RU2547054C2 - Method of production of cold-rolled pipes with size vn346(40 mm from steel of grade "08-18=10t-+" for nuclear power engineering facilities - Google Patents

Method of production of cold-rolled pipes with size vn346(40 mm from steel of grade "08-18=10t-+" for nuclear power engineering facilities Download PDFInfo

- Publication number

- RU2547054C2 RU2547054C2 RU2013133039/02A RU2013133039A RU2547054C2 RU 2547054 C2 RU2547054 C2 RU 2547054C2 RU 2013133039/02 A RU2013133039/02 A RU 2013133039/02A RU 2013133039 A RU2013133039 A RU 2013133039A RU 2547054 C2 RU2547054 C2 RU 2547054C2

- Authority

- RU

- Russia

- Prior art keywords

- size

- pipes

- diameter

- rolled

- rolling

- Prior art date

Links

Landscapes

- Heat Treatment Of Steel (AREA)

- Metal Rolling (AREA)

Abstract

Description

Изобретение относится к трубопрокатному производству, а именно к способу производства холоднокатаных труб размером вн.346×40 мм из стали марки 08Х18Н10Т-Ш для объектов атомной энергетики, и может быть использовано при прокатке предельных горячекатаных труб размером 480×58×5500-5800 мм на трубопрокатной установке 8-16″ с пилигримовыми станами из слитков-заготовок ЭШП размером 620×100×1750±50 мм с последующей механической обработкой - расточкой и обточкой в передельные трубы размером 470×47×5500-5800 мм, перекаткой их на стане ХПТ 450 в товарные трубы размером вн.346×40×6700-7200 мм и приемкой их на соответствие ТУ 14-3Р-197-2001 с повышенными требованиями по качеству поверхности.The invention relates to pipe rolling production, and in particular to a method for the production of cold-rolled pipes with a size of ext. 346 × 40 mm from steel grade 08X18H10T-Sh for nuclear power facilities, and can be used in rolling limiting hot-rolled pipes with a size of 480 × 58 × 5500-5800 mm per 8-16 ″ tube-rolling installation with pilgrim mills from ESR ingots-blanks measuring 620 × 100 × 1750 ± 50 mm, followed by mechanical processing - boring and turning into conversion pipes of 470 × 47 × 5500-5800 mm in size, rolling them on the HPT 450 mill into product pipes of size ext. 3 46 × 40 × 6700-7200 mm and their acceptance for compliance with TU 14-3R-197-2001 with increased requirements for surface quality.

В трубопрокатном производстве известен способ производства товарных и передельных труб из труднодеформируемых марок стали, включающий сверление центрального отверстия диаметром 100±5,0 мм в заготовках и слитках ЭШП диаметром 380-500 мм, выдержку их на колосниках методических печей при температуре 500-550°С в течение 70-95 минут в зависимости от диаметра, после чего нагрев до температуры 1120-1140°С со скоростью 1,4-1,5 град/мин, прошивку заготовок и слитков ЭШП в гильзы размер в размер по диаметру при скорости вращения рабочих валков 25-40 об/мин на оправке диаметром, обеспечивающим редуцирование на пилигримовом стане не менее 25 мм (Патент РФ №2175899, бюл. №32, 20.11.2001).In pipe rolling production, a method is known for the production of commodity and conversion pipes from hardly deformed steel grades, including drilling a central hole with a diameter of 100 ± 5.0 mm in blanks and ingots of EAWs with a diameter of 380-500 mm, holding them on the grates of method furnaces at a temperature of 500-550 ° C for 70-95 minutes depending on the diameter, after which heating to a temperature of 1120-1140 ° C at a speed of 1.4-1.5 deg / min, flashing blanks and ingots of ESR into the sleeves size in size by diameter at the speed of rotation of the workers rolls 25-40 rpm on the mandrel Diameter providing pilger reduction is at least 25 mm (RF Patent №2175899, Bul. №32, 20.11.2001).

