WO2015152086A1 - 運用計画作成評価装置及び運用計画作成評価方法 - Google Patents

運用計画作成評価装置及び運用計画作成評価方法 Download PDFInfo

- Publication number

- WO2015152086A1 WO2015152086A1 PCT/JP2015/059753 JP2015059753W WO2015152086A1 WO 2015152086 A1 WO2015152086 A1 WO 2015152086A1 JP 2015059753 W JP2015059753 W JP 2015059753W WO 2015152086 A1 WO2015152086 A1 WO 2015152086A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- operation plan

- parts

- evaluation

- event

- job

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02C—GAS-TURBINE PLANTS; AIR INTAKES FOR JET-PROPULSION PLANTS; CONTROLLING FUEL SUPPLY IN AIR-BREATHING JET-PROPULSION PLANTS

- F02C9/00—Controlling gas-turbine plants; Controlling fuel supply in air- breathing jet-propulsion plants

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/005—Repairing methods or devices

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B15/00—Systems controlled by a computer

- G05B15/02—Systems controlled by a computer electric

-

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q10/00—Administration; Management

- G06Q10/20—Administration of product repair or maintenance

-

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q50/00—Information and communication technology [ICT] specially adapted for implementation of business processes of specific business sectors, e.g. utilities or tourism

- G06Q50/10—Services

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2220/00—Application

- F05D2220/30—Application in turbines

- F05D2220/32—Application in turbines in gas turbines

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2260/00—Function

- F05D2260/80—Diagnostics

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2260/00—Function

- F05D2260/82—Forecasts

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2270/00—Control

- F05D2270/01—Purpose of the control system

- F05D2270/11—Purpose of the control system to prolong engine life

- F05D2270/112—Purpose of the control system to prolong engine life by limiting temperatures

Definitions

- the present invention relates to an operation plan creation and evaluation device for parts and an operation plan creation and evaluation method.

- an object of the present invention is to provide an operation plan creation evaluation apparatus and an operation plan creation evaluation method that can create an operation plan for an optimal part.

- the operation plan creation evaluation apparatus of the present invention is an operation plan creation evaluation apparatus for creating an operation plan for parts used in equipment and evaluating the created operation plan, and master information relating to the equipment and the parts, A storage unit storing generation information related to the equipment and the parts generated when the operation plan is created, and an initial factor used when creating the operation plan, the master information, the generation information, and A control unit that creates the operation plan based on the initial factor, and the control unit provides a factor setting process that gives a predetermined set value as the initial factor, and the initial factor that becomes the set value, Based on the master information and the generated information, the operation plan creation process for creating the operation plan, and the operation plan while changing the initial factor in the factor setting process Each of the plurality of the operation plan that is created by repeating the deposition process was evaluated, and executes a a production plan evaluation process of deriving the operational plan for the optimization.

- the operation plan creation evaluation method of the present invention is an operation plan creation evaluation method for creating an operation plan for parts used in equipment and evaluating the created operation plan.

- Factor setting step for giving a predetermined set value as an initial factor to be used, the initial factor to be the set value, master information on the equipment and the parts, and the equipment generated when creating the operation plan and the Based on generation information related to parts, an operation plan creating step for creating the operation plan, and a plurality of items created by repeatedly performing the operation plan creating step while changing the set values of the initial factors in the factor setting step

- Each of the operation plans is evaluated, and an operation plan evaluation step for deriving the optimum operation plan is performed.

- an operation plan can be created based on master information, generation information, and initial factors.

- a plurality of operation plans can be created by changing the setting values of the initial factors.

- an optimum operation plan can be derived by evaluating each of the plurality of operation plans.

- the master information includes operation job master information related to an operation job of the equipment

- the generation information includes individual item list information regarding individual usage status of the component

- the control unit includes the individual item list information.

- the master information includes operation job master information related to an operation job of the equipment, the generation information includes individual item list information regarding individual usage status of the component, and the control unit includes the individual item list information.

- the generation information includes individual remaining life information of the part, and the operation plan evaluation process calculates an evaluation value of the operation plan using an evaluation function for evaluating the operation plan.

- the evaluation function is preferably a function that includes at least one of a total remaining life, a predetermined evaluation scale, the number of new parts, and the number of discarded parts as a variable.

- the evaluation value of the created operation plan can be calculated using the evaluation function. Therefore, by comparing the evaluation values corresponding to the operation plans, the operation plan having the smallest evaluation value can be evaluated as the optimum operation plan.

- / N) ⁇ P i ⁇ ”, and the purity P i is expressed by“ purity P i (1 /

- ”, and the evaluation function is“ evaluation value w 1 ⁇ total remaining life of all components + w 2 ⁇ (1 ⁇ purity) P weighted average of i) + w 3 ⁇ new part of the quantity + w 4 ⁇ disposal unit It is preferable that a function represented by the quantity

- w 4 from w 1 is a weighting.

- an event generation process for generating an event including an operation start event for starting the operation of the facility and an operation end event for stopping the operation of the facility, and the component in the operation start event

- An operation start event process that simulates the operation of the operation and an operation end event process that simulates the operation of the part in the operation end event, and the initial factor selects the part used in the operation start event

- the part is selected based on the set value set in the factor setting process.

- an inspection end event for ending the inspection of the part and a repair end event for ending repair of the part are generated.

- the part of the part in the inspection end event is generated. It is preferable to execute inspection end event processing that simulates operation and repair end event processing that simulates operation of the component in the repair end event.

- Another operation plan creation / evaluation apparatus of the present invention is an operation plan creation / evaluation apparatus that creates an operation plan for parts used in equipment and evaluates the created operation plan, and master information relating to the equipment and the parts

- a storage unit that stores generation information related to the equipment and parts generated when the operation plan is created, an initial factor used when creating the operation plan, the master information, and the generation

- a control unit that creates the operation plan based on the information and the initial factor, the control unit including a factor setting process that gives a predetermined set value as the initial factor, and the initial factor that becomes the set value

- an operation plan creation process for creating the operation plan based on the master information and the generation information, and the operation plan creation process starts operation of the equipment.

