WO2014208740A1 - 含窒素カーボンアロイの製造方法、含窒素カーボンアロイ及び燃料電池触媒 - Google Patents

含窒素カーボンアロイの製造方法、含窒素カーボンアロイ及び燃料電池触媒 Download PDFInfo

- Publication number

- WO2014208740A1 WO2014208740A1 PCT/JP2014/067220 JP2014067220W WO2014208740A1 WO 2014208740 A1 WO2014208740 A1 WO 2014208740A1 JP 2014067220 W JP2014067220 W JP 2014067220W WO 2014208740 A1 WO2014208740 A1 WO 2014208740A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- nitrogen

- carbon alloy

- group

- carbon

- containing carbon

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 0 CC=CC(OCc1nc(COc2ccncc2)nc(COC(C=CC)=CC=C=C)n1)=CC=* Chemical compound CC=CC(OCc1nc(COc2ccncc2)nc(COC(C=CC)=CC=C=C)n1)=CC=* 0.000 description 3

- VXVXLUNBDNNDAF-UHFFFAOYSA-N C(c1ccccc1)c1nc(Cc2ccncc2)nc(Cc2ccncc2)n1 Chemical compound C(c1ccccc1)c1nc(Cc2ccncc2)nc(Cc2ccncc2)n1 VXVXLUNBDNNDAF-UHFFFAOYSA-N 0.000 description 1

- HHDSCPCUTZSXOW-CYMBIFCZSA-N C/C=C\C(\C1=NC(c2ccncc2)=[I]C(C)=N1)=C/C=C Chemical compound C/C=C\C(\C1=NC(c2ccncc2)=[I]C(C)=N1)=C/C=C HHDSCPCUTZSXOW-CYMBIFCZSA-N 0.000 description 1

- ZUSRBHIHGVVFKN-UHFFFAOYSA-N CC1(C(Nc2cnccc2)=O)N=C(C(Nc2cnccc2)=O)N=C(C(Nc2cnccc2)=O)N1 Chemical compound CC1(C(Nc2cnccc2)=O)N=C(C(Nc2cnccc2)=O)N=C(C(Nc2cnccc2)=O)N1 ZUSRBHIHGVVFKN-UHFFFAOYSA-N 0.000 description 1

- LIESXEPMSSBHNG-UHFFFAOYSA-N O=C(c1cc(C(Nc2cccnc2)=O)cc(C(Nc2cnccc2)=O)c1)Nc1cnccc1 Chemical compound O=C(c1cc(C(Nc2cccnc2)=O)cc(C(Nc2cnccc2)=O)c1)Nc1cnccc1 LIESXEPMSSBHNG-UHFFFAOYSA-N 0.000 description 1

- PFHCOOYBRXRFAM-UHFFFAOYSA-N O=C(c1cc(C(Nc2ccncc2)=O)cc(C(Nc2ccncc2)=O)c1)Nc1ccncc1 Chemical compound O=C(c1cc(C(Nc2ccncc2)=O)cc(C(Nc2ccncc2)=O)c1)Nc1ccncc1 PFHCOOYBRXRFAM-UHFFFAOYSA-N 0.000 description 1

- IYALGNJOJQVNEL-UHFFFAOYSA-N O=C(c1cc(C(Nc2ccncc2)=O)nc(C(Nc2ccncc2)=O)c1)Nc1ccncc1 Chemical compound O=C(c1cc(C(Nc2ccncc2)=O)nc(C(Nc2ccncc2)=O)c1)Nc1ccncc1 IYALGNJOJQVNEL-UHFFFAOYSA-N 0.000 description 1

- RZAGTEOPJCTJMA-UHFFFAOYSA-N O=C(c1nc(C(Nc2ccncc2)=O)nc(C(Nc2ccncc2)=O)c1)Nc1ccncc1 Chemical compound O=C(c1nc(C(Nc2ccncc2)=O)nc(C(Nc2ccncc2)=O)c1)Nc1ccncc1 RZAGTEOPJCTJMA-UHFFFAOYSA-N 0.000 description 1

- WPPCVRQXHZNCQA-UHFFFAOYSA-N O=C(c1nc(C(Nc2ccncc2)=O)nc(C(Nc2ccncc2)=O)n1)Nc1ccncc1 Chemical compound O=C(c1nc(C(Nc2ccncc2)=O)nc(C(Nc2ccncc2)=O)n1)Nc1ccncc1 WPPCVRQXHZNCQA-UHFFFAOYSA-N 0.000 description 1

- CBAHNJPYGBVJLV-UHFFFAOYSA-N O=C(c1nc(C(Nc2cnccc2)=O)nc(C(Nc2cnccc2)=O)c1)Nc1cccnc1 Chemical compound O=C(c1nc(C(Nc2cnccc2)=O)nc(C(Nc2cnccc2)=O)c1)Nc1cccnc1 CBAHNJPYGBVJLV-UHFFFAOYSA-N 0.000 description 1

- UDVTWJJQTPNZAG-UHFFFAOYSA-N OC(c1cc(C(Nc2cnccc2)=O)cc(C(Nc2cnccc2)=O)n1)Nc1cnccc1 Chemical compound OC(c1cc(C(Nc2cnccc2)=O)cc(C(Nc2cnccc2)=O)n1)Nc1cnccc1 UDVTWJJQTPNZAG-UHFFFAOYSA-N 0.000 description 1

- KEFOGWOYGLVUKA-UHFFFAOYSA-N c(cc1)ccc1-c1nc(-c2ccccc2)nc(-c2ccncc2)n1 Chemical compound c(cc1)ccc1-c1nc(-c2ccccc2)nc(-c2ccncc2)n1 KEFOGWOYGLVUKA-UHFFFAOYSA-N 0.000 description 1

- VACMVCGPXXITOG-UHFFFAOYSA-N c(cc1)ccc1-c1nc(-c2ccncc2)nc(-c2ccncc2)n1 Chemical compound c(cc1)ccc1-c1nc(-c2ccncc2)nc(-c2ccncc2)n1 VACMVCGPXXITOG-UHFFFAOYSA-N 0.000 description 1

- YTGOYWZAGSWPOK-UHFFFAOYSA-N c(cc1)ccc1-c1nc(-c2ccncc2)ncn1 Chemical compound c(cc1)ccc1-c1nc(-c2ccncc2)ncn1 YTGOYWZAGSWPOK-UHFFFAOYSA-N 0.000 description 1

- JJUHYOUNRYJQOE-UHFFFAOYSA-N c1cc(-c2nc(-c3ccncc3)ncn2)cnc1 Chemical compound c1cc(-c2nc(-c3ccncc3)ncn2)cnc1 JJUHYOUNRYJQOE-UHFFFAOYSA-N 0.000 description 1

- CMBFWILAGNQSCO-UHFFFAOYSA-N c1cc(-c2nc(-c3ccncc3)ncn2)ncc1 Chemical compound c1cc(-c2nc(-c3ccncc3)ncn2)ncc1 CMBFWILAGNQSCO-UHFFFAOYSA-N 0.000 description 1

- IZPIJKHBNCGHTI-UHFFFAOYSA-N c1ccnc(-c2nc(-c3ccncc3)nc(-c3ccncc3)n2)c1 Chemical compound c1ccnc(-c2nc(-c3ccncc3)nc(-c3ccncc3)n2)c1 IZPIJKHBNCGHTI-UHFFFAOYSA-N 0.000 description 1

- OFDVABAUFQJWEZ-UHFFFAOYSA-N c1cncc(-c2cnccc2)c1 Chemical compound c1cncc(-c2cnccc2)c1 OFDVABAUFQJWEZ-UHFFFAOYSA-N 0.000 description 1

- CBMYFVSIIYILRH-UHFFFAOYSA-N c1cnccc1-c1nc(-c2ccncc2)nc(-c2ccncc2)n1 Chemical compound c1cnccc1-c1nc(-c2ccncc2)nc(-c2ccncc2)n1 CBMYFVSIIYILRH-UHFFFAOYSA-N 0.000 description 1

- FDGOAUPCDXMTPA-UHFFFAOYSA-N c1cnccc1-c1nc(-c2ccncc2)ncn1 Chemical compound c1cnccc1-c1nc(-c2ccncc2)ncn1 FDGOAUPCDXMTPA-UHFFFAOYSA-N 0.000 description 1

- OAOYLHDSLIUMRV-UHFFFAOYSA-N c1cnccc1-c1ncncn1 Chemical compound c1cnccc1-c1ncncn1 OAOYLHDSLIUMRV-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/86—Inert electrodes with catalytic activity, e.g. for fuel cells

- H01M4/90—Selection of catalytic material

- H01M4/9008—Organic or organo-metallic compounds

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B32/00—Carbon; Compounds thereof

- C01B32/05—Preparation or purification of carbon not covered by groups C01B32/15, C01B32/20, C01B32/25, C01B32/30

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/10—Fuel cells with solid electrolytes

- H01M2008/1095—Fuel cells with polymeric electrolytes

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/30—Hydrogen technology

- Y02E60/50—Fuel cells

Definitions

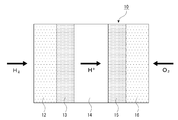

- the present invention relates to a method for producing a nitrogen-containing carbon alloy, a nitrogen-containing carbon alloy, and a fuel cell catalyst. Specifically, the present invention relates to a method for producing a nitrogen-containing carbon alloy including a step of firing a precursor containing a heteroaromatic ring compound having a nitrogen-containing aromatic group and an inorganic metal salt, a nitrogen-containing carbon alloy, and a nitrogen-containing compound. Fuel cell catalyst using carbon alloy

- a noble metal catalyst using platinum (Pt), palladium (Pd), etc. is used as a catalyst having a high oxygen reduction activity, for example, in a solid polymer electrolyte fuel cell used in automobiles, household electric heat supply systems, etc.