Недостатком данного способа является то, что он приемлем только для производства горячекатаных товарных и передельных труб среднего диаметра, а именно труб диаметром 219-325 мм, т.к. для прокатки труб диаметром более 325 мм необходима заготовка диаметром 540-620 мм, которую из-за малой мощности привода стана поперечно-винтовой прокатки прошить невозможно, а самое главное то, что данный способ не оговаривает припуск под механическую обработку передельных труб для изготовления товарных труб повышенного качества размером вн.346×40 мм из коррозионностойкой стали марки 08Х18Н10Т-Ш для объектов атомной энергетики.The disadvantage of this method is that it is acceptable only for the production of hot-rolled commodity and conversion pipes of medium diameter, namely pipes with a diameter of 219-325 mm, because for rolling pipes with a diameter of more than 325 mm, a workpiece with a diameter of 540-620 mm is required, which, due to the low power of the drive of the cross-helical rolling mill, cannot be sewn, and most importantly, this method does not stipulate the allowance for machining of conversion pipes for the manufacture of commodity pipes high quality ext. 346 × 40 mm in size made of corrosion-resistant steel grade 08X18H10T-Sh for nuclear facilities.

В трубопрокатном производстве известен способ производства товарных и передельных горячедеформированных труб большого и среднего диаметров из коррозионно-стойких труднодеформируемых марок стали и сплавов на трубопрокатных установках с пилигримовыми станами, включающий сверление центрального отверстия диаметром 100±5,0 мм в слитках-заготовках ЭШП и заготовках, нагрев их до температуры пластичности, первую прошивку слитков-заготовок ЭШП или кованых заготовок диаметром 460-600 мм в стане поперечно-винтовой прокатки с вытяжкой 1,2-1,4 при скорости вращения рабочих валков 15-25 об/мин, а вторую и последующие при необходимости прошивки - раскатки с подъемом или посадом по диаметру не более 5,0% и вытяжкой μ=1,4-1,75 при скорости вращения валков 20-50 об/мин, с использованием холодного или горячего посада гильз-заготовок в печь, процесс прошивки от захвата слитков-заготовок ЭШП или заготовок до полного нахождения на оправку ведут с уменьшением числа оборотов рабочих валков с 25 до 15, установившийся процесс прошивки при 15-20 об/мин, а на выходе гильзы-заготовки из валков число оборотов увеличивают до 35-40 об/мин, процесс прошивки - раскатки (вторую прошивку) от захвата гильзы-заготовки до полного нахождения на оправку ведут с уменьшением числа оборотов рабочих валков с 50 до 20, установившийся процесс раскатки при 20-25 об/мин, на выходе гильзы из валков число оборотов увеличивают до 45-50, а прокатку труб на пилигримовом стане ведут с вытяжкой μ=3,0-5,0 (Патент РФ №2247612, бюл. №7, 10.03.2005).In pipe rolling production, a method is known for the production of commodity and conversion hot-deformed pipes of large and medium diameters from corrosion-resistant hard-deformed steel grades and alloys in pipe rolling plants with pilgrim mills, including drilling a central hole with a diameter of 100 ± 5.0 mm in ESR ingots and billets, heating them to a plasticity temperature, the first flashing of ESR ingots-blanks or forged blanks with a diameter of 460-600 mm in a cross-helical rolling mill with a hood of 1.2-1.4 at a speed the axes of rotation of the work rolls are 15-25 rpm, and the second and subsequent, if necessary, firmware rolls with a rise or landing in diameter of not more than 5.0% and a hood μ = 1.4-1.75 at a speed of rotation of the rolls 20-50 rpm, using cold or hot insert of shell blanks into the furnace, the process of flashing from capturing ingots-blanks of ESRs or blanks to being completely on the mandrel is carried out with a decrease in the number of revolutions of the work rolls from 25 to 15, the steady-state flashing process at 15-20 rpm, and at the exit of the billet blank from the rolls I increase the speed t up to 35-40 rpm, the firmware process - rolling (second firmware) from gripping the billet blank to being completely on the mandrel is carried out with a decrease in the number of revolutions of the work rolls from 50 to 20, the steady rolling process at 20-25 rpm, at the exit of the sleeve from the rolls, the number of revolutions is increased to 45-50, and the tubes are rolled on a pilgrim mill with an extractor μ = 3.0-5.0 (RF Patent No. 2247612, bull. No. 7, 03/10/2005).