- An event generation process for generating an event including a turn start event and an operation end event for stopping the operation of the equipment, an operation start event process for simulating the operation of the component in the operation start event, and the operation end event.

- An operation end event process that simulates the operation of the part, and the initial factor is a factor for selecting the part to be used in the operation start event.

- the factor The component is selected based on the set value set in the setting process.

- an operation plan can be created based on master information, generation information, and initial factors.

- a plurality of operation plans can be created by changing the setting values of the initial factors. Therefore, it is possible to create an operation plan that is useful in deriving an optimal operation plan.

- Another operation plan creation / evaluation apparatus of the present invention is an operation plan creation / evaluation apparatus that creates an operation plan for parts used in equipment and evaluates the created operation plan, and master information relating to the equipment and the parts

- a storage unit that stores generation information related to the equipment and the parts that are generated when the operation plan is created, a control unit that creates the operation plan based on the master information and the generation information, The control unit evaluates each of the operation plan creation process for creating the operation plan and the plurality of operation plans created by the operation plan creation process based on the master information and the generation information.

- the operation plan evaluation process for deriving the optimum operation plan is executed, and the generation information includes individual remaining life information of the parts, and the operation plan evaluation process

- the evaluation value of the operation plan is calculated using an evaluation function for evaluating the operation plan, and the evaluation function is a total remaining life obtained by adding up the remaining lives of all the components, and a predetermined evaluation scale. And a function including at least one of the number of new parts and the number of discarded parts as a variable.

- the evaluation value of the created operation plan can be calculated using the evaluation function. Therefore, by comparing the evaluation values corresponding to a plurality of operation plans, the operation plan having the smallest evaluation value can be evaluated as the optimum operation plan.

- FIG. 1 is a schematic configuration diagram of an operation plan creation / evaluation apparatus according to the present embodiment.

- FIG. 2 is an explanatory diagram showing component master data.

- FIG. 3 is an explanatory diagram showing operation master data.

- FIG. 4 is an explanatory diagram showing operation condition master data.

- FIG. 5 is an explanatory diagram showing inspection master data.

- FIG. 6 is an explanatory diagram showing component damage master data.

- FIG. 7 is an explanatory diagram showing repair master data.

- FIG. 8 is an explanatory diagram showing event queue data.

- FIG. 9 is an explanatory diagram showing individual item list data.

- FIG. 10 is an explanatory diagram showing new input item list data.

- FIG. 11 is an explanatory diagram showing waste list data.

- FIG. 12 is an explanatory diagram showing job execution result data.

- FIG. 1 is a schematic configuration diagram of an operation plan creation / evaluation apparatus according to the present embodiment.

- FIG. 2 is an explanatory diagram showing component master data.

- FIG. 3 is

- FIG. 13 is an explanatory diagram showing component allocation result data.

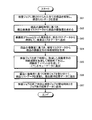

- FIG. 14 is a flowchart of the control operation related to the part operation plan creation / evaluation method.

- FIG. 15 is a flowchart of a control operation related to a part operation plan creation process.

- FIG. 16 is a flowchart of the control operation related to the operation start event process.

- FIG. 17 is a flowchart of the control operation related to the operation end event process.

- FIG. 18 is a flowchart of the control operation related to the examination end event process.

- FIG. 19 is a flowchart of the control operation related to the repair end event process.

- FIG. 20 is an explanatory diagram regarding the flow of various jobs in each facility.

- FIG. 21 is an explanatory diagram illustrating execution results of various jobs based on the part operation plan created by the operation plan creation / evaluation apparatus according to the present embodiment.

- FIG. 1 is a schematic configuration diagram of an operation plan creation / evaluation apparatus according to the present embodiment.

- 2 to 7 are explanatory diagrams showing various master data.

- 8 to 13 are explanatory diagrams showing various transaction data.

- FIG. 14 is a flowchart of the control operation related to the part operation plan creation / evaluation method.

- FIG. 15 is a flowchart of a control operation related to a part operation plan creation process.

- FIG. 16 is a flowchart of the control operation related to the operation start event process.

- FIG. 17 is a flowchart of the control operation related to the operation end event process.

- FIG. 18 is a flowchart of the control operation related to the examination end event process.

- FIG. 19 is a flowchart of the control operation related to the repair end event process.

- FIG. 20 is an explanatory diagram regarding the flow of various jobs in each facility.

- FIG. 21 is an explanatory diagram regarding an operation plan for parts created by the operation plan creation / evaluation apparatus according to the present embodiment

- an operation plan creation / evaluation apparatus 1 is an apparatus for creating an operation plan for parts and evaluating the created operation plan.

- parts for which an operation plan is made in this apparatus are high-temperature parts used in gas turbines (equipment).

- high-temperature parts include moving blades.

- the operation plan is a so-called handling plan in which replacement of high-temperature parts used and spare parts or replacement of high-temperature parts used and repaired high-temperature parts is performed. is there.

- This handling is not performed only between spare parts prepared in advance for the same gas turbine, but spare parts prepared in advance for different gas turbines of the same model, or different gases of the same or the same model. It is also performed between the repaired parts of the turbine.

- the operation plan creation / evaluation apparatus 1 includes an input unit 11, a display unit 12, a storage unit 13, and a control unit 14.

- the input unit 11 includes an input device such as a keyboard, and outputs a signal corresponding to an operation performed by the operator on the input device to the control unit 14.

- the display unit 12 includes a display device such as a liquid crystal panel, and display control is performed by the control unit 14.

- the storage unit 13 stores various programs and data.

- the programs stored in the storage unit 13 include an operation plan creation program for creating an operation plan for parts, an operation plan evaluation program for evaluating the created operation plan, and the like.

- the data stored in the storage unit 13 includes master data (master information), transaction data (generation information), and the like that are used in creating a part operation plan.

- Master data is basic data for creating parts operation plans, and is immutable (fixed) data. As shown in FIGS. 2 to 7, the master data includes parts master data D1, operation master data D2, operation condition master data D3, inspection master data D4, parts damage degree master data D5, repair master data D6, and the like. .

