部屋に設置された図示しないサーミスタにより検知され、予め設定された温度になるように、風路5に設置された図示しないダンパの開度、圧縮機2の能力及び送風ファン4の送風量を調整することで制御される。

図3は、操作表示パネル6の分解斜視図である。図4は、図3の操作表示パネル6の詳細図であり、(a)は透明電極シート12と支持部品13とを示し、(b)は支持部品13と電子基板14とを示している。操作表示パネル6は、静電容量の変化量を検知して動作する、静電容量式タッチセンサーから構成されている。また、透明電極シート12は、各機能を持った層が積層された積層シートから構成されており、本発明の「積層シート」に相当する。

図5は、透明電極シート12の外観図であり、図6は、透明電極シート12の断面図である。なお、図5は透明電極シート12の全ての表示要素を表示させた状態を示しているが、初期状態ではスタートボタン16だけが表示されている。透明電極シート12のスタートボタン16にタッチすると、操作アイコン17が表示(点灯)される。なお、図5は、作図の都合上、白黒を反転させた状態で図示されている。このことは、後述の図8及び図9においても同様である。

操作アイコン17が表示される時(点灯時)には発光源25が点灯しており、この光が透明導電インク層20、アイコン印刷層22及び光拡散印刷層23と、透明部材11とを介して、アイコンが表示されて視認される。また、操作アイコン17がタッチされると操作を受け付ける。なお、発光源25は、アイコン印刷層22に形成されたスタートボタン16、操作アイコン17、文言(文字群)毎に配置されており、光拡散印刷層23もまたアイコン又は文言毎に面発光するように構成されている。

図8は、本発明の実施の形態2に係る透明電極シート12の外観図である。

パターン配線層19の各配線パターンについて、引き回し方は多々あるが、例えばスタートボタン16の配線の引き方について説明する。スタートボタン16の配線を単独配線27のようなパターンの引き方をすると、この配線部分に指が触れた際に、スタートボタン16が反応してしまい、誤動作につながるおそれがある。これは単独配線にすると寄生容量が小さくなり、透明導電インク層20だけでなく、配線部も感度が高い状態となっており、その結果、スタートボタン16が反応してしまう。

図9に示されるように、透明電極シート12(及び透明な基材18)の形状を左側に一部延長させる。そして、スタートボタン16の単独配線27を延長させた部分に這わせるようにする。さらに、図10に示されるように、支持部品13に沿って透明電極シート12の延長した部分を湾曲させて支持部品13に貼付させ、透明部材11と透明電極シート12との間にエアギャップ30を作り出す。このように構成することによって、指が配線部分(特に単独配線27)のある透明部材11に触れたときでも、静電容量の変化を皆無にすることが可能である。このようにエアギャップ30を作り出すことによって、誤動作の防止が可能となる。

次に、面発光においてさらに視認性を向上させた例を実施の形態3として説明する。

図11は、本発明の実施の形態3に係る操作表示パネル6の断面図である。

図11に示されるように、支持部品13に隣接する発光源25からの光を遮光する遮光壁13aを形成し、遮光壁13aにテーパ面32を設ける。このように遮光壁13aを設けることによって、隣接する遮光壁13aと遮光壁13aとの間に形成される導光部にテーパ面が形成されることとなり、発光源25から出た光を遮ることなく、透明電極シート12のアイコン印刷層22まで光を届けることができる。

図12は、本発明の実施の形態4に係る操作表示パネルの分解斜視図であり、図13は、図12のコネクタ接続部分の詳細図である。

図12及び図13に示されるように、支持部品13に仕切り板34が形成されており、電子基板14には透明電極シート接続コネクタ35及び本体リード線接続コネクタ36がそれぞれ設けられている。透明電極シート接続部37は、透明電極シート12の一部として、図8の複合配線28に連続して帯状に形成されている。透明電極シート接続部37は、支持部品13に形成された開口部13bを介して、透明電極シート接続コネクタ35に接続される。また、冷蔵庫1の扉から引き回された本体リード線38は本体リード線接続コネクタ36に接続される。その際に、透明電極シート接続部37と本体リード線38とが密着した状態で、本体リード線38に電流が流れると、透明電極シート接続部37に誘導電流が流れ、各操作アイコン17を操作していなくても勝手に操作表示パネル6が作動してしまうおそれがある。これを防止するために、支持部品13に透明電極シート接続部37と本体リード線38とが密着しないように、上記の仕切り板34が設けられている。つまり、仕切り板34は、透明電極シート接続部37と本体リード線38とが接触しないように仕切って、透明電極シート接続部37を保護している。その結果、操作表示パネル6の意図しない動作を防ぐことができる。なお、透明電極シート接続部37は、透明電極シート12に形成された本発明の「複数の導電配線が形成された帯状の部位」に相当する。