Недостатком данного способа является то, что он также не оговаривает припуск под механическую обработку передельных труб для изготовления товарных труб повышенного качества размером вн.346×40 мм из коррозионностойкой стали 08Х18Н10Т-Ш для объектов атомной энергетики.The disadvantage of this method is that it also does not stipulate an allowance for machining conversion pipes for the manufacture of high-quality commodity pipes with a size of ext. 346 × 40 mm from 08Kh18N10T-Sh corrosion-resistant steel for nuclear power facilities.

Наиболее близким техническим решением является способ производства бесшовных горячедеформированных труб размером вн.279×36 и вн.346×40 мм из слитков-заготовок ЭШП коррозионностойкой стали 08Х18Н10Т-Ш с повышенным качеством поверхности для объектов атомной энергетики с расточенной внутренней и обточенной наружной поверхностью с шероховатостью Ra не более 10 мкм по ГОСТ 2789 (ТУ 14-158-131-2002 «Трубы бесшовные горячедеформированные из коррозионностойкой стали повышенного качества»).The closest technical solution is a method for the production of seamless hot-deformed pipes of dimensions ext. 279 × 36 and ext. 346 × 40 mm from ingots-blanks ESR of corrosion-resistant steel 08X18H10T-Sh with improved surface quality for nuclear power facilities with a bored inner and turned outer surface with roughness Ra no more than 10 microns in accordance with GOST 2789 (TU 14-158-131-2002 "Seamless hot-deformed pipes from high-quality corrosion-resistant steel").

Одним из главных недостатков данного способа является то, что при производстве по данной технологии более 80% труб после аустенизации имеют значения предела текучести при +350° от 12 до 18 кгс/мм2 (при норме по ТУ 14-3Р-197-2001 не менее 19 кгс/мм2). Другим недостатком является то, что припуск под механическую обработку (расточку и обточку) труб длиной 4000 мм должен быть не менее 10 мм на сторону. Таким образом, при механической обработке (обточке и расточке) с шероховатостью Ra не более 10 мкм в стружку на каждом погонном метре уходит от 134,68 до 147,52 кг дорогостоящего металла, т.е. от 26,2 до 34,5%) (в зависимости от диаметра и толщины стенки труб).One of the main disadvantages of this method is that in the production of this technology more than 80% of the pipes after austenization have yield strengths at + 350 ° from 12 to 18 kgf / mm 2 (with the norm according to TU 14-3Р-197-2001 less than 19 kgf / mm 2 ). Another disadvantage is that the allowance for machining (boring and turning) of pipes with a length of 4000 mm should be at least 10 mm per side. Thus, during machining (turning and boring) with a roughness Ra of not more than 10 μm, 134.68 to 147.52 kg of expensive metal, i.e. from 26.2 to 34.5%) (depending on the diameter and wall thickness of the pipes).

Задачей предложенного способа является производство холоднокатаных труб размером вн.346×40 мм повышенного качества для объектов атомной энергетики с механическими свойствами металла, отвечающими требованиям ТУ 14-3Р-197-2001, снижение припуска под механическую обработку (расточку и обточку) передельных горячедеформированных труб, снижение расходного коэффициента металла при переделе слиток-заготовка ЭШП - товарная труба повышенного качества по ТУ 14-3Р-197-2001, увеличение длины товарных труб, а следовательно, снижение их стоимости.The objective of the proposed method is the production of cold-rolled pipes with a size of ext. 346 × 40 mm of high quality for nuclear facilities with mechanical properties of metal that meet the requirements of TU 14-3R-197-2001, reducing the allowance for machining (boring and turning) of hot-deformed tubes, reduction of the expenditure coefficient of the metal during the redistribution of the ingot-billet ESR is a commodity pipe of high quality according to TU 14-3R-197-2001, an increase in the length of commodity pipes, and therefore, a decrease in their cost.