- the part master data D1 is master data including basic information about parts, and data that associates part numbers, part types, part classifications, design lifetimes, and production costs. It has become.

- the part number is handled by, for example, “part # 1”, “part # 2”, and is information for identifying the part.

- the component type is handled as, for example, “component type # 1”, “component type # 2”, and the like, and is information for identifying the type of component.

- the component classification is handled by, for example, “classification # 1”, “classification # 2”, and the like, and is information for identifying the classification of the component.

- the design life is information on the design life of the part.

- the production cost is information on the production cost of the part.

- the operation master data D2 is master data including basic information related to the operation of the gas turbine, and includes an operation job ID, equipment, start time, end time, and post-operation inspection type.

- the data is related to

- the operation job ID is handled, for example, as “operation # 1”, “operation # 2”, and the like, and is information for identifying the operation of the gas turbine in a predetermined period.

- the equipment is handled by, for example, “equipment # 1”, “equipment # 2”, and the like, and is information for identifying a gas turbine equipment (for example, a number machine).

- the start time is information relating to the start time of operation of the gas turbine in a predetermined facility.

- the end time is information relating to the end time of the operation of the gas turbine in the predetermined facility.

- the post-operation inspection type is information regarding the type of inspection performed after the operation of the gas turbine is completed.

- the operation condition master data D3 is master data including basic information regarding the operation conditions of the gas turbine, and includes an operation job ID, equipment, necessary component type, necessary component classification, and necessary information. This is data that associates the quantity with the consumption life. About operation job ID and equipment, since it is the same as that of the above-mentioned master data, explanation is omitted.

- the necessary parts classification is information on parts classification required for a predetermined operation job ID.

- the necessary quantity is information relating to the quantity of parts required for a predetermined operation job ID.

- the consumption life is information relating to the life of parts consumed in a predetermined operation job ID.

- the inspection master data D4 is master data including basic information on inspection, and is data in which an inspection type ID and an inspection period are associated with each other.

- the inspection type ID is handled by, for example, “inspection # 1”, “inspection # 2”, and is information for identifying the type of inspection.

- the inspection period is information related to the inspection period required for a predetermined inspection type.

- the part damage degree master data D5 is master data including basic information on the degree of damage of parts, and includes equipment, part type, operation time, part damage degree, and ratio.

- the associated data Since the equipment and the component type are the same as the master data described above, description thereof is omitted.

- the operation time is information related to the operation time accumulated by the parts, and different operation time ranges (for example, 0 to 12000, 12001 to 24000) are assigned to the predetermined parts.

- the part damage level is information for identifying the type of the damage level of the part. Examples of the damage level include “No Damage”, “Light”, “Medium”, “Heavy”, “Scrap”. (Disposal) ".

- the ratio is information indicating the ratio of parts reaching a predetermined degree of damage.

- the repair master data D6 is master data including basic information regarding repair, and includes equipment, a component type, a component damage degree (damage degree), a repair period, and a repair cost.

- the associated data The equipment, part type, and part damage level are the same as those in the master data described above, and thus description thereof is omitted.

- the repair period is information relating to a repair period required according to the degree of damage of the part.

- the repair cost is information relating to the repair cost required according to the degree of damage of the part.

- transaction data is data that is generated or updated when creating an operation plan for parts, and is variable data. As shown in FIG. 8 to FIG. 13, the transaction data includes event queue data D7, individual item list data D8, new input item list data D9, waste item list data D10, job execution result data D11 and component allocation result data D12. Etc.

- the event queue data D7 is data in which various events are arranged in a queue in the order of occurrence date, and is data in which an event ID, an event type, a job ID, and an occurrence date are associated with each other.

- the event ID is information for identifying the event that occurs.

- the event type is information for identifying the type of event that occurs, and examples of the event include a driving start event, a driving end event, an inspection end event, and a repair end event.

- the job ID is information for identifying the job type. Examples of the job include an operation job, an inspection job, and a repair job.

- the date of occurrence is information regarding the time of occurrence of the event.

- the individual item list data D8 is data related to the usage status of individual parts (hereinafter referred to as individual items), and includes individual item ID, component type, component classification, operation time, and allocation.

- the data is associated with the job ID. Since the component type and component classification are the same as the master data and transaction data described above, the description thereof is omitted.

- the individual item ID is information for identifying the individual item.

- the operation time is information related to the operation time accumulated by individual items.

- the allocation job ID is information relating to a job allocated to a predetermined individual product.

- the new input item list data D9 is data relating to a list of newly input individual items, and includes an individual item ID, a component type, a component classification, a component number, an operation time, The data is associated with the input date. Since the individual item ID, the component type, the component classification, the component number, and the operation time are the same as the master data and the transaction data, the description is omitted.

- the input date is information relating to the input timing of a newly introduced individual product.

- the waste item list data D10 is data relating to a list of individual items to be discarded, and includes an individual item ID, a component type, a component classification, a component number, an operation time, and a disposal date.

- the data is related to Since the individual item ID, the component type, the component classification, the component number, and the operation time are the same as the master data and the transaction data, the description is omitted.

- the disposal date is information regarding the disposal time of the discarded individual product.

- the job execution result data D11 is history data relating to various jobs that have been executed, and is data that associates the job ID, job type, start date, and end date. Since the job ID is the same as the transaction data described above, the description thereof is omitted.

- the job type is information regarding the job type.

- the start date is information related to the start time of a predetermined job.

- the end date is information relating to the end time of the predetermined job.

- the component allocation result data D12 is data relating to the history of jobs assigned to individual products, and data that associates individual product IDs, component types, component classifications, and allocation job IDs. It has become. Since the individual product ID, the component type, the component classification, and the allocation job ID are the same as the master data and transaction data described above, description thereof is omitted.

- the control unit 14 includes an integrated circuit, and executes various processes by executing a predetermined program. Specifically, the control unit 14 executes an operation plan creation process for creating an operation plan for parts by executing an operation plan creation program stored in the storage unit 13, or an operation stored in the storage unit 13. By executing the plan evaluation program, an operation plan evaluation process for evaluating the operation plan of the created part is executed.

