WO2013018433A1 - 吸収性物品およびその製造方法 - Google Patents

吸収性物品およびその製造方法 Download PDFInfo

- Publication number

- WO2013018433A1 WO2013018433A1 PCT/JP2012/064655 JP2012064655W WO2013018433A1 WO 2013018433 A1 WO2013018433 A1 WO 2013018433A1 JP 2012064655 W JP2012064655 W JP 2012064655W WO 2013018433 A1 WO2013018433 A1 WO 2013018433A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- adhesive

- adhesive portion

- absorbent article

- back sheet

- longitudinal direction

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/56—Supporting or fastening means

- A61F13/5605—Supporting or fastening means specially adapted for sanitary napkins or the like

- A61F13/5611—Supporting or fastening means specially adapted for sanitary napkins or the like using fastening strips, e.g. adhesive, on the undergarment-facing side

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15203—Properties of the article, e.g. stiffness or absorbency

- A61F13/15211—Properties of the article, e.g. stiffness or absorbency soluble or disintegratable in liquid

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15577—Apparatus or processes for manufacturing

- A61F13/15699—Forming webs by bringing together several webs, e.g. by laminating or folding several webs, with or without additional treatment of the webs

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/10—Methods of surface bonding and/or assembly therefor

- Y10T156/1052—Methods of surface bonding and/or assembly therefor with cutting, punching, tearing or severing

Definitions

- the present invention relates to an absorbent article and a method for producing the same, and more particularly to an absorbent article such as a water-degradable sanitary napkin, panty liner, urine removing pad and the like and a method for producing the same.

- Patent Literature 1 discloses an absorbent article having a surface material, a back sheet, and an absorbent layer positioned therebetween.

- a water-decomposable fiber nonwoven fabric is used as the surface material and the back sheet.

- the absorbent layer uses a water-decomposable core material such as pulp fiber.

- An adhesive part for attaching to the shorts is formed on the back surface of the back sheet. Therefore, since this absorbent article as a whole is water-degradable, it does not clog piping or the like even if it flows into a flush toilet after use.

- a plurality of adhesive portions are formed, and these adhesive portions are provided at intervals in the vertical direction and the horizontal direction.

- the adhesive portion has a diameter of 10 mm or less and 1 mm or more and is circular. Since such a relatively small pressure-sensitive adhesive portion has a weak adhesive force, it is necessary to use a pressure-sensitive adhesive material having a high pressure-sensitive adhesive force in order to securely fix the absorbent article to the shorts. Since such an absorbent article has its back sheet and shorts firmly bonded via an adhesive part, when trying to peel it off from the shorts after use, the entanglement of the fibers of the fiber nonwoven fabric of the back sheet is released, This fiber may remain in the shorts together with the adhesive part.

- An object of the present invention is to provide a water-decomposable absorbent article that can be easily peeled off from a worn article after use.

- the present invention includes first and second inventions.

- 1st invention has a vertical direction and a horizontal direction, the non-body side which is a body side and the opposite side, the water-decomposable surface sheet located in the said body side, and the water-degradability located in the said non-body side Back surface sheet, a water-decomposable bodily fluid absorber positioned between the front and back sheets, and an adhesive portion formed on the non-body side of the back sheet and capable of joining the back sheet to a wearing article.

- the back sheet is formed of a fiber nonwoven fabric, and the fibers of the fiber nonwoven fabric have an orientation extending in the longitudinal direction.

- a first adhesive portion extending in the vertical direction; and a second adhesive portion extending in the vertical direction and spaced apart from both lateral sides of the first adhesive portion, wherein the second adhesive portion is the vertical direction.

- a plurality of adhesive portions spaced apart from each other, and at least a part of the first adhesive portion is located in the lateral direction of the separation portion in the longitudinal direction of the second adhesive portion.

- that the absorbent article can be bonded to the worn article means that the absorbent article can be attached to the worn article via an adhesive portion and can be peeled off from the worn article after use. To do. Therefore, the adhesive strength at the adhesive portion is such that the absorbent article attached to the worn article can be peeled off.

- a so-called pressure-sensitive adhesive can be used in the bonded portion.

- the second invention includes a step of conveying the first fiber web in the machine direction, a step of laminating the absorbent body on the first fiber web and bonding them together, and the first fiber web via the absorbent body.

- improving the method for manufacturing an absorbent article comprising: laminating a release sheet on the adhesive portion; and cutting the first and second fiber webs, the absorbent body, and the laminate of the release sheet. Involved.

- the adhesive portion in the method for manufacturing an absorbent article, includes a first nozzle arranged in an intersecting direction orthogonal to the machine direction, and a second nozzle located outside the intersecting direction of the first nozzle. It is formed by applying an adhesive intermittently in the machine direction by an adhesive coating apparatus having a nozzle.

- the “water-decomposable sheet” refers to a non-woven fiber sheet formed of fibers having a fiber length of 7 mm or less, and the mechanical entanglement of the fibers is released by the flushing water in the flush toilet.

