WO2011086110A1 - Beverage can with disc - Google Patents

Beverage can with disc Download PDFInfo

- Publication number

- WO2011086110A1 WO2011086110A1 PCT/EP2011/050364 EP2011050364W WO2011086110A1 WO 2011086110 A1 WO2011086110 A1 WO 2011086110A1 EP 2011050364 W EP2011050364 W EP 2011050364W WO 2011086110 A1 WO2011086110 A1 WO 2011086110A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- disc

- beverage

- base

- entrant

- entrant bead

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D17/00—Rigid or semi-rigid containers specially constructed to be opened by cutting or piercing, or by tearing of frangible members or portions

- B65D17/02—Rigid or semi-rigid containers specially constructed to be opened by cutting or piercing, or by tearing of frangible members or portions of curved cross-section, e.g. cans of circular or elliptical cross-section

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D1/00—Rigid or semi-rigid containers having bodies formed in one piece, e.g. by casting metallic material, by moulding plastics, by blowing vitreous material, by throwing ceramic material, by moulding pulped fibrous material or by deep-drawing operations performed on sheet material

- B65D1/12—Cans, casks, barrels, or drums

- B65D1/14—Cans, casks, barrels, or drums characterised by shape

- B65D1/16—Cans, casks, barrels, or drums characterised by shape of curved cross-section, e.g. cylindrical

- B65D1/165—Cylindrical cans

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2517/00—Containers specially constructed to be opened by cutting, piercing or tearing of wall portions, e.g. preserving cans or tins

- B65D2517/0001—Details

- B65D2517/0047—Provided with additional elements other than for closing the opening

- B65D2517/0052—Prizes, tokens, badges or other information carrying devices

Definitions

- the present invention includes a conventional beverage can having a body, which incorporates an integrally domed base and a side-wall, and an end, which is fixed to the open end of the body using conventional techniques, a double seam for example.

- WO 96/24539 KOHORN INTERNATIONAL PTY LIMIT 19960815 describes a container formed with an open void separate from the main containment volume.

- containers are metal cans, which are formed with a generally concave or domed void in the base, as commonly used for soft drinks, beer etc.

- This document describes removal means that are provided to substantially close this void, thereby creating a second containment volume that may be used for promotional goods, a second active ingredient or such like.

- EP 0958182 B SCHMALBACH LUBECA 19991124 which describes a two piece beverage can made substantially of sheet metal having a base that is drawn-in to the inner side of the container, so that the diameter of the base is evidently smaller than the diameter of the container.

- This document also describes a separate disc-shaped component that is adapted to be fixed into the base. The separate disc-shaped component (“false bottom part”) is separately produced and may therefore be easily decorated etc.

- the present invention provides a beverage can (1) having a base (10) defining a re-entrant bead (17) in which a resilient disc (50) is held captive, characterised in that the diametric dimension of the disc (50) is larger than the internal diameter of the re-entrant bead (17) and when the resilient disc (50) is fitted into the re-entrant bead (17), the disc (50) adopts a concave, domed shape.

- a resilient disc is snapped into the re-entrant bead at the base of a beverage can.

- the disc has a means of removal, by which it can be prised out of the re-entrant bead by a user.

- the disc may have a cut–out that allows it to be prised out of the re-entrant, bead using a tab or a coin.

- the disc and domed base of the beverage can together define a compartment, which can be used to store additives for the contents of the container or an item such as seeds, a compass, USB device etc.

- the disc is preferably stamped from a printed sheet of thermoplastic material e.g. PP, PET or other polymer, although other materials such as metal or card are also possible

- the disc may be fitted into the base of the beverage can either before or after filling the can with product, by a canmaker or packer respectively.

- cut-outs are provided in the disc to allow drainage of any liquid that has collected in the compartment. This allows the disc to be optionally fitted prior to pasteurising or rinsing on the filling line.

- the disc can be manufactured to a much tighter tolerance than may be achieved for the diameter of the re-entrant bead and thus, during trials the disc was found to fit tightly in the reformed base of some cans, whereas it only fitted very loosely in the reformed base of other cans.

- the diametric dimension of the disc i.e. the maximum points of the disc plotted within a circle

- the disc could be snapped into the reformed base, but the stresses exerted on the disc by the re-entrant bead, causes the disc to and flex into a concave, dome configuration.

- the domed disc takes up a lesser or greater degree of doming.

- the degree of doming can accommodate any variance between the dimensions of the disc and that of the reformed base of the can.

- the disc can be manufactured having a tolerance of + - 0.1mm whereas the reformed base conventionally has a tolerance of + - 0.3mm.

- the disc proposed by the invention includes one or more cut-outs arranged on its periphery.

- the concave, domed shape of the disc once fitted in the reformed base of the can assists with the drainage of water from the internal surface of the disc and the stressed / fitted disc is more difficult to remove from the base of the can, reducing the risk of accidental separation from the can.

- the disc is provided with a removal means, which is sized and shaped to allow a user to remove the disc from the base of the can.

- the removal means takes the form of a cut-out, which allows a user to insert a lever e.g. a coin or tab, to prise the disc out of the base of the can.

- the disc and base of the can together define three contact points and the removal means is provided by a cut- away, which allows a user to apply a lever under the disc.

- the two contact points located on either side of the cut away serve as energising prongs. These energising prongs may be located immediately adjacent to the cut-away or they may be displaced from the cut-away, but they must be located within the same half of the disc as the cut-way.

- the contact point located diametrically opposite the cut away acts as a pivot.

- the energising prongs and the pivot causes the disc to spin upon release from the base of the can, much like the flipping of a coin. This provides the opportunity for a simple decision based game.

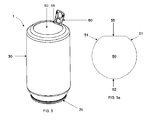

- Figure 1 is an isometric view of an upturned beverage can having a reformed base suitable for use in the invention.

- Figure 1a is a section taken through the base of the beverage can shown in figure 1.

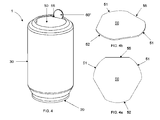

- Figure 2 is a section view of the beverage can according to the invention having a reformed base (as shown in figure 1a) with a disc constrained therein, illustrating where a user may apply a lever to prise the disc out of the beverage can base.

- Figure 3 is an isometric view of an upturned beverage can having a disc according to a first embodiment of the invention, illustrating how a tab may be used as a lever to prise the disc out of the beverage can base.

- Figure 3a is a plan view of the disc shown fitted in the reformed base of the beverage can shown in figure 3.

- Figure 4 is an isometric view of an upturned beverage can having a disc according to a second embodiment of the invention, illustrating how a coin may be used as a lever to prise the disc out of the beverage can base.

- Figure 4a is a plan view of the disc shown fitted in the reformed base of the beverage can shown in figure 4.

- Figure 4b is an isometric view of the disc shown in figures 4 and 4a.

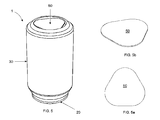

- Figure 5 is an isometric view of an upturned beverage can having a disc according to an enhanced third embodiment of the invention.

- Figure 5a is a plan view of the disc shown fitted in the reformed base of the beverage can shown in figure 5.

- Figure 5b is an isometric view of the disc shown in figures 5 and 5a.

- Figure 6 is a section view of the beverage can according to the enhanced third embodiment of the invention where the diametric dimension of the disc is larger than the maximum diameter of the cavity formed in the reformed base of the beverage can and when the disc is constrained therein, the disc adopts a concave, domed shape.

- Figure 1 generally shows a conventional beverage can 1 according to the prior art, having a base 10 with a stand annulus 15, a top 20 and a side-wall 30.

- figure 1a shows a cross section taken through the base 10 of the can illustrated in figure 1, which more clearly shows the stand annulus 15 and the concave dome 12 of the base 10.

- FIG 2 The base of the can according to the invention is illustrated in figure 2, where a resilient disc 50 is shown trapped in the re-entrant bead 17. A compartment (not labelled) is clearly shown, defined between the disc 50 and the domed base of the can 12. The disc 50 may be removed from the re-entrant bead 17, using a lever 60 inserted under the disc 50 via a cut-away 55.

- Figures 3 and 4 show alternative examples of levers 60 suitable for use in the invention.

- Figure 3 illustrates how a tab 60’ may be used as a lever upon opening and after separation from the top of the can and figure 4 illustrates the use of a coin 60’’.

- Figure 3a illustrates a plan view of a disc 50 suitable for use in the invention.

- This disc 50 has a cut-away 55 to allow insertion of a suitable lever 60 and the disc 50 also defines two energising prongs 51 and a pivot 52.

- the disc 50 Upon application of a lever 60’ by a user of the can (as shown in figure 3), the disc 50 is prised from the re-entrant bead (17) and the combined action of the energising prongs 51 and the pivot 52, causes the disc to spin (much like the flip of a coin) upon release from the re-entrant bead 17.

- Figures 4a and 4b show an alternative disc 50 suitable for use in the invention.

- This disc 50 has a cut-away 55 to allow insertion of a suitable lever 60, but the disc 50 is modified to include three large cut-outs (not labelled) between the energising prongs 51 and the pivot 52. These cut-outs minimise the amount of moisture trapped between the disc 50 and the base of the can 10 and also allow any moisture that is trapped to drain / dry out efficiently.

- Figure 5 shows a beverage can 1 according to the invention with an enhanced variant of the disc 50 illustrated in Figures 4, 4a and 4b inserted into the re-entrant bead 17.

- Figures 5a and 5b show a plan view and isometric view of the enhanced disc 50. Radiuses have been provided on the corners of the contact points (energising prongs and pivot) so there are no longer any sharp corners, as shown Fig. 5a. These smoothed corners provide a smooth release as the disc 50 is flipped out of the re-entrant bead 17. This is independent of the degree of doming of the disc (50) caused by the variation in dimensions of the disc and the diameter defined by the re-entrant bead of the reformed base.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Ceramic Engineering (AREA)

- Table Devices Or Equipment (AREA)

- Details Of Rigid Or Semi-Rigid Containers (AREA)

- Rigid Containers With Two Or More Constituent Elements (AREA)

Priority Applications (12)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CA2786219A CA2786219A1 (en) | 2010-01-12 | 2011-01-12 | Beverage can with disc |

| BR112012016148A BR112012016148A2 (pt) | 2010-01-12 | 2011-01-12 | lata para bebida, e, método de encher uma lata para bebida |

| ES11701043T ES2435475T3 (es) | 2010-01-12 | 2011-01-12 | Lata de bebida con disco |

| US13/521,921 US8973777B2 (en) | 2010-01-12 | 2011-01-12 | Beverage can with disc |

| AU2011206646A AU2011206646B2 (en) | 2010-01-12 | 2011-01-12 | Beverage can with disc |

| RU2012134324/12A RU2557518C2 (ru) | 2010-01-12 | 2011-01-12 | Банка для напитков с диском |

| CN201180005942.3A CN102712385B (zh) | 2010-01-12 | 2011-01-12 | 带有盘的饮料罐 |

| JP2012548427A JP5738315B2 (ja) | 2010-01-12 | 2011-01-12 | ディスクを備えた飲料缶 |

| MX2012008071A MX2012008071A (es) | 2010-01-12 | 2011-01-12 | Lata de bebida con disco. |

| SG2012050035A SG182397A1 (en) | 2010-01-12 | 2011-01-12 | Beverage can with disc |

| EP11701043.9A EP2523862B1 (en) | 2010-01-12 | 2011-01-12 | Beverage can with disc |

| TNP2012000289A TN2012000289A1 (en) | 2010-01-12 | 2012-06-05 | Beverage can with disc |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP10150507 | 2010-01-12 | ||

| EP10150507.1 | 2010-01-12 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2011086110A1 true WO2011086110A1 (en) | 2011-07-21 |

Family

ID=42268351

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/EP2011/050364 Ceased WO2011086110A1 (en) | 2010-01-12 | 2011-01-12 | Beverage can with disc |

Country Status (15)

| Country | Link |

|---|---|

| US (1) | US8973777B2 (enExample) |

| EP (1) | EP2523862B1 (enExample) |

| JP (1) | JP5738315B2 (enExample) |

| CN (1) | CN102712385B (enExample) |

| AU (1) | AU2011206646B2 (enExample) |

| BR (1) | BR112012016148A2 (enExample) |

| CA (1) | CA2786219A1 (enExample) |

| CO (1) | CO6541584A2 (enExample) |

| ES (1) | ES2435475T3 (enExample) |

| MX (1) | MX2012008071A (enExample) |

| MY (1) | MY159294A (enExample) |

| RU (1) | RU2557518C2 (enExample) |

| SG (1) | SG182397A1 (enExample) |

| TN (1) | TN2012000289A1 (enExample) |

| WO (1) | WO2011086110A1 (enExample) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8127588B1 (en) | 2011-03-23 | 2012-03-06 | Halpin Harold W | Apparatus and methods for forming a finger-engaging portion in a stay-on-tab of a lid of a container |

| EP2958710B1 (en) | 2013-03-15 | 2017-08-16 | Station 4 LLC | Devices and methods for bending a tab on a container |

| PL3423366T3 (pl) * | 2016-02-29 | 2020-06-15 | Crown Packaging Technology, Inc. | Wklęsłe wieczko puszki |

| US10875076B2 (en) | 2017-02-07 | 2020-12-29 | Ball Corporation | Tapered metal cup and method of forming the same |

| US11370579B2 (en) | 2017-02-07 | 2022-06-28 | Ball Corporation | Tapered metal cup and method of forming the same |

| USD950318S1 (en) | 2018-05-24 | 2022-05-03 | Ball Corporation | Tapered cup |

| USD906056S1 (en) | 2018-12-05 | 2020-12-29 | Ball Corporation | Tapered cup |

| USD968893S1 (en) | 2019-06-24 | 2022-11-08 | Ball Corporation | Tapered cup |

| USD953811S1 (en) | 2020-02-14 | 2022-06-07 | Ball Corporation | Tapered cup |

| USD974845S1 (en) | 2020-07-15 | 2023-01-10 | Ball Corporation | Tapered cup |

| US12370594B2 (en) | 2020-10-30 | 2025-07-29 | Ball Corporation | Tapered cup and method of forming the same |

| USD1012617S1 (en) | 2021-02-22 | 2024-01-30 | Ball Corporation | Tapered cup |

| USD1035386S1 (en) | 2021-12-08 | 2024-07-16 | Ball Corporation | Tapered cup |

| US20240270464A1 (en) * | 2023-02-09 | 2024-08-15 | Stolle Machinery Company, Llc | Metal container, friction coating therefor, and associated methods |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4181219A (en) * | 1979-02-01 | 1980-01-01 | Maryland Cup Corporation | Container having premium-containing-and-dispensing bottom structure and method and apparatus for providing same |

| EP0482581A1 (en) | 1990-10-22 | 1992-04-29 | Ball Corporation | Apparatus and method for strengthening bottom of container |

| DE29519352U1 (de) * | 1995-12-06 | 1996-02-29 | Hofer, Rudolf, 81245 München | Compact-Disc an Flaschenboden |

| WO1996024539A1 (en) | 1995-02-09 | 1996-08-15 | Kohorn International Pty. Limited | A container |

| DE19704522A1 (de) * | 1997-02-06 | 1998-08-20 | Schmalbach Lubeca | Behälter mit zweitem Schnappboden |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1209998A (en) * | 1916-02-23 | 1916-12-26 | Frank Pinckert | Milk-check. |

| US2174618A (en) * | 1937-01-09 | 1939-10-03 | Ralph V Burdick | Compartment box |

| JPH01130916U (enExample) * | 1988-03-03 | 1989-09-06 | ||

| JPH09285832A (ja) * | 1996-04-23 | 1997-11-04 | Kishimoto Akira | シームレス缶及びその成形法 |

| US5769263A (en) * | 1997-01-21 | 1998-06-23 | Alcoa Closure Systems International, Inc. | Compartmentalized top cover promotional closure |

| ATE327174T1 (de) * | 2002-01-30 | 2006-06-15 | Crebocan Ag | Dosenkörper mit einer äusseren bodenabdeckung |

-

2011

- 2011-01-12 SG SG2012050035A patent/SG182397A1/en unknown

- 2011-01-12 MX MX2012008071A patent/MX2012008071A/es active IP Right Grant

- 2011-01-12 BR BR112012016148A patent/BR112012016148A2/pt not_active IP Right Cessation

- 2011-01-12 CA CA2786219A patent/CA2786219A1/en not_active Abandoned

- 2011-01-12 AU AU2011206646A patent/AU2011206646B2/en not_active Ceased

- 2011-01-12 WO PCT/EP2011/050364 patent/WO2011086110A1/en not_active Ceased

- 2011-01-12 CN CN201180005942.3A patent/CN102712385B/zh not_active Expired - Fee Related

- 2011-01-12 EP EP11701043.9A patent/EP2523862B1/en not_active Not-in-force

- 2011-01-12 RU RU2012134324/12A patent/RU2557518C2/ru not_active IP Right Cessation

- 2011-01-12 US US13/521,921 patent/US8973777B2/en not_active Expired - Fee Related

- 2011-01-12 MY MYPI2012003088A patent/MY159294A/en unknown

- 2011-01-12 ES ES11701043T patent/ES2435475T3/es active Active

- 2011-01-12 JP JP2012548427A patent/JP5738315B2/ja not_active Expired - Fee Related

-

2012

- 2012-06-05 TN TNP2012000289A patent/TN2012000289A1/en unknown

- 2012-06-08 CO CO12097417A patent/CO6541584A2/es not_active Application Discontinuation

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4181219A (en) * | 1979-02-01 | 1980-01-01 | Maryland Cup Corporation | Container having premium-containing-and-dispensing bottom structure and method and apparatus for providing same |

| EP0482581A1 (en) | 1990-10-22 | 1992-04-29 | Ball Corporation | Apparatus and method for strengthening bottom of container |

| US5524468A (en) * | 1990-10-22 | 1996-06-11 | Ball Corporation | Apparatus and method for strengthening bottom of container |

| WO1996024539A1 (en) | 1995-02-09 | 1996-08-15 | Kohorn International Pty. Limited | A container |

| DE29519352U1 (de) * | 1995-12-06 | 1996-02-29 | Hofer, Rudolf, 81245 München | Compact-Disc an Flaschenboden |

| DE19704522A1 (de) * | 1997-02-06 | 1998-08-20 | Schmalbach Lubeca | Behälter mit zweitem Schnappboden |

| EP0958182B1 (de) | 1997-02-06 | 2003-12-10 | Ball Packaging Europe GmbH | Behälter mit einem schnappboden |

Also Published As

| Publication number | Publication date |

|---|---|

| RU2557518C2 (ru) | 2015-07-20 |

| SG182397A1 (en) | 2012-08-30 |

| MY159294A (en) | 2016-12-30 |

| TN2012000289A1 (en) | 2013-12-12 |

| CN102712385A (zh) | 2012-10-03 |

| CA2786219A1 (en) | 2011-07-21 |

| AU2011206646B2 (en) | 2015-03-19 |

| EP2523862B1 (en) | 2013-09-18 |

| MX2012008071A (es) | 2012-08-15 |

| CO6541584A2 (es) | 2012-10-16 |

| EP2523862A1 (en) | 2012-11-21 |

| CN102712385B (zh) | 2015-01-28 |

| US20130001230A1 (en) | 2013-01-03 |

| US8973777B2 (en) | 2015-03-10 |

| JP2013517184A (ja) | 2013-05-16 |

| JP5738315B2 (ja) | 2015-06-24 |

| RU2012134324A (ru) | 2014-02-20 |

| ES2435475T3 (es) | 2013-12-19 |

| AU2011206646A1 (en) | 2012-06-21 |

| BR112012016148A2 (pt) | 2016-05-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2523862B1 (en) | Beverage can with disc | |

| KR0168052B1 (ko) | 따기 쉬운 캔뚜껑 및 그 제조방법 | |

| US6575325B2 (en) | Articulated pull tab opener for container | |

| JP3617009B2 (ja) | カップ状容器及び蓋 | |

| US20140346174A1 (en) | Panel, and a Container Body and a Container Provided with such Panel | |

| CN105819081B (zh) | 具有开瓶器组件的非金属混合式瓶盖 | |

| WO2010114593A1 (en) | Aluminum container | |

| EP4177179B1 (en) | Easy key container lid | |

| JPH11105870A (ja) | 飲料缶の開口装置 | |

| US20180333008A1 (en) | Food serving apparatus | |

| HK1176593A (en) | Beverage can with disc | |

| KR20010016144A (ko) | 마개용 탭이 함께 형성된 캔뚜껑구조 | |

| KR200207440Y1 (ko) | 개방이 용이한 캔뚜껑 | |

| US20250206498A1 (en) | Food and beverage can tab | |

| US4253504A (en) | Drain funnel | |

| KR100369581B1 (ko) | 음료용 캔 제조 장치 | |

| JP4666952B2 (ja) | 缶蓋 | |

| KR200252140Y1 (ko) | 병따개 | |

| JP2002029520A (ja) | 樹脂製ボトル容器 | |

| US9850026B2 (en) | Easy-open can end opened by rotated bar | |

| JP2558746Y2 (ja) | 缶用開口装置 | |

| KR200319664Y1 (ko) | 개방이 용이한 음료용기용 탭 | |

| KR20170084536A (ko) | 캔 뚜껑 | |

| EP2974974A1 (en) | Can type container changeable to a type of cup or glass | |

| KR20010051339A (ko) | 파지 손잡이 측벽을 가진 저장 용기 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 201180005942.3 Country of ref document: CN |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 11701043 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2011206646 Country of ref document: AU |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 12097417 Country of ref document: CO |

|

| ENP | Entry into the national phase |

Ref document number: 2011206646 Country of ref document: AU Date of ref document: 20110112 Kind code of ref document: A |

|

| ENP | Entry into the national phase |

Ref document number: 2786219 Country of ref document: CA |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2012548427 Country of ref document: JP Ref document number: MX/A/2012/008071 Country of ref document: MX |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 1201003108 Country of ref document: TH Ref document number: 13521921 Country of ref document: US |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2012134324 Country of ref document: RU Ref document number: 2011701043 Country of ref document: EP |

|

| REG | Reference to national code |

Ref country code: BR Ref legal event code: B01A Ref document number: 112012016148 Country of ref document: BR |

|

| ENP | Entry into the national phase |

Ref document number: 112012016148 Country of ref document: BR Kind code of ref document: A2 Effective date: 20120628 |