- the operation plan creation process is a process for creating an operation plan based on the above master data and transaction data.

- an event generation process an operation start event process, an operation end event process, an inspection end event process, and a repair end event process are executed.

- the event generation process is a process for generating various events. For example, the event generation process generates a driving start event, a driving end event, an inspection end event, and a repair end event, and adds the generated event to the event queue data D7. ing.

- the operation start event process is a process for simulating the operation of parts in the operation start event, and details will be described later.

- the operation end event process is a process for simulating the operation of components in the operation end event, and details of this process will be described later.

- the inspection end event process is a process for simulating the operation of a part in the inspection end event, and details of this process will be described later.

- the repair end event process is a process for simulating the operation of parts in the repair end event, and details of this process will be described later.

- parts are selected based on initial parameters (initial factors) for selecting parts at the operation start event, and are selected at the operation start event.

- the operation plan of parts is created based on the parts. That is, when executing the operation plan creation process, the control unit 14 executes a factor setting process that gives a predetermined set value as an initial parameter. Details of the factor setting process will be described later.

- an evaluation value of the operation plan is calculated using an evaluation function for evaluating the operation plan.

- the evaluation function is a function including, as a variable, at least one of the total remaining life of all the individual products, the predetermined evaluation scale, the number of new parts, and the number of discarded parts in the created operation plan. It has become.

- k is the total number of individual items.

- the evaluation function f (z) becomes a better evaluation value as the calculated evaluation value is smaller.

- N is the number of driving jobs i

- C i is the set of individual items assigned to driving job i

- h is the driving job assigned to driving job i last time. a set of a certain individual product and a h.

- the weighted average of the purity P i is a calculation formula represented by the following formula (1)

- the purity P i has a calculation formula represented by the following formula (2) .

- / N) ⁇ P i ⁇ (1) Purity P i (1 /

- the weighted average of purity P i is applied as the evaluation measure, but instead of this, the number of driving jobs assigned last time among the individual items assigned to driving job i. H may be applied, or so-called entropy in clustering analysis may be applied, and there is no particular limitation.

- control unit 14 of the operation plan creation / evaluation apparatus 1 sets a predetermined set value as an initial parameter for selecting a part in an operation start event by executing a factor setting process (step S11: factor setting). Process).

- the control unit 14 executes an operation plan creation process, and creates a part operation plan z based on the set initial parameters, master data, and transaction data (step S12: operation plan creation step). Details of the control operation related to the creation of the part operation plan will be described later.

- control part 14 performs an operation plan evaluation process, and calculates the evaluation value of the operation plan z of the produced components using the evaluation function f (z) (step S13: operation plan evaluation process).

- control unit 14 resets initial parameters different from the initial parameters set in step S11 by executing a factor setting process (step S14: factor setting step).

- the control unit 14 executes an operation plan creation process, and creates a part operation plan z 'based on the reset initial parameters, master data, and transaction data (step S15: operation plan creation step).

- control part 14 performs an operation plan evaluation process, and calculates the evaluation value of the operation plan z 'of the produced components using the evaluation function f (z') (step S16: operation plan evaluation process) ).

- the control unit 14 determines whether or not the evaluation value f (z ′) of the operation plan z ′ calculated in step S16 is better than the evaluation value f (z) of the operation plan z calculated in step S13. Is determined (step S17). That is, when the evaluation value f (z ′) is an evaluation value (f (z ′) ⁇ f (z)) smaller than the evaluation value f (z), the evaluation value f (z ′) is the evaluation value f (z ) Is a better evaluation value.

- step S17 determines that f (z ′) is an evaluation value better than f (z) (step S17: Yes)

- the provisional solution is set as the operation plan z ′ (step S18), and the next step S19 is performed. Transition.

- step S17: No when determining that f (z ′) is not an evaluation value better than f (z) (step S17: No), the control unit 14 proceeds to the next step S19 without executing step S18.

- step S19 the control unit 14 determines whether the initial parameter resetting has been repeated a predetermined number of times. That is, one part operation plan is created for one initial parameter setting. For this reason, parts operation plans are created for the initial parameters set. At this time, the initial parameter to be set is changed little by little with respect to the other initial parameters.

- the control unit 14 may determine that the operation has been repeated a predetermined number of times when a part operation plan is created for all of the initial parameters prepared in advance in step S19. Further, in step S19, the control unit 14 may determine that the process has been repeated a predetermined number of times, or if the provisional solution has not been updated, the process has been repeated the predetermined number of times. That is, the predetermined number of times in step S19 can be arbitrarily set.

- step S19: Yes When it is determined in step S19 that the control unit 14 has been repeated a predetermined number of times (step S19: Yes), the provisional solution is determined as the optimal solution (step S20), and the control operation related to the operation plan creation evaluation method is terminated. On the other hand, if it determines with the control part 14 not having repeated predetermined number of times in step S19 (step S19: No), it will progress to step S14 again and will perform the control operation after step S14. As described above, the control unit 14 creates an operation plan for parts a predetermined number of times while changing the initial parameters little by little, and derives an operation plan with a good evaluation value (small evaluation value).

- the part operation plan is created by simulating (simulating) the handling of parts along the virtual date and time.

- control unit 14 of the operation plan creation / evaluation apparatus 1 acquires information on all the operation jobs from the operation master data D2 stored in the storage unit 13 (step S21). And the control part 14 performs an event production

- the control unit 14 determines whether or not there is an event in the event queue data D7 (step S23). When it is determined that there is no event in the event queue data D7 (step S23: Yes), the control unit 14 ends the control operation related to the creation of the part operation plan. On the other hand, when determining that there is an event in the event queue data D7 (step S23: No), the control unit 14 acquires the event from the event queue data D7, and deletes the acquired event from the event queue data D7 (step S23). S24). When acquiring the event, the control unit 14 sets the virtual date and time to the occurrence date (occurrence time) of the acquired event (step S25).

