WO2012132182A1 - 高温用エアフィルタ - Google Patents

高温用エアフィルタ Download PDFInfo

- Publication number

- WO2012132182A1 WO2012132182A1 PCT/JP2012/000555 JP2012000555W WO2012132182A1 WO 2012132182 A1 WO2012132182 A1 WO 2012132182A1 JP 2012000555 W JP2012000555 W JP 2012000555W WO 2012132182 A1 WO2012132182 A1 WO 2012132182A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- filter

- comb

- filter medium

- heat

- temperature air

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/10—Particle separators, e.g. dust precipitators, using filter plates, sheets or pads having plane surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D39/00—Filtering material for liquid or gaseous fluids

- B01D39/14—Other self-supporting filtering material ; Other filtering material

- B01D39/20—Other self-supporting filtering material ; Other filtering material of inorganic material, e.g. asbestos paper, metallic filtering material of non-woven wires

- B01D39/2003—Glass or glassy material

- B01D39/2017—Glass or glassy material the material being filamentary or fibrous

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/52—Particle separators, e.g. dust precipitators, using filters embodying folded corrugated or wound sheet material

- B01D46/521—Particle separators, e.g. dust precipitators, using filters embodying folded corrugated or wound sheet material using folded, pleated material

- B01D46/523—Particle separators, e.g. dust precipitators, using filters embodying folded corrugated or wound sheet material using folded, pleated material with means for maintaining spacing between the pleats or folds

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4209—Inorganic fibres

- D04H1/4218—Glass fibres

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/54—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties by welding together the fibres, e.g. by partially melting or dissolving

- D04H1/559—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties by welding together the fibres, e.g. by partially melting or dissolving the fibres being within layered webs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2239/00—Aspects relating to filtering material for liquid or gaseous fluids

- B01D2239/06—Filter cloth, e.g. knitted, woven non-woven; self-supported material

- B01D2239/065—More than one layer present in the filtering material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2239/00—Aspects relating to filtering material for liquid or gaseous fluids

- B01D2239/12—Special parameters characterising the filtering material

- B01D2239/1233—Fibre diameter

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2273/00—Operation of filters specially adapted for separating dispersed particles from gases or vapours

- B01D2273/20—High temperature filtration

Definitions

- the present invention relates to a high-temperature air filter suitable for use in high-circulation air cleaning equipment attached to a dryer or the like that dries articles with high-temperature clean air such as a dryer of a tunnel-type drying sterilizer.

- a high-temperature air filter for purifying circulating air.

- a high-temperature air filter which is mainly composed of glass fiber, paper made using an organic binder, and is folded and folded in a zigzag manner in a frame body.

- the organic binder in the paper constituting the filter medium is carbonized.

- carbide on the outflow side surface and near the inside of the layer generate dust and scatter.

- Such carbonization of the organic binder is accompanied by deterioration of bonding between glass fibers and deterioration of filter action.

- the filter medium expands and contracts in the vertical direction as the ambient temperature changes during use, but the expansion and contraction does not maintain the airtight state of the upper and lower edges of the filter medium and the upper and lower frame bodies that accommodate and fix the filter medium.

- the present applicant has disclosed a patent document as a high-temperature air filter that can be used stably over a long period of time without the occurrence of dusting and scattering of carbides even when the dryer is used repeatedly.

- a zigzag filter body comprising a filter medium made of a glass fiber molded sheet not containing a binder and a heat-resistant mesh body sandwiching the filter medium from both side surfaces is formed between the upper and lower edges of the filter body and the frame body.

- a high-temperature air filter was proposed in which a heat-resistant sealing material that maintains the airtightness between the filter body and the frame body is interposed between the filter body and the frame body.

- a pair of comb-like pressing plates that horizontally sandwich the filter body from the upstream and downstream sides of the airflow are provided at the upper and lower edges of the filter body, and the upper and lower comb-teeth shapes are provided.

- a plurality of rod-shaped spacers provided with a corrugated base provided with a space protection projection on a linear base to horizontally sandwich the filter body from the upstream and downstream sides of the airflow with a gap between the press plates. The shape of the filter body is maintained.

- high-temperature air filters used in the dryers of tunnel-type dry sterilizers have been used in conventional 10 CMMs, but can be used in high air volumes because they can be sterilized in large quantities in a short time by using high air volumes.