- platinum palladium

- noble metal-based catalysts are expensive, it is difficult to further spread them. For this reason, technological development of a catalyst in which platinum is greatly reduced or a catalyst formed without using platinum is being promoted.

- Patent Document 1 discloses a polymer electrolyte fuel cell catalyst comprising a composite of an s-triazine ring derivative and a metal.

- Patent Document 2 discloses a nitrogen-containing carbon alloy catalyst produced by firing a nitrogen-containing heterocyclic compound having a molecular weight of 60 to 2000 and an inorganic metal or inorganic metal salt.

- Non-Patent Document 1 discloses a non-platinum catalyst for a fuel cell prepared by heating and firing a mixture of 2- pyridyltriazine Fe complex [Fe (TPTZ) 2 ] supported on carbon.

- TPTZ 2- pyridyltriazine Fe complex

- it has been proposed to fire a mixture of 2-pyridyltriazine and a metal complex, and there is no description about using an inorganic metal or firing an inorganic metal.

- the nitrogen-containing carbon alloy catalyst containing a nitrogen-containing compound can exhibit catalytic activity without using platinum.

- recent applications such as fuel cells are required to have higher oxygen reduction activity, and the oxygen reduction activity of conventional carbon catalysts may be insufficient. For this reason, it has been desired to produce a nitrogen-containing carbon alloy that can exhibit higher oxygen reduction activity.

- the yield is poor, and further improvement in productivity has been demanded.

- the present inventors proceeded with studies for the purpose of producing a nitrogen-containing carbon alloy having higher oxygen reduction activity. Furthermore, the present inventors have studied for the purpose of increasing the yield of nitrogen-containing carbon alloy and increasing productivity.

- the present inventors calcined a precursor containing a heteroaromatic ring compound having a nitrogen-containing aromatic group having a specific structure and an inorganic metal salt, It has been found that oxygen reduction activity can be sufficiently enhanced by producing a nitrogen-containing carbon alloy. Furthermore, the present inventors succeeded in increasing the yield of nitrogen-containing carbon alloy, and completed the present invention. Specifically, the present invention has the following configuration.

- a precursor containing an inorganic metal salt and at least one selected from a heteroaromatic ring compound having a nitrogen-containing aromatic group represented by the following general formula (1), a salt thereof and a hydrate thereof is calcined.

- a method for producing a nitrogen-containing carbon alloy comprising a step;

- A represents an atomic group composed of a 5- to 11-membered non-fused heteroaromatic ring

- L represents a single bond or a (x + 1) -valent linking group

- B represents a hydrogen atom, a substituted or Represents an unsubstituted aromatic group, or a substituted or unsubstituted nitrogen-containing aromatic group, and at least one B is a substituted or unsubstituted nitrogen-containing aromatic group, and at least one of the nitrogen-containing aromatic groups ,

- Any one or both of the ring skeleton constituent atoms at the 3-position and the 4-position with respect to the bonding site with L are nitrogen atoms.

- the number of heteroatoms in the non-fused heteroaromatic ring of A is the same as or more than the number of heteroatoms per one nitrogen-containing aromatic group of B.

- X and y each independently represents an integer of 1 or more.

- the heteroaromatic ring compound having a nitrogen-containing aromatic group represented by the general formula (1) is a nitrogen-containing carbon alloy according to [1] or [2] represented by the following general formula (2).

- Q 1 to Q 3 each independently represent a hetero atom or a carbon atom, at least one of Q 1 to Q 3 is a nitrogen atom, b1 to b3 are each independently a hydrogen atom, Represents a substituted or unsubstituted aromatic group, or a substituted or unsubstituted nitrogen-containing aromatic group, and at least one of b1 to b3 is a substituted or unsubstituted nitrogen-containing aromatic group, and a nitrogen-containing aromatic group

- one or both of the ring skeleton constituent atoms at the 3-position and the 4-position with respect to the binding site are nitrogen atoms.

- the number of heteroatoms in the non-condensed heteroaromatic ring containing Q 1 to Q 3 is the same as or larger than the number of heteroatoms per one nitrogen-containing aromatic group of b1 to b3.

- the heteroaromatic ring compound having a nitrogen-containing aromatic group is a compound represented by the following formula (3) or (4): the nitrogen-containing carbon alloy according to any one of [1] to [6] Production method.

- the heteroaromatic ring compound having a nitrogen-containing aromatic group represented by the general formula (1) is a nitrogen-containing carbon alloy according to [1] or [2] represented by the following general formula (5).

- A represents an atomic group composed of a 5- to 11-membered non-fused heteroaromatic ring

- L represents a single bond or a (x + 1) -valent linking group

- B represents a hydrogen atom, substituted Or an unsubstituted aromatic group or a substituted or unsubstituted nitrogen-containing aromatic group, and at least one B is a substituted or unsubstituted nitrogen-containing aromatic group, and at least one of the nitrogen-containing aromatic groups

- any one or both of the ring skeleton constituting atoms at the 3rd and 4th positions relative to the bonding site with L are nitrogen atoms.

- the number of heteroatoms in the non-fused heteroaromatic ring of A is the same as or more than the number of heteroatoms per one nitrogen-containing aromatic group of B.

- X represents an integer of 1 or more.

- the method for producing a nitrogen-containing carbon alloy according to [1] or [2], wherein the heteroaromatic ring compound having a nitrogen-containing aromatic group is a compound selected from the following compound group.

- [16] The method for producing a nitrogen-containing carbon alloy according to [14] or [15], wherein the organometallic complex is an acetylacetone iron (II) complex.

- the firing step is a step of firing the precursor at 400 ° C. or higher.

- a nitrogen-containing carbon alloy having a sufficiently high oxygen reduction activity can be obtained.

- the nitrogen-containing carbon alloy obtained by the production method of the present invention can be used as a carbon catalyst, and such a carbon catalyst is preferably used for a fuel cell or an environmental catalyst.

- the yield of a nitrogen-containing carbon alloy can be raised and productivity can be improved.

- a numerical range expressed using “to” means a range including numerical values described before and after “to” as a lower limit value and an upper limit value.

- the present invention includes a step of firing a precursor containing an inorganic metal salt and at least one selected from a heteroaromatic ring compound having a nitrogen-containing aromatic group having a specific structure, a salt thereof and a hydrate thereof.

- the present invention relates to a method for producing a nitrogen carbon alloy.

- the hetero aromatic ring compound which has a nitrogen-containing aromatic group, an inorganic metal salt, etc. are demonstrated in detail.

- Heteroaromatic ring compound having nitrogen-containing aromatic group used in the present invention is represented by the following general formula (1). Note that the heteroaromatic ring compound having a nitrogen-containing aromatic group includes salts thereof or hydrates thereof.

- A represents an atomic group composed of a 5- to 11-membered non-condensed heteroaromatic ring, and L represents a single bond or a (x + 1) -valent linking group.

- B represents a hydrogen atom, a substituted or unsubstituted aromatic group, or a substituted or unsubstituted nitrogen-containing aromatic group, and at least one B is a substituted or unsubstituted nitrogen-containing aromatic group, In at least one of the group groups, either one or both of the ring skeleton constituent atoms at the 3rd and 4th positions relative to the bonding site with L is a nitrogen atom.

- the number of heteroatoms in the non-fused heteroaromatic ring of A is the same as or more than the number of heteroatoms per one nitrogen-containing aromatic group of B.

- X and y each independently represents an integer of 1 or more.

- A represents an atomic group composed of a 5- to 11-membered non-condensed heteroaromatic ring.

- the non-fused heteroaromatic ring is a heteroaromatic ring having no fused ring, and the atomic group composed of such a non-fused heteroaromatic ring has at least one non-fused heteroaromatic ring.

- the atomic group composed of a non-fused heteroaromatic ring may be composed of two or more non-fused heteroaromatic rings, but is preferably composed of one non-fused heteroaromatic ring.

- the number of ring members in one non-fused heteroaromatic ring may be 5 to 11, preferably 5 to 10, more preferably 5 to 8, and still more preferably 5 or 6.

- hetero atom constituting the 5- to 11-membered non-condensed heteroaromatic ring examples include 1 to 3 heteroatoms selected from the group consisting of a nitrogen atom, an oxygen atom and a sulfur atom.

- the non-fused heteroaromatic ring examples include a pyridine ring, a pyrimidine ring, a triazine ring, an imidazole ring, a pyrroline ring, an imidazole group, a furan ring, and a thiophene ring.

- a pyridine ring, a pyrimidine ring, and a triazine ring Preferred examples include an imidazole ring and a pyrroline ring.

- L represents a single bond or a (x + 1) -valent linking group.