- step S26 determines whether or not the acquired event is a driving start event.

- step S26: Yes the control unit 14 executes a driving start event process (step S27), and proceeds to step S23 again.

- the operation start event process will be described later.

- step S26: No it will transfer to step S28.

- step S28 the control unit 14 determines whether or not the acquired event is a driving end event.

- step S28: Yes the control unit 14 executes a driving end event process (step S29), and proceeds to step S23 again.

- the operation end event process will be described later.

- step S28: No the control part 14 determines in step S28 that the acquired event is not a driving

- step S30 it will transfer to step S30.

- step S30 the control unit 14 determines whether the acquired event is an inspection end event.

- the control unit 14 determines that the acquired event is an inspection end event (step S30: Yes)

- the control unit 14 executes an inspection end event process (step S31), and proceeds to step S23 again.

- the inspection end event process will be described later.

- step S30: No the control unit 14 proceeds to step S32.

- the controller 14 determines that the acquired event is a repair end event in step S32, executes a repair end event process (step S32), and proceeds to step S23 again.

- control unit 14 executes various event processes until there is no event in the event queue data D7.

- the control part 14 performs the priority provision process which gives a priority with respect to the extracted several goods (step S43).

- a calculation formula represented by “priority coefficient ⁇ i ⁇ remaining life of individual product + (1 ⁇ coefficient ⁇ i ) ⁇ removal time of individual product removed last time” is used. Priorities are given to individual items. The calculation formula related to the priority has a higher priority as the calculated evaluation value is smaller. Then, the control unit 14 arranges the individual items in order of the calculated priority. At this time, the coefficient ⁇ i is in a range of 0 ⁇ ⁇ i ⁇ 1, and is handled as an initial parameter.

- the coefficient ⁇ i is a coefficient that determines the ratio between the remaining life of the individual product and the removal timing of the previously removed individual product.

- the control part 14 sets coefficient (alpha) i as a predetermined setting value in the setting of the initial parameter in FIG.14 S11 and step S14.

- a calculation formula represented by “priority” may be used.

- the control unit 14 executes a part selection process for selecting an individual item from among the individual items arranged in descending order of priority (step S44).

- a part selection process for selecting an individual item from among the individual items arranged in descending order of priority.

- the necessary quantity to be used in operating jobs Individual items are selected in order of priority.

- the predetermined quantity mi is handled as an initial parameter.

- the control unit 14 sets the predetermined quantity mi as a predetermined set value in the initial parameter setting in step S11 and step S14 of FIG.

- control unit 14 determines whether or not the remaining number of individual items is greater than or equal to the necessary amount (step S45).

- step S45 determines that the quantity of the remaining individual items is equal to or greater than the necessary quantity (step S45: Yes)

- the operation unit is allocated to the necessary quantity of individual items, and the individual item list data D8 is updated. It is added (recorded) to the component allocation result data D12 (step S47).

- step S45 determines that the quantity of the remaining individual items is less than the necessary quantity

- step S45: No the data of the deficient quantity of individual items is added to the individual item list data D8

- step S46 After adding the data for the short quantity of individual products to the new input product list data D9 (step S46), the process proceeds to step S47.

- step S47 the control unit 14 adds (records) the start time of the operation job to the job execution result data D11 (step S48), ends the control operation of the operation start event process, and FIG. The process proceeds to step S23.

- step S29 in FIG. 15 When the control unit 14 executes the operation end event process in step S29 in FIG. 15, first, for all the individual items to which the operation job is assigned, the consumption life of the operation job is subtracted from the remaining life of the individual item.

- the list data D8 is updated (step S51). Thereafter, the control unit 14 releases (releases the allocation) all the individual items to which the operation job is allocated, and updates the individual item list data D8 (step S52). Then, the control unit 14 deletes, from the individual item list data D8, individual items having a remaining life shorter than the consumption lifetimes of all the operation jobs included in the operation master data D2, and adds (records) them to the waste item list data D10. (Step S53).

- the control unit 14 acquires the inspection type after the operation job from the operation master data D2 (step S54).

- the control unit 14 acquires the inspection period from the inspection master data D4 based on the acquired inspection type (step S55).

- the control unit 14 adds the acquired inspection period to the end time of the operation job to obtain an inspection end date (occurrence date), generates an inspection end event, and adds (records) it to the event queue data D7 (step S56).

- the control unit 14 assigns the inspection job to the individual product, updates the individual product list data D8, and adds (records) it to the component allocation result data D12 (step S57).

- the control unit 14 adds (records) the end time of the operation job and the start time of the inspection job to the job execution result data D11 (step S58), thereby ending the control operation related to the operation end event process. .

- the control unit 14 first releases (releases the assignment) all the individual items to which the inspection job is assigned, and updates the individual item list data D8 (step S31). S61). Based on the operation time recorded in the individual item list data D8, the control unit 14 obtains the individual item damage degree from the component damage degree master data D5 (step S62). Then, the control unit 14 deletes the discarded product (parts to be discarded) whose damage degree is “Scrap” from the individual item list data D8 and adds (records) it to the discarded item list data D10 (step). S63).

- the control unit 14 determines the repair period for each damage degree from the repair master data D6 based on the damage degree of the individual parts other than the individual parts that are “Scrap” and “No Damage”. Obtain (step S64).

- the control unit 14 adds the repair period for each degree of damage acquired to the end time of the inspection job to obtain a repair end date (occurrence date), generates a repair end event, and adds (records) it to the event queue data D7 (Step S65).

- the control unit 14 allocates a repair job based on the degree of damage of the individual item, updates the individual item list data D8, and adds (records) it to the component allocation result data D12 (step S66).

- the individual item list data D8 is updated without assigning a repair job. Then, the control unit 14 adds (records) the end time of the inspection job and the start time of the repair job to the job execution result data D11 (step S67), thereby ending the control operation related to the inspection end event process. .

- control unit 14 first releases (releases the assignment) all the individual items to which the repair job is assigned, and updates the individual item list data D8 (step). S71). The control unit 14 adds (records) the end time of the repair job to the job execution result data D11 (step S72), thereby ending the control operation related to the repair end event process.

- control unit 14 generates the job execution result data D11 and the component allocation result data D12 by executing the operation plan creation process, and based on the job execution result data D11 and the component allocation result data D12, the component Create an operational plan for.

- the job includes an operation job, an inspection job, and a repair job.

- the operation job is predetermined based on the operation plan of the equipment, and similarly, the inspection job is predetermined according to the operation job. Yes.

- the repair job is appropriately determined according to the degree of damage based on the operation time of the individual item.

- the operation job, inspection job, and repair job are determined according to each facility. For these jobs, a predetermined operation job is first performed along the virtual date and time, and an inspection job is performed after the operation job is completed. Then, after the inspection job is completed, a repair job is performed. On the other hand, the operation job may be performed continuously along a predetermined virtual date and time. In this case, the individual product used in the previous operation job is used in the next operation job. Not exclusively.

- the parts operation plan z includes new input item list data D9 in FIG. 10, waste item list data D10 in FIG. 11, job execution result data D11 in FIG. 12, component assignment result data D12 in FIG.

- the operation plan z of parts created based on the job execution result data D11 is performed continuously in the order of operation # 1, operation # 2, and operation # 3 in the operation # 1 of the facility # 1.

- the operation job in the facility # 2 is continuously performed in the order of operation # 4, operation # 5, and operation # 6.

- the part set A to be mounted on the operation job of the operation # 1 is, for example, a newly introduced part that has been manufactured and stored, and is removed after the operation of the operation # 1 and inspected.

- the repair job # 1 is performed.

- the parts set A that has undergone the repair # 1 is mounted in the operation job of the operation # 5 in the facility # 2, is removed after the operation of the operation # 5, and the inspection job of the inspection # 4 is performed.

- a repair job of repair # 4 is performed.

- the component set B to be mounted on the operation job of the operation # 4 is, for example, a newly introduced component that has been manufactured and stored, and is removed after the operation of the operation # 4, and the inspection # After the second inspection job is performed, the repair job of repair # 2 is performed.

- the parts set B that has undergone the repair # 2 is mounted in the operation job of the operation # 3 in the equipment # 1, is removed after the operation of the operation # 3, and the inspection job of the inspection # 5 is performed.

- a repair job of repair # 5 is performed.

- the component set C to be attached to the operation job of the operation # 2 is, for example, a newly introduced component that has been manufactured and stored, and is removed after the operation of the operation # 2, and the inspection # After the third inspection job is performed, the repair job of repair # 3 is performed.

- the parts set C that has undergone the repair # 3 is mounted in the operation job of the operation # 6 in the equipment # 2, and is removed after the operation of the operation # 6.

- an operation plan z for parts based on master data, transaction data, and initial parameters.

- an optimum operation plan z can be derived by evaluating each of the plurality of operation plans z.

- a plurality of operation plans z can be created by changing the set value of the coefficient ⁇ i that is the initial parameter. Therefore, by evaluating a plurality of operation plan z having different coefficients alpha i, respectively, can be derived optimal operation plan z relates coefficient alpha i.

- the evaluation value of the created operation plan z can be calculated using the evaluation function f (z). For this reason, by comparing the evaluation values corresponding to the operation plan z, the operation plan z having the highest evaluation value can be evaluated as the optimum operation plan.

- the operation plan z since the evaluation value of the operation plan z can be obtained using the calculation formula of the evaluation function f (z), the operation plan z can be optimally evaluated.

- various events can be generated and the operation plan z can be created, so that the operation plan z can be accurately simulated and created.

Landscapes

- Engineering & Computer Science (AREA)

- Business, Economics & Management (AREA)

- General Engineering & Computer Science (AREA)

- Human Resources & Organizations (AREA)

- Tourism & Hospitality (AREA)

- General Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- General Business, Economics & Management (AREA)

- Economics (AREA)

- Theoretical Computer Science (AREA)

- Marketing (AREA)

- Strategic Management (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Entrepreneurship & Innovation (AREA)

- Quality & Reliability (AREA)

- Operations Research (AREA)

- Health & Medical Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Primary Health Care (AREA)

- Automation & Control Theory (AREA)

- Management, Administration, Business Operations System, And Electronic Commerce (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020167027380A KR101921805B1 (ko) | 2014-04-04 | 2015-03-27 | 운용 계획 작성 평가 장치 및 운용 계획 작성 평가 방법 |

| US15/301,145 US10161315B2 (en) | 2014-04-04 | 2015-03-27 | Equipment maintenance component replacement prioritization planning system and method |

| CN201580017156.3A CN106133785B (zh) | 2014-04-04 | 2015-03-27 | 运用计划制作评价装置以及运用计划制作评价方法 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014078102A JP6341729B2 (ja) | 2014-04-04 | 2014-04-04 | 運用計画作成評価装置及び運用計画作成評価方法 |

| JP2014-078102 | 2014-04-04 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2015152086A1 true WO2015152086A1 (ja) | 2015-10-08 |

Family

ID=54240410

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2015/059753 Ceased WO2015152086A1 (ja) | 2014-04-04 | 2015-03-27 | 運用計画作成評価装置及び運用計画作成評価方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US10161315B2 (enExample) |

| JP (1) | JP6341729B2 (enExample) |

| KR (1) | KR101921805B1 (enExample) |

| CN (1) | CN106133785B (enExample) |

| WO (1) | WO2015152086A1 (enExample) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110383326A (zh) | 2017-03-17 | 2019-10-25 | 三菱日立电力系统株式会社 | 运用计划制作装置、运用计划制作系统、运用计划制作方法及程序 |

| EP3451246A1 (en) * | 2017-08-28 | 2019-03-06 | Hewlett-Packard Enterprise Development LP | Eol notification generation |

| CN108648811A (zh) * | 2018-05-11 | 2018-10-12 | 南方医科大学 | 一种基于指征项预测的自动放疗计划质量评价方法 |

| SG11202011786VA (en) * | 2018-07-18 | 2020-12-30 | Mitsubishi Electric Corp | Air-conditioning apparatus and air-conditioning method |

| EP3957386A1 (de) * | 2020-08-18 | 2022-02-23 | UMICORE AG & Co. KG | Katalysator zur reduzierung von ammoniak-emmisionen |

| CN117131833B (zh) * | 2023-10-24 | 2024-01-19 | 北京超星未来科技有限公司 | 用于模块化电路行为仿真的方法和系统 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH10176546A (ja) * | 1996-12-16 | 1998-06-30 | Hitachi Ltd | ガスタービン高温部品の長寿命化方法およびその装置 |

| JPH10196403A (ja) * | 1997-01-10 | 1998-07-28 | Toshiba Corp | ガスタービン部品管理装置及びプラント設備管理装置及びプラント設備管理プログラムを記録した媒体 |

| WO2001023725A1 (en) * | 1999-09-27 | 2001-04-05 | Hitachi, Ltd. | Service life management system for high-temperature part of gas turbine |

| JP2002195056A (ja) * | 2000-12-22 | 2002-07-10 | Central Res Inst Of Electric Power Ind | ガスタービン高温部品の廃却損最小化方法及びシステム及びガスタービン保守最適化支援プログラムを記録したコンピュータ読取可能な記録媒体 |

| JP2004005461A (ja) * | 2002-04-02 | 2004-01-08 | Hitachi Ltd | ローテーション計画方法およびローテーション計画装置 |

| JP2011048688A (ja) * | 2009-08-27 | 2011-03-10 | Hitachi Ltd | プラントライフサイクル評価装置及び方法 |

Family Cites Families (35)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5685507A (en) * | 1979-12-17 | 1981-07-11 | Hitachi Ltd | Monitoring method of performance of steam turbine plant |

| US5216612A (en) * | 1990-07-16 | 1993-06-01 | R. J. Reynolds Tobacco Company | Intelligent computer integrated maintenance system and method |

| JP3147586B2 (ja) * | 1993-05-21 | 2001-03-19 | 株式会社日立製作所 | プラントの監視診断方法 |

| US5623404A (en) * | 1994-03-18 | 1997-04-22 | Minnesota Mining And Manufacturing Company | System and method for producing schedules of resource requests having uncertain durations |

| US5817958A (en) * | 1994-05-20 | 1998-10-06 | Hitachi, Ltd. | Plant monitoring and diagnosing method and system, as well as plant equipped with the system |

| US5920846A (en) * | 1996-02-27 | 1999-07-06 | Southwestern Bell Telephone Co. | Method and system for processing a service request relating to installation, maintenance or repair of telecommunications services provided to a customer premises |

| US6104988A (en) * | 1998-08-27 | 2000-08-15 | Automotive Electronics, Inc. | Electronic control assembly testing system |

| US6067486A (en) * | 1999-02-01 | 2000-05-23 | General Electric Company | Method and system for planning repair of an aircraft engine |

| US7783507B2 (en) * | 1999-08-23 | 2010-08-24 | General Electric Company | System and method for managing a fleet of remote assets |

| US6820038B1 (en) * | 2001-09-04 | 2004-11-16 | Accenture Global Services Gmbh | Component provisioning or issuance in a maintenance, repair or overhaul environment |

| US6738748B2 (en) * | 2001-04-03 | 2004-05-18 | Accenture Llp | Performing predictive maintenance on equipment |

| US7124059B2 (en) * | 2000-10-17 | 2006-10-17 | Accenture Global Services Gmbh | Managing maintenance for an item of equipment |

| US6343251B1 (en) * | 2000-10-20 | 2002-01-29 | General Electric Company | Method and system for monitoring the operation of and predicting part life consumption for turbomachinery |

| US6687634B2 (en) * | 2001-06-08 | 2004-02-03 | Hewlett-Packard Development Company, L.P. | Quality monitoring and maintenance for products employing end user serviceable components |

| US8504396B2 (en) * | 2002-12-24 | 2013-08-06 | Sap Aktiengeselleschaft | Flexible maintenance planning |

| US7672921B1 (en) * | 2004-02-25 | 2010-03-02 | Rockwell Automation Technologies, Inc. | Systems and methods for automatically determining and/or inferring component end of life (EOL) |

| US7584024B2 (en) * | 2005-02-08 | 2009-09-01 | Pegasus Technologies, Inc. | Method and apparatus for optimizing operation of a power generating plant using artificial intelligence techniques |

| US20060273918A1 (en) * | 2005-06-07 | 2006-12-07 | Ram Satish N | System for providing multiple maintenance profiles using wireless communications |

| US20090076874A1 (en) * | 2005-06-30 | 2009-03-19 | Siemens Aktiengesellschaft | Method and Tool for Optimized System Maintenance |

| US7457786B2 (en) * | 2005-08-23 | 2008-11-25 | General Electric Company | Performance enhancement of optimization processes |

| CN101008998A (zh) * | 2006-01-24 | 2007-08-01 | 中芯国际集成电路制造(上海)有限公司 | 零部件管理系统 |

| US20080082345A1 (en) * | 2006-09-29 | 2008-04-03 | Caterpillar Inc. | System and method for evaluating risks associated with delaying machine maintenance |

| US8396571B2 (en) * | 2007-03-19 | 2013-03-12 | United Technologies Corporation | Process and system for multi-objective global optimization of maintenance schedules |

| US7881825B2 (en) * | 2007-03-28 | 2011-02-01 | Praxair Technology, Inc. | Production control utilizing real time optimization |

| US8473956B2 (en) * | 2008-01-15 | 2013-06-25 | Microsoft Corporation | Priority based scheduling system for server |

| US20090187449A1 (en) * | 2008-01-22 | 2009-07-23 | Van Tulder Paul A | System and method for managing unscheduled maintenance and repair decisions |

| JP5401176B2 (ja) * | 2009-06-03 | 2014-01-29 | 株式会社日立製作所 | 動的保守計画装置 |

| US8340948B1 (en) * | 2009-09-29 | 2012-12-25 | The Boeing Company | Fleet performance optimization tool for aircraft health management |

| EP2393067A1 (en) * | 2010-06-04 | 2011-12-07 | BAE Systems Bofors AB | Condition based maintenance support schedule management |

| US8639480B2 (en) * | 2010-09-20 | 2014-01-28 | General Electric Company | Methods and systems for modeling turbine operation |

| US20120283963A1 (en) * | 2011-05-05 | 2012-11-08 | Mitchell David J | Method for predicting a remaining useful life of an engine and components thereof |

| US8972067B2 (en) * | 2011-05-11 | 2015-03-03 | General Electric Company | System and method for optimizing plant operations |

| US8560368B1 (en) * | 2011-11-18 | 2013-10-15 | Lockheed Martin Corporation | Automated constraint-based scheduling using condition-based maintenance |

| JP5638560B2 (ja) * | 2012-03-27 | 2014-12-10 | 株式会社東芝 | 保守計画決定装置およびその方法 |

| JP6104643B2 (ja) * | 2013-03-04 | 2017-03-29 | 三菱重工業株式会社 | 運用計画作成装置、運用計画作成方法および運用計画作成プログラム |

-

2014

- 2014-04-04 JP JP2014078102A patent/JP6341729B2/ja active Active

-

2015

- 2015-03-27 KR KR1020167027380A patent/KR101921805B1/ko active Active

- 2015-03-27 CN CN201580017156.3A patent/CN106133785B/zh active Active

- 2015-03-27 US US15/301,145 patent/US10161315B2/en active Active

- 2015-03-27 WO PCT/JP2015/059753 patent/WO2015152086A1/ja not_active Ceased

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH10176546A (ja) * | 1996-12-16 | 1998-06-30 | Hitachi Ltd | ガスタービン高温部品の長寿命化方法およびその装置 |

| JPH10196403A (ja) * | 1997-01-10 | 1998-07-28 | Toshiba Corp | ガスタービン部品管理装置及びプラント設備管理装置及びプラント設備管理プログラムを記録した媒体 |

| WO2001023725A1 (en) * | 1999-09-27 | 2001-04-05 | Hitachi, Ltd. | Service life management system for high-temperature part of gas turbine |

| JP2002195056A (ja) * | 2000-12-22 | 2002-07-10 | Central Res Inst Of Electric Power Ind | ガスタービン高温部品の廃却損最小化方法及びシステム及びガスタービン保守最適化支援プログラムを記録したコンピュータ読取可能な記録媒体 |

| JP2004005461A (ja) * | 2002-04-02 | 2004-01-08 | Hitachi Ltd | ローテーション計画方法およびローテーション計画装置 |

| JP2011048688A (ja) * | 2009-08-27 | 2011-03-10 | Hitachi Ltd | プラントライフサイクル評価装置及び方法 |

Non-Patent Citations (1)

| Title |

|---|

| "Combined Cycle Hatsuden' (revised version) Dai VIII Sho Operation and Maintenance for Combined Cycle Plants", THE THERMAL AND NUCLEAR POWER, vol. 61, no. 12, 15 December 2010 (2010-12-15), pages 55 - 72 * |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2015200970A (ja) | 2015-11-12 |

| US20170016400A1 (en) | 2017-01-19 |

| JP6341729B2 (ja) | 2018-06-13 |

| CN106133785A (zh) | 2016-11-16 |

| CN106133785B (zh) | 2020-01-07 |

| US10161315B2 (en) | 2018-12-25 |

| KR101921805B1 (ko) | 2018-11-23 |

| KR20160127816A (ko) | 2016-11-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6341729B2 (ja) | 運用計画作成評価装置及び運用計画作成評価方法 | |

| US8868287B2 (en) | Prediction of maintenance operations on an aircraft engine | |

| US9058216B2 (en) | Method for estimating job run time | |

| CN105829982B (zh) | 用于预测将应用于航空发动机的维护操作的方法和系统 | |

| JP6764776B2 (ja) | 生産管理支援装置、生産管理支援方法、及び生産管理支援プログラム | |

| JP6467264B2 (ja) | 計画作成支援装置および計画作成支援方法 | |

| CN117818056A (zh) | 基于ai的骨科3d打印方法和装置 | |

| EP4167034A1 (en) | Method and system for optimizing a manufacturing process based on a surrogate model of a part | |

| JP2013097625A (ja) | 業務割当支援装置、業務割当支援方法、業務割当支援プログラム | |

| CN101652727A (zh) | 作业指示系统、作业指示方法、作业指示程序、存储了作业指示程序的计算机可读取的存储介质以及作业指示装置 | |

| JP2015200970A5 (enExample) | ||

| JP5911831B2 (ja) | 生産管理装置および生産管理プログラム | |

| JP5063444B2 (ja) | ライン生産管理支援方法および装置 | |

| JP3883449B2 (ja) | ソフトウェアシステムのテスト計画作成支援方法およびテスト計画作成支援プログラム | |

| JP2009289056A (ja) | 人員配置計画支援装置 | |

| CN113614662B (zh) | 提高生产效率的支援系统 | |

| JP2023023386A (ja) | 作業順序列生成装置および作業順序列生成方法 | |

| JP4058013B2 (ja) | 回収計画立案支援装置、方法およびプログラム | |

| JP7774230B2 (ja) | 情報処理方法及び情報処理装置 | |

| CN114691951B (zh) | 处理装置、处理方法以及存储介质 | |

| Sobaszek et al. | Effect of machine failure prediction on selected parameters of manufacturing schedule in a job-shop environment | |

| JP2008204142A (ja) | 投資上限額決定方法及び装置 | |

| JP2007148729A (ja) | 生産計画作成システム及び生産工程の効率化支援方法 | |

| JP5388722B2 (ja) | 基準工期設定装置 | |

| JP2007072754A (ja) | 生産工程効率化支援方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 15773500 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 15301145 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 1020167027380 Country of ref document: KR |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 15773500 Country of ref document: EP Kind code of ref document: A1 |