- the air filter for high temperature of patent document 1 has a filter medium area of less than 50 m 2 / m 3 , pressure loss due to filter medium resistance and filter medium deformation becomes too large during high air flow processing, There was a problem that the capacity was insufficient or a larger capacity had to be used.

- the high-temperature air filter of the present invention has been made on the basis of such knowledge, and as described in claim 1, a filter medium comprising a glass fiber molded sheet not containing a binder and a heat-resistant network body sandwiching the filter medium from both sides.

- a zigzag filter body comprising: a heat-resistant sealing material that maintains the airtightness of the filter body and the frame body between the upper and lower edges of the filter body and the frame body;

- a high-temperature air filter that is housed and fixed and has a filter medium area of 50 to 65 m 2 / m 3 per unit filter volume, and the filter body is horizontally sandwiched from the upstream and downstream sides of the airflow at the upper and lower edges of the filter body.

- a plurality of comb-shaped spacer plates that are provided with a pair of comb-shaped pressing plates and sandwich the filter body horizontally from the upstream and downstream sides of the airflow with a space of 90 to 120 mm between the upper and lower comb-shaped pressing plates.

- the high temperature air filter according to claim 2 is characterized in that in the high temperature air filter according to claim 1, the glass fibers are made of glass fibers having an average fiber diameter of 0.6 to 0.8 ⁇ m.

- the high temperature air filter according to claim 3 is the high temperature air filter according to claim 1 or 2, wherein the filter medium is a molded sheet having a thickness of 7.5 to 10.5 mm and a basis weight of 75 to 84 g / m 2 . It is characterized by comprising.

- the high temperature air filter according to claim 4 is the high temperature air filter according to any one of claims 1 to 3, wherein the filter medium is a laminate of a plurality of the molded sheets. .

- the air filter for high temperature comprises a zigzag filter body comprising a filter medium composed of a glass fiber molded sheet not containing a binder and a heat-resistant mesh body sandwiching the filter medium from both sides, and upper and lower edges of the filter body.

- a heat-resistant sealing material that maintains the airtightness of the filter body and the frame body is interposed between the filter body and the frame body, and is housed and fixed in the frame body, and a filter medium area of 50 to 65 m 2 / m per unit filter volume.

- the high-temperature air filter according to the present invention uses a molded sheet made only of glass fibers that does not contain a binder as a filter medium.

- High temperature air can be circulated without generating.

- the glass fiber is not softened and does not sag due to wind pressure, and it can be used for a long time without causing an increase in pressure loss due to density unevenness caused by the sag of the glass fiber.

- a filter medium composed of the molded sheet since the zigzag-shaped filter body by sandwiching from both sides with a heat-resistant net body, the filter medium stably retained for a long period of time, and performs good high temperature filter effect over a long period be able to.

- a pair of comb-like pressing plates that horizontally sandwich the filter body from the upstream and downstream sides of the air flow are provided at the upper and lower edges of the filter body, and the heat-resistant sealing material is connected to the frame body and the comb teeth. Because it is airtightly housed and fixed to the frame with a heat-resistant sealing material interposed between the upper and lower edge portions of the filter body, with the change in ambient temperature when using a high-temperature air filter Even when the filter medium expands and contracts in the vertical direction, the heat-resistant sealing material absorbs the expansion and contraction of the filter medium due to the buffering action of the heat-resistant sealing material interposed between the filter body and the frame body.

- the airtightness between the upper and lower edges of the filter body and the frame body can be maintained and good sealing performance can be maintained over a long period of time, stable filter performance can be maintained over a long period of time without causing leakage problems.

- the at intervals of 90 ⁇ 120 mm in the upper and lower comb-shaped retainer plates since the filter body provided with a plurality of pairs of comb-shaped spacer plate sandwiching horizontally from the upper and lower stream side of the air flow, these comb-like Combined with the shape retention of the filter body by the spacer plate, independent closed spaces can be formed between the comb-like spacer plates and between the comb-like presser plate and the comb-like spacer plates. Since a laminar flow can be formed, the shape of the filter can be reliably prevented from being deformed even at a high air flow rate.

- the high-temperature filter of the present invention comprises a zigzag filter body comprising a filter medium made of a glass fiber molded sheet not containing a binder and a heat-resistant mesh body sandwiching the filter medium from both sides, and upper and lower edges of the filter body.

- a heat-resistant sealing material that maintains the airtightness between the filter body and the frame body is interposed between the filter body and the frame body, and is housed and fixed in the frame body, and the filter medium area is 50 to 65 m 2 / m 3 per unit filter volume.

- a high-temperature air filter is provided with a pair of comb-like pressing plates that horizontally sandwich the filter body from the upstream and downstream sides of the airflow at the upper and lower edges of the filter body, and the upper and lower comb-teeth shapes

- a plurality of pairs of comb-like spacer plates for horizontally sandwiching the filter body from the upstream and downstream sides of the airflow are provided with a spacing of 90 to 120 mm between the pressing plates.

- a filter medium made of a glass fiber molded sheet containing no binder is used as the filter medium composed of the molded sheet.

- the filter medium using E glass (non-alkali glass, softening point 750 to 1100 ° C.) fiber is 500 ° C.

- the filter medium that has been used can be used as a 400 ° C specification.

- the glass fiber preferably has a softening point of 600 to 1100 ° C. This is because, when the softening point of the glass fiber is less than 600 ° C., the heat resistance is insufficient and the filter medium is subjected to wind pressure in a softened state when used at a high temperature, so the density of the filter medium increases and the pressure loss increases. If the softening point exceeds 1100 ° C., it is difficult to shorten the fiber by a flame method or the like, and there is a problem that a molded sheet cannot be formed.

- the said glass fiber uses short fibers, such as C glass, E glass, and S glass.

- short fibers such as C glass, E glass, and S glass.

- the molded sheet is used as a filter medium for a high-temperature air filter of a dryer used at a high temperature of 400 to 500 ° C.

- the glass fibers constituting the molded sheet are softened and drooped by wind pressure. Therefore, it is possible to prevent the occurrence of density unevenness caused by the sag of the glass fiber.

- the molded sheet is preferably a sheet formed by short glass fibers spun from a glass melting furnace by a flame method, a centrifugal method, or the like so as to have a uniform density distribution in the width direction and the flow direction by a cotton collecting machine.

- the glass fiber was felted by a cotton collecting machine, the felted glass fiber cotton was manually formed into a sheet-shaped filter medium in an unformed state without maintaining the shape of the sheet. Although uneven density occurred, as described above, the glass fiber was formed into a sheet shape so as to have a uniform density distribution in the width direction and the flow direction by a cotton collecting machine, and the shape of the molded sheet was maintained

- the filter medium is preferably used as a filter medium having a uniform density distribution in both the width direction and the flow direction.

- the rolled-up formed sheet is again formed into a sheet shape More preferably, it is used as a filter medium.

- the filter medium used in the high temperature air filter preferably has a basis weight of 75 to 84 g / m 2 .

- the filter medium is inferior in handleability during assembly when it is sandwiched between heat-resistant mesh bodies, and a desired efficiency of 90% or more (at 0.2 to 0) .5 ⁇ m) cannot be obtained.

- the basis weight exceeds 84 g / m 2 , the pressure loss is high at a filter medium passing wind speed of 8 m / s, and 360 Pa or less cannot be obtained, and it is bulky and inferior in assemblability.

- the filter medium preferably has a thickness of 7.5 to 10.5 mm.

- the filter medium When the thickness of the filter medium is less than 7.5 mm, the filter medium is inferior in handleability during assembly when the filter medium is sandwiched between heat-resistant mesh bodies, and the desired efficiency is 90% or more (at 0.2 to 0). .5 ⁇ m) cannot be obtained.

- the thickness of the filter medium exceeds 10.5 mm, the pressure loss is high at a filter medium passing air speed of 8 m / s, and 360 Pa or less cannot be obtained, and it is bulky and inferior in assemblability.

- the thickness of the filter media may be set so that the thickness after lamination is in the range of 7.5 to 10.5 mm.

- the filter medium used for the high-temperature air filter is inevitably generated in the molded sheet even when a molded sheet formed into a sheet shape with a uniform density distribution in the width direction and the flow direction is used by a cotton collecting machine.

- a molded sheet having a basis weight of 25 to 28 g / m 2 it is preferable to use a molded sheet having a basis weight of 25 to 28 g / m 2 .

- molding sheet at the time of assembling a filter body as a fabric weight is less than 25 g / m ⁇ 2 >.

- the basis weight exceeds 28 g / m 2

- the molded sheet is a high-temperature air filter having a desired collection efficiency and pressure loss by appropriately selecting the average fiber diameter of the glass fibers constituting the molded sheet and the basis weight when the molded sheet is used as a filter medium.

- a suitable filter medium can be produced.

- glass fibers constituting a molded sheet used for an air filter having a collection efficiency of 90% (at 0.2 to 0.5 ⁇ m) or more are short glass fibers having an average fiber diameter of 0.6 to 0.8 ⁇ m. It is preferable.

- the average fiber diameter of the glass fiber is less than 0.6 ⁇ m, fiberization and sheeting are difficult, and when the average fiber diameter exceeds 0.8 ⁇ m, a filter medium made of a molded sheet formed from the glass fiber, This is because the desired collection efficiency cannot be obtained.

- the heat-resistant net is preferably formed using a metal such as stainless steel that can withstand the heat of the dryer, a heat-resistant synthetic resin, or the like.

- the heat-resistant net body preferably has as low a pressure loss as possible, and preferably has a fine mesh so that a filter medium made of a glass fiber molded sheet can be reliably held.

- a wire mesh on the inflow side is 36 ⁇ 40 mesh wire diameter 0.193 mm, equal to the outflow side is composed of a wire mesh 38 ⁇ 60 mesh wire diameter 0.1524 mm, coarser mesh member on the inflow side, and a thick line, the outflow It is preferable to form the side densely and with a thin line.

- the comb-shaped holding plate only needs to be able to sandwich the filter body horizontally from the upstream and downstream sides of the airflow at the upper and lower edges of the filter body, and the shape of the comb teeth corresponds to the zigzag shape of the filter medium.

- a heat resistant material such as a metal plate such as a stainless steel plate or a synthetic resin plate.

- the shape of the comb-teeth is Similar to the comb-teeth shape of the holding plate, it corresponds to the zigzag shape of the filter medium, and considering heat resistance, it is preferably composed of a heat-resistant material such as a metal plate such as a stainless steel plate or a heat-resistant synthetic resin plate. .

- the comb-like spacer plate may have the same shape as the comb-like holding plate.

- the distance between the comb-shaped spacer plates and the distance between the comb-shaped pressing plate and the comb-shaped spacer plates must be 90 to 120 mm. If the distance is less than 90 mm, the gap between the comb-like presser plate and the comb-like presser plate is increased, thereby forming an airtight (isolation) that forms an independent closed space between the comb-like presser plate and the comb-like presser plate.

- the frame which comprises the high temperature air filter by this invention uses heat resistant materials, such as metal plates, such as stainless steel which can endure the atmospheric temperature of the dryer using a high temperature air filter, and a synthetic resin board.

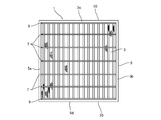

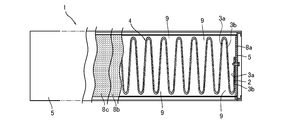

- a high-temperature air filter 1 includes a filter medium 2 formed of a glass fiber molded sheet not containing a binder and heat-resistant nets 3a and 3b sandwiching the filter medium 2 from both sides.

- the zigzag filter body 4 is housed in the frame body 5 with heat-resistant sealing materials 8a, 8b, 8c for maintaining airtightness with the frame body 5 (5a, 5b, 5c, 5d) interposed therebetween. It has a fixed configuration.

- the zigzag filter body 4 is inserted into the zigzag space of the filter body 3 and a pair of comb-like spacer plates 7 that contact the front and back surfaces of the filter body 3, that is, the upper and lower side surfaces of the airflow, Before and after the filter body 4, that is, horizontally inserted from the upstream and downstream sides of the airflow, 5 pairs of such comb-like spacer plates 7 are inserted at regular intervals in the vertical direction, so that the zigzag spacing of the filter body 4 is increased. It is fixed between the side frames 5a, 5a in a stable state.

- the filter body 4 is airtightly fixed to the side frame bodies 5a and 5b with bolts (not shown) with a heat-resistant sealing material 8a interposed between the filter body 4 and the side frame bodies 5a and 5b.

- the means for fixing the filter body 4 to the both side frames 5a and 5b via the heat-resistant sealing material 8a is not limited to bolts, and can be fixed by other fixing means.

- a comb-like presser plate 9 that is inserted into a zigzag-shaped space of the filter body 4 and contacts the front and back surfaces of the filter body 4, that is, the upstream and downstream sides of the airflow.

- a comb-like presser plate 9 that is inserted into a zigzag-shaped space of the filter body 4 and contacts the front and back surfaces of the filter body 4, that is, the upstream and downstream sides of the airflow.

- a comb-like pressing plate 9 is interposed between the heat-resistant sealing material 8b filled and the upper and lower frame bodies 5c and 5d by interposing a heat-resistant sealing material 8c in which a plurality of molded sheets made of glass fibers similar to the filter medium 2 are laminated.

- 9 and the upper and lower frame bodies 5c, 5d sandwich and press the heat-resistant sealing materials 8b, 8c as a whole, and the heat-resistant sealing materials 8b, 8c are interposed at the upper and lower edges of the filter body 4.

- the filter body 4 is accommodated in the frame body 5 while being pressure-bonded to the upper and lower frame bodies 5b and 5b and maintaining the airtightness between the filter body 4 and the upper and lower frame bodies 5c and 5d by the buffering action of the heat-resistant sealing materials 8b and 8c. It is fixed. For this reason, even when the filter medium 2 expands and contracts in the vertical direction due to use at a high temperature, the heat-resistant sealing materials 8b and 8c interposed between the comb-like pressing plate 9 and the upper and lower frame bodies 5c and 5d. However, the expansion and contraction of the filter medium 2 is absorbed, and the airtightness between the upper and lower edges of the filter body 4 and the upper and lower frame bodies 5c and 5d can be maintained, and the high-temperature air filter 1 can maintain good sealing performance.

- heat-resistant sealing materials 8a and 8c molded sheets having a basis weight of 25 g / m 2 made of C (containing ground glass) glass fibers having an average fiber diameter of 0.8 ⁇ m were used. Further, as the heat-resistant sealing material 8b, felt-like C (containing ground glass) glass fiber cotton having an average fiber diameter of 0.8 ⁇ m was used.

- the same heat-resistant material as the filter medium 2 can be used as 8a, 8b, 8c, it is not limited to the case where a felt-like piece of glass cotton and a molded sheet similar to the filter medium 2 are used in combination as described above.

- As a heat-resistant sealing material it is possible to use a felt-like lump of glass cotton as a whole, and cut or laminate so as to be able to be filled with the same molded sheet as the filter medium 2. Is possible.

- the frame 5 (5a, 5a, 5b, 5b) can also be made of a metal such as stainless steel or a synthetic resin that can withstand the atmospheric temperature of a dryer using a high-temperature air filter.

- Example 1 The high-temperature air filter according to the present embodiment has the structure shown in FIGS. 1 to 3 and uses only a C glass (alkali-containing glass) fiber having an average fiber diameter of 0.6 ⁇ m spun by a flame method as a filter medium.

- the sheet was formed into a sheet having a basis weight of 25 g / m 2 by using a cotton collecting machine, and three sheets were formed to have a basis weight of 75 g / m 2 .

- a heat-resistant net that sandwiches the filter medium from both sides in a zigzag shape, it consists of a stainless steel wire mesh with an inflow side of 36 ⁇ 40 mesh, a wire diameter of 0.193 mm, an outflow side of 38 ⁇ 60 mesh, and a wire diameter of 0.1524 mm was used to form a zigzag filter body with a filter medium area of 53.6 m 2 / m 3 (mountain folded filter medium area 5.6 m 2 / unit) per unit filter volume.

- a heat-resistant sealing material 20 g / unit (610 ⁇ 290 mm) of a glass fiber cotton made of felt-like C glass fiber having an average fiber diameter of 0.6 ⁇ m and a molded sheet made of C glass fiber having an average fiber diameter of 0.6 ⁇ m. Were used in two places (upper and lower). Further, a heat-resistant sealing material in which C (containing ground glass) glass fiber having an average fiber diameter of 0.8 ⁇ m was formed into a molded sheet having a basis weight of 25 g / m 2 was used for the left and right side frames. Moreover, the said comb-shaped pressing board was provided in both the upper-and-lower-edge parts of the said filter body as illustration.

- the comb-like spacer plates were fixed by sandwiching the filter bodies with a total of 5 pairs of 5 pieces on each side at intervals of about 100 mm.

- the frame, the comb-shaped holding plate, and the comb-shaped spacer plate constituting the high-temperature air filter were all made of stainless steel.

- Comparative Example 1 The high-temperature air filter of Comparative Example 1 is replaced with the five pairs of comb-like spacer plates, and a zigzag filter body is formed on a linear base horizontally fixed as described in Patent Document 1. Except that the heat-resistant spacer with the corrugated base provided with the space protection projections that keep the space of the space stable is fixed and the filter medium is sandwiched and fixed in 3 pairs of 3 on each side at intervals of about 150 mm. In the same manner as in Example 1, a high temperature air filter was obtained.

- Comparative Example 2 The high-temperature air filter of Comparative Example 2 is replaced with the five pairs of comb-like spacer plates, and a zigzag filter body is formed on a linear base horizontally fixed as described in Patent Document 1. Except that the heat-resistant spacer with the corrugated base provided with the space-protecting protrusions that stably maintain the spacing of the space is fixed by sandwiching and fixing the filter body with 5 pairs of 5 pieces on each side at intervals of about 100 mm. In the same manner as in Example 1, a high temperature air filter was obtained.

- Example 1 the air was passed through a high-temperature air filter having the dimensions of 610 ⁇ 610 ⁇ 290 mm in Example 1 and Comparative Examples 1, 2 and 3 obtained in this way at 400 ° C.

- the pressure loss after a heat cycle test of 10 cycles at 1 ° C. was measured at room temperature, and the heat resistance performance of the high temperature air filter was evaluated. The results are shown in Table 1 below.

- the pressure loss was measured as follows. [Pressure loss] The passage resistance when air was passed through each high temperature air filter at a passing wind speed of 8 m / s was measured with a manometer. Judgment criteria: ⁇ when the value after heat cycle test of pressure loss was 360 Pa or less, and over 360 Pa were marked as x.

- Example 1 The results shown in Table 1 revealed the following.

- the filter body is sandwiched and fixed by a total of five pairs of comb-like pressing plates, five on each side, and the comb-shaped pressing plate and the comb-shaped pressing plate are spaced at an interval of about 100 mm.

- Comparative Example 1 is only fixed at approximately 150mm intervals nipping the filter body in heat spacer made of a total of three pairs each three side, the filter body in use because there is no airtight (isolated) structures as in Example 1

- the result of the worst pressure loss of 850 Pa in the state after the heat cycle test (after ventilation) was obtained from the problem of the deterioration of the pressure loss caused by being deformed by being pushed by the wind pressure.

- Comparative Example 2 only fixed at approximately 100mm intervals nipping the filter body in heat spacer made of five pairs each five side, since there is no airtight (isolated) structures as in Example 1, filtered in use although the body is slightly improved the deterioration problem of the pressure loss to cause it to deform by being pushed by the wind pressure, the result of poor pressure loss that 600Pa was obtained in a state after the heat cycle test (after ventilation) .

- the filter medium is sandwiched and fixed by three pairs of comb-like pressing plates, three on each side, and the comb-shaped pressing plate and the comb-shaped pressing plate are spaced at an interval of about 150 mm.

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Geology (AREA)

- Inorganic Chemistry (AREA)

- Filtering Materials (AREA)

- Filtering Of Dispersed Particles In Gases (AREA)

- Nonwoven Fabrics (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP12763008.5A EP2692409B1 (en) | 2011-03-31 | 2012-01-30 | High temperature resistant air filter |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011080915A JP5805976B2 (ja) | 2011-03-31 | 2011-03-31 | 高温用エアフィルタ |

| JP2011-080915 | 2011-03-31 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2012132182A1 true WO2012132182A1 (ja) | 2012-10-04 |

Family

ID=46929979

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2012/000555 Ceased WO2012132182A1 (ja) | 2011-03-31 | 2012-01-30 | 高温用エアフィルタ |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP2692409B1 (enExample) |

| JP (1) | JP5805976B2 (enExample) |

| WO (1) | WO2012132182A1 (enExample) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104606983B (zh) * | 2015-02-02 | 2016-03-02 | 苏州华泰空气过滤器有限公司 | 梯形通风通道式耐高温过滤器 |

| CN105214411A (zh) * | 2015-09-18 | 2016-01-06 | 广州金田瑞麟净化设备制造有限公司 | 一种处理pm2.5的空气过滤器装置 |

| JP6564894B2 (ja) * | 2018-02-06 | 2019-08-21 | みすず精工株式会社 | フィルタ装置、フィルタ装置の交換方法及びフィルタ装置の製造方法 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5662113U (enExample) * | 1979-10-17 | 1981-05-26 | ||

| JPH0429710A (ja) * | 1990-05-28 | 1992-01-31 | Sanyo Electric Co Ltd | エアフィルタ |

| JP2004313888A (ja) * | 2003-04-14 | 2004-11-11 | Nippon Muki Co Ltd | 高温用エアフィルタ |

| JP2008260016A (ja) | 2008-05-30 | 2008-10-30 | Nippon Muki Co Ltd | 高温用エアフィルタの製造方法 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4547950A (en) * | 1984-05-29 | 1985-10-22 | Honeywell Inc. | Method of spacing the folds of a folded filter media |

| JP4640895B2 (ja) * | 2001-03-29 | 2011-03-02 | 日本無機株式会社 | ガスタービン吸気用高性能フィルタ及びそれを用いたガスタービン吸気用フィルタユニット |

| US7004989B2 (en) * | 2003-08-22 | 2006-02-28 | Camfil Farr, Inc. | Filter assembly with compressed media edge seal |

| JP4662763B2 (ja) * | 2004-12-28 | 2011-03-30 | 日本無機株式会社 | 清浄乾燥気体供給システム用エアフィルタ及び清浄乾燥気体供給システム |

| JP4825703B2 (ja) * | 2007-03-06 | 2011-11-30 | 日本バイリーン株式会社 | フィルタエレメントの製造方法、及びその製造に使用するフィルタエレメント製造用治具 |

-

2011

- 2011-03-31 JP JP2011080915A patent/JP5805976B2/ja active Active

-

2012

- 2012-01-30 EP EP12763008.5A patent/EP2692409B1/en active Active

- 2012-01-30 WO PCT/JP2012/000555 patent/WO2012132182A1/ja not_active Ceased

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5662113U (enExample) * | 1979-10-17 | 1981-05-26 | ||

| JPH0429710A (ja) * | 1990-05-28 | 1992-01-31 | Sanyo Electric Co Ltd | エアフィルタ |

| JP2004313888A (ja) * | 2003-04-14 | 2004-11-11 | Nippon Muki Co Ltd | 高温用エアフィルタ |

| JP2008260016A (ja) | 2008-05-30 | 2008-10-30 | Nippon Muki Co Ltd | 高温用エアフィルタの製造方法 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP2692409A4 * |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2012213722A (ja) | 2012-11-08 |

| EP2692409A1 (en) | 2014-02-05 |

| JP5805976B2 (ja) | 2015-11-10 |

| EP2692409A4 (en) | 2015-08-12 |

| EP2692409B1 (en) | 2017-01-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103857455B (zh) | 空气过滤器用滤材及空气过滤器单元 | |

| CN103764251B (zh) | 空气过滤器用滤材、空气过滤器单元以及空气过滤器用滤材的制造方法 | |

| CN100553734C (zh) | 折叠排列网过滤器 | |

| US9393513B2 (en) | Air filter unit | |

| JP5966282B2 (ja) | エアフィルタ用濾材及びエアフィルタユニット | |

| US9174152B2 (en) | Filter medium and method of fabricating the same | |

| JP5805976B2 (ja) | 高温用エアフィルタ | |

| JP4315419B2 (ja) | 高温用エアフィルタ | |

| JP2014133200A (ja) | 集塵デバイスおよびそれを用いた空気清浄装置 | |

| JP4110628B2 (ja) | 布帛およびその製造方法 | |

| JP4722965B2 (ja) | 高温用エアフィルタの製造方法 | |

| WO2024203820A1 (ja) | 積層ろ材及びエアフィルター | |

| JP2012170914A (ja) | エレクトレットろ材 | |

| JPH03293008A (ja) | エレクトレットフィルター及びその製造方法 | |

| JP2014064969A (ja) | エレクトレット濾材 | |

| JP5795860B2 (ja) | エアフィルタ装置 | |

| JP4472398B2 (ja) | エアフィルタ | |

| JP7117174B2 (ja) | ガラスフィルタ | |

| JPH0626333Y2 (ja) | 高温用エアフイルタ | |

| JP4142991B2 (ja) | 高温用エアフィルタ | |

| JP4552249B2 (ja) | 高温用エアフィルタ用濾材 | |

| JP2004190161A (ja) | ポリエステル系難燃性積層不織布およびそれを用いたフィルター | |

| JP6579876B2 (ja) | 濾材及びこれを用いたフィルターユニット | |

| JP2011152520A (ja) | 濾材およびそれを用いたフィルター | |

| JP2025060073A (ja) | 積層ろ材、フィルター、フィルターユニット、及び積層ろ材の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 12763008 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| REEP | Request for entry into the european phase |

Ref document number: 2012763008 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2012763008 Country of ref document: EP |