- the first adhesive portion is located in the longitudinally separated portion of the second adhesive portion, the portion of the back sheet on which the first and second adhesive portions are formed is large when the first adhesive portion is poured into the flush toilet. It does not become a lump, and it can be prevented that they are clogged in the piping.

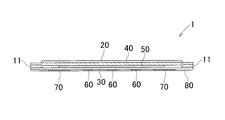

- FIG. 3 is an end view taken along line III-III in FIG. 1.

- FIG. 1 is a plan view of the panty liner 1 as viewed from the top sheet 20 side as an example of the absorbent article of the present invention

- FIG. 2 is an exploded perspective view of the panty liner 1

- FIG. 3 is a line III-III in FIG. 4 is a plan view of the panty liner 1 as viewed from the back sheet 30 side.

- the peeling sheet 80 is peeled to expose the adhesive portion for the sake of explanation.

- the panty liner 1 has a vertical vertical center line PP having a vertical direction Y and a horizontal direction X orthogonal to the vertical direction Y, and bisecting the dimension in the horizontal direction X, and And a virtual horizontal center line QQ that bisects the dimension in the direction Y.

- Both side edges 11 extending in the vertical direction Y are curved so that the distance between them is reduced along the virtual horizontal center line QQ, and the front and rear end edges 12 and 13 extending in the horizontal direction X are virtual vertical center lines PP. Are curved so that the distance between them increases, that is, projects outward.

- the panty liner 1 is a body fluid located between the top sheet 20 located on the wearer's body side, the back sheet 30 located on the opposite side (non-body side) (clothing side), and the front and back sheets 20, 30. It has the absorber 40 and the leak prevention sheet 50 located between the back surface sheet 30 and the absorber 40.

- the front and back sheets 20 and 30 can be made of a fiber nonwoven fabric, more specifically, a spunlace fiber nonwoven fabric having a mass per unit area of about 30 to 40 g / m 2 .

- the top sheet 20 is desirably liquid-permeable, and the back sheet 30 is coated with a water-dispersible resin on the non-body side in order to improve material strength and make it difficult to permeate liquid.

- the water dispersible resin for example, “AQ55S (trade name)” manufactured by Eastman Chemical Co., Ltd. can be used.

- the fiber nonwoven fabric forming the front and back sheets 20 and 30 has water decomposability.

- the water-decomposable fiber nonwoven fabric is a nonwoven fabric formed with fibers having a fiber length of 7 mm or less, and the mechanical entanglement of the fibers is released by the flushing flow in the flush toilet. Therefore, the front and back sheets 20 and 30 do not clog piping or the like even if they are passed through a flush toilet.

- the fiber length of the fibers forming the back sheet 30 is measured by JIS L 1015 8.4.1: chemical fiber staple test method (c: direct method). Specifically, the panty liner is immersed in toluene, the adhesive bonding the sheets is eluted, the back sheet 30 is taken out, and the fibers are entangled. In order to unwind the fibers, the back sheet 30 is placed in a 300 ml beaker with 300 ml of water and stirred with a magnetic stirrer at a speed of 600 ⁇ 10 times / minute.

- the back sheet 30 is placed in a 2000 ml wide-mouth bottle together with 1200 ml of water and shaken at 270 ⁇ 20 rotations / minute with a shaker.

- the fiber length of the unentangled fiber is measured by the method described in the above JIS. For the measured value, an average value ⁇ standard deviation is calculated, and this is defined as the fiber length in the back sheet 30.

- At least the fibers forming the back sheet 30 have an orientation that extends in the longitudinal direction Y.

- the fiber having orientation in the longitudinal direction Y means that the breaking strength in the transverse direction X is 75% or less of the breaking strength in the longitudinal direction Y.

- the orientation was measured by the following method.

- the back sheet 30 was cut into a size of 150 mm in the vertical direction Y and a size of 25 mm in the horizontal direction X to obtain vertical sample pieces.

- the back surface sheet 30 was cut into a size of 25 mm in the vertical direction Y and a size of 150 mm in the horizontal direction X to obtain a horizontal sample piece.

- the breaking strengths of the vertical sample piece and the horizontal sample piece were measured, respectively. The measurement was performed using a tensile tester (Instron).

- the distance between grips of the testing machine was set to 100 mm, both ends in the longitudinal direction of the vertical sample piece and the horizontal sample piece were held between grips, the sample piece was pulled at a speed of 100 mm / min, and the maximum strength at break was measured.

- the measurement was performed under the WET conditions for measuring after immersing the sample piece in water and the DRY conditions for measuring without immersing in the water. In each of WET conditions and DRY conditions, the orientation was determined by the following formula. Maximum strength of horizontal sample piece / Maximum strength of vertical sample piece ⁇ 100

- the orientation under the WET condition was 29% and the orientation under the DRY condition was 36%, both of which had a longitudinal orientation.