- the (x + 1) -valent linking group includes a substituted or unsubstituted aromatic group, a substituted or unsubstituted alkylene group, a substituted or unsubstituted alkenylene group, a substituted or unsubstituted alkynylene group, a substituted or unsubstituted cycloalkylene X ⁇ 1 groups from the group, —CO—, —CO 2 —, —O—, —NH—, —SO—, —SO 2 —, —S—, —CONH—, —NHCO—, or combinations thereof.

- the aromatic group preferably has 6 to 20 carbon atoms, more preferably a phenylene group, a biphenylene group, or a naphthylene group, further preferably a phenylene group or a biphenylene group, and more preferably a phenylene group. Particularly preferred.

- the alkylene group preferably has 1 to 20 carbon atoms, more preferably 1 to 15 carbon atoms, still more preferably 1 to 10 carbon atoms, and particularly preferably 1 to 6 carbon atoms.

- the alkenylene group preferably has 2 to 20 carbon atoms, more preferably 2 to 15 carbon atoms, still more preferably 2 to 10 carbon atoms, and particularly preferably 2 to 6 carbon atoms.

- the alkynylene group preferably has 2 to 20 carbon atoms, more preferably 2 to 15 carbon atoms, still more preferably 2 to 10 carbon atoms, and particularly preferably 2 to 6 carbon atoms.

- the cycloalkylene group preferably has 4 to 20 carbon atoms, more preferably 4 to 15 carbon atoms, still more preferably 5 to 12 carbon atoms, and particularly preferably 5 to 10 carbon atoms.

- the substituent When having a substituent, the substituent includes a halogen atom (fluorine atom, chloro atom, bromine atom or iodine atom), hydroxy group, cyano group, aliphatic group (aralkyl group, cycloalkyl group, active methine group, etc.

- halogen atom fluorine atom, chloro atom, bromine atom or iodine atom

- hydroxy group cyano group

- aliphatic group aralkyl group, cycloalkyl group, active methine group, etc.

- a halogen atom (a fluorine atom, a chloro atom, a bromine atom or an iodine atom), a vinyl group, an allyl group, an acetylenyl group, an aryl group (regarding the position of substitution) and an amino group are preferable as a substituent.

- L represents a single bond or a divalent linking group

- L represents a trivalent linking group.

- divalent linking group examples include a substituted or unsubstituted alkylene group, a substituted or unsubstituted alkenylene group, an alkynylene group, a substituted or unsubstituted cycloalkylene group, a substituted or unsubstituted phenylene group, a substituted or unsubstituted group.

- Examples of the trivalent linking group include:>CH—,> N—, a group obtained by removing one hydrogen atom from a group having a substituent among the groups listed as examples of the divalent linking group, and the like. Can be mentioned.

- L may be a group obtained by combining two or more of the above linking groups. For example, a combination of two or more substituted or unsubstituted alkylene groups, alkenylene groups, and alkynylene groups, or a combination of two or more substituted or unsubstituted alkylene groups, alkenylene groups, alkynylene groups, and substituted or unsubstituted phenylene groups. It can be based.

- the plurality of L may be the same or different.

- the (x + 1) -valent linking group include a phenylene group, an alkylene group having 1 to 6 carbon atoms, an alkenylene group having 2 to 6 carbon atoms, an alkynylene group having 2 to 6 carbon atoms, —CO 2 —, —CONH—, — O- or a combination of x + 1 valences in which x-1 arbitrary hydrogen atoms are removed from a combination thereof, phenylene group, alkylene group having 1 to 4 carbon atoms, alkenylene group having 2 to 6 carbon atoms Further, an alkynylene group having 2 to 6 carbon atoms, —CONH—, or a combination of x + 1 valences in which any hydrogen atom of x-1 is removed from a combination thereof is more preferable.

- B represents a hydrogen atom, a substituted or unsubstituted aromatic group, or a substituted or unsubstituted nitrogen-containing aromatic group, and at least one B is a substituted or unsubstituted nitrogen-containing aromatic group

- the nitrogen-containing aromatic group means a group having a nitrogen atom as a constituent atom of the aromatic group.

- at least one of the Bs may be a substituted or unsubstituted nitrogen-containing aromatic group, but it is preferable that all Bs are substituted or unsubstituted nitrogen-containing aromatic groups.

- the nitrogen-containing aromatic group is preferably a pyridyl group, a pyrimidyl group, a triazyl group, or an imidazolyl group.

- a plurality of B may be the same or different.

- B is preferably a hydrogen atom, a phenyl group, a pyridyl group, a pyrimidyl group, a triazine group, or an imidazolyl group.

- the number of carbon atoms is preferably 6 to 14, more preferably 6 to 10, and particularly preferably a phenyl group.

- At least one B is a nitrogen-containing aromatic group, and in this case, it is preferably 5 to 11 members, more preferably 5 to 8 members, more preferably 5 or 6 members, and a pyridyl group , A pyrimidyl group, a triazine group, or an imidazolyl group is particularly preferable.

- aromatic group or nitrogen-containing aromatic group represented by B has a substituent

- preferable substituents include a halogen atom (a fluorine atom, a chloro atom, a bromine atom or an iodine atom), a hydroxy group, and a cyano group.

- Aliphatic groups including aralkyl groups, cycloalkyl groups, active methine groups, etc.

- vinyl groups including aralkyl groups, cycloalkyl groups, active methine groups, etc.

- vinyl groups allyl groups, acetylenyl groups, aryl groups (regardless of the position of substitution), acyl groups, aliphatic oxy groups (alkoxy groups) Or an aryloxy group, a heterocyclic oxy group, an aliphatic carbonyl group, an arylcarbonyl group, a heterocyclic carbonyl group, an aliphatic oxycarbonyl group.

- Substituents containing unsaturated groups are more preferred, vinyl group, allyl group, acetylenyl group, aryl group (phenyl group, naphthyl group, phenanthrene group, anthracenyl group, triphenyl group, pyrenyl group, perylenyl group, benzhydryl group, benzyl group. Group, cinamyl group, cumenyl group, methicyl group, phenylethyl group, styryl group, tolyl group, trityl group, xylyl group). These substituent groups may be further substituted, and examples of the further substituent include groups selected from the substituents and heteroaromatic groups described above (regardless of the position of substitution).

- either one or both of the ring skeleton constituting atoms at the 3-position and the 4-position with respect to the bonding site with L are nitrogen atoms.

- either one or both of the ring skeleton constituting atoms at the 3-position and the 4-position with respect to the bonding site with L may be a nitrogen atom.

- it is more preferable that either one or both of the ring skeleton constituent atoms at the 3-position and the 4-position with respect to the bonding site with L is a nitrogen atom.

- the ring skeleton constituting atom at the 3rd or 4th position with respect to the bonding position with L is a nitrogen atom, but the ring skeleton constituting atom other than the corresponding site is a nitrogen atom. May be.

- the ring skeleton constituent atoms at the 3rd and 1st positions relative to the bond position with L are nitrogen atoms

- the ring skeleton constituent atoms at the 3rd and 2nd positions are nitrogen atoms

- the ring skeleton constituent atom may be a nitrogen atom.

- the ring skeleton constituting atom at the 3rd or 4th position is a nitrogen atom, for example, it is preferred that one or both of the ring skeleton constituting atoms at the 3rd and 4th positions are nitrogen atoms.

- the atomic group composed of the non-condensed heteroaromatic ring includes a triazine ring, it is preferable that the ring skeleton constituent atom at the 2-position in the nitrogen-containing aromatic group is not a nitrogen atom.

- the number of heteroatoms in the non-condensed heteroaromatic ring of A is the same as or larger than the number of heteroatoms per one nitrogen-containing aromatic group of B.

- the number of heteroatoms per all nitrogen-containing aromatic groups satisfies the above condition.

- the atomic group of A is composed of two or more non-fused heteroaromatic rings

- the number of heteroatoms in the non-fused heteroaromatic ring of A represents the number of heteroatoms per one non-fused heteroaromatic ring. .

- x and y each independently represent an integer of 1 or more.

- x is preferably an integer of 1 to 6, more preferably an integer of 1 to 5, more preferably an integer of 1 to 4, and still more preferably an integer of 1 to 3. 1 or 2 is particularly preferable.

- y is preferably an integer of 1 to 8, more preferably an integer of 1 to 6, more preferably an integer of 1 to 5, and more preferably an integer of 1 to 3. Further preferred.

- the nitrogen-containing aromatic group is coordinated with an inorganic metal or a salt thereof to form a porous structure.

- the central atomic group of the heteroaromatic ring compound is thermally decomposed to form an oxygen reduction reaction (ORR) active site, and a highly active nitrogen-containing carbon alloy can be obtained.

- ORR oxygen reduction reaction

- the thermal decomposition of the non-fused heteroaromatic part (central atomic group) can be easily advanced. . Thereby, formation of an oxygen reduction reaction (ORR) active site can be promoted, and a higher activity nitrogen-containing carbon alloy can be obtained.

- the coordination between the inorganic metal and the nitrogen-containing aromatic group is such that either one or both of the ring skeleton constituent atoms at the 3-position and the 4-position with respect to the bonding position with L in the nitrogen-containing aromatic group are nitrogen atoms. In some cases, it becomes easier to proceed. This is because, when the ring skeleton constituent atom at the 2-position is a nitrogen atom, the distance between the hetero atom of the central atomic group and the nitrogen atom of the nitrogen-containing aromatic group is reduced, so that the inorganic metal is the central atomic group. This is thought to be due to coordination with a heteroatom to form a complex.