Технический результат достигается тем, что в известном способе производства холоднокатаных труб размером вн.346×40 мм из стали марки 08Х18Н10Т-Ш для объектов атомной энергетики, включающем нагрев слитков-заготовок электрошлакового переплава размером 620×100×1750±50 мм в методических печах до температуры 1260-1270°С, прошивку их в стане поперечно-винтовой прокатки в гильзы-заготовки размером 620×вн.265×1985-2105 мм на оправке диаметром 250 мм размер в размер по наружному диаметру и вытяжкой μ=1,17, нагрев их с холодного или горячего посада в методических печах до температуры 1260-1270°С, прошивку - раскатку в стане поперечно-винтовой прокатки размер в размер по наружному диаметру в гильзы размером 620×вн.390×2630-2800 мм на оправке диаметром 375 мм с вытяжкой μ=1,33, прокатку гильз на ТПУ 8-16″ с пилигримовыми станами в передельные горячекатаные трубы размером 480×58×5500-5800 мм с обжатием по диаметру Δ=21,8% и вытяжкой μ=2,37, передельные горячекатаные трубы обтачивают и растачивают в передельные механически обработанные трубы размером 470×47×5500-5800 мм со съемом металла по наружной поверхности ≤5,0 мм, а по внутренней поверхности <6,0 мм, и перекатку передельных горячекатаных механически обработанных труб размером 470×47×5500-5800 мм на стане ХПТ 450 в товарные холоднокатаные трубы размером вн.346×40×6700-7200 мм с вытяжкой μ=1,29 и обжатием по диаметру Δ=9,36%, вн.346×40×6700-7200 мм с вытяжкой μ=1,29 и обжатием по диаметру Δ=9,36%, шероховатостью наружной и внутренней поверхностей Ra не более 2,5 мкм, осуществляют подрезку концов и аустенизацию.The technical result is achieved by the fact that in the known method for the production of cold-rolled pipes with a size of ext. 346 × 40 mm from steel grade 08Kh18N10T-Sh for nuclear power facilities, which includes heating ingots-blanks of electroslag remelting with a size of 620 × 100 × 1750 ± 50 mm in methodical furnaces up to temperature 1260-1270 ° С, piercing them in a cross-helical rolling mill into blanks 620 × ext. 265 × 1985-2105 mm in diameter on a mandrel with a diameter of 250 mm; size in outer diameter and exhaust hood μ = 1.17; heating them from cold or hot posad in methodological furnaces to temperature 1260-1270 ° С, firmware - rolling out in a cross-screw rolling mill, size to outer diameter in sleeves of size 620 × ext. 390 × 2630-2800 mm on a mandrel with a diameter of 375 mm with hood μ = 1.33, rolling of sleeves on TPU 8-16 ″ with pilgrim mills into hot-rolled chimneys of size 480 × 58 × 5500-5800 mm with a diameter reduction of Δ = 21.8% and a draft of μ = 2.37, hot-rolled chimneys are turned and bored into mechanically processed pipes 470 × 47 × 5500-5800 mm in size with removal of metal on the outer surface ≤5.0 mm, and on the inner surface <6.0 mm, and the rolling of hot-rolled mechanically processed pipes of 470 × 47 × 5500-5800 mm in size at the KhPT 450 mill into commodity cold-rolled pipes with dimensions of ext. 346 × 40 × 6700-7200 mm with a hood μ = 1.29 and compression in diameter Δ = 9.36%, ext. 346 × 40 × 6700-7200 mm with hood μ = 1.29 and compression in diameter Δ = 9.36%, roughness of the outer and inner surfaces Ra not more than 2.5 μm , trim the ends and austenization.