- the absorber 40 has the same shape and size as the front and back sheets 20 and 30 and can be formed of airlaid pulp having a mass per unit of about 60 to 80 g / m 2 .

- the absorber 40 is formed by binding fluff pulp with a spray binder.

- Such an absorbent body 40 has water decomposability, and the fluff pulp is unbound by the flushing flow in the flush toilet, so that even if this is passed to the flush toilet, the pipes and the like are not clogged.

- the leak-proof sheet 50 is liquid-impermeable, and specifically, a water-degradable tissue paper having a mass per unit area of about 10 to 20 g / m 2 and laminated with polylactic acid can be used.

- the leak prevention sheet 50 has a smaller area than the front and back sheets 20 and 30 and the absorber 40 and is substantially rectangular. Since polylactic acid is reduced in molecular weight by moisture, the leakage preventing sheet 50 as a whole has water decomposability and is subdivided by the flushing water in the flush toilet, so that piping and the like are not clogged.

- Adhesive means such as hot melt (not shown) is applied between the top sheet 20 and the absorber 40, between the absorber 40 and the leakage preventing sheet 50, and between the leakage preventing sheet 50 and the back sheet 30, respectively. These are joined together. Moreover, the inner side is heated and pressurized along the both side edges 11 and the front and rear end edges 12 and 13 of the panty liner 1, and the top sheet 20, the absorber 40, and the back sheet 30 are joined together.

- the bonding portion includes a first bonding portion 60 located in the vicinity of the virtual vertical center line PP in the horizontal direction X and a second bonding portion 70 positioned apart from both sides of the first bonding portion 60 in the horizontal direction X.

- a hot melt adhesive can be used as the first and second bonding portions 60 and 70.

- a water-insoluble adhesive such as a rubber-based hot melt adhesive or an olefin-based hot melt adhesive is used.

- a water-soluble adhesive is not excluded, and any of them can be used.

- the first adhesive portion 60 includes a first front adhesive portion 61 that is separated in the longitudinal direction Y, a first rear adhesive portion 63, and a first central adhesive portion 62 that is positioned therebetween, and in the lateral direction X A plurality of each is formed.

- each of the bonding portions 61 to 63 is arranged in the horizontal direction X, and the middle one is positioned on the virtual vertical center line PP.

- the three first front adhesive portions 61 arranged in the horizontal direction X have their front edge 61a and rear edge 61b aligned in the horizontal direction X, and the first central adhesive portion 62 has its front edge 62a and rear edge. 62b respectively match in the horizontal direction X, and the front end edge 63a and the rear end edge 63b of the plurality of first rear adhesive portions 63 match in the horizontal direction X.

- the dimension d1 in the longitudinal direction Y of the first adhesive portion 60 is larger than the fiber length of the fiber nonwoven fabric forming the back sheet 30 and smaller than 50.0 mm, and in this embodiment is about 30.0 mm. Yes.

- the separation dimension d2 in the longitudinal direction Y of the first adhesive portion 60 is about 5.0 to 50.0 mm, and is preferably larger than the fiber length of the fiber nonwoven fabric forming the back sheet 30, and in this embodiment about 17 .6 mm.

- the dimension d3 in the lateral direction X of the first adhesive portion 60 is about 2.0 to 15.0 mm.

- the dimension d3 is about 3.0 mm

- the separation dimension d4 in the lateral direction X is about 3.0 to It is 10.0 mm, preferably smaller than the fiber length of the fiber nonwoven fabric forming the back sheet 30, and is about 5.0 mm in this embodiment.

- the second adhesive portion 70 includes a second front adhesive portion 71 and a second rear adhesive portion 72 that are separated in the longitudinal direction Y.

- the second front and rear adhesive regions 71, 72 are longitudinally Y 2 two spaced apart to form, are arranged almost on the straight line parallel to the imaginary longitudinal center line P-P, respectively.

- the dimension D1 in the longitudinal direction Y of the second front and rear adhesive portions 71 and 72 is larger than the fiber length of the fiber nonwoven fabric forming the back sheet 30 and smaller than 50.0 mm, and in this embodiment is about 43.0 mm. It is said that.

- a second front adhesive regions 71 spaced distance D2 in the longitudinal direction Y of the second rear adhesive regions 72 is about 5.0 ⁇ 50.0 mm, preferably than the fiber length of the fibrous nonwoven fabric forming the back sheet 30 In this embodiment, it is about 28.6 mm.

- the dimension D3 in the lateral direction X of these adhesion portions 71 and 72 is about 2.0 to 15.0 mm, and in this embodiment is about 7.0 mm.

- Spaced distance D4 between the first adhesive portion 60 adjacent in the transverse direction X between the second adhesive portion 70 is about 3.0 ⁇ 10.0 mm, preferably than the fiber length of the fibrous nonwoven fabric forming the back sheet 30 In this embodiment, the size is reduced to about 5.0 mm.

