WO2015001743A1 - 車両用空調装置 - Google Patents

車両用空調装置 Download PDFInfo

- Publication number

- WO2015001743A1 WO2015001743A1 PCT/JP2014/003289 JP2014003289W WO2015001743A1 WO 2015001743 A1 WO2015001743 A1 WO 2015001743A1 JP 2014003289 W JP2014003289 W JP 2014003289W WO 2015001743 A1 WO2015001743 A1 WO 2015001743A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- compressor

- rotational speed

- air conditioning

- air conditioner

- vehicle

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/00642—Control systems or circuits; Control members or indication devices for heating, cooling or ventilating devices

- B60H1/00735—Control systems or circuits characterised by their input, i.e. by the detection, measurement or calculation of particular conditions, e.g. signal treatment, dynamic models

- B60H1/0075—Control systems or circuits characterised by their input, i.e. by the detection, measurement or calculation of particular conditions, e.g. signal treatment, dynamic models the input being solar radiation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/00357—Air-conditioning arrangements specially adapted for particular vehicles

- B60H1/00385—Air-conditioning arrangements specially adapted for particular vehicles for vehicles having an electrical drive, e.g. hybrid or fuel cell

- B60H1/004—Air-conditioning arrangements specially adapted for particular vehicles for vehicles having an electrical drive, e.g. hybrid or fuel cell for vehicles having a combustion engine and electric drive means, e.g. hybrid electric vehicles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/00642—Control systems or circuits; Control members or indication devices for heating, cooling or ventilating devices

- B60H1/00814—Control systems or circuits characterised by their output, for controlling particular components of the heating, cooling or ventilating installation

- B60H1/00878—Control systems or circuits characterised by their output, for controlling particular components of the heating, cooling or ventilating installation the components being temperature regulating devices

- B60H1/00885—Controlling the flow of heating or cooling liquid, e.g. valves or pumps

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H1/3204—Cooling devices using compression

- B60H1/3205—Control means therefor

- B60H1/3208—Vehicle drive related control of the compressor drive means, e.g. for fuel saving purposes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H1/3204—Cooling devices using compression

- B60H1/3205—Control means therefor

- B60H1/3211—Control means therefor for increasing the efficiency of a vehicle refrigeration cycle

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H2001/3236—Cooling devices information from a variable is obtained

- B60H2001/3266—Cooling devices information from a variable is obtained related to the operation of the vehicle

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H2001/3269—Cooling devices output of a control signal

- B60H2001/327—Cooling devices output of a control signal related to a compressing unit

- B60H2001/3272—Cooling devices output of a control signal related to a compressing unit to control the revolving speed of a compressor

Definitions

- the present disclosure relates to a vehicle air conditioner.

- an evaporator that cools the air blown into the passenger compartment is disposed in the air conditioning case. Further, a bypass passage is formed in which air is bypassed to bypass the evaporator.

- the bypass passage By forming the bypass passage, the amount of air passing through the evaporator can be reduced by the amount of air passing through the bypass passage. In accordance with the temperature required by this, it is possible to adjust the amount of air that is cooled by passing through the evaporator and the amount of air that is not cooled by passing through the bypass passage. Therefore, the required cooling capacity of the evaporator can be reduced and the driving force of the compressor can be saved.

- This disclosure is intended to provide a vehicle air conditioner that can save power by controlling the rotation speed of a compressor while suppressing the influence on the air conditioning performance.

- a vehicle air conditioner includes a refrigeration cycle mounted on a vehicle, a compressor that compresses a refrigerant for air conditioning the vehicle interior, and a detection that detects a thermal load of the air conditioning in the vehicle interior. And a control unit that controls the rotational speed of the compressor so that the thermal load detected by the detection unit satisfies a preset air conditioning requirement in the vehicle interior.

- the control unit controls the rotation speed of the compressor and satisfies the air conditioning request

- the control unit sets the rotation speed within a predetermined range including the rotation speed that satisfies the air conditioning request as a reference rotation speed.

- the reference rotational speed and a low rotational speed lower than the reference rotational speed are periodically switched so as to maintain a state that satisfies the requirement.