Сопоставительный анализ заявляемого решения с прототипом показывает, что заявляемый способ отличается от известного тем, что в качестве заготовок используют слитки-заготовки электрошлакового переплава размером 620×100×1750±50 мм, которые нагревают в методических печах до температуры 1260-1270°С, прошивают в стане поперечно-винтовой прокатки в гильзы-заготовки размером 620×вн.265×1985-2105 мм на оправке диаметром 250 мм размер в размер по наружному диаметру и вытяжкой μ=1,17, нагревают их с холодного или горячего посада в методических печах до температуры 1260-1270°С, прошивают - раскатывают в стане поперечно-винтовой прокатки размер в размер по наружному диаметру в гильзы размером 620×вн.390×2630-2800 мм на оправке диаметром 375 мм с вытяжкой µ=1,33, гильзы прокатывают на ТПУ 8-16″ с пилигримовыми станами в передельные горячекатаные трубы размером 480×58×5500-5800 мм с обжатием по диаметру Δ=21,8% и вытяжкой µ=2,37, передельные горячекатаные трубы обтачивают и растачивают в передельные механически обработанные трубы размером 470×47×5500-5800 мм со съемом металла по наружной поверхности ≤5,0 мм, а по внутренней поверхности ≤6,0 мм, и перекатывают передельные горячекатаные механически обработанные трубы размером 470×47×5500-5800 мм на стане ХПТ 450 в товарные холоднокатаные трубы с вытяжкой µ=1,29 и обжатием по диаметру Δ=9,36%, шероховатостью наружной и внутренней поверхностей Ra не более 2,5 мкм, осуществляют подрезку концов и аустенизацию. Таким образом, эти отличия позволяют сделать вывод о соответствии критерию «изобретательский уровень».A comparative analysis of the proposed solution with the prototype shows that the claimed method differs from the known one in that 620 × 100 × 1750 ± 50 mm ingots-billets of electroslag remelting are used as billets, which are heated in methodological furnaces to a temperature of 1260-1270 ° C, stitched in a mill of cross-helical rolling into billet sleeves measuring 620 × ext. 265 × 1985-2105 mm on a mandrel with a diameter of 250 mm, size in outer diameter and exhaust hood μ = 1.17, they are heated from cold or hot planting in methodical furnaces to temperature 1260-1270 ° C, flashed - rolled out in a cross-rolling mill to a size in outer diameter into sleeves of size 620 × ext. 390 × 2630-2800 mm on a mandrel with a diameter of 375 mm with a hood µ = 1.33, sleeves are rolled onto TPU 8-16 ″ with pilgrim mills in hot-rolled chimneys of size 480 × 58 × 5500-5800 mm with a diameter reduction of Δ = 21.8% and a hood µ = 2.37, hot-rolled chimneys are turned and bored into mechanically processed pipes 470 × 47 × 5500-5800 mm in size with metal removal on the outer surface ≤5.0 mm, and on the inner surface 6.0 mm, and rolled hot rolled mechanically processed pipes of 470 × 47 × 5500-5800 mm in size on the KhPT 450 mill into commodity cold-rolled pipes with an extract of µ = 1.29 and a compression in diameter of Δ = 9.36%, the roughness of the outer and inner surfaces Ra not more than 2.5 microns, carry out trimming of the ends and austenization. Thus, these differences allow us to conclude that the criterion of "inventive step" is met.

Сравнение заявляемого способа не только с прототипом, но и с другими техническими решениями в данной области техники, не позволило выявить в них признаки, отличающие заявляемый способ от прототипа, что соответствует патентоспособности «изобретательский уровень».Comparison of the proposed method not only with the prototype, but also with other technical solutions in this technical field, did not reveal the signs that distinguish the claimed method from the prototype, which corresponds to patentability "inventive step".