- the first central adhesive portion 62 is a separation portion between the second front adhesive portion 71 and the second rear adhesive portion 72 and is positioned in the lateral direction X thereof. That is, an imaginary line in contact with the rear end edge 71b of the second front adhesive portion 71 and parallel to the virtual lateral center line QQ, and an imaginary line in contact with the front end edge 72a of the second rear adhesive portion 72 and the virtual lateral center line QQ.

- 1st center adhesion part 62 is located between the virtual lines parallel to.

- the 1st middle adhesion part 62 may have a magnitude

- the front end edge 62a of the first central adhesive portion 62 overlaps the second front adhesive portion 71 in the lateral direction X

- the rear end edge 62b overlaps the second rear adhesive portion 72 in the lateral direction X.

- a virtual line that is in contact with the front edge 62a and parallel to the virtual horizontal center line QQ intersects the second front adhesive portion 71, is in contact with the rear edge 62b, and is parallel to the virtual horizontal center line QQ.

- the line intersects the second rear adhesive portion 72.

- the first front adhesive portion 61 has a front end edge 61a located on the outer side in the vertical direction Y with respect to the front end edge 71a of the second front adhesive portion 71, and the rear end edge 61b extends to the second front adhesive portion 71 in the lateral direction X. overlapping. That is, an imaginary line that is in contact with the rear edge 61b and is parallel to the imaginary horizontal center line QQ intersects the second front adhesive portion 71.

- the rear end edge 63b of the first rear adhesive portion 63 is positioned outside the rear end edge 72b of the second rear adhesive portion 72 in the vertical direction Y, and the front end edge 63a extends to the second rear adhesive portion 73 in the lateral direction X. overlapping. That is, an imaginary line that is in contact with the front end edge 63a and is parallel to the imaginary lateral center line QQ intersects the second rear adhesive portion 73.

- the front and rear non-adhesive regions 64 and 65 where the adhesive portions are not formed are formed outside the first front and rear adhesive portions 61 and 63 in the vertical direction Y.

- the front non-adhesion region 64 is larger in dimension in the longitudinal direction Y than the rear non-adhesion region 65, and its area is widened.

- the first and second adhesive portions 60 and 70 as described above are covered with a release sheet 80 having the same shape and size as the front and back sheets 20 and 30.

- a release sheet 80 having the same shape and size as the front and back sheets 20 and 30.

- the release sheet 80 can be peeled from the first and second adhesive portions 60 and 70, it can be exposed while maintaining the adhesive force of the first and second adhesive portions 60 and 70.

- the panty liner 1 can be fixed to the wearing article through the exposed first and second adhesive portions 60 and 70.

- the release sheet 80 can be easily peeled off from the front and rear non-adhesive regions 64 and 65.

- the front non-adhesion region 64 has a larger area than the rear non-adhesion region 65, the release sheet 80 can be easily picked and peeled off more easily in the front non-adhesion region 64.

- the panty liner 1 since the first central adhesive portion 62 is positioned in the separated portion of the second front and rear adhesive portions 71 and 72, the attached panty liner 1 is prevented from being lifted from the wearing article. be able to. If the first central adhesive portion 62 is not formed in the separated portions of the second front and rear adhesive portions 71 and 72 and these separated portions are not adhered to the worn article, the separated portions are separated from the worn article. It floats up and attaches to the wearer's body, which can cause rashes. Since the panty liner 1 is likely to float in the vicinity of the virtual horizontal center line QQ, it is desirable that an adhesive portion be formed at least in the vicinity of the virtual horizontal center line QQ.

- the adhesive force to the wearing article can be improved, and the panty liner It is possible to prevent the side edges 11 of 1 from being peeled off from the worn article and turned up. Note that either one of the vertical direction Y and the horizontal direction X may be increased.

- the panty liner 1 as described above can be poured into a flush toilet after use. That is, the panty liner 1 becomes fine due to the flushing flow of the flush toilet, and does not clog the piping of the flush toilet.

- the 1st and 2nd adhesion parts 60 and 70 are formed, and these adhesion parts are hard to be decomposed

- the first and second adhesive portions 60 and 70 have a dimension in the longitudinal direction Y longer than the fiber length of the back sheet 30 and shorter than 50 mm, the first and second adhesive portions 60 and 70 are Even if the part of the attached back sheet 30 remains without being decomposed, the size thereof can sufficiently flow through the piping or the like.

- the back sheet 30 on which the adhesive portions 60 and 70 are formed is longitudinally Y when the first and second adhesive portions 60 and 70 are disassembled by the water washing flow. It remains in a long state without being disassembled, and the remaining portions are entangled with each other to form a larger lump, which may clog the piping of the flush toilet.

- the fiber of the part in which the 1st and 2nd adhesion parts 60 and 70 were formed is a back surface sheet. There is a possibility that it will unwind from 30 and remain in the panty through the adhesive portion.

- the first and second adhesive portions 60 and 70 can be made longer than the fiber length, these disadvantages can be solved, and the panty liner 1 can be securely fixed to the wearing article.