- Such coordination is not a preferred coordination mode of the inorganic metal and the nitrogen-containing aromatic group, and causes the thermal decomposition of the central atomic group to hardly proceed. For this reason, it is considered that when the ring skeleton constituent atom at the 2-position is a nitrogen atom, formation of an oxygen reduction reaction (ORR) active site is suppressed, and the catalytic activity of the nitrogen-containing carbon alloy is lowered.

- ORR oxygen reduction reaction

- the heteroaromatic ring compound having a nitrogen-containing aromatic group represented by the general formula (1) is preferably represented by the following general formula (2).

- Q 1 to Q 3 each independently represent a hetero atom or a carbon atom, at least one of Q 1 to Q 3 is a nitrogen atom, b1 to b3 are each independently a hydrogen atom, Represents a substituted or unsubstituted aromatic group, or a substituted or unsubstituted nitrogen-containing aromatic group, and at least one of b1 to b3 is a substituted or unsubstituted nitrogen-containing aromatic group, In at least one, either one or both of the ring skeleton constituent atoms at the 3-position and the 4-position with respect to the binding site are nitrogen atoms.

- the number of heteroatoms in the non-condensed heteroaromatic ring containing Q 1 to Q 3 is the same as or larger than the number of heteroatoms per one nitrogen-containing aromatic group of b1 to b3.

- the binding site of b1 to b3 refers to a binding site of b1 to b3 and a linking group between non-condensed heteroaromatic rings including Q 1 to Q 3 .

- Q 1 to Q 3 each independently represents a hetero atom or a carbon atom, and at least one of Q 1 to Q 3 represents a nitrogen atom.

- Q 1 to Q 3 are each independently preferably a nitrogen atom, a sulfur atom, or a carbon atom, particularly preferably a nitrogen atom or a carbon atom, and any one is a nitrogen atom.

- the atoms in Q 1 to Q 3 may be ionized.

- it is preferable that at least one of Q 1 ⁇ Q 3 is a nitrogen atom, and more preferably all of Q 1 ⁇ Q 3 is a nitrogen atom.

- B1 to b3 in the general formula (2) have the same meaning as B in the general formula (1), and the preferred range is also the same.

- b1 to b3 preferably represent a substituted or unsubstituted nitrogen-containing aromatic group, and b1 to b3 are preferably 5 or 6 membered rings, preferably 6 membered rings. Is more preferable.

- substituents that can be taken by b1 to b3 include the same substituents as those that can be taken by B in the general formula (1).

- b1 to b3 are preferably a pyridyl group, a pyrimidyl group or a triazyl group, and more preferably a pyridyl group or a pyrimidyl group.

- either one or both of the ring skeleton constituting atoms at the 3-position and the 4-position with respect to the bonding site with L are nitrogen atoms.

- the ring skeleton constituting atom at the 2-position with respect to the binding site is not a nitrogen atom.

- Q 1 and Q 3 are preferably carbon atoms

- Q 1 And Q 2 are preferably carbon atoms.

- Q 2 and Q 3 are preferably carbon atoms. That is, the distance between the nitrogen atom constituting the central atomic group and the nitrogen atom of the nitrogen-containing aromatic group represented by b1 to b3 is preferably a certain distance or more, and the distance between the nitrogen atoms of the nitrogen-containing aromatic group Is preferably 4 atoms or more.

- the number of heteroatoms in the non-condensed heteroaromatic ring containing Q 1 to Q 3 is the same as or larger than the number of heteroatoms per one nitrogen-containing aromatic group of b1 to b3.

- the number of heteroatoms per one nitrogen-containing aromatic group satisfies the above condition.

- the number of heteroatoms in the non-fused heteroaromatic ring represents the number of heteroatoms per one non-fused heteroaromatic ring.

- the heteroaromatic ring compound having a nitrogen-containing aromatic group represented by the general formula (1) is preferably a compound represented by the following formula (3) or (4).

- the heteroaromatic ring compound having a nitrogen-containing aromatic group may be a compound represented by the following general formula (5).

- A represents an atomic group composed of a 5- to 11-membered non-fused heteroaromatic ring

- L represents a single bond or a (x + 1) -valent linking group

- B represents a hydrogen atom, substituted Or an unsubstituted aromatic group or a substituted or unsubstituted nitrogen-containing aromatic group, and at least one B is a substituted or unsubstituted nitrogen-containing aromatic group, and at least one of the nitrogen-containing aromatic groups

- any one or both of the ring skeleton constituting atoms at the 3rd and 4th positions relative to the bonding site with L are nitrogen atoms.

- the number of heteroatoms in the non-fused heteroaromatic ring of A is the same as or more than the number of heteroatoms per one nitrogen-containing aromatic group of B.

- X represents an integer of 1 or more.

- a in the general formula (5) is the same as A in the general formula (1), and the preferred range is also the same.

- L in General formula (5) is the same as L in General formula (1), and its preferable range is also the same.

- B represents a hydrogen atom, a substituted or unsubstituted aromatic group, or a substituted or unsubstituted nitrogen-containing aromatic group, and at least one B is a substituted or unsubstituted nitrogen-containing aromatic group Represents a group.

- the nitrogen-containing aromatic group means a group having a nitrogen atom as a constituent atom of the aromatic group.

- B in the general formula (5) is the same as B in the general formula (1), and the preferred range is also the same.

- at least one of B may be a substituted or unsubstituted nitrogen-containing aromatic group, but it is preferable that all B are substituted or unsubstituted nitrogen-containing aromatic groups.

- the nitrogen-containing aromatic group is preferably a pyridyl group, a pyrimidyl group, a triazyl group, or an imidazolyl group.

- one or both of the ring skeleton constituting atoms at the 3-position and 4-position with respect to the bonding site with L are nitrogen atoms. is there.

- the substituted or unsubstituted nitrogen-containing aromatic group represented by at least one B one or both of the ring skeleton constituting atoms at the 3-position and the 4-position with respect to the bonding site with L are nitrogen atoms.

- the preferred configuration is the same as B in the general formula (1).

- the number of heteroatoms in the non-condensed heteroaromatic ring of A is the same as or larger than the number of heteroatoms per one nitrogen-containing aromatic group of B.

- the number of heteroatoms per all nitrogen-containing aromatic groups satisfies the above condition.

- x represents an integer of 1 or more.

- x is preferably an integer of 1 to 6, more preferably an integer of 1 to 5, more preferably an integer of 1 to 4, and still more preferably an integer of 1 to 3. 1 or 2 is particularly preferable.

- heteroaromatic ring compound having a nitrogen-containing aromatic group represented by the general formula (1) include the following compounds. However, the present invention is not limited to the following specific examples.

- the nitrogen-containing aromatic group of a terminal part corresponds to the non-condensed heteroaromatic ring represented by A of General formula (1), and the connection part containing a benzene ring is common. It corresponds to the linking group represented by L in formula (1).

- heteroaromatic ring compound having a nitrogen-containing aromatic group represented by the general formula (1) the following compounds are preferably used among the above compounds.

- the heteroaromatic ring compound having a nitrogen-containing aromatic group described above forms a crystal structure by two or more bonds or interactions selected from ⁇ - ⁇ interaction, coordination bond, charge transfer interaction and hydrogen bond. It is preferable. This is because by using a low molecular weight compound having a crystal structure, the intermolecular interaction can be improved and vaporization during firing when obtaining a nitrogen-containing carbon alloy can be suppressed.

- the crystal structure here refers to the arrangement and arrangement of molecules in the crystal. In other words, the crystal structure consists of a repeating structure of unit cell, and the molecules are arranged at any position in the unit cell and oriented. In the crystal, the molecules have a uniform appearance.

- each molecular interaction is the same inside or outside the unit cell.

- a heteroaromatic compound having a nitrogen-containing aromatic group having a laminated structure an aromatic ring, a heterocyclic ring, a condensed polycyclic ring, a condensed heterocyclic polycyclic ring, an unsaturated group (nitrile group, vinyl group, allyl group, acetylene) Group) and the like (for example, an aromatic ring is a face-to-face ⁇ - ⁇ interaction ( ⁇ - ⁇ stack)).

- Stacking is performed by SP 2 orbits of carbons derived from unsaturated bonds in these rings and groups and regularly overlapping at equal intervals between molecules to form a stacked column structure.

- the adjacent stacked columns have a uniform structure in which the intermolecular distance is defined by hydrogen bonding or van der Waals interaction. For this reason, it has the effect that the heat transfer in a crystal

- the heteroaromatic ring compound having a nitrogen-containing aromatic group used in the present invention preferably has crystallinity.

- the heteroaromatic ring compound having a nitrogen-containing aromatic group is preferable because the crystallinity is crystallinity, and the compound can be controlled in orientation during firing, so that it becomes a uniform carbon material.

- the heteroaromatic ring compound having a nitrogen-containing aromatic group preferably further has a melting point of 25 ° C. or higher.

- the melting point is 25 ° C. or higher, there is an air layer that contributes to heat resistance during firing, boiling or bumping can be prevented from the relationship between temperature and vapor pressure, and a carbon material can be easily obtained.

- the heteroaromatic ring compound having a nitrogen-containing aromatic group is not particularly limited in molecular weight, but in the case of a low molecular weight compound or oligomer, it is preferably 60 to 2000, more preferably 100 to 1500, and 130 to 1000. It is particularly preferred that By setting it within the above range, purification before firing becomes easy.