図14は、本発明の実施の形態5に係る操作表示パネルの分解斜視図であり、操作表示パネルの全体の構成要素を示しており、図15は、図14の操作表示パネルが取り付けられた冷蔵庫の正面図である。図14及び図15において、図3及び図1と同じ符号のものは同一又は相当部を示すものとする。

操作表示パネル6は、透明部材11、透明電極シート12、導光部品41、外郭部品42、電子基板14及び保持部品15を備えており、大きく6つの要素に分けられる。図3の支持部品13の機能を、本実施の形態においては、導光部品41及び外郭部品42が担っている。導光部品41は発光源25からの光を透明電極シート12に導くためのものであり、外郭部品42は導光部品41を支持するものである。

Claims (11)

- 操作表示部を備えた冷蔵庫において、

前記操作表示部は、

透明な板部材と、

前記透明な板部材の裏面側に設けられ、少なくなくとも静電容量の変化を検知する積層シートと、

前記積層シートの前記透明な板部材側とは反対側に設けられ、前記積層シートに光を照射する複数の発光源、及び前記積層シートによって検知された信号を操作信号として取り込むとともに、前記複数の発光源の点灯を制御する制御装置が搭載された電子基板と、

を備え、

前記積層シートは、

透明な基材と、

前記透明な基材の前記透明な板部材側に設けられ、静電容量の変化を検知する複数の透明な導電部材と、

前記透明な基材の前記電子基板側に設けられ、文字及び図柄の少なくとも1以上の形状を表示させるためのパターンを有する遮光層と、

前記遮光層の前記電子基板側に設けられ、前記発光源から照射された光を拡散する光拡散層と

を備えた、冷蔵庫。 - 前記複数の発光源の間に設けられた遮蔽壁をさらに備えた、

請求項1に記載の冷蔵庫。 - 前記導電部材及び前記遮光層は、前記透明な基材にそれぞれ印刷された、

請求項1又は2に記載の冷蔵庫。 - 前記光拡散層は、前記遮光層の上に印刷された

ことを特徴とする請求項3に記載の冷蔵庫。 - 前記積層シートは、前記複数の導電部材によって検知された信号を前記電子基板に伝達するための複数の導電配線をさらに備え、前記複数の導電配線は並行して配設された、

請求項1~4の何れか一項に記載の冷蔵庫。 - 前記積層シートの前記導電配線が配設された部分と、前記透明な板部材との間に隙間を設けた、

請求項5に記載の冷蔵庫。 - 前記遮蔽壁は、壁面が白色である、

請求項2、又は請求項2に従属する請求項3~6の何れか一項に記載の冷蔵庫。 - 前記遮蔽壁は、前記発光源から前記透明な板部材に向かって間口が広がるように、角度をつけて形成されている、

請求項2、又は請求項2に従属する請求項3~7の何れか一項に記載の冷蔵庫。 - 前記積層シートと前記電子基板との間に介在するように設けられ、前記積層シートを支持する支持部材を備え、

前記遮蔽壁は前記支持部材に形成された、

請求項8に記載の冷蔵庫。 - 前記積層シートは、前記電子基板と接続するために、前記複数の導電配線が形成された帯状の部位を備え、

前記支持部材は、前記帯状の部位と前記電子基板との結合部に、当該帯状の部位を保護するように設けられた仕切り板を備えた、

請求項9に記載の冷蔵庫。 - 前記支持部材は、

前記発光源からの光を前記積層シートに導く導光部品と、

前記導光部品を支持する外郭部品とを備えた、

請求項9又は10に記載の冷蔵庫。

Priority Applications (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| RU2017101960A RU2653098C1 (ru) | 2014-06-24 | 2015-02-05 | Холодильник |