- the fibers forming the back sheet 30 are oriented in the longitudinal direction Y and the first and second adhesive portions 60 and 70 are formed to extend in the longitudinal direction Y, the fibers can be made more difficult to unwind. it can.

- the separation dimension d2 in the longitudinal direction Y of the first adhesion part 60 and the separation dimension D2 in the longitudinal direction of the second adhesion part 70 are preferably larger than the fiber length of the fiber nonwoven fabric forming the back sheet 30. Therefore, it is possible to prevent the bonding portions arranged in the vertical direction Y from being connected to each other by the fibers oriented in the vertical direction of the back sheet 30. In such a back sheet 30, the bonded portions arranged in the vertical direction Y are easily separated by the water washing flow, and do not remain as a large lump.

- the separation dimensions d4 and D4 in the lateral direction X of the first adhesive portion 60 and the second adhesive portion 70 are preferably smaller than the fiber length of the fiber nonwoven fabric forming the back sheet 30. Since the back sheet 30 is oriented in the vertical direction, it is not necessary to make the separation dimension larger than the fiber length. That is, even if the separation dimension is made smaller than the fiber length of the back sheet 30, the connection between the first adhesive portion and the second adhesive portion 70 in the lateral direction can be released by flushing. In addition, by reducing the distance between the first and second adhesion portions 60 and 70, the adhesion area of the entire back sheet 30 can be increased, and the adhesion strength to the wearing article can be improved.

- the rear end edge 71b of the second front adhesive portion 71 and the front end edge 62a of the first central adhesive portion 62 are positioned so as to overlap each other in the lateral direction X, and the front end edge of the second rear adhesive portion 72

- 72a and the rear end edge 62b of the 1st center adhesion part 62 are set as the positional relationship which mutually overlaps in the horizontal direction X, they may be spaced apart in the vertical direction, without overlapping.

- the separation dimension between the rear end edge 71b and the front end edge 62a and the separation dimension between the front end edges 72a and 62b are preferably about 1.0 to 5.0 mm.

- the first joints 60 are formed in a plurality of rows in the lateral direction X

- the second joints 70 are formed in a row on the outer side in the lateral direction X of the first joints 60. Since the dimension in the lateral direction X of the second joint portion 70 is increased, the panty liner 1 can be reliably adhered to the wearing article. Further, by forming a plurality of first joint portions 60 and second joint portions 70 in the lateral direction X and separating them from each other, water disintegration can be maintained.

- the number and dimension in the vertical direction Y and the horizontal direction X of the 1st adhesion part 60, and the number and dimension in the vertical direction Y and the horizontal direction X of the 2nd adhesion part 70 are not limited to the said Example. And can be changed as appropriate.

- FIG. 5 is a diagram for explaining a method of manufacturing the panty liner 1.

- FIG. 6 is a diagram for explaining a process in which the first and second adhesion portions 60 and 70 are formed, and schematically shows the coating device 98 so that the positional relationship between the nozzle and the adhesion portion can be understood. ing.

- the first fiber web 2 forming the top sheet 20 is conveyed in the machine direction MD via the first roll 91.

- the absorbent web 4 forming the absorbent body 40 is conveyed through the second roll 92 in the machine direction MD.

- a hot melt adhesive is applied to the absorbent web 4 by the coating device 93, and the absorbent web 4 is laminated on the first fiber web 2 and joined together.

- a hot melt adhesive is applied to the surface of the absorbent web 4 opposite to the surface facing the first fiber web 2 by the coating device 94.

- the leakage prevention film 5 forming the leakage prevention sheet 50 is conveyed in the machine direction MD by the third roll 95 and laminated on the absorbent web 4 so that the absorbent web 4 and the leakage prevention film 5 are joined.

- the leakage prevention film 5 is cut in advance in the machine direction MD by the third roll 95 and then intermittently supplied to the absorbent web 4.

- a hot melt adhesive is applied to the surface of the leakage prevention film 5 opposite to the surface facing the absorbent web 4 by the coating device 96.

- the second fiber web 3 forming the back sheet 30 is conveyed in the machine direction MD via the fourth roll 97, laminated on the leakage prevention film 5 via a hot melt adhesive, and these are joined.

- the hot melt adhesive applied by the coating apparatuses 93, 94, and 96 is uniformly applied to almost the entire area of each web or film by, for example, spray coating.

- a hot melt adhesive is applied to the surface of the second fiber web 3 opposite to the surface facing the leakage prevention film 5 using a coating device 98 to form first and second adhesive portions 60 and 70. Is done. As shown in FIG. 6, the coating device 98 is positioned outside the first nozzle 6 forming the first adhesive portion 60 and the cross direction CD perpendicular to the machine direction MD of the first nozzle 6 and the second adhesive. It has the 2nd nozzle 7 which forms the part 70. FIG. That is, the first nozzle 6 and the second nozzle 7 are disposed in the same coating apparatus. The hot melt adhesive discharged from the first and second nozzles 6 and 7 enables formation of a linear and continuous adhesive portion.