- the heteroaromatic ring compound having a nitrogen-containing aromatic group is a polymer

- the number average molecular weight is preferably from 2,000 to 1,000,000, and more preferably from 2,000 to 100,000.

- the molecular weight distribution (dispersion degree weight average molecular weight / number average molecular weight) is not particularly limited, but is preferably 3.0 or less, more preferably 2.0 or less, and even more preferably 1.5 or less.

- the electroconductivity of the carbon material obtained by setting it as the said range improves, it is preferable.

- JIS K 7252 shows to obtain the average molecular weight and molecular weight distribution of a polymer by plastic size exclusion chromatography

- SEC size exclusion chromatography

- the heteroaromatic ring compound having a nitrogen-containing aromatic group may be a polymer such as Poly (4-VinylPyridine), a low molecular compound or an oligomer in the above exemplary compounds.

- the degree of polymerization n is preferably 20 to 1.0 ⁇ 10 4 , more preferably 20 to 1.0 ⁇ 10 3 , and further preferably 20 to 1.0 ⁇ 10 2. preferable.

- the degree of polymerization n is preferably 2 to 20, and more preferably 4 to 10.

- the heteroaromatic compound having a nitrogen-containing aromatic group is a polymer

- the nitrogen-containing aromatic group is arranged by a covalent bond, by setting the degree of polymerization within the above range, adjacent carbons are bonded together during firing. This is preferable because it is easy to be performed and conductivity is improved.

- the heteroaromatic ring compound having a nitrogen-containing aromatic group is a low molecular weight compound or oligomer

- the nitrogen-containing aromatic group is bonded by a covalent bond.

- the nitrogen aromatic group is preferred because it is oriented with the metal, the nitrogen-containing aromatic group is easily arranged, and vacancies are easily formed.

- the heteroaromatic ring compound having a nitrogen-containing aromatic group is preferably contained in an amount of more than 0.1% by mass, and 0.5 to 99% by mass with respect to the total mass in the precursor. Is more preferable, and 5 to 90% by mass is more preferable.

- a carbon alloy having higher oxygen reduction activity can be generated.

- the heteroaromatic ring compound having a nitrogen-containing aromatic group may be used alone or in combination of two or more. Moreover, it is preferable that the metal content in the hetero aromatic ring compound which has nitrogen-containing aromatic groups other than the inorganic metal salt mentioned later is 10 ppm or less.

- the nitrogen content of the heteroaromatic ring compound having a nitrogen-containing aromatic group is preferably 0.1% by mass to 55% by mass, and preferably 1% by mass to 30% by mass with respect to the total mass of the precursor. Is more preferable, and further 4 to 20% by mass is particularly preferable.

- N nitrogen atom

- the nitrogen atom and metal are regularly positioned uniformly on the crystal edge, and the nitrogen and metal are It becomes easy to interact. Thereby, the composition ratio of nitrogen atom and metal can be a composition ratio having higher oxygen reduction activity.

- the heteroaromatic ring compound having a nitrogen-containing aromatic group is preferably a hardly volatile compound having a ⁇ TG of ⁇ 95% to ⁇ 0.1% at 400 ° C. in a nitrogen atmosphere, and is ⁇ 95% to ⁇ It is more preferably a hardly volatile compound of 1%, particularly preferably -90% to -5%.

- the heteroaromatic ring compound having a nitrogen-containing aromatic group is preferably a hardly volatile compound that is carbonized without being vaporized during firing.

- ⁇ TG is increased from 30 ° C. to 1000 ° C.

- the heteroaromatic ring compound having a nitrogen-containing aromatic group is also preferably a pigment having a structure represented by the general formula (1).

- the pigment forms a stacked column structure by ⁇ - ⁇ interaction between molecules, and has a uniform structure with a defined intermolecular distance by hydrogen bonds or van der Waals interactions between the stacked columns. It has the effect that heat transfer is easily achieved. In addition, it has crystallinity, and is vibration-reduced and heat-resistant by phonon (quantized lattice vibration) against heat. Therefore, the decomposition temperature is maintained up to the carbonization temperature, and there is an effect that the vaporization of the decomposition product is reduced and the carbonization is achieved.

- isoindoline pigments isoindolinone pigments, diketopyrrolopyrrole pigments, quinacridone pigments, oxazine pigments, phthalocyanine pigments, quinophthalone pigments, and latent pigments or dyes obtained by converting the above pigments into

- a pigment such as a lake pigment pigmented with a metal ion is preferred, and a diketopyrrolopyrrole pigment, a quinacridone pigment, an isoindoline pigment, an isoindolinone pigment, a quinophthalone pigment, and a latent pigment obtained by laminating the above pigment ( (Described later) is more preferable.

- An inorganic metal salt is used for the preparation of the precursor described above.

- the inorganic metal salt is not particularly limited, but may be a hydroxide, oxide, nitride, sulfite, sulfide, sulfonate, carbonylate, nitrate, nitrite, halide or the like.

- the counter ion is a halogen ion or a nitrate ion.

- the counter ion is a halide or nitrate that is a halogen ion, nitrate ion or sulfate ion, it is preferable because it can bind to carbon on the surface of the carbon produced during thermal decomposition and increase the specific surface area.

- the inorganic metal salt is preferably a halide, and particularly preferably an inorganic metal chloride.

- the inorganic metal salt can contain crystal water, and the inorganic metal salt is preferably a hydrated salt. Since the inorganic metal salt contains crystal water, the thermal conductivity is improved, which is preferable in that it can be uniformly fired.

- the inorganic metal salt containing crystal water for example, cobalt chloride (III) hydrate salt, iron chloride (III) hydrate salt, cobalt chloride (II) hydrate salt, iron chloride (II) hydrate salt is preferably used. it can.

- the metal species of the inorganic metal salt is preferably at least one of Fe, Co, Ni, Mn, and Cr, and more preferably Fe or Co.

- Fe, Co, Ni, Mn, and Cr salts are excellent in forming a nano-sized shell structure that improves the catalytic activity of the carbon catalyst, and in particular, Co and Fe form a nano-sized shell structure. It is preferable because it is particularly excellent.

- Co and Fe contained in the carbon catalyst can improve the oxygen reduction activity of the catalyst in the carbon catalyst. Most preferably, it is Fe as a transition metal.

- the Fe-containing nitrogen-containing carbon alloy has a high rising potential, has a higher number of reaction electrons than Co, and can relatively improve the durability of the fuel cell.

- elements other than transition metals for example, B, alkali metals (Na, K, Cs), alkaline earths (Mg, Ca, Ba), lead, tin, indium, thallium, etc. ) May be included in one or more types.

- the precursor includes the total of the heteroaromatic ring compound having a nitrogen-containing aromatic group and the inorganic metal salt contained in the precursor (however, the total includes the mass of hydrated water), It is preferable that the inorganic metal salt (however, the inorganic metal salt here includes the mass of hydrated water) exceeds 5 mass%.

- the carbon alloy which has higher oxygen reduction activity can be produced

- the decomposition product interacts with the metal (forms a complex), and the performance of the nitrogen-containing carbon alloy catalyst is further improved. Further, due to the catalytic action of a specific transition metal compound added to a heteroaromatic ring compound having a nitrogen-containing aromatic group containing a nitrogen atom (N) as a constituent element, the nitrogen atom (N) is increased on the carbon catalyst surface. It is preferable to form carbon fine particles containing a transition metal compound which forms a nitrogen-containing carbon alloy fixed at a concentration and interacts with the nitrogen atom (N). In addition, the transition metal compound which interacted with some nitrogen atoms (N) by the acid treatment mentioned later may drop off.

- the nitrogen-containing carbon alloy obtained in the present invention is based on the total of the heteroaromatic ring compound having a nitrogen-containing aromatic group and the inorganic metal salt contained in the precursor (however, the total includes the mass of hydrated water)

- the inorganic metal salt (however, the inorganic metal salt here includes the mass of hydrated water) exceeds 0.1% by mass, and exceeds 0.5% by mass and is 85% by mass or less. More preferably, it is contained more than 1 mass% and 70 mass% or less. By setting it within this range, a carbon alloy having high oxygen reduction reaction activity (ORR activity) can be generated.

- the ORR activity can be measured as an ORR activity value by obtaining a potential by the method described in detail in Examples.

- the value of potential at the time of oxygen reduction is high, specifically, the potential of the current density values -1 mA / cm 2 in the electrode coating weight of 0.05 mg / cm 2 is 0 .39V or more is preferable, 0.43V or more is more preferable, and 0.45V or more is more preferable.

- the potential of the current density values -1 mA / cm 2 in the electrode coating amount of 0.5 mg / cm 2 is preferably not less than 0.70 V, more preferably at least 0.72V, and even more preferably 0.74 V.

- the coating amount and the current density increase linearly, but as the coating amount increases, the current density decreases from the assumed straight line due to an increase in resistance between carbon alloy particles, an increase in diffusion resistance of oxygen and water, and the like. According to Ohm's law, the application amount and the potential are similarly deviated from linear and lower in the relationship between the application amount and the potential.

- the value of the potential at 0.5 mg / cm 2 is a value that takes into account the catalytic activity and the conductivity of the carbon alloy shown at 0.05 mg / cm 2 , and is particularly preferable because of its excellent conductivity.