| SG11201609736WA SG11201609736WA (en) | 2014-06-24 | 2015-02-05 | Refrigerator |

| AU2015282309A AU2015282309B2 (en) | 2014-06-24 | 2015-02-05 | Refrigerator |

| TW104105995A TWI616630B (zh) | 2014-06-24 | 2015-02-25 | refrigerator |

| CN201510290017.XA CN105318645B (zh) | 2014-06-24 | 2015-05-29 | 冰箱 |

| CN201520363743.5U CN204923677U (zh) | 2014-06-24 | 2015-05-29 | 冰箱 |

| HK16107981.8A HK1219998A1 (zh) | 2014-06-24 | 2016-07-08 | 冰箱 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014129408A JP6198682B2 (ja) | 2014-06-24 | 2014-06-24 | 冷蔵庫 |

| JP2014-129408 | 2014-06-24 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2015198619A1 true WO2015198619A1 (ja) | 2015-12-30 |

Family

ID=54937723

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2015/053289 WO2015198619A1 (ja) | 2014-06-24 | 2015-02-05 | 冷蔵庫 |

Country Status (9)

| Country | Link |

|---|---|

| JP (1) | JP6198682B2 (ja) |

| CN (2) | CN105318645B (ja) |

| AU (1) | AU2015282309B2 (ja) |

| HK (1) | HK1219998A1 (ja) |

| MY (1) | MY174807A (ja) |

| RU (1) | RU2653098C1 (ja) |

| SG (1) | SG11201609736WA (ja) |

| TW (1) | TWI616630B (ja) |

| WO (1) | WO2015198619A1 (ja) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPWO2017149680A1 (ja) * | 2016-03-01 | 2018-07-05 | 三菱電機株式会社 | 静電容量式タッチパネル |

| JPWO2020255245A1 (ja) * | 2019-06-18 | 2021-11-18 | 三菱電機株式会社 | 冷蔵庫 |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6198682B2 (ja) * | 2014-06-24 | 2017-09-20 | 三菱電機株式会社 | 冷蔵庫 |

| JP6188668B2 (ja) * | 2014-11-27 | 2017-08-30 | 三菱電機株式会社 | 冷蔵庫 |

| JP7080677B2 (ja) * | 2018-03-07 | 2022-06-06 | 株式会社オカムラ | 表面構成部材 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS50146072U (ja) * | 1974-05-22 | 1975-12-03 | ||

| JP2009043473A (ja) * | 2007-08-07 | 2009-02-26 | Kojima Press Co Ltd | スイッチ |

| JP2010015557A (ja) * | 2008-06-30 | 2010-01-21 | Seoul Semiconductor Co Ltd | 電子装置及び電子装置用タッチセンサーフィルム |

| JP2011058696A (ja) * | 2009-09-09 | 2011-03-24 | Hitachi Appliances Inc | 冷蔵庫 |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101237564B1 (ko) * | 2006-11-18 | 2013-02-26 | 엘지전자 주식회사 | 냉장고용 디스플레이부 |

| JP2010067551A (ja) * | 2008-09-12 | 2010-03-25 | Koha Co Ltd | バックライト装置 |

| JP2012018465A (ja) * | 2010-07-06 | 2012-01-26 | Tokai Rika Co Ltd | 操作入力装置及びその制御方法 |

| JP2012099438A (ja) * | 2010-11-05 | 2012-05-24 | Sharp Corp | タッチスイッチ |

| JP5779485B2 (ja) * | 2011-09-08 | 2015-09-16 | 日立アプライアンス株式会社 | 冷蔵庫 |

| JP5996174B2 (ja) * | 2011-09-27 | 2016-09-21 | 東芝ライフスタイル株式会社 | 冷蔵庫 |

| CN102707487B (zh) * | 2012-06-04 | 2014-11-19 | 青岛海信电器股份有限公司 | 透明显示装置及具有透明显示装置的电子设备 |

| JP2014031956A (ja) * | 2012-08-03 | 2014-02-20 | Panasonic Corp | 冷蔵庫及び表示装置 |

| JP5881554B2 (ja) * | 2012-08-09 | 2016-03-09 | 三菱電機株式会社 | 操作装置及び冷凍冷蔵庫 |

| JP6198682B2 (ja) * | 2014-06-24 | 2017-09-20 | 三菱電機株式会社 | 冷蔵庫 |

-

2014

- 2014-06-24 JP JP2014129408A patent/JP6198682B2/ja active Active

-

2015

- 2015-02-05 WO PCT/JP2015/053289 patent/WO2015198619A1/ja active Application Filing