- the size of the discharge port in the cross direction CD of the first and second nozzles 6 and 7 is larger in the second nozzle 7 than in the first nozzle 6. Moreover, the discharge timing of the hot melt adhesive at the first and second nozzles 6 and 7 can be controlled separately by different control programs. Therefore, the first and second adhesive portions 60 and 70 having different dimensions in the vertical direction Y and the horizontal direction X can be formed. Thus, according to this embodiment, the 1st and 2nd adhesion parts 60 and 70 which have a different pattern can be formed using one coating device. Therefore, it is not necessary to increase the number of other devices in order to form the adhesive portions having different patterns, and the increase in cost can be suppressed accordingly. Further, since the first and second adhesive portions 60 and 70 can be formed at a time, the production time does not increase.

- the release web 8 forming the release sheet 80 is laminated on the second fiber web 3 on which the first and second adhesive portions 60 and 70 are formed by the coating apparatus 98.

- the release web 8 is joined to the second fiber web 3 via the first and second adhesive portions 60 and 70.

- Such a laminated body is cut along a virtual line 99 shown in FIG. 6 by a cutter (not shown) to form the panty liner 1.

- the above-described laminated body is configured such that the first and second bonding portions 60 and 70 and the virtual line 99 do not overlap. Therefore, when cutting with the cutter along the virtual line 99, it is possible to prevent the adhesives of the first and second adhesive portions 60 and 70 from adhering to the cutter blade. By cutting the continuous laminated body in this way, a large amount of panty liner 1 can be formed in a short time.

- the present invention includes first and second inventions.

- the first invention relates to the improvement of the following absorbent article 1.

- the absorbent article 1 has a longitudinal direction Y and a transverse direction X, and is located on the non-body side, the water-degradable surface sheet 20 located on the body side, the non-body side that is the body side and the opposite side.

- a water-decomposable back sheet 30, a water-decomposable bodily fluid absorber 40 positioned between the front and back sheets 20 and 30, and the back sheet 30 formed on the non-body side of the back sheet 20. It includes adhesive portions 60 and 70 that can be bonded to each other.

- the back sheet 30 is formed of a fiber nonwoven fabric, and the fibers of the fiber nonwoven fabric have an orientation extending in the longitudinal direction Y.

- the adhesive portion includes a first adhesive portion 60 that extends in the longitudinal direction Y, and a second adhesive portion 70 that is spaced apart from both lateral sides X of the first adhesive portion 60 and extends in the longitudinal direction Y.

- the second adhesive portion 70 has a plurality of adhesive portions that are separated in the longitudinal direction Y, and at least a part of the first adhesive portion 60 is a portion of the separated portion in the longitudinal direction Y of the second adhesive portion 70. Located in the horizontal direction X.

- the first invention can include at least the following embodiments.

- the dimension in the longitudinal direction Y of the bonding portions 60 and 70 is made larger than the fiber length of the fiber nonwoven fabric forming the back sheet 30.

- the first adhesive portion 60 includes a first front adhesive portion 61 and a first rear adhesive portion 63 that are arranged apart from each other in the longitudinal direction Y, and a first central adhesive portion 62 positioned therebetween.

- the second adhesive portion 70 includes a second front adhesive portion 71 and a second rear adhesive portion 72 that are spaced apart from each other in the longitudinal direction Y.

- the dimension of the first and second adhesive portions 60 and 70 in the lateral direction X is 2.0 to 15.0 mm.

- the separation dimension in the longitudinal direction Y of the first and second adhesive portions 60 and 70 is made larger than the fiber length of the fiber nonwoven fabric forming the back sheet.

- the separation dimension in the lateral direction X of the first and second adhesive portions 60 and 70 is made smaller than the fiber length of the fiber nonwoven fabric forming the back sheet.

- the second adhesive portion 70 is larger in dimension in the longitudinal direction Y than the first adhesive portion 60.

- Non-adhesive regions 64 and 65 are formed outside the first adhesive portion 60 in the longitudinal direction Y.

- a liquid-impervious leak prevention sheet 50 is attached between the absorber 40 and the back sheet 30, and at least one of the first and second adhesive portions 60 and 70 is the leak.

- the prevention sheet 50 has a positional relationship overlapping with both side edges.

- the manufacturing method of the absorbent article 1 includes the step of conveying the first fiber web 2 in the machine direction MD, the step of laminating the absorbent body 4 on the first fiber web 2 and bonding them together, and the first fiber A step of laminating the second fiber web 3 on the web 2 via the absorbent body 4 and bonding them together, and the absorbent body 4 of one of the first fiber web 2 and the second fiber web 3; Forming the adhesive portions 60 and 70 on the opposite surface, laminating the release sheet 8 on the adhesive portions 60 and 70, the first and second fiber webs 2 and 3, and the absorption Cutting the laminated body of the body 4 and the release sheet 8.