- the heteroaromatic ring compound having a nitrogen-containing aromatic group and the inorganic metal salt do not need to be uniformly dispersed in the organic material before firing. That is, when a heteroaromatic ring compound having a nitrogen-containing aromatic group undergoes calcination decomposition, if the decomposition product is in contact with a vaporized product such as an inorganic metal salt, an active species having oxygen reduction reaction activity is formed. Therefore, the oxygen reduction reaction activity of the carbon alloy is not affected by the mixed state of the heteroaromatic ring compound and the inorganic metal salt at room temperature.

- the particle diameter of the inorganic metal salt is preferably 0.001 to 100 ⁇ m. More preferably, it is 0.01 to 10 ⁇ m. By making the particle size of the inorganic metal salt within this range, it becomes possible to uniformly mix with the heteroaromatic ring compound having a nitrogen-containing aromatic group, and the heteroaromatic ring compound is likely to form a complex when it is decomposed. .

- the precursor preferably further contains at least one organometallic complex.

- organometallic complexes include compounds described in the Basic Complex Engineering Study Group, Coordination Chemistry-Fundamentals and Latest Topics, and Kodansha Scientific (1994).

- a compound in which a ligand is coordinated can be preferably exemplified, and a metal acetate complex or a ⁇ -diketone metal complex can be preferably used.

- the organometallic complex can take the coordination number of various ligands, may be a coordination geometric isomer, and may have different valences of metal ions.

- the organometallic complex may be an organometallic compound having a metal-carbon bond.

- Preferable metal ions are Fe, Co, Ni, Mn and Cr ions.

- Preferable ligands include monodentate ligands (halide ions, cyanide ions, ammonia, pyridine (py), triphenylphosphine, carboxylic acid, etc.), bidentate ligands (ethylenediamine (en), ⁇ - Diketonate (acetylacetonate (acac), pivaloylmethane (DPM), diisobutoxymethane (DIBM), isobutoxypivaloylmethane (IBPM), tetramethyloctadione (TMOD)), trifluoroacetylacetonate (TFA), bipyridine (Bpy), phenanthrene (phen), etc.), multidentate ligands (ethylenediaminetetraacetate ion (edta), etc.).

- ⁇ -diketone metal complexes bis (acetylacetonato) iron (II) [Fe (acac) 2 ], tris (acetylacetonato) iron (III) [Fe ( acac) 3 ], bis (acetylacetonato) cobalt (II) [Co (acac) 2 ], tris (acetylacetonato) cobalt (III) [Co (acac) 3 ], bis (dipivaloylmethane) iron (II) [Fe (DPM) 2 ], tris (dipivaloylmethane) iron (III) [Fe (DPM) 3 ], tris (dipivaloylmethane) cobalt (III) [Co (DPM) 3 ] , bis (diisobutoxyphenyl methane) iron (II) [Fe (DIBM) 2], tris (diisobutoxyphen

- ⁇ -diketone metal complexes bis (acetylacetonato) iron (II) [Fe (acac) 2 ], tris (acetylacetonato) iron (III) [Fe (acac) 3 ], bis (dipivaloyl) Methane) iron (II) [Fe (DPM) 2 ], bis (diisobutoxymethane) iron (II) [Fe (DIBM) 2 ], bis (isobutoxypivaloylmethane) iron (II) [Fe (IBPM) 2 ], bis (tetramethyloctadione) iron (II) [Fe (TMOD) 2 ]), N, N′-ethylenediaminebis (salicylideneaminato) iron (II) [Fe (salen)], tris (2,2′-bipyridine) iron (II) chloride [Fe (bpy) 3 ] Cl 2

- the organometallic complex preferably contains a ⁇ -diketone metal complex.

- a ⁇ -diketone metal complex may be used alone, or a ⁇ -diketone metal complex and another organometallic complex may be mixed and used.

- the ⁇ -diketone metal complex represents a compound represented by the following general formula (6) and tautomers thereof.

- M represents a metal

- R 1 and R 3 each independently represents a hydrocarbon group which may have a substituent

- R 2 has a hydrogen atom or a substituent.

- the hydrocarbon group which may be made is shown.

- R 1 , R 2 and R 3 may be bonded to each other to form a ring.

- n represents an integer of 0 or more

- m represents an integer of 1 or more.

- the ⁇ -diketone or its ion is coordinated or bonded to the atom or ion of the metal M.

- Preferred metals include Fe, Co, Ni, Mn and Cr, more preferably Fe and Co, and still more preferably Fe.

- Examples of the “hydrocarbon group” in the hydrocarbon group optionally having a substituent for R 1 , R 2 , and R 3 include an aliphatic hydrocarbon group, an alicyclic hydrocarbon group, and an aromatic hydrocarbon group. , Heterocyclic (heterocyclic) hydrocarbon groups, and groups in which a plurality of these are bonded.

- Examples of the aliphatic hydrocarbon group include alkyl groups such as methyl, ethyl, propyl, isopropyl, butyl, isobutyl, s-butyl, t-butyl, and hexyl groups (C 1-6 alkyl groups and the like); An alkenyl group ( C2-6 alkenyl group etc.) etc.

- Examples of the alicyclic hydrocarbon group include cycloalkyl groups such as cyclopentyl and cyclohexyl groups (3 to 15-membered cycloalkyl groups and the like); cycloalkenyl groups such as cyclohexenyl groups (3 to 15-membered cycloalkenyl groups and the like) ); A bridged carbocyclic group such as an adamantyl group (such as a bridged carbocyclic group having about 6 to 20 carbon atoms).

- Examples of the aromatic hydrocarbon group include an aromatic hydrocarbon group (aryl group) having about 6 to 20 carbon atoms such as a phenyl group and a naphthyl group.

- Heterocyclic (heterocyclic) hydrocarbon groups include, for example, nitrogen-containing five-membered hydrocarbon groups such as pyrrolyl, imidazolyl and pyrazolyl groups; nitrogen-containing six-membered pyridyl, pyrazinyl, pyrimidinyl and pyridazinyl groups Member ring hydrocarbon group: pyrrolidinyl group, indolizinyl group, isoindolyl group, isoinindolinyl group, indolyl group, indazolyl group, purinyl group, quinolidinyl group, quinolinyl group, naphthyridinyl group, phthalazinyl group, quinoxalinyl group, cinnolinyl group, pteridinyl group Nitrogen-containing condensed bicyclic hydrocarbon groups such as carbazolyl group, ⁇ -carbolinyl group, phenanthridinyl group, a

- Examples of the substituent that the hydrocarbon group may have include, for example, a halogen atom such as fluorine, chlorine, bromine atom; an alkoxy group such as methoxy, ethoxy, propoxy, isopropyloxy, butoxy, isobutyloxy, t-butyloxy group (C 1-4 alkoxy group etc.); hydroxy group; alkoxycarbonyl groups such as methoxycarbonyl and ethoxycarbonyl groups (C 1-4 alkoxy-carbonyl group etc.); acyl groups such as acetyl, propionyl and benzoyl groups (C 1- 10 acyl group); cyano group; nitro group and the like.

- a halogen atom such as fluorine, chlorine, bromine atom

- an alkoxy group such as methoxy, ethoxy, propoxy, isopropyloxy, butoxy, isobutyloxy, t-butyloxy group (C 1-4 alkoxy group etc

- Examples of the ring formed by combining R 1 , R 2 , and R 3 with each other include, for example, a 5- to 15-membered cycloalkane ring or cycloalkene ring such as a cyclopentane ring, cyclopentene ring, cyclohexane ring, cyclohexene ring, etc. Is mentioned.

- R 1 and R 3 are an alkyl group (C 1-6 alkyl group etc.), an alkenyl group (C 2-6 alkenyl group etc.), a cycloalkyl group (3-15 membered cycloalkyl group etc.), a cycloalkenyl group (3- to 15-membered cycloalkenyl group etc.), aryl group (C 6-15 aryl group etc.), aryl group having a substituent (C 6 having a substituent such as p-methylphenyl group, p-hydroxyphenyl group) -15 aryl group).

- R 2 is a hydrogen atom, an alkyl group (C 1-6 alkyl group etc.), an alkenyl group (C 2-6 alkenyl group etc.), a cycloalkyl group (3-15 membered cycloalkyl group etc.), a cycloalkenyl group (3- to 15-membered cycloalkenyl group etc.), aryl group (C 6-15 aryl group etc.), aryl group having a substituent (C 6 having a substituent such as p-methylphenyl group, p-hydroxyphenyl group) -15 aryl group).

- the valence n of the metal may be any of 0, 1, 2, 3 and the like, but is usually divalent or trivalent.

- the ⁇ -diketone coordinates as the corresponding anion, ⁇ -diketonate.

- the coordination number m is usually the same.

- a solvent or the like may be axially coordinated with the metal. In that case, the valence n and the coordination number m of the metal may be different. Examples of the solvent that may be axially coordinated include pyridine, acetonitrile, alcohol, and the like, but any solvent that can be axially coordinated may be used.

- ⁇ -diketone iron complex As the ⁇ -diketone iron complex, a commercially available product may be used as it is or after purification, or it may be prepared and used. It can also be generated and used in a reaction system. When it is generated in the reaction system, for example, iron chloride, hydroxide and ⁇ -diketone such as acetylacetone may be added. At this time, a base such as ammonia, amines, alkali metal or alkaline earth metal hydroxides, carbonates or carboxylates can be added as necessary.