- the reference rotational speed and a low rotational speed lower than the reference rotational speed are periodically switched by the control unit.

- the power can be reduced by the amount of time required to control the compressor so as to achieve a low rotational speed as compared with the case where the compressor is controlled so as to always have the reference rotational speed in order to maintain the air conditioning requirement. Since the number of revolutions is controlled periodically so as to maintain the air conditioning request, it is possible to save power while suppressing the influence on the air conditioning performance.

- the vehicle air conditioner 10 of this embodiment is an air conditioner mounted on a hybrid vehicle.

- the vehicle air conditioner 10 of the present embodiment is provided with a refrigeration cycle, and an electric compressor 11 driven by an electric motor 12 mounted on the vehicle is adopted as a compressor 11 that is a component of the refrigeration cycle.

- the electric motor 12 is driven by power supplied from the on-vehicle battery 13.

- the refrigeration cycle includes a condenser for condensing and liquefying the high-temperature and high-pressure refrigerant compressed by the electric compressor 11, a receiver for separating the condensed and liquefied refrigerant into a gas and a liquid, an expansion valve for decompressing and expanding the liquid refrigerant from the receiver, And an evaporator for evaporating and evaporating the expanded low-temperature and low-pressure refrigerant.

- the vehicle air conditioner 10 of the present embodiment is provided with an air conditioning unit that supplies conditioned air to the vehicle interior.

- the air conditioning unit includes a blower 14, an evaporator, a heater core, a suction port switching door 15 as an inside / outside air suction mode switching unit, an air mix door 16 as a temperature control unit, a window glass inner surface of the passenger compartment, an occupant upper body, and an occupant. It has a blower outlet switching door 17 or the like that switches between a plurality of blower outlets that blow off toward the lower body.

- the vehicle air conditioner 10 includes an air conditioner ECU 18 as a calculation unit including a CPU, a ROM, a RAM, and the like (not shown).

- the air conditioner ECU 18 is a control unit, and when an ignition switch, which is a vehicle travel switch, is turned on, electric power is supplied from the in-vehicle battery 13 to enter an activated state.

- the air conditioner ECU 18 includes an inside air temperature sensor 19 that detects the vehicle interior temperature Tr, an outside air temperature sensor 20 that detects the outside air temperature Tam, a solar radiation sensor 21 that detects the amount of solar radiation Ts radiated into the vehicle interior, and a state immediately after passing through the evaporator.

- a signal from the operation panel 25 of the instrument panel is input to the air conditioner ECU 18.

- the operation panel 25 is provided with a temperature setter for setting a target temperature in the passenger compartment, an air conditioner switch for instructing activation of the electric compressor 11, and the like.

- the rotation speed of the electric motor 12 is controlled by the inverter 26, and the operation of the inverter 26 is controlled by the air conditioner ECU 18. Specifically, the air conditioner ECU 18 outputs a rotation speed instruction value to the inverter 26, and the inverter 26 performs rotation speed control so that the electric motor 12 has the rotation speed of the rotation speed instruction value. In addition to the rotation speed instruction value signal, a start signal for giving an operation permission to the inverter 26 is output from the air conditioner ECU 18 to the inverter 26.

- S1 various setting values are initialized, and the process proceeds to S2.

- various signals are read from the operation panel 25, and the process proceeds to S3.

- S3 signals from various sensors are read, and the process proceeds to S4.

- the target blowing temperature TAO is calculated based on the set temperature Tset, the outside air temperature Tam, the vehicle interior temperature Tr, and the solar radiation amount Ts, and the process proceeds to S5.

- the blower air volume is calculated based on the calculated target blowing temperature TAO, and the process proceeds to S6.

- the inlet mode is determined, and the process proceeds to S7.

- the opening degree of the air mix door 16 is calculated, and the process proceeds to S8.

- a target post-evaporation temperature TEO that is a target value of the post-evaporation temperature TE is calculated, and the process proceeds to S9.

- fuzzy control is performed so that the post-evaporation temperature TE becomes the target post-evaporation temperature TEO, the rotational speed of the electric compressor 11 is controlled by the inverter 26 according to an instruction from the air conditioner ECU 18, and the process proceeds to S10.