- 2015-02-05 AU AU2015282309A patent/AU2015282309B2/en active Active

- 2015-02-05 MY MYPI2016704699A patent/MY174807A/en unknown

- 2015-02-05 RU RU2017101960A patent/RU2653098C1/ru active

- 2015-02-05 SG SG11201609736WA patent/SG11201609736WA/en unknown

- 2015-02-25 TW TW104105995A patent/TWI616630B/zh active

- 2015-05-29 CN CN201510290017.XA patent/CN105318645B/zh active Active

- 2015-05-29 CN CN201520363743.5U patent/CN204923677U/zh not_active Withdrawn - After Issue

-

2016

- 2016-07-08 HK HK16107981.8A patent/HK1219998A1/zh unknown

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS50146072U (ja) * | 1974-05-22 | 1975-12-03 | ||

| JP2009043473A (ja) * | 2007-08-07 | 2009-02-26 | Kojima Press Co Ltd | スイッチ |

| JP2010015557A (ja) * | 2008-06-30 | 2010-01-21 | Seoul Semiconductor Co Ltd | 電子装置及び電子装置用タッチセンサーフィルム |

| JP2011058696A (ja) * | 2009-09-09 | 2011-03-24 | Hitachi Appliances Inc | 冷蔵庫 |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPWO2017149680A1 (ja) * | 2016-03-01 | 2018-07-05 | 三菱電機株式会社 | 静電容量式タッチパネル |

| JPWO2020255245A1 (ja) * | 2019-06-18 | 2021-11-18 | 三菱電機株式会社 | 冷蔵庫 |

| JP7195429B2 (ja) | 2019-06-18 | 2022-12-23 | 三菱電機株式会社 | 冷蔵庫 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN204923677U (zh) | 2015-12-30 |

| RU2653098C1 (ru) | 2018-05-07 |

| AU2015282309A1 (en) | 2016-12-15 |

| JP2016009586A (ja) | 2016-01-18 |

| TW201600821A (zh) | 2016-01-01 |

| TWI616630B (zh) | 2018-03-01 |

| SG11201609736WA (en) | 2016-12-29 |

| AU2015282309B2 (en) | 2017-11-02 |

| HK1219998A1 (zh) | 2017-04-21 |

| CN105318645A (zh) | 2016-02-10 |

| JP6198682B2 (ja) | 2017-09-20 |

| CN105318645B (zh) | 2017-09-15 |

| MY174807A (en) | 2020-05-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6198682B2 (ja) | 冷蔵庫 | |

| US10941982B2 (en) | Refrigerator | |

| KR102011019B1 (ko) | 냉장고 | |

| CN107388705B (zh) | 冰箱 | |

| US10619909B2 (en) | Refrigerator | |

| JP2012021696A (ja) | 冷蔵庫 | |

| JP2014137147A (ja) | 冷蔵庫 | |

| JP6437756B2 (ja) | 冷蔵庫 | |

| JP2016102603A (ja) | 冷蔵庫 | |

| KR101883320B1 (ko) | 냉장고 | |

| US20100225499A1 (en) | Device for inputting control commands | |

| JP2015203525A (ja) | 冷蔵庫 | |

| TW201804185A (zh) | 顯示裝置及具備其之冰箱 | |

| JP2014126304A (ja) | 冷蔵庫 | |

| WO2014024631A1 (ja) | 操作装置及び冷蔵冷凍庫 | |

| KR100993054B1 (ko) | 냉장고 | |

| JP2019027759A (ja) | 冷蔵庫 | |

| JP7195429B2 (ja) | 冷蔵庫 | |

| JP7178771B2 (ja) | 冷蔵庫 | |

| US10527344B2 (en) | Appliance user interface and display | |

| JP2020034168A (ja) | 冷蔵庫 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 15810819 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2015282309 Country of ref document: AU Date of ref document: 20150205 Kind code of ref document: A |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 2017101960 Country of ref document: RU Kind code of ref document: A |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 15810819 Country of ref document: EP Kind code of ref document: A1 |