Способ опробован на ТПУ 8-16″ с пилигримовыми станами ОАО «ЧТПЗ» при прокатке передельных труб размером 445×58×5200 мм из слитков-заготовок ЭШП размером 585×100×1650 мм по существующей технологии и передельных труб размером 480×58×5600 мм из слитков-заготовок ЭШП размером 620×100×1750 мм по предлагаемой технологии.The method was tested on TPU 8-16 ″ with Pilgrim mills of ChTPZ OJSC when rolling parcel pipes of size 445 × 58 × 5200 mm from ingot blanks EShP of size 585 × 100 × 1650 mm using existing technology and conversion tubes of size 480 × 58 × 5600 mm from ingots-blanks ESR size 620 × 100 × 1750 mm according to the proposed technology.

Передельные трубы размером 445×58×5200 мм были расточены и обточены в цехе №1 в товарные трубы размером вн.346×40×5200 мм, с шероховатостью наружных и внутренних поверхностей Ra не более 10 мкм, от которых были отобраны барабаны, изготовлены образцы и проведены механические испытания. Трубы прошли УЗК. Из 3-х труб размером вн.346×40 мм испытания по пределу текучести при температуре +350°С после аустенизации выдержала одна труба, которая сдана по прямому назначению, а две трубы приняты как условно годные. Расходный коэффициент металла составил 1,811. По предлагаемой технологии передельные трубы размером 480×58×5600 мм были расточены и обточены в передельные механически обработанные трубы размером 470×47×5600 мм. На одной трубе не выведенная чернота была удалена шлифовкой абразивными кругами. Передельные горячекатаные механически обработанные трубы размером 470×47×5600 мм были перекатаны на стане ХПТ 450 в товарные холоднокатаные трубы размером вн.346×40×6900 мм с шероховатостью наружной и внутренней поверхностей Ra не более 2,5 мкм. От трех труб были отобраны барабаны, изготовлены образцы и проведены механические испытания. Трубы прошли УЗК. Две трубы размером вн.346×40 мм приняты по ТУ 14-3Р-197-2001 по прямому назначению для объектов атомной энергетики, а одна как условно годная, т.к. не выдержала испытание по пределу текучести при температуре +350°С после аустенизации. Данная труба сдана по другому назначению. Расходный коэффициент металла по трубам данной партии составил 1,538. Труба размером вн.346×40 мм, не выдержавшая испытание по пределу текучести при температуре +350°С после аустенизации была перекатана на стане ХПТ 450 в трубу размером вн.279×36×9000 мм, выдержала все испытания и сдана по прямому назначению для АЭС.Conversion pipes 445 × 58 × 5200 mm in size were bored and turned in workshop No. 1 into commodity pipes with a size of ext. 346 × 40 × 5200 mm, with a roughness of the outer and inner surfaces Ra of not more than 10 μm, from which the drums were taken, samples were made and mechanical tests were performed. The pipes passed the ultrasonic inspection. Out of 3 pipes with a size of ext. 346 × 40 mm, one pipe, which was delivered for its intended purpose, passed the yield strength tests at a temperature of + 350 ° C after austenization, and two pipes were accepted as conditionally suitable. The expenditure coefficient of the metal was 1.811. According to the proposed technology, the conversion pipes of size 480 × 58 × 5600 mm were bored and turned into conversion machined pipes of size 470 × 47 × 5600 mm. On one pipe, unreduced blackness was removed by grinding with abrasive wheels. Converted hot-rolled machined pipes with a size of 470 × 47 × 5600 mm were rolled at the KhPT 450 mill into commercial cold-rolled pipes with a dimension of ext. 346 × 40 × 6900 mm with a roughness of the outer and inner surfaces Ra of no more than 2.5 μm. Drums were taken from three pipes, samples were made and mechanical tests were carried out. The pipes passed the ultrasonic inspection. Two pipes with a size of ext. 346 × 40 mm were adopted according to TU 14-3R-197-2001 for their intended purpose for nuclear facilities, and one as conditionally suitable, because did not pass the yield strength test at a temperature of + 350 ° C after austenization. This pipe has been commissioned for another purpose. The expenditure coefficient of the metal in the pipes of this batch was 1.538. A pipe with a size of ext. 346 × 40 mm, which did not pass the yield strength test at a temperature of + 350 ° C after austenization, was rolled on a KPT 450 mill into a pipe with a size of ext. 279 × 36 × 9000 mm, passed all tests and passed for its intended purpose NUCLEAR POWER STATION.

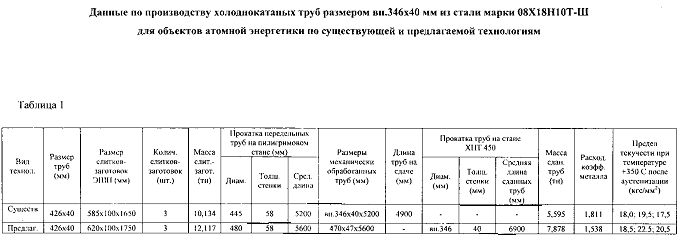

Данные по производству холоднокатаных труб размером вн.345×40 мм из стали марки 08Х18Н10Т-Ш для объектов атомной энергетики по существующей и предлагаемой технологиям приведены в таблице 1. Из таблицы видно, что выход годного по прямому назначению при прокатке труб для АЭС по существующей технологии составил 33,3%, а по предлагаемой технологии с первого предъявления 66,7%. После переката трубы размером вн.346×40 мм в трубу размером вн.279×36 мм выход годного составил 100%. Расходный коэффициент металла при прокатке труб размером вн.346×40 мм по предлагаемой технологии снижен на 273 кг. По предлагаемой технологии при прокатке труб размером вн.346×40 мм среднее увеличение длины труб составило в 1,41 раза, а шероховатость наружной и внутренней поверхностей снижена более чем в 4,0 раза.Data on the production of cold-rolled pipes with a size of ext. 345 × 40 mm from 08Kh18N10T-Sh steel for nuclear facilities according to the existing and proposed technologies is shown in Table 1. It can be seen from the table that the yield for its intended purpose when rolling pipes for nuclear power plants using existing technology amounted to 33.3%, and according to the proposed technology from the first presentation 66.7%. After rolling the pipe with a size of ext. 346 × 40 mm into a pipe with a size of ext. 279 × 36 mm, the yield was 100%. The expenditure coefficient of the metal when rolling pipes ext. 346 × 40 mm in size by the proposed technology is reduced by 273 kg. According to the proposed technology, when rolling pipes ext. 346 × 40 mm in size, the average increase in pipe length was 1.41 times, and the roughness of the outer and inner surfaces was reduced by more than 4.0 times.

Использование предлагаемого способа производства холоднокатаных труб размером вн.346×40 мм повышенного качества из стали марки 08Х18Н10Т-Ш для объектов атомной энергетики позволит снизить расход дорогостоящего металла, увеличить выход труб для АЭС с первого предъявления, снизить шероховатость наружной и внутренней поверхностей, увеличить их длину, а следовательно, снизить стоимость труб и снизить количество сварочных стыков при монтаже трубопроводов на АЭС.Using the proposed method for the production of cold-rolled pipes of size 346 × 40 mm in high quality from steel grade 08Kh18N10T-Sh for nuclear power facilities will reduce the cost of expensive metal, increase the yield of pipes for nuclear power plants from the first presentation, reduce the roughness of the outer and inner surfaces, increase their length and, therefore, reduce the cost of pipes and reduce the number of welding joints when installing pipelines at nuclear power plants.

Claims (1)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| RU2013133039/02A RU2547054C2 (en) | 2013-07-16 | 2013-07-16 | Method of production of cold-rolled pipes with size vn346(40 mm from steel of grade "08-18=10t-+" for nuclear power engineering facilities |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| RU2013133039/02A RU2547054C2 (en) | 2013-07-16 | 2013-07-16 | Method of production of cold-rolled pipes with size vn346(40 mm from steel of grade "08-18=10t-+" for nuclear power engineering facilities |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| RU2013133039A RU2013133039A (en) | 2015-01-27 |

| RU2547054C2 true RU2547054C2 (en) | 2015-04-10 |

Family

ID=53280945

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| RU2013133039/02A RU2547054C2 (en) | 2013-07-16 | 2013-07-16 | Method of production of cold-rolled pipes with size vn346(40 mm from steel of grade "08-18=10t-+" for nuclear power engineering facilities |