- a base such as ammonia, amines, alkali metal or alkaline earth metal hydroxides, carbonates or carboxylates can be added as necessary.

- the amount of ⁇ -diketone iron complex added is usually about 0.001 to 50 mol%, preferably 0.01 to 20 mol%, particularly preferably about 0.1 to 10 mol%.

- a conductive assistant may be added to the precursor and fired, or may be added to the carbon alloy. Since the conductive auxiliary agent is uniformly dispersed, it is preferable to add a conductive auxiliary agent and fire.

- a conductive support agent For example, Norit (made by NORIT), Ketjen black (made by Lion), Vulcan (made by Cabot), black pearl (made by Cabot), acetylene black (Chevron) Carbon black such as (manufactured) (all are trade names), graphite, and carbon materials such as fullerenes such as C60 and C70, carbon nanotubes, carbon nanohorns, and carbon fibers.

- the addition ratio of the conductive auxiliary agent is preferably 0.01% by mass to 50% by mass, more preferably 0.1% by mass to 20% by mass with respect to the total mass of the precursor. More preferably, the content is from 10% to 10% by mass. If too much conductive additive is added, the aggregation / growth of the metal produced from the inorganic metal salt in the system becomes non-uniform and the desired porous nitrogen-containing carbon cannot be obtained, which is not suitable.

- the step of firing the precursor is as follows: (1) A step of preparing a precursor by mixing a heteroaromatic ring compound having a nitrogen-containing aromatic group and an inorganic metal salt containing one or more of Fe, Co, Ni, Mn and Cr; (2) a temperature raising step of raising the temperature of the precursor from 1 to 2000 ° C. per minute from room temperature to the carbonization temperature under an inert atmosphere; (3) a carbonization step of holding at 400 to 2000 ° C. for 0.1 to 100 hours; (4) It is preferable to include a cooling step of cooling from the carbonization temperature to room temperature.

- the manufacturing method of the nitrogen-containing carbon alloy of the present invention is the firing step, (6) It preferably includes a step of washing the baked nitrogen-containing carbon alloy with an acid, (7) More preferably, after the acid cleaning step, a step of refiring the acid-cleaned nitrogen-containing carbon alloy is included.

- the steps (1) to (7) will be described in order with respect to the method for producing a nitrogen-containing carbon alloy of the present invention.

- Precursor preparation step In the precursor preparation step, the above-described heteroaromatic ring compound having a nitrogen-containing aromatic group and the above-described inorganic metal salt are mixed to prepare a precursor.

- the precursor adjusted in the manufacturing process of a nitrogen-containing carbon alloy is baked after that, it is preferable to further include the process of grind

- the production method of the present invention includes a heteroaromatic ring compound having a nitrogen-containing aromatic group having a specific structure and an inorganic metal salt. It is preferable that the precursor is heated to the carbonization temperature and cooled to room temperature after the heat treatment.

- the temperature may be raised in multiple stages in the temperature raising process of the temperature raising process and the re-baking process described later.

- the latter stage of the temperature raising process may be carried out by holding the temperature after the completion of the preceding temperature raising process or by raising the temperature as it is.

- the temperature may be raised and a subsequent temperature increase process may be performed.

- the sample after a process may be grind

- the metal may be removed by acid cleaning of the sample after the treatment in (6) acid cleaning step described later.

- the sample before treatment may be inserted into a carbonization device and then heated from room temperature to a predetermined temperature, or may be increased by inserting the sample before treatment into a carbonization device or the like at a predetermined temperature. May be warm.

- the temperature of the sample before processing is raised from room temperature to a predetermined temperature.

- the temperature rising rate is preferably 1 to 2000 ° C./min, more preferably 1 to 1000 ° C./min, and 1 to 500 ° C./min. Is more preferable.

- Preliminary carbide In order to obtain a pre-carbide having pores formed, it is preferable to perform the previous treatment of the organic material containing a heteroaromatic ring compound having a nitrogen-containing aromatic group and an inorganic metal salt at a relatively low temperature. In such a low temperature treatment, a constant temperature may be maintained. By doing so, only a heat-stable structure can be maintained, and unstable impurity components, solvents, and the like can be removed.

- the temperature raising treatment performed at a relatively low temperature it is preferable to raise the temperature of an organic material containing a heteroaromatic ring compound having a nitrogen-containing aromatic group and an inorganic metal salt to 100 ° C. to 1500 ° C., preferably 150 ° C. to 1050 ° C. It is more preferable to raise the temperature to 200 ° C to 1000 ° C. By doing so, a uniform preliminary carbide is obtained.

- the inert atmosphere refers to a gas atmosphere such as a nitrogen gas or a rare gas atmosphere. Note that even if oxygen is contained, the atmosphere may be any atmosphere in which the amount of oxygen is limited to such an extent that the workpiece is not combusted.

- the inert atmosphere may be either a closed system or a distribution system that distributes a new gas, and is preferably a distribution system.

- the gas flow rate is preferably 0.01 to 2.0 liters / min per 36 mm ⁇ inner diameter, and the gas flow rate is 0.05 to 1.0 per 36 mm ⁇ inner diameter. It is more preferable to circulate a liter / min gas, and it is particularly preferable that the gas flow rate is 0.1 to 0.5 liter / min gas per an inner diameter of 36 mm ⁇ .

- the temperature holding time is 0.1 to 100 hours, preferably 0.2 to 10 hours, and more preferably 0.5 to 5 hours. Even if the carbonization treatment is performed for more than 100 hours, an effect corresponding to the treatment time may not be obtained.

- the heating device used in the above temperature raising treatment is not particularly limited, but is a tubular furnace (Kantar wire furnace, imaging furnace), muffle furnace, vacuum gas replacement furnace, rotary furnace (rotary kiln), roller hearth kiln, pusher kiln, multistage It is preferable to use a furnace, a tunnel furnace, a fluidized firing furnace, etc., more preferably a tubular furnace (a cantal wire furnace, an imaging furnace), a muffle furnace, a rotary furnace (rotary kiln), a fluidized firing furnace, a tubular furnace (a cantal wire) Furnaces, imaging furnaces) and muffle furnaces are particularly preferred.

- the portions of the temperature raising treatment are collectively infusible.

- the subsequent temperature increase treatment is continued following the temperature increase treatment of the precursor containing the heteroaromatic ring compound having a nitrogen-containing aromatic group having the specific structure in the previous stage and the inorganic metal salt. It is preferable to do so.

- the residual heat of the previous stage can be utilized, the decomposition reaction and the carbonization reaction of the organic material can be continuously performed, and the decomposition product and the metal interact with each other, so that the metal is more active. It can be stabilized with.

- the subsequent temperature increase treatment is preferably performed in an inert atmosphere

- the inert atmosphere may be either a closed system or a distribution system for circulating a new gas, and is preferably a distribution system.

- the gas flow rate is preferably 0.01 ml to 2.0 liters / min per 36 mm ⁇ inside diameter, and the gas flow rate is 0.02 ml to 1 per 36 mm ⁇ inside diameter. More preferably, a gas of 0.0 liter / min is circulated, and the flow rate of the gas is particularly preferably 0.05 to 0.5 liter / min.

- the downstream gas flow rate may be different from the upstream gas flow rate.

- the temperature holding time is 0.1 to 100 hours, preferably 0.2 to 10 hours, and more preferably 0.5 to 5 hours. Even if the carbonization treatment is performed for more than 100 hours, an effect corresponding to the treatment time may not be obtained.

- the heating device used in the above temperature raising treatment is not particularly limited, but is a tubular furnace (Kantar wire furnace, imaging furnace), muffle furnace, vacuum gas replacement furnace, rotary furnace (rotary kiln), roller hearth kiln, pusher kiln, multistage It is preferable to use a furnace, a tunnel furnace, a fluidized firing furnace or the like, and it is more preferable to use a tubular furnace (a cantal wire furnace, an imaging furnace), a muffle furnace, a rotary furnace (rotary kiln), a fluidized firing furnace, a tubular furnace (a cantal wire) Furnaces, imaging furnaces) and muffle furnaces are particularly preferred.

- the firing temperature of the carbonization treatment of the precursor containing a heteroaromatic ring compound having a nitrogen-containing aromatic group having a specific structure and an inorganic metal salt is such that the heteroaromatic ring compound having a nitrogen-containing aromatic group is thermally decomposed and carbonized.

- the upper limit of the carbonization temperature needs to be 2000 ° C., although it is not particularly limited as long as it is a temperature to be converted.

- the lower limit of the reaction temperature is preferably 400 ° C, more preferably 500 ° C, even more preferably 600 ° C, and even more preferably 700 ° C. .

- reaction temperature is 2000 degrees C or less, nitrogen will remain in carbon skeleton and it can be set as desired N / C atomic ratio, and sufficient oxygen reduction reaction activity will be obtained.

- the firing temperature is preferably 700 to 1200 ° C, particularly preferably 700 to 1000 ° C.

- carbonization treatment is performed within this range, the yield of carbon alloy may be reduced, but the crystallite size of the obtained carbon alloy is uniform, so that the metal is uniformly distributed and the state of high activity is maintained. The As a result, it becomes possible to produce a carbon alloy having excellent oxygen reduction performance. Further, by performing the carbonization treatment within the above range, nitrogen easily remains in the carbon skeleton due to the action of the generated inorganic metal, and the oxygen reduction reaction activity can be enhanced.