- the 2nd invention is the manufacturing method of the said absorbent article 1,

- the said adhesive parts 60 and 70 are the 1st nozzle 6 located in the cross direction CD orthogonal to the said machine direction MD, and the said intersection of the said 1st nozzle 6. It is formed by applying an adhesive intermittently in the machine direction MD by an adhesive application device 98 having a second nozzle 7 located outside the direction CD.

- the second invention can include at least the following embodiments.

- the laminate is cut between the bonding portions 60 and 70 that are spaced apart in the longitudinal direction Y.

- panty liner 1 that is an example of an absorbent article. Can be used.

- the terms “first”, “second”, “third”, and “fourth” are simply used to distinguish similar elements, positions, and the like.

Landscapes

- Health & Medical Sciences (AREA)

- Epidemiology (AREA)

- Engineering & Computer Science (AREA)

- Vascular Medicine (AREA)

- Biomedical Technology (AREA)

- Heart & Thoracic Surgery (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Manufacturing & Machinery (AREA)

- Absorbent Articles And Supports Therefor (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP12819796.9A EP2737886B1 (en) | 2011-07-29 | 2012-06-07 | Absorbent article and method for producing same |

| US14/130,172 US9439817B2 (en) | 2011-07-29 | 2012-06-07 | Absorbent article and method for producing the same |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011-167750 | 2011-07-29 | ||

| JP2011167750A JP5896639B2 (ja) | 2011-07-29 | 2011-07-29 | 吸収性物品 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2013018433A1 true WO2013018433A1 (ja) | 2013-02-07 |

Family

ID=47628973

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2012/064655 Ceased WO2013018433A1 (ja) | 2011-07-29 | 2012-06-07 | 吸収性物品およびその製造方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US9439817B2 (enExample) |

| EP (1) | EP2737886B1 (enExample) |

| JP (1) | JP5896639B2 (enExample) |

| TW (1) | TWI538664B (enExample) |

| WO (1) | WO2013018433A1 (enExample) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6174977B2 (ja) * | 2013-11-15 | 2017-08-02 | 花王株式会社 | 吸収性物品 |

| US10017309B2 (en) | 2014-06-13 | 2018-07-10 | Sca Hygiene Products Ab | Packaging unit for hygiene articles and a method of forming a packaging unit |

| CN106456418A (zh) | 2014-06-13 | 2017-02-22 | Sca卫生用品公司 | 具有改良密封性和使用者提示装置的包装单元及用于制造此包装单元的方法 |

| CN106535849A (zh) | 2014-06-13 | 2017-03-22 | Sca卫生用品公司 | 用于卫生物品的包装单元及用于形成包装单元的方法 |

| JP2017524409A (ja) * | 2014-06-13 | 2017-08-31 | エスセーアー・ハイジーン・プロダクツ・アーベー | 向上された封止を有する包みシートを形成するための方法 |

| CA2952001C (en) | 2014-06-13 | 2021-01-19 | Sca Hygiene Products Ab | A packaging unit having improved sealing, and a method for forming such a packaging unit |

| JP6474169B1 (ja) * | 2017-10-04 | 2019-02-27 | 株式会社光洋 | 吸収パッド |

| JP7093184B2 (ja) * | 2018-01-09 | 2022-06-29 | 株式会社リブドゥコーポレーション | 使い捨ておむつ |

| CN113164309B (zh) * | 2018-12-10 | 2022-06-24 | 宝洁公司 | 用于吸收制品的粘附 |

| US11819397B2 (en) * | 2019-03-05 | 2023-11-21 | The Procter And Gamble Company | Absorbent article with adhesive pattern |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06500485A (ja) * | 1990-09-12 | 1994-01-20 | ザ、プロクター、エンド、ギャンブル、カンパニー | 吸収体物品の形状及び吸収体物品の接着剤止め手段 |

| JPH11504846A (ja) * | 1996-02-28 | 1999-05-11 | ザ、プロクター、エンド、ギャンブル、カンパニー | 吸収体 |

| JP2005518251A (ja) * | 2002-02-22 | 2005-06-23 | ザ プロクター アンド ギャンブル カンパニー | 改善された接着パターンを有する下着留め接着剤を包含する吸収性物品 |

| JP2005319333A (ja) * | 2005-08-04 | 2005-11-17 | Uni Charm Corp | ウィング部材を有する吸収性物品 |

| JP3748022B2 (ja) | 1999-11-19 | 2006-02-22 | ユニ・チャーム株式会社 | 水解性の吸収性物品およびその製造方法 |

| JP2009268537A (ja) * | 2008-04-30 | 2009-11-19 | Uni Charm Corp | 吸収性物品及び吸収性物品の製造方法 |

| WO2009157476A1 (ja) * | 2008-06-24 | 2009-12-30 | ユニ・チャーム株式会社 | 吸収性物品及び吸収性物品の製造方法 |