- the upper limit control value IVOmax of the target compressor speed is calculated, and the process proceeds to S92.

- the upper limit control value IVOmax is a value that satisfies the air conditioning requirement, and is set so that the vibration of the compressor 11 and the noise from the compressor 11 become a rotational speed that is less than a predetermined value.

- a lower limit control value IVOmin for the target compressor speed is calculated, and the process proceeds to S93.

- the lower limit control value IVOmin is set to a minimum value for operating the compressor 11 in consideration of oil return of the compressor 11 and the like.

- the difference between the target post-evaporation temperature TEO and the detected post-evaporation temperature TE is calculated, and the process proceeds to S94.

- the target compressor speed IVOn is calculated from a pre-stored fuzzy map, and the process proceeds to S95.

- S95 it is determined whether or not the state in which the value calculated in S93 is less than 1 has continued for 30 seconds or more. If so, the process proceeds to S96, and if not, this flow ends. To do. Therefore, when it does not continue for 30 seconds or more, since the air conditioning load is in a transition period in which the air conditioning load is not stable, the compressor 11 is controlled to reach the target compressor speed.

- the lower limit control value IVOmin is increased by 100 rpm, and this flow is finished.

- the lower limit control value IVOmin is increased stepwise by 100 rpm.

- safety can be improved as compared with the case where the lower limit control value IVOmin is suddenly increased.

- the maximum value of the lower limit control value IVOmin is set to a value lower than the upper limit control value IVOmax by a predetermined value, for example, ⁇ 500 rpm so that the lower limit control value IVOmin and the upper limit control value IVOmax are close to each other and the controllability is not deteriorated. preferable. Therefore, for example, when the upper limit control value IVOmax is 2000 rpm, the maximum value of the lower limit control value IVOmin is set to 1500 rpm.

- the compressor 11 is controlled based on the upper limit control value IVOmax, the target compressor speed IVOn and the lower limit control value IVOmin determined in S9.

- [TEO-TE] used for fuzzy control is monitored, and if [TEO-TE] ⁇ 1 continues for 30 seconds, it is determined that the thermal load and the refrigeration cycle are balanced (S5). Thereafter, in S6 and S7, the minimum number of revolutions is increased at 100 rpm / 10 seconds, and the process shifts to optimum ON / OFF power saving control corresponding to the heat load. Therefore, when comfort and dehumidifying performance are ensured, the compressor 11 is actively turned on / off (rotational speed control), and the operation rate of the compressor 11 is lowered, thereby enabling power saving control.

- the rotational speed Nc is stabilized.

- the lower limit control value IVOmin is increased by 100 rpm.

- the state where the difference between TEO and TE is smaller than 1 continues for 30 seconds or more and has not changed to the lower limit control value IVOmin within 10 seconds, so the lower limit control value IVOmin is further increased by 100 rpm.

- the compressor 11 is controlled to stop.

- the compressor 11 is stopped, the compression of the refrigerant is stopped, so the post-evaporation temperature TE rises, and the difference between TEO and TE becomes 1 or more at time t5. Therefore, at time t5, the compressor 11 is started again with a value larger than the lower limit control value IVOmin, and is controlled to lower TE.

- the compressor 11 is controlled to stop.

- the compressor 11 is periodically turned on and off.

- the lower limit control value IVOmin is a constant value.

- the lower limit control value IVOmin is Raised in stages. Thereby, the on / off control of the compressor 11 is realized.

- Table 1 shows the average post-evaporation temperature, cooling performance, power consumption, and power saving effect when the minimum number of revolutions is set to 5 levels and the operating rate of the compressor 11 is changed.

- Table 1 shows the experimental results when the intake air is 30 ° C., the humidity is 40%, and the air amount is 160 m 3 / h.

- the operating rate is 100%.

- the power saving effect is highest at 30% when the minimum rotational speed is 1350. Therefore, it can be seen that the last rotation speed (1350 rpm) at which the compressor 11 is turned on and off is effective. Moreover, even if the power saving control is performed, the cooling performance is the same as in the case of 1345 rpm, and it can be seen that the power saving can be achieved while satisfying the air conditioning requirements.