- the temperature raising treatment is preferably performed under a flow of an inert gas or a non-oxidizing gas, and such an atmosphere may be either a closed system or a flow system for flowing a new gas, preferably a flow system. It is.

- the gas flow rate is preferably 0.01 to 2.0 liters / min per 36 mm ⁇ inner diameter, and 0.02 to 1.0 liter / min per 36 mm ⁇ inner diameter. More preferably, it is particularly preferable to circulate a gas of 0.05 ml to 0.5 liter / min per 36 mm ⁇ inside diameter. It is preferable for the flow rate to be within this range because the desired nitrogen-containing carbon alloy can be suitably obtained.

- the treatment time for the carbonization treatment is 0.1 to 100 hours, preferably 0.2 to 10 hours, and more preferably 0.5 to 5 hours. Even if the carbonization treatment is performed for more than 100 hours, an effect corresponding to the treatment time may not be obtained.

- the heating device used in the above temperature raising treatment is not particularly limited, but is a tubular furnace (Kantar wire furnace, imaging furnace), muffle furnace, vacuum gas replacement furnace, rotary furnace (rotary kiln), roller hearth kiln, pusher kiln, multistage It is preferable to use a furnace, a tunnel furnace, a fluidized firing furnace or the like, and it is more preferable to use a tubular furnace (a cantal wire furnace, an imaging furnace), a muffle furnace, a rotary furnace (rotary kiln), a fluidized firing furnace, a tubular furnace (a cantal wire) Furnaces, imaging furnaces) and muffle furnaces are particularly preferred.

- the carbon alloy may be cooled to room temperature and then crushed.

- the pulverization treatment can be performed by any method known to those skilled in the art.

- the pulverization can be performed using a ball mill, agate pulverization, mechanical pulverization, or the like.

- the method for producing a nitrogen-containing carbon alloy of the present invention may include an acid washing process for washing the fired nitrogen-containing carbon alloy with an acid after the firing process.

- the ORR activity can be improved by acid cleaning of the metal on the surface of the produced carbon alloy catalyst. Without being bound by any theory, it is expected that a porous nitrogen-containing carbon alloy having optimum porosity can be obtained by this acid cleaning treatment.

- any aqueous Bronsted (proton) acid including a strong acid or a weak acid having a pH of 7 or less can be used in the acid cleaning step.

- an inorganic acid (mineral acid) or an organic acid can be used.

- Suitable acids include HCI, HBr, HI, H 2 SO 4 , H 2 SO 3 , HNO 3 , HClO 4 , [HSO 4 ] ⁇ , [HSO 3 ] ⁇ , [H 3 O] + , H 2 [C 2 O 4 ], HCO 2 H, HCIO 3 , HBrO 3 , HBrO 4 , HIO 3 , HIO 4 , FSO 3 H, CF 3 SO 3 H, CF 3 CO 2 H, CH 3 CO 2 H, B (OH) 3 , etc. (including any combination thereof), but are not limited to these. Further, the method described in JP-T-2010-524195 can also be used in the present invention.

- the manufacturing method of the nitrogen-containing carbon alloy of this invention further includes the process of grind

- the calcining temperature in the refiring process is preferably 500 to 2000 ° C, and preferably 600 to 1500 ° C. Is more preferable, and a temperature of 1000 to 1500 ° C. is even more preferable.

- firing may be performed in a pressurized state during the reaction.

- the gas discharge port may be trapped with water and fired in a state where back pressure is applied.

- the pressure in the carbonization step is 0.01 to 5 MPa, preferably 0.05 to 1 MPa, more preferably 0.08 to 0.3 MPa, and particularly preferably 0.09 to 0.15 MPa.

- High-pressure treatment is not preferable because it has a diamond structure constituted by sp 3 orbitals.

- the method of the refiring step is not particularly limited, but preferably a tubular furnace, a rotary furnace (rotary kiln), a roller hearth kiln, a pusher kiln, a multi-stage furnace, a vacuum gas replacement furnace, a tunnel furnace, a fluidized firing furnace, and the like are more preferable.

- a rotary furnace rotary kiln

- a vacuum gas replacement furnace a vacuum gas replacement rotary furnace (rotary kiln)

- a tunnel furnace and a fluidized firing furnace

- a vacuum gas replacement rotary furnace vacuum gas replacement rotary furnace

- the apparatus used for deaeration is not particularly limited as long as it can be deaerated, but it is preferable to use a vacuum gas replacement furnace or a vacuum gas replacement rotary furnace (rotary kiln).

- the pressure during vacuum degassing is not particularly limited, but is preferably 4 ⁇ 10 4 Pa or less, more preferably 4 ⁇ 10 3 Pa or less, and particularly preferably 2 ⁇ 10 2 Pa or less.

- the apparatus used at this time is not particularly limited as long as it can flow the carbon alloy, but it is preferable to use a rotary furnace (rotary kiln), a vacuum gas replacement rotary furnace (rotary kiln), or a fluidized firing furnace.

- a rotary furnace rotary kiln

- a vacuum gas replacement rotary furnace rotary kiln

- the sample tube is rotated at the time of firing, but is not limited to the rotation speed, speed change, and the like.

- the rotation speed is preferably 10 rpm or less, more preferably 5 rpm or less.

- the method for producing a nitrogen-containing carbon alloy of the present invention it is preferable to perform a carbonization treatment in the presence of an activator (activation step).

- an activator activation step

- the surface area of the carbide can be measured by the N 2 adsorption amount.

- the activator that can be used is not particularly limited.

- carbon dioxide, ammonia gas, water vapor, air, oxygen gas, hydrogen gas, carbon monoxide gas, methane gas, alkali metal hydroxide, zinc chloride, and phosphoric acid At least one selected from the group consisting of carbon dioxide, ammonia gas, water vapor, air, and oxygen gas can be used, more preferably at least one selected from the group consisting of:

- the gas activator is preferably diluted with an inert gas.

- the inert gas to be diluted include nitrogen gas and rare gases (for example, argon gas, helium gas, and neon gas).

- the gas activator may be contained in the atmosphere of carbonization treatment in an amount of 2 to 80 mol%, preferably 10 to 60 mol%. If it is 2 mol% or more, a sufficient activation effect can be obtained, while if it exceeds 80 mol%, the activation effect becomes remarkable and the yield of carbide is remarkably reduced, making it impossible to produce carbide efficiently. There is a fear.

- the solid activator such as alkali metal hydroxide may be mixed with the carbonized substance in a solid state, or after being dissolved or diluted with a solvent such as water, impregnated with the carbonized substance or in a slurry state. And may be kneaded into the article to be carbonized.

- the liquid activator may be diluted with water or the like and then impregnated with the carbonized material or kneaded into the carbonized material.

- the pressure in the gas phase may be any of normal pressure, pressurization, and depressurization, but is preferably pressurized at a high temperature.

- the gas may be stationary or distributed, but is preferably distributed from the viewpoint of discharging generated impurities.

- Nitrogen atoms can be introduced after carbonization.

- a liquid phase doping method a gas phase doping method, or a gas phase-liquid phase doping method can be used.

- nitrogen atoms can be introduced into the surface of the carbon catalyst by heat treatment by maintaining the carbon alloy in an ammonia atmosphere as a nitrogen source at 200 to 1200 ° C. for 5 to 180 minutes.

- the nitrogen-containing carbon alloy of the present invention is produced by the above-described method for producing a nitrogen-containing carbon alloy.

- the nitrogen-containing carbon alloy of the present invention obtained by firing the precursor is a nitrogen-containing carbon alloy into which nitrogen has been introduced.

- the nitrogen-containing carbon alloy of the present invention preferably contains graphene, which is an aggregate of carbon atoms having a hexagonal network structure in which carbon is chemically bonded by sp 2 hybrid orbitals and spreads in two dimensions.

- the content of surface nitrogen atoms in the carbon catalyst is more preferably 0.02 to 0.3 in terms of atomic ratio (N / C) to surface carbon.

- the atomic ratio (N / C) of the nitrogen atom to the carbon atom is less than 0.02, the number of effective nitrogen atoms bonded to the metal is reduced, and sufficient oxygen reduction catalyst characteristics cannot be obtained.

- the atomic ratio (N / C) of nitrogen atoms to carbon atoms exceeds 0.3, the strength of the carbon skeleton of the carbon alloy is lowered, and the electrical conductivity is lowered.

- the skeleton of the carbon alloy may be formed of at least carbon atoms and nitrogen atoms, and may contain hydrogen atoms, oxygen atoms, and the like as other atoms.

- the atomic ratio ((other atoms) / (C + N)) of other atoms to carbon atoms and nitrogen atoms is preferably 0.3 or less.

- carbon alloy is placed in a predetermined container, cooled to liquid nitrogen temperature (-196 ° C), nitrogen gas is introduced into the container and adsorbed, and the adsorption amount of single molecules and adsorption parameters are determined from the adsorption isotherm.

- a BET Brunauer-Emmett-Teller

- the pore shape of the carbon alloy is not particularly limited, and for example, pores may be formed only on the surface, or pores may be formed not only on the surface but also inside.

- pores may be tunnel-shaped, and it has a shape in which polygonal cavities such as spherical or hexagonal columns are connected to each other. It may be.