| JP2011139847A (ja) * | 2010-01-08 | 2011-07-21 | Unicharm Corp | 流体吐出装置 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3688771A (en) | 1971-06-03 | 1972-09-05 | Kimberly Clark Co | Sanitary napkin with convertible attachment means |

| US4690680A (en) * | 1986-06-27 | 1987-09-01 | The Procter & Gamble Company | Adhesive attachment means for absorbent articles |

| US20090062761A1 (en) * | 2007-08-30 | 2009-03-05 | Kimberly-Clark Worldwide, Inc. | Attachment Pattern for Undergarment Attached Absorbent Articles |

| JP4540127B2 (ja) * | 2007-09-26 | 2010-09-08 | 大王製紙株式会社 | 吸収性物品 |

-

2011

- 2011-07-29 JP JP2011167750A patent/JP5896639B2/ja active Active

-

2012

- 2012-06-07 WO PCT/JP2012/064655 patent/WO2013018433A1/ja not_active Ceased

- 2012-06-07 EP EP12819796.9A patent/EP2737886B1/en not_active Not-in-force

- 2012-06-07 US US14/130,172 patent/US9439817B2/en not_active Expired - Fee Related

- 2012-07-10 TW TW101124781A patent/TWI538664B/zh not_active IP Right Cessation

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06500485A (ja) * | 1990-09-12 | 1994-01-20 | ザ、プロクター、エンド、ギャンブル、カンパニー | 吸収体物品の形状及び吸収体物品の接着剤止め手段 |

| JPH11504846A (ja) * | 1996-02-28 | 1999-05-11 | ザ、プロクター、エンド、ギャンブル、カンパニー | 吸収体 |

| JP3748022B2 (ja) | 1999-11-19 | 2006-02-22 | ユニ・チャーム株式会社 | 水解性の吸収性物品およびその製造方法 |

| JP2005518251A (ja) * | 2002-02-22 | 2005-06-23 | ザ プロクター アンド ギャンブル カンパニー | 改善された接着パターンを有する下着留め接着剤を包含する吸収性物品 |

| JP2005319333A (ja) * | 2005-08-04 | 2005-11-17 | Uni Charm Corp | ウィング部材を有する吸収性物品 |

| JP2009268537A (ja) * | 2008-04-30 | 2009-11-19 | Uni Charm Corp | 吸収性物品及び吸収性物品の製造方法 |

| WO2009157476A1 (ja) * | 2008-06-24 | 2009-12-30 | ユニ・チャーム株式会社 | 吸収性物品及び吸収性物品の製造方法 |

| JP2011139847A (ja) * | 2010-01-08 | 2011-07-21 | Unicharm Corp | 流体吐出装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP5896639B2 (ja) | 2016-03-30 |

| TWI538664B (zh) | 2016-06-21 |

| JP2013027676A (ja) | 2013-02-07 |

| EP2737886B1 (en) | 2017-07-26 |

| US20140155852A1 (en) | 2014-06-05 |

| EP2737886A1 (en) | 2014-06-04 |

| EP2737886A4 (en) | 2015-04-15 |

| US9439817B2 (en) | 2016-09-13 |

| TW201315449A (zh) | 2013-04-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5896639B2 (ja) | 吸収性物品 | |

| JP6647015B2 (ja) | 吸収性物品 | |

| AU2010221060B2 (en) | Absorber forming and transferring mechanism and method of manufacturing absorbent article | |

| CN101754737A (zh) | 吸收性物品 | |

| JP5290615B2 (ja) | 吸収性物品及び吸収性物品の製造方法 | |

| CN103079513B (zh) | 吸收性物品、及该吸收性物品的制造方法 | |

| JP2001145669A (ja) | 水解性の吸収性物品 | |

| US20120123378A1 (en) | Wrapped absorbent article | |

| JP5140729B2 (ja) | 吸収性物品及び吸収性物品の製造方法 | |

| JP5508060B2 (ja) | 吸収性物品の製造方法 | |

| JP5791332B2 (ja) | 吸収性物品および吸収性物品の製造方法 | |

| CN100544694C (zh) | 吸收性物品 | |

| TW201526884A (zh) | 用後即棄式紙尿褲及其製造方法 | |

| JP4566108B2 (ja) | 吸収性物品 | |

| JP4964310B2 (ja) | 吸収性物品 | |

| US20240238131A1 (en) | Apparatus and method | |

| JP4393426B2 (ja) | 吸収性物品 | |

| JP4471895B2 (ja) | 吸収性物品 | |

| JP4197221B2 (ja) | 吸収性物品 | |

| JP2007167130A (ja) | 使い捨ておむつ | |

| JP2007167131A (ja) | 使い捨ておむつ | |

| JP2002113044A (ja) | 吸収性物品 | |

| SE523689C2 (sv) | Fastsättningsorgan till en absorberande artikel |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 12819796 Country of ref document: EP Kind code of ref document: A1 |

|

| REEP | Request for entry into the european phase |

Ref document number: 2012819796 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2012819796 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 14130172 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |