WO2010114049A1 - 固体電解質型燃料電池 - Google Patents

固体電解質型燃料電池 Download PDFInfo

- Publication number

- WO2010114049A1 WO2010114049A1 PCT/JP2010/055916 JP2010055916W WO2010114049A1 WO 2010114049 A1 WO2010114049 A1 WO 2010114049A1 JP 2010055916 W JP2010055916 W JP 2010055916W WO 2010114049 A1 WO2010114049 A1 WO 2010114049A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- fuel cell

- fuel

- cell module

- power generation

- supply amount

- Prior art date

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/04—Auxiliary arrangements, e.g. for control of pressure or for circulation of fluids

- H01M8/04298—Processes for controlling fuel cells or fuel cell systems

- H01M8/04694—Processes for controlling fuel cells or fuel cell systems characterised by variables to be controlled

- H01M8/04791—Concentration; Density

- H01M8/04798—Concentration; Density of fuel cell reactants

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/04—Auxiliary arrangements, e.g. for control of pressure or for circulation of fluids

- H01M8/04298—Processes for controlling fuel cells or fuel cell systems

- H01M8/04313—Processes for controlling fuel cells or fuel cell systems characterised by the detection or assessment of variables; characterised by the detection or assessment of failure or abnormal function

- H01M8/04537—Electric variables

- H01M8/04604—Power, energy, capacity or load

- H01M8/04619—Power, energy, capacity or load of fuel cell stacks

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/04—Auxiliary arrangements, e.g. for control of pressure or for circulation of fluids

- H01M8/04298—Processes for controlling fuel cells or fuel cell systems

- H01M8/04313—Processes for controlling fuel cells or fuel cell systems characterised by the detection or assessment of variables; characterised by the detection or assessment of failure or abnormal function

- H01M8/0444—Concentration; Density

- H01M8/04447—Concentration; Density of anode reactants at the inlet or inside the fuel cell

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/04—Auxiliary arrangements, e.g. for control of pressure or for circulation of fluids

- H01M8/04298—Processes for controlling fuel cells or fuel cell systems

- H01M8/04313—Processes for controlling fuel cells or fuel cell systems characterised by the detection or assessment of variables; characterised by the detection or assessment of failure or abnormal function

- H01M8/0444—Concentration; Density

- H01M8/04455—Concentration; Density of cathode reactants at the inlet or inside the fuel cell

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/04—Auxiliary arrangements, e.g. for control of pressure or for circulation of fluids

- H01M8/04298—Processes for controlling fuel cells or fuel cell systems

- H01M8/04313—Processes for controlling fuel cells or fuel cell systems characterised by the detection or assessment of variables; characterised by the detection or assessment of failure or abnormal function

- H01M8/04664—Failure or abnormal function

- H01M8/04679—Failure or abnormal function of fuel cell stacks

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/04—Auxiliary arrangements, e.g. for control of pressure or for circulation of fluids

- H01M8/04298—Processes for controlling fuel cells or fuel cell systems

- H01M8/04694—Processes for controlling fuel cells or fuel cell systems characterised by variables to be controlled

- H01M8/04746—Pressure; Flow

- H01M8/04753—Pressure; Flow of fuel cell reactants

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/04—Auxiliary arrangements, e.g. for control of pressure or for circulation of fluids

- H01M8/04298—Processes for controlling fuel cells or fuel cell systems

- H01M8/04694—Processes for controlling fuel cells or fuel cell systems characterised by variables to be controlled

- H01M8/04858—Electric variables

- H01M8/04925—Power, energy, capacity or load

- H01M8/0494—Power, energy, capacity or load of fuel cell stacks

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/10—Fuel cells with solid electrolytes

- H01M8/12—Fuel cells with solid electrolytes operating at high temperature, e.g. with stabilised ZrO2 electrolyte

- H01M2008/1293—Fuel cells with solid oxide electrolytes

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M2250/00—Fuel cells for particular applications; Specific features of fuel cell system

- H01M2250/40—Combination of fuel cells with other energy production systems

- H01M2250/405—Cogeneration of heat or hot water

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/04—Auxiliary arrangements, e.g. for control of pressure or for circulation of fluids

- H01M8/04298—Processes for controlling fuel cells or fuel cell systems

- H01M8/04313—Processes for controlling fuel cells or fuel cell systems characterised by the detection or assessment of variables; characterised by the detection or assessment of failure or abnormal function

- H01M8/0432—Temperature; Ambient temperature

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/04—Auxiliary arrangements, e.g. for control of pressure or for circulation of fluids

- H01M8/04298—Processes for controlling fuel cells or fuel cell systems

- H01M8/04313—Processes for controlling fuel cells or fuel cell systems characterised by the detection or assessment of variables; characterised by the detection or assessment of failure or abnormal function

- H01M8/0432—Temperature; Ambient temperature

- H01M8/04373—Temperature; Ambient temperature of auxiliary devices, e.g. reformers, compressors, burners

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/04—Auxiliary arrangements, e.g. for control of pressure or for circulation of fluids

- H01M8/04298—Processes for controlling fuel cells or fuel cell systems

- H01M8/04313—Processes for controlling fuel cells or fuel cell systems characterised by the detection or assessment of variables; characterised by the detection or assessment of failure or abnormal function

- H01M8/0438—Pressure; Ambient pressure; Flow

- H01M8/04425—Pressure; Ambient pressure; Flow at auxiliary devices, e.g. reformers, compressors, burners

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/04—Auxiliary arrangements, e.g. for control of pressure or for circulation of fluids

- H01M8/04298—Processes for controlling fuel cells or fuel cell systems

- H01M8/04313—Processes for controlling fuel cells or fuel cell systems characterised by the detection or assessment of variables; characterised by the detection or assessment of failure or abnormal function

- H01M8/0444—Concentration; Density

- H01M8/0447—Concentration; Density of cathode exhausts

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/04—Auxiliary arrangements, e.g. for control of pressure or for circulation of fluids

- H01M8/04298—Processes for controlling fuel cells or fuel cell systems

- H01M8/04313—Processes for controlling fuel cells or fuel cell systems characterised by the detection or assessment of variables; characterised by the detection or assessment of failure or abnormal function

- H01M8/04537—Electric variables

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/24—Grouping of fuel cells, e.g. stacking of fuel cells

- H01M8/241—Grouping of fuel cells, e.g. stacking of fuel cells with solid or matrix-supported electrolytes

- H01M8/2425—High-temperature cells with solid electrolytes

- H01M8/243—Grouping of unit cells of tubular or cylindrical configuration

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/24—Grouping of fuel cells, e.g. stacking of fuel cells

- H01M8/2465—Details of groupings of fuel cells

- H01M8/247—Arrangements for tightening a stack, for accommodation of a stack in a tank or for assembling different tanks

- H01M8/2475—Enclosures, casings or containers of fuel cell stacks

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/24—Grouping of fuel cells, e.g. stacking of fuel cells

- H01M8/2465—Details of groupings of fuel cells

- H01M8/2484—Details of groupings of fuel cells characterised by external manifolds

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02B—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO BUILDINGS, e.g. HOUSING, HOUSE APPLIANCES OR RELATED END-USER APPLICATIONS

- Y02B90/00—Enabling technologies or technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02B90/10—Applications of fuel cells in buildings

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/30—Hydrogen technology

- Y02E60/50—Fuel cells

Definitions

- the present invention relates to a solid oxide fuel cell, and more particularly to a solid oxide fuel cell in which output power is variable according to a required power generation amount.

- Solid Oxide Fuel Cell uses an oxide ion conductive solid electrolyte as an electrolyte, has electrodes on both sides, supplies fuel gas on one side, and supplies the other This is a fuel cell that operates at a relatively high temperature by supplying an oxidizing agent (air, oxygen, etc.) to the side.

- SOFC Solid Oxide Fuel Cell

- Patent Document 1 Japanese Unexamined Patent Publication No. 2007-87756 (Patent Document 1) describes a solid oxide fuel cell. In this fuel cell, it is described that the deterioration of the fuel cell is reduced by adjusting the flow rate of the fuel.

- Patent Document 2 describes a fuel supply amount control device, a fuel supply amount control method, and a power supply system.

- the fuel supply amount control device is configured to compensate the fuel supply amount when the power that can be taken out with respect to the predetermined fuel supply amount is reduced due to deterioration of the fuel cell.

- Patent Document 2 As described above, in the fuel supply amount control device described in Japanese Patent Laid-Open No. 2003-217627 (Patent Document 2), the fuel supply amount is compensated based on the output power with respect to a constant fuel supply amount. However, if control is performed to increase the fuel supply amount of the fuel cell in which the output power relative to the fuel supply amount has decreased due to deterioration and maintain the output power at the level before deterioration, this control is reversed. There is a problem of promoting deterioration. If further compensation is performed on a fuel cell whose deterioration has been promoted by compensation, a vicious cycle of further degradation will occur, and in some cases, the life of the fuel cell will be significantly shortened.

- an object of the present invention is to provide a solid oxide fuel cell that can suppress the progress of deterioration of a fuel cell that has deteriorated.

- the present invention provides a solid oxide fuel cell that varies the generated power in accordance with the required power generation amount, and includes a fuel cell module including a plurality of solid electrolyte fuel cell cells, A fuel supply device that supplies fuel to the fuel cell module, an oxidant gas supply device that supplies oxidant gas to the fuel cell module, and a fuel supply amount that is supplied from the fuel supply device according to the required power generation amount

- the controller is characterized in that when the deterioration of the fuel cell module is estimated or determined, the rate of change of the fuel supply amount per hour when the required power generation amount changes thereafter is reduced.

- the controller controls the fuel supply device and the oxidant gas supply device to supply fuel and oxidant gas to the fuel cell module.

- the controller subsequently reduces the rate of change per hour in the fuel supply amount with respect to the change in the required power generation amount.

- the rate of change of the fuel supply amount per hour is lowered, so that the temperature change of the fuel cell module becomes gradual.

- the progress of deterioration of the fuel cell module can be suppressed.

- the controller estimates the deterioration of the fuel cell module based on the operation time of the fuel cell module. According to the present invention configured as described above, since the deterioration of the fuel cell module is estimated based on the operation time, it is possible to easily control the progress of the deterioration.

- the controller is preferably configured so that the fuel supply amount time when the required power generation amount changes as the deterioration of the fuel cell module progresses or the fuel cell module is operated for a long period of time. The rate of change per hit is greatly reduced.

- the rate of change of the fuel supply amount is changed in accordance with the degree of progress of the deterioration of the fuel cell module. Progress of deterioration of the battery module can be suppressed.

- the controller stops the control corresponding to the required power generation amount and supplies the predetermined power from the fuel supply device. Control the amount of fuel supplied.

- the temperature change of the fuel cell module can be further reduced, and the fuel cell module The progress of deterioration can be suppressed.

- the present invention also relates to a solid oxide fuel cell that varies the generated power in accordance with the required power generation amount, the fuel cell module having a plurality of solid electrolyte fuel cells, and fuel to the fuel cell module

- the control means is characterized in that when the deterioration of the fuel cell module is estimated or determined, the rate of change of the fuel supply amount per hour when the required power generation amount changes thereafter is reduced.

- the solid oxide fuel cell of the present invention it is possible to suppress the progress of deterioration of a fuel cell that has deteriorated.

- FIG. 1 is an overall configuration diagram showing a solid oxide fuel cell (SOFC) according to an embodiment of the present invention.

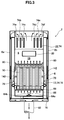

- 1 is a front sectional view showing a solid oxide fuel cell (SOFC) fuel cell module according to an embodiment of the present invention.

- FIG. 3 is a sectional view taken along line III-III in FIG. 2. It is a fragmentary sectional view showing a fuel cell unit of a solid oxide fuel cell (SOFC) according to one embodiment of the present invention.

- 1 is a perspective view showing a fuel cell stack of a solid oxide fuel cell (SOFC) according to an embodiment of the present invention.

- 1 is a block diagram illustrating a solid oxide fuel cell (SOFC) according to an embodiment of the present invention.

- FIG. 1 is an overall configuration diagram showing a solid oxide fuel cell (SOFC) according to an embodiment of the present invention.

- a solid oxide fuel cell (SOFC) 1 according to an embodiment of the present invention includes a fuel cell module 2 and an auxiliary unit 4.

- the fuel cell module 2 includes a housing 6, and a sealed space 8 is formed inside the housing 6 via a heat insulating material (not shown, but the heat insulating material is not an essential component and may not be necessary). Is formed. In addition, you may make it not provide a heat insulating material.

- a fuel cell assembly 12 that performs a power generation reaction with fuel gas and an oxidant (air) is disposed in a power generation chamber 10 that is a lower portion of the sealed space 8.

- the fuel cell assembly 12 includes ten fuel cell stacks 14 (see FIG. 5), and the fuel cell stack 14 includes 16 fuel cell unit 16 (see FIG. 4). Yes.

- the fuel cell assembly 12 has 160 fuel cell units 16, and all of these fuel cell units 16 are connected in series.

- a combustion chamber 18 is formed above the above-described power generation chamber 10 in the sealed space 8 of the fuel cell module 2.

- this combustion chamber 18 the remaining fuel gas that has not been used for the power generation reaction and the remaining oxidant (air) ) And combusted to generate exhaust gas.

- a reformer 20 for reforming the fuel gas is disposed above the combustion chamber 18, and the reformer 20 is heated to a temperature at which a reforming reaction can be performed by the combustion heat of the residual gas.

- an air heat exchanger 22 for receiving combustion heat and heating air is disposed above the reformer 20.

- the auxiliary unit 4 stores a pure water tank 26 that stores water from a water supply source 24 such as tap water and uses the filter to obtain pure water, and a water flow rate that adjusts the flow rate of the water supplied from the water storage tank.

- An adjustment unit 28 (such as a “water pump” driven by a motor) is provided.

- the auxiliary unit 4 also includes a gas shut-off valve 32 that shuts off the fuel gas supplied from a fuel supply source 30 such as city gas, a desulfurizer 36 for removing sulfur from the fuel gas, and a flow rate of the fuel gas.

- a fuel flow rate adjusting unit 38 (such as a “fuel pump” driven by a motor) is provided.

- the auxiliary unit 4 includes an electromagnetic valve 42 that shuts off air that is an oxidant supplied from the air supply source 40, a reforming air flow rate adjusting unit 44 that adjusts the flow rate of air, and a power generation air flow rate adjusting unit. 45 (such as an “air blower” driven by a motor), a first heater 46 for heating the reforming air supplied to the reformer 20, and a second for heating the power generating air supplied to the power generation chamber And a heater 48.

- the first heater 46 and the second heater 48 are provided in order to efficiently raise the temperature at startup, but may be omitted.

- a hot water production apparatus 50 to which exhaust gas is supplied is connected to the fuel cell module 2.

- the hot water production apparatus 50 is supplied with tap water from the water supply source 24, and the tap water is heated by the heat of the exhaust gas and supplied to a hot water storage tank of an external hot water heater (not shown).

- the fuel cell module 2 is provided with a control box 52 for controlling the amount of fuel gas supplied and the like. Furthermore, the fuel cell module 2 is connected to an inverter 54 that is a power extraction unit (power conversion unit) for supplying the power generated by the fuel cell module to the outside.

- FIG. 2 is a side sectional view showing a solid oxide fuel cell (SOFC) fuel cell module according to an embodiment of the present invention

- FIG. 3 is a sectional view taken along line III-III in FIG.

- the fuel cell assembly 12, the reformer 20, and the air heat exchange are sequentially performed from below.

- a vessel 22 is arranged.

- the reformer 20 is provided with a pure water introduction pipe 60 for introducing pure water and a reformed gas introduction pipe 62 for introducing reformed fuel gas and reforming air to the upstream end side thereof.

- a pure water introduction pipe 60 for introducing pure water

- a reformed gas introduction pipe 62 for introducing reformed fuel gas and reforming air to the upstream end side thereof.

- an evaporation unit 20a and a reforming unit 20b are formed in order from the upstream side, and the reforming unit 20b is filled with a reforming catalyst.

- the fuel gas and air mixed with the steam (pure water) introduced into the reformer 20 are reformed by the reforming catalyst filled in the reformer 20.

- the reforming catalyst a catalyst obtained by imparting nickel to the alumina sphere surface or a catalyst obtained by imparting ruthenium to the alumina sphere surface is appropriately used.

- a fuel gas supply pipe 64 is connected to the downstream end side of the reformer 20, and the fuel gas supply pipe 64 extends downward and further in an manifold 66 formed below the fuel cell assembly 12. It extends horizontally.

- a plurality of fuel supply holes 64 b are formed in the lower surface of the horizontal portion 64 a of the fuel gas supply pipe 64, and the reformed fuel gas is supplied into the manifold 66 from the fuel supply holes 64 b.

- a lower support plate 68 having a through hole for supporting the fuel cell stack 14 described above is attached above the manifold 66, and the fuel gas in the manifold 66 flows into the fuel cell unit 16. Supplied.

- the air heat exchanger 22 includes an air aggregation chamber 70 on the upstream side and two air distribution chambers 72 on the downstream side.

- the air aggregation chamber 70 and the air distribution chamber 72 include six air flow path tubes 74. Connected by.

- three air flow path pipes 74 form a set (74a, 74b, 74c, 74d, 74e, 74f), and the air in the air collecting chamber 70 is in each set. It flows into each air distribution chamber 72 from the air flow path pipe 74.

- the air flowing through the six air flow path pipes 74 of the air heat exchanger 22 is preheated by exhaust gas that burns and rises in the combustion chamber 18.

- An air introduction pipe 76 is connected to each of the air distribution chambers 72, the air introduction pipe 76 extends downward, and the lower end side communicates with the lower space of the power generation chamber 10, and the air that has been preheated in the power generation chamber 10. Is introduced.

- an exhaust gas chamber 78 is formed below the manifold 66. Further, as shown in FIG. 3, an exhaust gas passage 80 extending in the vertical direction is formed inside the front surface 6 a and the rear surface 6 b which are surfaces along the longitudinal direction of the housing 6, and the upper end of the exhaust gas chamber passage 80 is formed. The side communicates with the space in which the air heat exchanger 22 is disposed, and the lower end side communicates with the exhaust gas chamber 78. Further, an exhaust gas discharge pipe 82 is connected to substantially the center of the lower surface of the exhaust gas chamber 78, and the downstream end of the exhaust gas discharge pipe 82 is connected to the above-described hot water producing apparatus 50 shown in FIG. As shown in FIG. 2, an ignition device 83 for starting combustion of fuel gas and air is provided in the combustion chamber 18.

- FIG. 4 is a partial cross-sectional view showing a fuel cell unit of a solid oxide fuel cell (SOFC) according to an embodiment of the present invention.

- the fuel cell unit 16 includes a fuel cell 84 and inner electrode terminals 86 respectively connected to the vertical ends of the fuel cell 84.

- the fuel cell 84 is a tubular structure that extends in the vertical direction, and includes a cylindrical inner electrode layer 90 that forms a fuel gas flow path 88 therein, a cylindrical outer electrode layer 92, an inner electrode layer 90, and an outer side.

- An electrolyte layer 94 is provided between the electrode layer 92 and the electrode layer 92.

- the inner electrode layer 90 is a fuel electrode through which fuel gas passes and becomes a ( ⁇ ) electrode, while the outer electrode layer 92 is an air electrode in contact with air and becomes a (+) electrode.

- the upper portion 90 a of the inner electrode layer 90 includes an outer peripheral surface 90 b and an upper end surface 90 c exposed to the electrolyte layer 94 and the outer electrode layer 92.

- the inner electrode terminal 86 is connected to the outer peripheral surface 90b of the inner electrode layer 90 through a conductive sealing material 96, and is further in direct contact with the upper end surface 90c of the inner electrode layer 90, thereby Electrically connected.

- a fuel gas passage 98 communicating with the fuel gas passage 88 of the inner electrode layer 90 is formed at the center of the inner electrode terminal 86.

- the inner electrode layer 90 includes, for example, a mixture of Ni and zirconia doped with at least one selected from rare earth elements such as Ca, Y, and Sc, and Ni and ceria doped with at least one selected from rare earth elements.

- the mixture is formed of at least one of Ni and a mixture of lanthanum garade doped with at least one selected from Sr, Mg, Co, Fe, and Cu.

- the electrolyte layer 94 is, for example, zirconia doped with at least one selected from rare earth elements such as Y and Sc, ceria doped with at least one selected from rare earth elements, lanthanum gallate doped with at least one selected from Sr and Mg, Formed from at least one of the following.

- the outer electrode layer 92 includes, for example, lanthanum manganite doped with at least one selected from Sr and Ca, lanthanum ferrite doped with at least one selected from Sr, Co, Ni and Cu, Sr, Fe, Ni and Cu. It is formed from at least one of lanthanum cobaltite doped with at least one selected from the group consisting of silver and silver.

- FIG. 5 is a perspective view showing a fuel cell stack of a solid oxide fuel cell (SOFC) according to an embodiment of the present invention.

- the fuel cell stack 14 includes 16 fuel cell units 16, and the lower end side and the upper end side of these fuel cell units 16 are a ceramic lower support plate 68 and an upper side, respectively. It is supported by the support plate 100.

- the lower support plate 68 and the upper support plate 100 are formed with through holes 68a and 100a through which the inner electrode terminal 86 can pass.

- the current collector 102 includes a fuel electrode connection portion 102a that is electrically connected to an inner electrode terminal 86 attached to the inner electrode layer 90 that is a fuel electrode, and an entire outer peripheral surface of the outer electrode layer 92 that is an air electrode. And an air electrode connecting portion 102b electrically connected to each other.

- the air electrode connecting portion 102b is formed of a vertical portion 102c extending in the vertical direction on the surface of the outer electrode layer 92 and a plurality of horizontal portions 102d extending in a horizontal direction along the surface of the outer electrode layer 92 from the vertical portion 102c. Has been.

- the fuel electrode connecting portion 102a is linearly directed obliquely upward or obliquely downward from the vertical portion 102c of the air electrode connecting portion 102b toward the inner electrode terminal 86 positioned in the vertical direction of the fuel cell unit 16. It extends.

- the inner electrode terminals 86 at the upper end and the lower end of the two fuel cell units 16 located at the ends of the fuel cell stack 14 are external terminals, respectively. 104 is connected. These external terminals 104 are connected to the external terminals 104 (not shown) of the fuel cell unit 16 at the end of the adjacent fuel cell stack 14, and as described above, the 160 fuel cell units 16 Everything is connected in series.

- FIG. 6 is a block diagram illustrating a solid oxide fuel cell (SOFC) according to an embodiment of the present invention.

- the solid oxide fuel cell 1 includes a control unit 110, and the control unit 110 includes operation buttons such as “ON” and “OFF” for operation by the user.

- a device 112 a display device 114 for displaying various data such as a power generation output value (wattage), and a notification device 116 for issuing an alarm (warning) in an abnormal state are connected.

- the notification device 116 may be connected to a remote management center and notify the management center of an abnormal state.

- the combustible gas detection sensor 120 is for detecting a gas leak, and is attached to the fuel cell module 2 and the auxiliary unit 4.

- the CO detection sensor 122 detects whether or not CO in the exhaust gas originally discharged to the outside through the exhaust gas passage 80 or the like leaks to an external housing (not shown) that covers the fuel cell module 2 and the auxiliary unit 4. Is to do.

- the hot water storage state detection sensor 124 is for detecting the temperature and amount of hot water in a water heater (not shown).

- the power state detection sensor 126 is for detecting the current and voltage of the inverter 54 and the distribution board (not shown).

- the power generation air flow rate detection sensor 128 is for detecting the flow rate of power generation air supplied to the power generation chamber 10.

- the reforming air flow sensor 130 is for detecting the flow rate of the reforming air supplied to the reformer 20.

- the fuel flow sensor 132 is for detecting the flow rate of the fuel gas supplied to the reformer 20.

- the water flow rate sensor 134 is for detecting the flow rate of pure water (steam) supplied to the reformer 20.

- the water level sensor 136 is for detecting the water level of the pure water tank 26.

- the pressure sensor 138 is for detecting the pressure on the upstream side outside the reformer 20.

- the exhaust temperature sensor 140 is for detecting the temperature of the exhaust gas flowing into the hot water production apparatus 50.

- the power generation chamber temperature sensor 142 is provided on the front side and the back side in the vicinity of the fuel cell assembly 12, and detects the temperature in the vicinity of the fuel cell stack 14 to thereby detect the fuel cell stack. 14 (ie, the fuel cell 84 itself) is estimated.

- the combustion chamber temperature sensor 144 is for detecting the temperature of the combustion chamber 18.

- the exhaust gas chamber temperature sensor 146 is for detecting the temperature of the exhaust gas in the exhaust gas chamber 78.

- the reformer temperature sensor 148 is for detecting the temperature of the reformer 20, and calculates the temperature of the reformer 20 from the inlet temperature and the outlet temperature of the reformer 20.

- the outside air temperature sensor 150 is for detecting the temperature of the outside air when the solid oxide fuel cell (SOFC) is disposed outdoors. Further, a sensor for measuring the humidity or the like of the outside air may be provided.

- SOFC solid oxide fuel cell

- Signals from these sensors are sent to the control unit 110, and the control unit 110, based on data based on these signals, the water flow rate adjustment unit 28, the fuel flow rate adjustment unit 38, the reforming air flow rate adjustment unit 44, A control signal is sent to the power generation air flow rate adjusting unit 45 to control each flow rate in these units. Further, the control unit 110 sends a control signal to the inverter 54 to control the power supply amount.

- FIG. 7 is a time chart showing the operation at the time of startup of the solid oxide fuel cell (SOFC) according to one embodiment of the present invention.

- reforming air is supplied from the reforming air flow rate adjustment unit 44 to the reformer 20 of the fuel cell module 2 via the first heater 46.

- the power generation air is supplied from the power generation air flow rate adjustment unit 45 to the air heat exchanger 22 of the fuel cell module 2 via the second heater 48, and this power generation air is supplied to the power generation chamber 10 and the combustion chamber.

- the fuel gas is also supplied from the fuel flow rate adjustment unit 38, and the fuel gas mixed with the reforming air passes through the reformer 20, the fuel cell stack 14, and the fuel cell unit 16, and It reaches the combustion chamber 18.

- the ignition device 83 is ignited to burn the fuel gas and air (reforming air and power generation air) in the combustion chamber 18.

- Exhaust gas is generated by the combustion of the fuel gas and air, and the power generation chamber 10 is warmed by the exhaust gas, and when the exhaust gas rises in the sealed space 8 of the fuel cell module 2, The fuel gas containing the reforming air is warmed, and the power generation air in the air heat exchanger 22 is also warmed.

- the fuel gas mixed with the reforming air is supplied to the reformer 20 by the fuel flow rate adjusting unit 38 and the reforming air flow rate adjusting unit 44.

- the heated fuel gas is supplied to the lower side of the fuel cell stack 14 through the fuel gas supply pipe 64, whereby the fuel cell stack 14 is heated from below, and the combustion chamber 18 also has the fuel gas and air.

- the fuel cell stack 14 is also heated from above, and as a result, the fuel cell stack 14 can be heated substantially uniformly in the vertical direction. Even if the partial oxidation reforming reaction POX proceeds, the combustion reaction between the fuel gas and air continues in the combustion chamber 18.

- the reformer temperature sensor 148 detects that the reformer 20 has reached a predetermined temperature (for example, 600 ° C.) after the partial oxidation reforming reaction POX is started, the water flow rate adjustment unit 28 and the fuel flow rate adjustment unit 38 are detected.

- the reforming air flow rate adjusting unit 44 supplies a gas in which fuel gas, reforming air, and water vapor are mixed in advance to the reformer 20.

- an autothermal reforming reaction ATR in which the partial oxidation reforming reaction POX described above and a steam reforming reaction SR described later are used proceeds. Since the autothermal reforming reaction ATR is thermally balanced internally, the reaction proceeds in the reformer 20 in a thermally independent state.

- the reformer temperature sensor 146 detects that the reformer 20 has reached a predetermined temperature (for example, 700 ° C.) after the start of the autothermal reforming reaction ATR shown in Formula (2), the reforming air flow rate The supply of reforming air by the adjustment unit 44 is stopped, and the supply of water vapor by the water flow rate adjustment unit 28 is increased. As a result, the reformer 20 is supplied with a gas that does not contain air and contains only fuel gas and water vapor, and the steam reforming reaction SR of formula (3) proceeds in the reformer 20.

- a predetermined temperature for example, 700 ° C.

- this steam reforming reaction SR is an endothermic reaction, the reaction proceeds while maintaining a heat balance with the combustion heat from the combustion chamber 18. At this stage, since the fuel cell module 2 is in the final stage of start-up, the power generation chamber 10 is heated to a sufficiently high temperature. Therefore, even if the endothermic reaction proceeds, the power generation chamber 10 is greatly reduced in temperature. There is nothing. Even if the steam reforming reaction SR proceeds, the combustion reaction continues in the combustion chamber 18.

- the partial oxidation reforming reaction POX, the autothermal reforming reaction ATR, and the steam reforming reaction SR proceed in sequence, so that the inside of the power generation chamber 10 The temperature gradually increases.

- the circuit including the fuel cell module 2 is closed, and the fuel cell Power generation by the module 2 is started, so that a current flows in the circuit. Due to the power generation of the fuel cell module 2, the fuel cell 84 itself also generates heat, and the temperature of the fuel cell 84 also rises.

- the rated temperature at which the fuel cell module 2 is operated becomes, for example, 600 ° C. to 800 ° C.

- FIG. 8 is a time chart showing the operation when the solid oxide fuel cell (SOFC) is stopped according to this embodiment.

- the fuel flow rate adjustment unit 38 and the water flow rate adjustment unit 28 are operated to supply fuel gas and water vapor to the reformer 20. Reduce the amount.

- the amount of fuel gas and water vapor supplied to the reformer 20 is reduced, and at the same time, the fuel cell module for generating air by the reforming air flow rate adjusting unit 44

- the supply amount into 2 is increased, the fuel cell assembly 12 and the reformer 20 are cooled by air, and these temperatures are lowered.

- the temperature of the power generation chamber decreases to a predetermined temperature, for example, 400 ° C.

- the supply of fuel gas and steam to the reformer 20 is stopped, and the steam reforming reaction SR of the reformer 20 is ended.

- This supply of power generation air continues until the temperature of the reformer 20 decreases to a predetermined temperature, for example, 200 ° C., and when this temperature is reached, the power generation air from the power generation air flow rate adjustment unit 45 is supplied. Stop supplying.

- the steam reforming reaction SR by the reformer 20 and the cooling by the power generation air are used in combination.

- the operation of the fuel cell module can be stopped.

- FIG. 9 is a time chart for explaining deterioration determination in the solid oxide fuel cell of the present embodiment.

- FIG. 10 is a graph showing an example of the relationship between the required power generation amount input to the control unit 110 and the fuel supply amount necessary to generate the required power generation amount.

- FIG. 11 is a graph illustrating an example of a temporal change in the fuel supply amount with respect to a change in the required power generation amount.

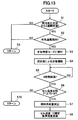

- FIG. 12 is a flowchart showing a procedure of deterioration determination by the deterioration determination means.

- the solid oxide fuel cell 1 performs load following operation so that output power corresponding to the required power generation amount from the inverter 54 (FIG. 6) is obtained. That is, as shown in FIG. 6, the controller 110 that is a controller, according to the required power generation amount from the inverter 54, the fuel flow rate adjustment unit 38 that is a fuel supply device, and the power generation air flow rate that is an oxidant gas supply device. Signals are sent to the adjustment unit 45 and the water flow rate adjustment unit 28, which is a water supply device, to supply fuel, air, and water at the required flow rates to the fuel cell module 2. As a result, as shown in FIG.

- the output power of the solid oxide fuel cell 1 changes so as to follow the required power generation amount from the inverter 54.

- the control unit 110, the fuel flow rate adjustment unit 38, the power generation air flow rate adjustment unit 45, and the water flow rate adjustment unit 28 function as a control unit, a fuel supply unit, an oxidant gas supply unit, and a water supply unit, respectively. .

- the control unit 110 determines the fuel supply amount based on the graph shown in FIG. 10 according to the required power generation amount from the inverter 54, and adjusts the fuel flow rate so that the determined flow rate of fuel is supplied to the fuel cell module 2.

- the unit 38 is controlled. After the initial use of the solid oxide fuel cell 1 is started, until it is determined that the fuel cell module 2 has deteriorated, the control unit 110 sets the fuel supply amount with respect to the required power generation amount according to the curve F0 in FIG. decide. As shown in FIG. 10, the fuel supply amount is determined so as to increase monotonously with an increase in the required power generation amount. However, the fuel supply amount is set to a substantially constant value when the required power generation amount is less than about 200 W.

- FIG. 11 is a graph showing an example of a change in the fuel supply amount with respect to time when the required power generation amount is changed in a step shape from 500 W to 700 W. As shown in FIG. 11, when the required power generation amount is changed from 500 W to 700 W at time t10, the required fuel supply amount suddenly changes from the supply amount corresponding to the power output of 500 W to the supply amount corresponding to 700 W. Changed.

- control unit 110 controls the fuel flow rate adjustment unit 38 so that the fuel supply amount is gradually increased as shown by an imaginary line in FIG. 11 so that the fuel supply amount does not increase rapidly. Control.

- the controller 110 increases the fuel supply amount according to the line F10 in FIG. 11 until it is determined that the fuel cell module 2 has deteriorated after the initial use of the solid oxide fuel cell 1 is started.

- the control unit 110 gradually increases the fuel supply amount according to the line F10 in FIG. 11 so that the fuel supply amount does not rapidly decrease. Decrease. Note that the rate of change of the fuel supply amount is set more gently when the supply amount is increased than when the supply amount is decreased. 10 and 11 relate to the fuel supply amount, the air supply amount and the water supply amount are similarly changed according to the required power generation amount.

- FIG. 9 is a time chart for explaining deterioration determination in the solid oxide fuel cell of the present embodiment.

- FIG. 10 is a graph showing an example of the relationship between the required power generation amount input to the control unit 110 and the fuel supply amount necessary to generate the required power generation amount.

- FIG. 11 is a graph illustrating an example of a temporal change in the fuel supply amount with respect to a change in the required power generation amount.

- FIG. 13 is a flowchart showing a procedure of deterioration determination by the deterioration determination means.

- the solid oxide fuel cell 1 performs load following operation so that output power corresponding to the required power generation amount from the inverter 54 (FIG. 6) is obtained. That is, as shown in FIG. 6, the controller 110 that is a controller, according to the required power generation amount from the inverter 54, the fuel flow rate adjustment unit 38 that is a fuel supply device, and the power generation air flow rate that is an oxidant gas supply device. Signals are sent to the adjustment unit 45 and the water flow rate adjustment unit 28, which is a water supply device, to supply fuel, air, and water at the required flow rates to the fuel cell module 2. As a result, as shown in FIG.

- the output power of the solid oxide fuel cell 1 changes so as to follow the required power generation amount from the inverter 54.

- the output power changes with a delay with respect to changes in the fuel supply amount, etc. The power hardly changes.

- the control unit 110 determines the fuel supply amount based on the graph shown in FIG. 10 according to the required power generation amount from the inverter 54, and adjusts the fuel flow rate so that the determined flow rate of fuel is supplied to the fuel cell module 2.

- the unit 38 is controlled. After the initial use of the solid oxide fuel cell 1 is started, until it is determined that the fuel cell module 2 has deteriorated, the control unit 110 sets the fuel supply amount with respect to the required power generation amount according to the curve F0 in FIG. decide. As shown in FIG. 10, the fuel supply amount is determined so as to increase monotonously with an increase in the required power generation amount. However, the fuel supply amount is set to a substantially constant value when the required power generation amount is less than about 200 W.

- FIG. 11 is a graph showing an example of a change in the fuel supply amount with respect to time when the required power generation amount is changed in a step shape from 500 W to 700 W.

- the controller 110 prevents the fuel supply amount from increasing sharply, as shown by an imaginary line in FIG.

- the fuel flow rate adjustment unit 38 is controlled so that the rate of change per hour of time becomes a predetermined value.

- the controller 110 increases the fuel supply amount according to the line F10 in FIG. 11 until it is determined that the fuel cell module 2 has deteriorated after the initial use of the solid oxide fuel cell 1 is started.

- the control unit 110 gradually increases the fuel supply amount according to the line F10 in FIG. 11 so that the fuel supply amount does not rapidly decrease. Decrease. Note that the rate of change of the fuel supply amount per hour is set more gently when the supply amount is increased than when the supply amount is decreased. 10 and 11 relate to the fuel supply amount, the air supply amount and the water supply amount are similarly changed according to the required power generation amount.

- FIG. 12 is a time chart showing an example of temperature band restriction control of the solid oxide fuel cell according to the present embodiment.

- the control unit 110 stores an upper limit temperature Tb of the fuel cell module 2 corresponding to 700 W, which is a rated output of the solid oxide fuel cell 1, and a lower limit temperature Ta for properly operating the solid oxide fuel cell 1. ing.

- the control unit 110 performs temperature band restriction control of the solid oxide fuel cell 1 with the temperature band between the upper limit temperature Tb and the lower limit temperature Ta as a temperature monitoring band W. That is, when the temperature of the fuel cell module 2 deviates from the temperature monitoring band W, the control unit 110 adaptively corrects the fuel supply amount and the air supply amount, and the temperature of the fuel cell module 2 quickly enters the temperature monitoring band W. Control to return.

- the fuel supply amount and the air supply amount are increased following the increase in the required power for the solid oxide fuel cell 1, and the temperature of the fuel cell unit 16 also increases accordingly.

- the control unit 110 executes adaptive correction, and decreases the fuel supply amount and the air supply amount by a predetermined amount. That is, the curve F0 shown in FIG. 10 is shifted downward by a predetermined amount by adaptive correction. Thereby, the temperature of the fuel cell unit 16 is lowered.

- the fuel supply amount and the air supply amount after the adaptive correction are held for a predetermined time regardless of the subsequent temperature transition of the fuel cell unit 16.

- the fuel supply amount and air supply amount after adaptive correction are held for 5 hours.

- the control unit 110 performs adaptive correction, and decreases the fuel supply amount and the air supply amount by a predetermined amount.

- load follow-up control is resumed.

- the control unit 110 performs adaptive correction, and increases the fuel supply amount and the air supply amount by a predetermined amount. That is, by the adaptive correction, the curve F0 after the adaptive correction at time t22 is shifted upward by a predetermined amount. Thereby, the temperature of the fuel cell unit 16 is raised.

- the curve F0 is shifted to an appropriate position so that the fuel cell unit 16 is operated within the temperature monitoring band W.

- the individual difference of the fuel cell unit 16 and the like can be absorbed, and the solid oxide fuel cell 1 can be operated with an appropriate fuel supply amount and air supply amount.

- the total number of shifts of the curve F0 is regulated so as not to exceed a predetermined number. That is, the fuel supply amount increases excessively when only the shift that raises the curve F0 is repeated excessively, or the fuel supply amount decreases excessively when only the shift that lowers the curve F0 is excessively repeated. It is preventing.

- the deterioration determination unit 110a (FIG. 6) built in the control unit 110 starts operation in the deterioration determination mode.

- the deterioration determination unit 110a is a deterioration determination circuit configured by a microprocessor, a memory, and a program (not shown above) for operating these.

- FIG. 13 is a flowchart showing a process performed by the deterioration determining unit 110a.

- step S1 an elapsed time from the previous operation in the deterioration determination mode is determined.

- step S9 an elapsed time from the previous operation in the deterioration determination mode is determined.

- step S2 When two weeks or more have passed since the previous deterioration determination mode operation, the process proceeds to step S2 and whether or not the external environment of the solid oxide fuel cell 1 is in a predetermined deterioration determination outside air state suitable for the deterioration determination mode operation. Is judged. Specifically, it is determined whether or not the outside air temperature and the outside air humidity detected by the outside air temperature sensor 150 (FIG. 6) and the outside air humidity sensor (not shown) meet predetermined conditions. In this embodiment, when the outside air temperature is 5 to 30 ° C. and the outside air humidity is 30 to 70%, it is determined that the external environment is in the deterioration determination outside air state suitable for the deterioration determination mode operation. When it is determined that the external environment is not in the deterioration determination outside air state, the process proceeds to step S9, and the one-time process of this flowchart is ended.

- step S4 the fuel supply amount, the air supply amount, and the water supply amount are fixed to values corresponding to predetermined predetermined deterioration determination power generation amounts.

- the deterioration determination means 110a allows the fuel flow rate adjustment unit 38, the power generation air flow rate adjustment unit 45, and the water flow rate adjustment unit 28 to maintain a constant supply amount regardless of the required power generation amount for the control unit 110. Control these adjustment units to maintain.

- the deterioration determination fuel supply amount is 3 L / min

- the deterioration determination oxidant gas supply amount is 100 L / min

- the deterioration determination water supply amount is 8 mL / min.

- the fixed values corresponding to these deterioration determination power generation amounts are supply amounts corresponding to 700 W, which is the rated power generation amount of the solid oxide fuel cell 1 according to the present embodiment. Therefore, while fuel, air, and water are supplied at fixed values, the solid oxide fuel cell 1 has the ability to output 700 W of electric power. However, if the required power generation amount is less than 700 W, an extra power is required. The new fuel is not used for power generation but is burned in the combustion chamber 18.

- step S5 of FIG. 13 it is determined whether or not a sufficient time has elapsed after the operation with the fixed value is started and the operation state is stable.

- a stable operation state is determined based on whether or not 5 hours as the deterioration determination time has elapsed. If 5 hours have not elapsed since the start of operation with a fixed value, the process of step S5 is repeated. As a result, the operation with the fixed value started in step S4 is maintained for 5 hours (FIG. 9, times t1 to t2).

- step S6 it is determined whether or not the temperature of the fuel cell module 2 measured by the power generation chamber temperature sensor 142 is equal to or higher than a predetermined temperature. . That is, the deterioration of the fuel cell module 2 is determined by comparing the temperature of the fuel cell module 2 that is the operation result of operating the fuel cell module 2 in a stable operation state with a reference temperature that is a predetermined reference value for determining deterioration. To do.

- the reference temperature T0 of the fuel cell module 2 when the rated output operation of 700 W is performed in the initial state is about 700 ° C., and the deterioration of the fuel cell module 2 proceeds. This temperature rises. This is because the internal resistance of the fuel cell stack 14 increases due to deterioration of the fuel cell unit 16 itself, which is a solid oxide fuel cell, and deterioration of the contact portion that electrically connects each fuel cell unit 16. This is due to Joule heat and the like.

- the deterioration determination unit 110a determines that the fuel cell module 2 has deteriorated when the temperature T1 measured by the power generation chamber temperature sensor 142 is 30 ° C. or more higher than the reference temperature T0. If the fuel cell module 2 has not deteriorated, the process proceeds to step S10, where one process of this flowchart is terminated, and the operating conditions such as the fuel supply amount are not changed.

- step S7 the fuel supply correction is executed, and the fuel supply amount with respect to the required power generation amount and the gain of the fuel supply amount are changed. That is, when it is first determined that the fuel cell module 2 has deteriorated after the use of the solid oxide fuel cell 1 is started, the fuel supply amount with respect to the required power generation amount is changed from the curve F0 of FIG. 10 by the fuel supply correction. After that, the fuel supply amount is determined using the curve F1. Further, the rate of change per unit time of the fuel supply amount when changing the fuel supply amount is changed from the line F10 in FIG.

- the control unit 110 executes the deterioration mode operation in which the operation conditions are changed, and the changed fuel supply amount indicates that the fuel cell module 2 has further deteriorated. Until it is determined.

- the fuel supply amount is determined according to the curve F1 in which the fuel supply amount is increased by 10% with respect to the curve F0. Correct the decrease in output power. Further, when the fuel supply amount of the deteriorated fuel cell module 2 is rapidly changed, the deterioration is further advanced, so that the rate of change of the fuel supply amount is further reduced.

- the fuel supply amount is changed from the curve F1 to the curve F2, and when it is determined again, the fuel supply amount is changed from the curve F2 to the curve F3.

- the curve F2 is increased by 18% with respect to the curve F0

- the curve F3 is increased by 23% with respect to the curve F0.

- 10% of the initial fuel supply amount is increased, and for the second time, 8% of the initial fuel supply amount is further increased (18% in total).

- 5% of the initial fuel supply amount is increased (a total of 23%).

- the fuel supply correction to be executed is set so that the fuel increase becomes smaller as it is executed later.

- the gain of the fuel supply amount is also changed from the line F11 to the line F12 when the deterioration is determined for the second time, and from the line F12 to the line F13 when the deterioration is determined for the third time. That is, as the deterioration of the fuel cell module 2 proceeds, the change in the fuel supply amount per hour is moderated.

- the increment of the fuel supply amount when it is determined that the fuel has deteriorated is set to a preset fixed value. For this reason, for example, unlike the case where the correction amount of the fuel supply amount is calculated based on the temperature rise of the fuel cell module 2 or the correction amount is calculated based on the decrease amount of the output power, a greatly incorrect correction is made. Can be prevented. That is, the temperature and output power of the fuel cell module 2 are affected by various factors and change their values. If abnormal temperature or output power is measured for some reason, correction is made based on these values. If the amount is calculated, an abnormal correction will be performed.

- step S8 the temperature T2 of the fuel cell module 2 when the solid oxide fuel cell 1 is operated with the corrected fuel supply amount is the power generation chamber temperature. Measured by sensor 142. The measured temperature T2 is stored in a memory (not shown) of the deterioration determining means 110a as a new reference temperature T0. This new reference temperature T0 is used as a reference temperature in the next deterioration determination.

- the operation is performed with the fuel supply amount kept constant for a predetermined time, and then the temperature T2 of the fuel cell module 2 is measured. Thereby, it is possible to measure an accurate temperature from which the influence of the change in the fuel supply amount due to the correction is eliminated.

- the degradation determination means 110a terminates the degradation determination mode operation, and the control unit 110 resumes normal operation corresponding to the required power generation amount (FIG. 9, time t2).

- the required power generation amount sent from the inverter 54 to the control unit 110 is the solid electrolyte. This is the rated power of the fuel cell 1.

- the amount of fuel, air, and water supplied to the fuel cell module 2 is a constant value corresponding to the rated power for a long time. (FIG. 9, times t3 to t4).

- the deterioration determination means 110a also executes deterioration determination even when such a stable operation state continues for 5 hours or more which is the deterioration determination time. That is, the degradation determination unit 110a compares the temperature T1 measured by the power generation chamber temperature sensor 142 with the reference temperature T0 at time t4 in FIG. 9, and determines whether the temperature T1 is 30 ° C. or more higher than the reference temperature T0. Determine whether. When the temperature T1 is higher than the reference temperature T0 by 30 ° C. or more, the deterioration determination unit 110a determines that the deterioration of the fuel cell module 2 has further progressed, and changes the operating conditions so as to correct this deterioration. . When the determination of the deterioration is the second time, the fuel supply amount is changed from the curve F1 to the curve F2, and the rate of change of the fuel supply amount per time is changed from the line F11 to the further lowered line F12. The

- the correction of the fuel supply amount is not executed if the predetermined minimum correction interval of 0.5 years has not elapsed since the previous fuel supply correction. As a result, excessive fuel supply correction is executed in a short time, and deterioration of the fuel cell module 2 is prevented from proceeding faster than expected.

- the deterioration determination means 110a starts the deterioration determination mode operation.

- the supply amounts of fuel, air, and water are fixed to the supply amounts corrected by the deterioration determination. That is, when it is determined that the fuel cell module 2 has deteriorated twice in the past, the fuel supply amount determined based on the curve F2 of FIG. 10 is fixed to the fuel supply amount corresponding to the rated output.

- the deterioration determination unit 110a measures the temperature T1 of the fuel cell module 2 at time t6 after five hours have elapsed from the start of the deterioration determination mode operation, and executes deterioration determination.

- the fuel supply amount changes from the curve F2 to the curve F3

- the change rate of the fuel supply amount changes from the line F12 to the line F12.

- Each is changed to F13.

- the deterioration determining unit 110a determines that the deterioration of the fuel cell module 2 is determined when the measured temperature T1 of the fuel cell module 2 exceeds a predetermined correction prohibition temperature of 900 ° C. The fuel supply amount is not corrected.

- the deterioration determining unit 110a does not perform further correction of the fuel supply amount or the like. Thereafter, the control unit 110 performs control so as to always output predetermined power without performing control to change the output power according to the required power generation amount.

- the deterioration determining means 110a stops the operation of the solid oxide fuel cell 1 when the output power for a predetermined fuel supply amount set in advance becomes equal to or lower than the predetermined power. Furthermore, the deterioration determination means 110a sends a signal to the notification device 116 to notify the user that the product life of the solid oxide fuel cell 1 has come. This prevents waste of fuel due to the use of the solid oxide fuel cell 1 that has deteriorated and has reduced power generation efficiency.

- the rate of change of the fuel supply amount per hour is reduced, so that the temperature change of the fuel cell module is reduced. It becomes gentle and the progress of deterioration of the fuel cell module can be suppressed.

- the deterioration determination means determines the deterioration of the fuel cell module in a stable operation state, so that the deterioration of the fuel cell module can be grasped more accurately,

- the control unit can perform appropriate control so as to suppress the progress of deterioration.

- control unit controls the temperature change range of the solid oxide fuel cell to be limited to a predetermined range. Furthermore, it becomes more gradual, and the progress of deterioration of the fuel cell module can be effectively suppressed.

- the rate of change of the fuel supply amount is changed in accordance with the progress of the deterioration of the fuel cell module. For this reason, in a state where deterioration has not progressed, the required power generation amount can be quickly followed by changing the fuel supply amount relatively quickly, and in a state where deterioration has progressed, the rate of change in the fuel supply amount can be reduced. Progress of deterioration of the fuel cell module can be suppressed. Thereby, the lifetime of the fuel cell module can be extended while ensuring the followability of the output power with respect to the required power generation amount.

- control unit performs control so that constant power is output after the deterioration has progressed to a predetermined state, so that the temperature change of the fuel cell module And the progress of deterioration of the fuel cell module can be suppressed.

- the control unit of the solid oxide fuel cell includes a deterioration determination unit.

- the deterioration determination unit determines that the fuel cell module has deteriorated, the fuel supply amount with respect to the change in the required power generation amount thereafter.

- the present invention can be configured such that the control unit estimates the deterioration. For example, when a predetermined period elapses from the start of initial use of the solid oxide fuel cell, the control unit estimates that the fuel cell module has deteriorated, and thereafter reduces the rate of change of the fuel supply amount per hour with respect to the change in the required power generation amount.

- the present invention can also be configured as described above. Thereby, this invention can be comprised simply, without providing a special deterioration determination means.

- the present invention can be configured to perform the estimation of deterioration a plurality of times.

- the present invention can be configured so that the first deterioration is estimated from the start of the initial use when the predetermined period elapses, and the second and subsequent deteriorations are estimated when the predetermined period elapses.

- the present invention can be configured such that the rate of change per hour in the fuel supply amount with respect to the change in the required power generation amount is greatly reduced as the period from the start of initial use becomes longer.

- the determination of deterioration is performed a plurality of times.

- the present invention can be configured such that the determination of deterioration is performed only once.

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Sustainable Development (AREA)

- Sustainable Energy (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Fuel Cell (AREA)

Abstract

Description

このように構成された本発明によれば、燃料電池モジュールの劣化が運転時間に基づいて推定されるので、簡便に劣化の進行を抑制する制御を行うことができる。

図1は、本発明の一実施形態による固体電解質型燃料電池(SOFC)を示す全体構成図である。この図1に示すように、本発明の一実施形態による固体電解質型燃料電池(SOFC)1は、燃料電池モジュール2と、補機ユニット4を備えている。

また、この燃焼室18の上方には、燃料ガスを改質する改質器20が配置され、前記残余ガスの燃焼熱によって改質器20を改質反応が可能な温度となるように加熱している。さらに、この改質器20の上方には、燃焼熱を受けて空気を加熱するための空気用熱交換器22が配置されている。

また、燃料電池モジュール2には、燃料ガスの供給量等を制御するための制御ボックス52が取り付けられている。

さらに、燃料電池モジュール2には、燃料電池モジュールにより発電された電力を外部に供給するための電力取出部(電力変換部)であるインバータ54が接続されている。

図2及び図3に示すように、燃料電池モジュール2のハウジング6内の密閉空間8には、上述したように、下方から順に、燃料電池セル集合体12、改質器20、空気用熱交換器22が配置されている。

空気分配室72のそれぞれには、空気導入管76が接続され、この空気導入管76は、下方に延び、その下端側が、発電室10の下方空間に連通し、発電室10に余熱された空気を導入する。

図2に示すように、燃料ガスと空気との燃焼を開始するための点火装置83が、燃焼室18に設けられている。

図4に示すように、燃料電池セルユニット16は、燃料電池セル84と、この燃料電池セル84の上下方向端部にそれぞれ接続された内側電極端子86とを備えている。

燃料電池セル84は、上下方向に延びる管状構造体であり、内部に燃料ガス流路88を形成する円筒形の内側電極層90と、円筒形の外側電極層92と、内側電極層90と外側電極層92との間にある電解質層94とを備えている。この内側電極層90は、燃料ガスが通過する燃料極であり、(-)極となり、一方、外側電極層92は、空気と接触する空気極であり、(+)極となっている。

図5に示すように、燃料電池セルスタック14は、16本の燃料電池セルユニット16を備え、これらの燃料電池セルユニット16の下端側及び上端側が、それぞれ、セラミック製の下支持板68及び上支持板100により支持されている。これらの下支持板68及び上支持板100には、内側電極端子86が貫通可能な貫通穴68a及び100aがそれぞれ形成されている。

図6に示すように、固体電解質型燃料電池1は、制御部110を備え、この制御部110には、使用者が操作するための「ON」や「OFF」等の操作ボタンを備えた操作装置112、発電出力値(ワット数)等の種々のデータを表示するための表示装置114、及び、異常状態のとき等に警報(ワーニング)を発する報知装置116が接続されている。なお、この報知装置116は、遠隔地にある管理センタに接続され、この管理センタに異常状態を通知するようなものであっても良い。

先ず、可燃ガス検出センサ120は、ガス漏れを検知するためのもので、燃料電池モジュール2及び補機ユニット4に取り付けられている。

CO検出センサ122は、本来排気ガス通路80等を経て外部に排出される排気ガス中のCOが、燃料電池モジュール2及び補機ユニット4を覆う外部ハウジング(図示せず)へ漏れたかどうかを検知するためのものである。

貯湯状態検出センサ124は、図示しない給湯器におけるお湯の温度や水量を検知するためのものである。

発電用空気流量検出センサ128は、発電室10に供給される発電用空気の流量を検出するためのものである。

改質用空気流量センサ130は、改質器20に供給される改質用空気の流量を検出するためのものである。

燃料流量センサ132は、改質器20に供給される燃料ガスの流量を検出するためのものである。

水位センサ136は、純水タンク26の水位を検出するためのものである。

圧力センサ138は、改質器20の外部の上流側の圧力を検出するためのものである。

排気温度センサ140は、温水製造装置50に流入する排気ガスの温度を検出するためのものである。

燃焼室温度センサ144は、燃焼室18の温度を検出するためのものである。

排気ガス室温度センサ146は、排気ガス室78の排気ガスの温度を検出するためのものである。

改質器温度センサ148は、改質器20の温度を検出するためのものであり、改質器20の入口温度と出口温度から改質器20の温度を算出する。

外気温度センサ150は、固体電解質型燃料電池(SOFC)が屋外に配置された場合、外気の温度を検出するためのものである。また、外気の湿度等を測定するセンサを設けるようにしても良い。

また、制御ユニット110は、インバータ54に、制御信号を送り、電力供給量を制御するようになっている。

最初は、燃料電池モジュール2を温めるために、無負荷状態で、即ち、燃料電池モジュール2を含む回路を開いた状態で、運転を開始する。このとき、回路に電流が流れないので、燃料電池モジュール2は発電を行わない。

この直ぐ後、燃料流量調整ユニット38からも燃料ガスが供給され、改質用空気が混合された燃料ガスが、改質器20及び燃料電池セルスタック14、燃料電池セルユニット16を通過して、燃焼室18に到達する。

CmHn+xH2O → aCO2+bCO+cH2 (3)

図8に示すように、燃料電池モジュール2の運転停止を行う場合には、先ず、燃料流量調整ユニット38及び水流量調整ユニット28を操作して、燃料ガス及び水蒸気の改質器20への供給量を減少させる。

図9は、本実施形態の固体電解質型燃料電池における劣化判定を説明するタイムチャートである。図10は、制御部110に入力される要求発電量と、要求発電量を生成するために必要な燃料供給量の関係の一例を示すグラフである。図11は、要求発電量の変更に対する燃料供給量の時間的変化の一例を示すグラフである。図12は、劣化判定手段による劣化判定の手順を示すフローチャートである。

なお、図10及び11は、燃料供給量に関するものであるが、空気供給量、水供給量も、要求発電量に応じて、同様に変更される。

なお、図10及び11は、燃料供給量に関するものであるが、空気供給量、水供給量も、要求発電量に応じて、同様に変更される。

制御部110には、固体電解質型燃料電池1の定格出力である700Wに対応する燃料電池モジュール2の上限温度Tb、及び固体電解質型燃料電池1を適正に運転するための下限温度Taが記憶されている。制御部110は、これらの上限温度Tbと下限温度Taの間の温度帯域を温度監視帯域Wとして固体電解質型燃料電池1を温度帯域規制制御している。即ち、制御部110は、燃料電池モジュール2の温度が温度監視帯域W内から外れると、燃料供給量及び空気供給量を適応補正し、燃料電池モジュール2の温度が温度監視帯域W内に早期に復帰するように制御する。

図9の時刻t1において、制御部110に内蔵された劣化判定手段110a(図6)は劣化判定モードの運転を開始する。なお、劣化判定手段110aは、マイクロプロセッサ、メモリ及びこれらを作動させるプログラム(以上図示せず)等により構成された劣化判定回路である。図13は、劣化判定手段110aによる処理を示すフローチャートである。

2 燃料電池モジュール

4 補機ユニット

8 密封空間

10 発電室

12 燃料電池セル集合体

14 燃料電池セルスタック

16 燃料電池セルユニット(固体電解質型燃料電池セル)

18 燃焼室

20 改質器

22 空気用熱交換器

24 水供給源

26 純水タンク

28 水流量調整ユニット(水供給装置、水供給手段)

30 燃料供給源

38 燃料流量調整ユニット(燃料供給装置、燃料供給手段)

40 空気供給源

44 改質用空気流量調整ユニット

45 発電用空気流量調整ユニット(酸化剤ガス供給装置、酸化剤ガス供給手段)

46 第1ヒータ

48 第2ヒータ

50 温水製造装置

52 制御ボックス

54 インバータ

83 点火装置

84 燃料電池セル

110 制御部(コントローラ、制御手段)

110a 劣化判定手段

112 操作装置

114 表示装置

116 警報装置

126 電力状態検出センサ

142 発電室温度センサ(温度検出手段)

150 外気温度センサ

Claims (5)

- 要求発電量に応じて発電電力を可変する固体電解質型燃料電池であって、

複数の固体電解質型燃料電池セルを備えた燃料電池モジュールと、

この燃料電池モジュールに燃料を供給する燃料供給装置と、

上記燃料電池モジュールに酸化剤ガスを供給する酸化剤ガス供給装置と、

要求発電量に対応して、上記燃料供給装置から供給する燃料供給量を変化させるコントローラと、を有し、

上記コントローラは、上記燃料電池モジュールの劣化が推定又は判定されると、以後要求発電量が変化した際の燃料供給量の時間当たりの変化率を低下させることを特徴とする固体電解質型燃料電池。 - 上記コントローラは、上記燃料電池モジュールの運転時間に基づいて、上記燃料電池モジュールの劣化を推定する請求項1記載の固体電解質型燃料電池。