- the optimum minimum rotational speed varies depending on the use environment conditions and the like, and varies depending on, for example, the outside temperature and humidity, the amount of solar radiation, the set temperature, the suction mode, the vehicle speed, and the number of passengers. Therefore, the optimum minimum rotational speed may be increased stepwise as described above, or may be uniquely determined in advance by a fuzzy map or the like, and stepwise based on the minimum rotational speed determined by the fuzzy map. It may be raised.

- the lower limit control value IVOmin is increased to perform the on / off control, but in the state where the air conditioning request is satisfied, the on / off control is not necessarily performed. For example, when it is determined that window fogging is a concern and cooling performance of a predetermined level or higher is necessary, the above-described on / off control (power saving control) is not performed.

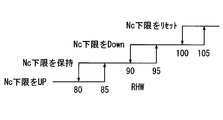

- RHW is the relative humidity near the glass to the haze limit.

- the fogging control is necessary. Therefore, for example, when the RHW increases to 105% or more, the lower limit control value IVOmin is reset so that the power saving control is not performed. Return to normal continuous control. Similarly, the state where the lower limit control value IVOmin is reset is continued until the RHW decreases to less than 100%.

- the lower limit control value IVOmin When the RHW rises and exceeds 95%, the lower limit control value IVOmin is decreased, the on state is lengthened, and the off time is controlled to be shortened. Similarly, the state where the lower limit control value IVOmin is decreased is continued until RHW decreases to less than 90%.

- the lower limit control value IVOmin is maintained at the current value, and the power saving control is performed because the possibility of window fogging is low even if the power saving control is performed.

- the lower limit control value IVOmin is maintained at the current value until RHW decreases to less than 80%. Further, when the RHW decreases to 80% or less, the lower limit control value IVOmin is increased, and the power saving control is performed.

- FIG. 5 shows the control when a sensor for detecting RHW is mounted.

- the occurrence of window fogging is predicted by using outside air temperature, inside / outside air, vehicle speed, and the like. Then, the same control as in FIG. 5 is performed.

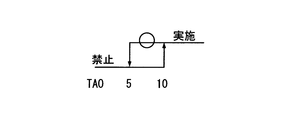

- control for ensuring a cooling feeling and comfort will be described with reference to FIG.

- TAO target blowing temperature

- control is performed so as to prohibit power saving control.

- the target blowing temperature TAO ⁇ 5 it is determined that the required cooling performance is low, and the operation proceeds to ON / OFF operation. In other words, when the required cooling capacity required for the refrigeration cycle is smaller than the predetermined value, the operation shifts to ON / OFF operation.

- the lower limit control value IVOmin is decreased as follows.

- the lower limit control value IVOmin is lowered, and the ON / OFF operation is performed at a low rotation speed Nc.

- the lower limit control value IVOmin is set to ⁇ 300 rpm to once make continuous operation, and then the lower limit control value IVOmin is raised to perform optimal ON / OFF control.

- the lower limit control value IVOmin is reduced at a rate of ⁇ 300 rpm / 1 stage, as in (1).

- the reference rotational speed lower limit control value

- a low rotational speed lower than the reference rotational speed low rotational speed in the present embodiment.

- the number is 0

- the air conditioner ECU 18 control unit

- the air conditioner ECU 18 drives the compressor 11 at the reference rotation speed when the air conditioning request is satisfied, and the low rotation speed is 0 and the compressor 11 is stopped. Are switched periodically. By stopping the compressor 11, the power saving effect can be further enhanced.

- the lower limit control value which is the reference for the air conditioner ECU 18 and the power saving control, is the rotation speed at which the vibration of the compressor 11 and the noise from the compressor 11 become less than a predetermined value.

- power saving control can be realized by positively performing ON / OFF operation and rotation speed control of the compressor 11 in a region that does not affect the air conditioning performance.

- the post-evacuation temperature sensor 22 which is an existing sensor can be used to accurately grasp the load in the passenger compartment (the occupant's thermal feeling), it is not necessary to add a new sensor or the like to perform this control. Therefore, it is possible to perform optimal control with high accuracy at low cost.

- the stable state of the heat load and the refrigeration cycle is determined based on the difference between the target post-evaporation temperature TEO and the post-evaporation temperature TE in the fuzzy control, and the minimum rotational speed of the compressor 11 is increased in that state. Shift to / OFF operation (rotational speed control). As a result, more fuel-saving ON / OFF operation is possible according to the heat load.

- the temperature of air that has passed through the evaporator constituting the refrigeration cycle is used as the heat load, but the heat load is not limited to the post-evaporation temperature TE.

- a thermal load a sensor that detects the temperature in the passenger compartment or the surface temperature of an occupant in the passenger compartment may be used, and power saving control may be performed using these values.

- the IR sensor may be used when the thermal sensation of the passenger such as an IR sensor can be directly detected. .

- the case where the air conditioner ECU 18 satisfies the air conditioning request is a case where the post-evaporation temperature TE is in a constant range for 30 seconds, but is not limited to such a case.

- the air conditioner ECU 18 may determine that the air conditioning request is satisfied when the degree of change in the thermal load detected by the detection unit is a predetermined value or less. Therefore, for example, when the degree of change in the post-evaporation temperature TE is equal to or less than a predetermined value, it may be determined that the air conditioning request is satisfied.

- power saving control can be performed at an earlier timing, so that the power saving effect can be further enhanced.

- the vehicle air conditioner 10 even when the vehicle air conditioner 10 is in transition immediately after startup, it may be shifted to stepwise ON / OFF operation if the gradient of change in the passenger compartment temperature becomes gentle. In this case, it is preferable to prepare in advance a MAP gradient that may shift to ON / OFF according to the heat load from the outside air temperature, TAO, or the like.

- the transition to ON / OFF is performed in a steady state, but it is also possible to limit the performance to a certain low speed without going to OFF.

- the reference rotation speed may be 2500 rpm and the low rotation speed may be controlled at 1000 rpm with respect to ON / OFF where the reference rotation speed is 2500 rpm and the low rotation speed is 0 rpm.

- the power saving effect is reduced, but the area where power saving control is possible can be expanded for continuous operation. For example, it is effective at idle when ON-OFF noise is conspicuous.

- the compressor 11 is electric, but may be applied to the belt-driven compressor 11. Further, for example, by combining an evaporator having a cold storage function and power saving control, the power saving effect can be further enhanced.

- the lower limit control value IVOmin (reference rotational speed) is set to a value larger than the target compressor rotational speed IVOn, but is not limited to a large value.

- the reference rotational speed may be a rotational speed within a predetermined range including the rotational speed (target compressor rotational speed IVOn) that satisfies the air conditioning requirement. Accordingly, the reference rotational speed may be the target compressor rotational speed IVOn or a value smaller than the target compressor rotational speed IVOn.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Mechanical Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Sustainable Development (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Sustainable Energy (AREA)

- Air-Conditioning For Vehicles (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020167000701A KR101757264B1 (ko) | 2013-07-02 | 2014-06-19 | 차량용 공조 장치 |

| CN201480037907.3A CN105377600B (zh) | 2013-07-02 | 2014-06-19 | 车辆用空调装置 |

| US14/901,674 US9919580B2 (en) | 2013-07-02 | 2014-06-19 | Air conditioner for vehicle |

| EP14819319.6A EP3017982B1 (en) | 2013-07-02 | 2014-06-19 | Vehicular air conditioning device |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013139245A JP5962601B2 (ja) | 2013-07-02 | 2013-07-02 | 車両用空調装置 |

| JP2013-139245 | 2013-07-02 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2015001743A1 true WO2015001743A1 (ja) | 2015-01-08 |