- 上記コントローラは、上記燃料電池モジュールの劣化が進行しているほど、又は、上記燃料電池モジュールが長期間運転されているほど、要求発電量が変化した際の燃料供給量の時間当たりの変化率を大きく低下させる請求項1記載の固体電解質型燃料電池。

- 上記コントローラは、劣化が所定の状態まで進行したと推定又は判定すると、以後、要求発電量に対応した制御を中止し、所定の電力が出力されるよう上記燃料供給装置から供給する燃料供給量を制御する請求項3記載の固体電解質型燃料電池。

- 要求発電量に応じて発電電力を可変する固体電解質型燃料電池であって、

複数の固体電解質型燃料電池セルを備えた燃料電池モジュールと、

この燃料電池モジュールに燃料を供給する燃料供給手段と、

上記燃料電池モジュールに酸化剤ガスを供給する酸化剤ガス供給手段と、

要求発電量に対応して、上記燃料供給手段から供給する燃料供給量を変化させる制御手段と、を有し、

上記制御手段は、上記燃料電池モジュールの劣化が推定又は判定されると、以後要求発電量が変化した際の燃料供給量の時間当たりの変化率を低下させることを特徴とする固体電解質型燃料電池。

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201080021348.9A CN102422475B (zh) | 2009-03-31 | 2010-03-31 | 固体电解质型燃料电池 |

| EP10758820.4A EP2416426B1 (en) | 2009-03-31 | 2010-03-31 | Solid electrolyte fuel cell |

| US13/262,141 US8980496B2 (en) | 2009-03-31 | 2010-03-31 | Solid oxide fuel cell |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009087351A JP4622005B2 (ja) | 2009-03-31 | 2009-03-31 | 固体電解質型燃料電池 |

| JP2009-087351 | 2009-03-31 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2010114049A1 true WO2010114049A1 (ja) | 2010-10-07 |

Family

ID=42828338

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2010/055916 WO2010114049A1 (ja) | 2009-03-31 | 2010-03-31 | 固体電解質型燃料電池 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US8980496B2 (ja) |

| EP (1) | EP2416426B1 (ja) |

| JP (1) | JP4622005B2 (ja) |

| CN (1) | CN102422475B (ja) |

| WO (1) | WO2010114049A1 (ja) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6122326B2 (ja) * | 2013-03-29 | 2017-04-26 | 京セラ株式会社 | 燃料電池システム |

| JP6290558B2 (ja) | 2013-09-03 | 2018-03-07 | 三菱日立パワーシステムズ株式会社 | 制御装置及び方法、それを備えた複合発電システム |

| JP6003878B2 (ja) * | 2013-12-25 | 2016-10-05 | トヨタ自動車株式会社 | 燃料電池システム |

| JP6901231B2 (ja) * | 2014-05-21 | 2021-07-14 | 森村Sofcテクノロジー株式会社 | 燃料電池の制御装置及び燃料電池の制御方法 |

| CN106299401B (zh) | 2015-05-20 | 2019-07-16 | 通用电气公司 | 燃料电池系统及其控制方法 |

Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH053041A (ja) * | 1991-06-24 | 1993-01-08 | Hitachi Ltd | 燃料電池装置の制御方法 |

| JP2003217627A (ja) | 2002-01-28 | 2003-07-31 | Mitsubishi Heavy Ind Ltd | 燃料供給量制御装置、燃料供給量制御方法及び電力供給システム |

| JP2004164909A (ja) * | 2002-11-11 | 2004-06-10 | Denso Corp | 燃料電池システム |

| JP2004220949A (ja) * | 2003-01-16 | 2004-08-05 | Tokyo Gas Co Ltd | 固体高分子形燃料電池付改質装置システム及びその運転方法 |

| JP2006164740A (ja) * | 2004-12-07 | 2006-06-22 | Nissan Motor Co Ltd | 燃料電池システムの制御装置 |

| JP2006164741A (ja) * | 2004-12-07 | 2006-06-22 | Nissan Motor Co Ltd | 燃料電池システムの制御装置 |

| JP2006244821A (ja) * | 2005-03-02 | 2006-09-14 | Nissan Motor Co Ltd | 燃料電池システム及び燃料電池システムの制御方法 |

| JP2006302578A (ja) * | 2005-04-18 | 2006-11-02 | Nissan Motor Co Ltd | 燃料電池の運転方法及び燃料電池システム |

| JP2007087756A (ja) | 2005-09-21 | 2007-04-05 | Toto Ltd | 固体酸化物型燃料電池 |

| JP2007157604A (ja) * | 2005-12-08 | 2007-06-21 | Toyota Motor Corp | 燃料電池システム及び移動体 |

| JP2008159362A (ja) * | 2006-12-22 | 2008-07-10 | Osaka Gas Co Ltd | 固体酸化物形燃料電池システム |

| JP2009059556A (ja) * | 2007-08-31 | 2009-03-19 | Toyota Motor Corp | 燃料電池システム |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3736474B2 (ja) * | 2002-02-22 | 2006-01-18 | 日産自動車株式会社 | 燃料電池システム |

| JP2006339072A (ja) * | 2005-06-03 | 2006-12-14 | Nissan Motor Co Ltd | 燃料電池システム |

| US7993787B2 (en) * | 2007-09-21 | 2011-08-09 | GM Global Technology Operations LLC | Method for fast and reliable fuel cell system start-ups |

| JP4656610B2 (ja) * | 2009-03-31 | 2011-03-23 | Toto株式会社 | 固体電解質型燃料電池 |

| EP2416425B1 (en) * | 2009-03-31 | 2017-10-18 | Toto Ltd. | Solid electrolyte fuel cell |

| JP4656611B2 (ja) * | 2009-03-31 | 2011-03-23 | Toto株式会社 | 固体電解質型燃料電池 |

| JP5565749B2 (ja) * | 2009-03-31 | 2014-08-06 | Toto株式会社 | 固体電解質型燃料電池 |

-

2009

- 2009-03-31 JP JP2009087351A patent/JP4622005B2/ja active Active

-

2010

- 2010-03-31 WO PCT/JP2010/055916 patent/WO2010114049A1/ja active Application Filing

- 2010-03-31 EP EP10758820.4A patent/EP2416426B1/en not_active Not-in-force

- 2010-03-31 US US13/262,141 patent/US8980496B2/en not_active Expired - Fee Related

- 2010-03-31 CN CN201080021348.9A patent/CN102422475B/zh not_active Expired - Fee Related

Patent Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH053041A (ja) * | 1991-06-24 | 1993-01-08 | Hitachi Ltd | 燃料電池装置の制御方法 |

| JP2003217627A (ja) | 2002-01-28 | 2003-07-31 | Mitsubishi Heavy Ind Ltd | 燃料供給量制御装置、燃料供給量制御方法及び電力供給システム |

| JP2004164909A (ja) * | 2002-11-11 | 2004-06-10 | Denso Corp | 燃料電池システム |

| JP2004220949A (ja) * | 2003-01-16 | 2004-08-05 | Tokyo Gas Co Ltd | 固体高分子形燃料電池付改質装置システム及びその運転方法 |

| JP2006164740A (ja) * | 2004-12-07 | 2006-06-22 | Nissan Motor Co Ltd | 燃料電池システムの制御装置 |

| JP2006164741A (ja) * | 2004-12-07 | 2006-06-22 | Nissan Motor Co Ltd | 燃料電池システムの制御装置 |

| JP2006244821A (ja) * | 2005-03-02 | 2006-09-14 | Nissan Motor Co Ltd | 燃料電池システム及び燃料電池システムの制御方法 |

| JP2006302578A (ja) * | 2005-04-18 | 2006-11-02 | Nissan Motor Co Ltd | 燃料電池の運転方法及び燃料電池システム |

| JP2007087756A (ja) | 2005-09-21 | 2007-04-05 | Toto Ltd | 固体酸化物型燃料電池 |

| JP2007157604A (ja) * | 2005-12-08 | 2007-06-21 | Toyota Motor Corp | 燃料電池システム及び移動体 |

| JP2008159362A (ja) * | 2006-12-22 | 2008-07-10 | Osaka Gas Co Ltd | 固体酸化物形燃料電池システム |

| JP2009059556A (ja) * | 2007-08-31 | 2009-03-19 | Toyota Motor Corp | 燃料電池システム |