Family

ID=52143346

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2014/003289 Ceased WO2015001743A1 (ja) | 2013-07-02 | 2014-06-19 | 車両用空調装置 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US9919580B2 (enExample) |

| EP (1) | EP3017982B1 (enExample) |

| JP (1) | JP5962601B2 (enExample) |

| KR (1) | KR101757264B1 (enExample) |

| CN (1) | CN105377600B (enExample) |

| WO (1) | WO2015001743A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115264850A (zh) * | 2022-06-30 | 2022-11-01 | 北京小米移动软件有限公司 | 控制方法、装置、设备及存储介质 |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6590551B2 (ja) * | 2015-06-26 | 2019-10-16 | サンデン・オートモーティブクライメイトシステム株式会社 | 車両用空気調和装置 |

| CN107618338B (zh) * | 2016-07-15 | 2020-12-11 | 株式会社电装 | 空气循环器 |

| JP6583195B2 (ja) * | 2016-09-07 | 2019-10-02 | 株式会社デンソー | 車両用空調装置 |

| CN110525171A (zh) * | 2019-08-30 | 2019-12-03 | 奇瑞商用车(安徽)有限公司 | 新能源汽车空调制冷系统vcu控制方法 |

| DE102021118448B4 (de) | 2021-07-16 | 2025-02-27 | Bayerische Motoren Werke Aktiengesellschaft | Steuereinheit zur Reduzierung des Betriebsgeräusches mittels Ausblendung eines definierten Drehzahlbereichs eines elektrischen Kältemittelverdichters |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5896935A (ja) * | 1981-12-07 | 1983-06-09 | Sharp Corp | 空気調和機の制御回路 |

| JPH02267445A (ja) * | 1989-04-05 | 1990-11-01 | Mitsubishi Electric Corp | 空気調和機 |

| JP2002036868A (ja) * | 2000-07-31 | 2002-02-06 | Zexel Valeo Climate Control Corp | 空調装置 |

| JP2003127655A (ja) * | 2001-10-29 | 2003-05-08 | Mitsubishi Heavy Ind Ltd | 車両用空調装置および車両の空調制御方法 |

| JP2006112700A (ja) * | 2004-10-14 | 2006-04-27 | Matsushita Electric Ind Co Ltd | 空気調和機の除湿運転制御方法 |

| JP2008081121A (ja) | 1998-10-23 | 2008-04-10 | Denso Corp | 車両用空調装置 |

| JP2010030326A (ja) * | 2008-07-24 | 2010-02-12 | Denso Corp | 車両用空調装置 |

| JP2010100264A (ja) * | 2008-10-27 | 2010-05-06 | Denso Corp | 車両用空調装置 |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS58101281A (ja) | 1981-12-10 | 1983-06-16 | Sharp Corp | 冷蔵庫の制御回路 |

| JP3327053B2 (ja) * | 1995-06-06 | 2002-09-24 | 株式会社デンソー | 空調装置 |

| JPH115439A (ja) * | 1997-06-17 | 1999-01-12 | Denso Corp | 車両用空気調和装置 |

| JP4174929B2 (ja) | 1998-10-23 | 2008-11-05 | 株式会社デンソー | 車両用空調装置 |

| JP3841039B2 (ja) * | 2002-10-25 | 2006-11-01 | 株式会社デンソー | 車両用空調装置 |

| JP4048968B2 (ja) | 2003-02-12 | 2008-02-20 | 株式会社デンソー | 車両用空調装置 |

| JP4165330B2 (ja) * | 2003-04-16 | 2008-10-15 | 株式会社デンソー | 空調装置 |

| CN101171464B (zh) * | 2005-05-04 | 2011-11-23 | 开利公司 | 具有变速涡旋压缩机和经济器回路的制冷系统及运行方法 |

| US8015833B2 (en) * | 2009-05-28 | 2011-09-13 | Ford Global Technologies, Llc | Automotive climate system and method of controlling same |

| JP5582118B2 (ja) | 2011-09-08 | 2014-09-03 | 株式会社デンソー | 車両用空調装置 |

-

2013

- 2013-07-02 JP JP2013139245A patent/JP5962601B2/ja not_active Expired - Fee Related

-

2014

- 2014-06-19 CN CN201480037907.3A patent/CN105377600B/zh not_active Expired - Fee Related

- 2014-06-19 WO PCT/JP2014/003289 patent/WO2015001743A1/ja not_active Ceased

- 2014-06-19 KR KR1020167000701A patent/KR101757264B1/ko not_active Expired - Fee Related

- 2014-06-19 US US14/901,674 patent/US9919580B2/en active Active

- 2014-06-19 EP EP14819319.6A patent/EP3017982B1/en active Active

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5896935A (ja) * | 1981-12-07 | 1983-06-09 | Sharp Corp | 空気調和機の制御回路 |

| JPH02267445A (ja) * | 1989-04-05 | 1990-11-01 | Mitsubishi Electric Corp | 空気調和機 |

| JP2008081121A (ja) | 1998-10-23 | 2008-04-10 | Denso Corp | 車両用空調装置 |

| JP2002036868A (ja) * | 2000-07-31 | 2002-02-06 | Zexel Valeo Climate Control Corp | 空調装置 |

| JP2003127655A (ja) * | 2001-10-29 | 2003-05-08 | Mitsubishi Heavy Ind Ltd | 車両用空調装置および車両の空調制御方法 |

| JP2006112700A (ja) * | 2004-10-14 | 2006-04-27 | Matsushita Electric Ind Co Ltd | 空気調和機の除湿運転制御方法 |

| JP2010030326A (ja) * | 2008-07-24 | 2010-02-12 | Denso Corp | 車両用空調装置 |

| JP2010100264A (ja) * | 2008-10-27 | 2010-05-06 | Denso Corp | 車両用空調装置 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP3017982A4 |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115264850A (zh) * | 2022-06-30 | 2022-11-01 | 北京小米移动软件有限公司 | 控制方法、装置、设备及存储介质 |

| CN115264850B (zh) * | 2022-06-30 | 2024-06-04 | 北京小米移动软件有限公司 | 控制方法、装置、设备及存储介质 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3017982B1 (en) | 2019-09-25 |

| CN105377600A (zh) | 2016-03-02 |

| JP2015009795A (ja) | 2015-01-19 |

| JP5962601B2 (ja) | 2016-08-03 |

| KR20160018803A (ko) | 2016-02-17 |

| KR101757264B1 (ko) | 2017-07-12 |

| US20160137024A1 (en) | 2016-05-19 |

| CN105377600B (zh) | 2017-05-31 |

| EP3017982A1 (en) | 2016-05-11 |

| EP3017982A4 (en) | 2017-03-22 |

| US9919580B2 (en) | 2018-03-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3480410B2 (ja) | 車両用空調装置 | |

| JP5516537B2 (ja) | 車両用空調装置 | |

| JP5533816B2 (ja) | 車両用空調装置 | |

| CN103209846B (zh) | 车辆空气调节器 | |

| JP5532029B2 (ja) | 車両用空調装置 | |

| JP5962601B2 (ja) | 車両用空調装置 | |

| JP2002213270A (ja) | ハイブリッド車両およびその空調装置 | |

| US20130213631A1 (en) | Air conditioner for vehicle | |

| JP6278214B2 (ja) | 車両用空調装置 | |

| JP2011073668A (ja) | 車両用空調装置 | |

| JP2011005982A (ja) | 車両用空調装置 | |

| JP2003326959A (ja) | 車両用空調装置 | |

| JP2010126136A (ja) | 車両用空調装置 | |

| CN107635805A (zh) | 车辆用空调装置 | |

| JP2012081870A (ja) | 車両用空調装置 | |

| JP5472015B2 (ja) | 車両の運転モード入力装置 | |

| JP2012066793A (ja) | 車両用空調装置 | |

| JP5533516B2 (ja) | 車両用空調装置 | |

| JP5494595B2 (ja) | 車両用空調装置 | |

| JPH11170856A (ja) | ハイブリッド自動車用空調装置 | |

| JP2013014327A (ja) | 車両用空調装置 | |

| JP2002283839A (ja) | 車両用冷房装置 | |

| JP5582118B2 (ja) | 車両用空調装置 | |

| JP2012180053A (ja) | 車両用空調制御装置 | |

| JP3323111B2 (ja) | 車両用空気調和装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 14819319 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2014819319 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 14901674 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 20167000701 Country of ref document: KR Kind code of ref document: A |