Country Status (1)

| Country | Link |

|---|---|

| RU (1) | RU2547054C2 (en) |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3717698A1 (en) * | 1986-06-25 | 1988-01-14 | Kocks Technik | METHOD AND SYSTEM FOR PRODUCING SEAMLESS TUBES |

| RU2175899C2 (en) * | 1999-09-23 | 2001-11-20 | Открытое акционерное общество "Челябинский трубопрокатный завод" | Method for making tubes of hard-to-form kinds of steel |

| RU2247612C2 (en) * | 2003-05-06 | 2005-03-10 | ОАО "Челябинский трубопрокатный завод" | Method for making hot deformed and conversion mean- and large-diameter tubes of corrosion resistant hard-to-form steels and alloys in tube rolling aggregate with pilger mills |

| RU2401169C2 (en) * | 2008-04-18 | 2010-10-10 | ОАО "Челябинский трубопрокатный завод" | Method of producing high-quality pipes from antirust steel 08x18h10t-"+" for nuclear power engineering structures |

-

2013

- 2013-07-16 RU RU2013133039/02A patent/RU2547054C2/en not_active IP Right Cessation

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3717698A1 (en) * | 1986-06-25 | 1988-01-14 | Kocks Technik | METHOD AND SYSTEM FOR PRODUCING SEAMLESS TUBES |

| RU2175899C2 (en) * | 1999-09-23 | 2001-11-20 | Открытое акционерное общество "Челябинский трубопрокатный завод" | Method for making tubes of hard-to-form kinds of steel |

| RU2247612C2 (en) * | 2003-05-06 | 2005-03-10 | ОАО "Челябинский трубопрокатный завод" | Method for making hot deformed and conversion mean- and large-diameter tubes of corrosion resistant hard-to-form steels and alloys in tube rolling aggregate with pilger mills |

| RU2401169C2 (en) * | 2008-04-18 | 2010-10-10 | ОАО "Челябинский трубопрокатный завод" | Method of producing high-quality pipes from antirust steel 08x18h10t-"+" for nuclear power engineering structures |

Also Published As

| Publication number | Publication date |

|---|---|

| RU2013133039A (en) | 2015-01-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| RU2401169C2 (en) | Method of producing high-quality pipes from antirust steel 08x18h10t-"+" for nuclear power engineering structures | |

| RU2523398C1 (en) | PRODUCTION OF SEAMLESS COLD-FORMED OIL-WELL TUBING SIZED TO 114,3×6, 8×9000-10700 mm FROM CORROSION-RESISTANT ALLOY OF "ХН30МДБ-Ш" GRADE | |

| RU2527578C2 (en) | PRODUCTION OF SEAMLESS COLD-FORMED OIL-WELL TUBING SIZED TO 88,9×6,45×9000-10700 mm FROM CORROSION-RESISTANT ALLOY OF "ХН30МДБ-Ш" GRADE | |

| RU2322316C2 (en) | Method for producing ingot-blanks by electroslag refining of hard-to-form steels and alloys and for rolling of them commercial tubes of large and mean diameters in tube rolling plants with pilger mills and conversion tubes for rerolling in tube cold rolling mills | |

| RU2639183C1 (en) | METHOD OF PRODUCING SEAMLESS COLD-DEFORMED COUPLING PIPES OF 88,9 × 6,45 mm SIZE FROM CORROSION-RESISTANT ALLOY OF "ХН30МДБ-Ш" GRADE | |

| RU2547054C2 (en) | Method of production of cold-rolled pipes with size vn346(40 mm from steel of grade "08-18=10t-+" for nuclear power engineering facilities | |

| RU2311979C1 (en) | Method for producing hot rolled commercial and conversion tubes of large and mean diameters of hard-to-form steels and alloys in tube rolling plants with pilger mills | |

| RU2615920C1 (en) | METHOD FOR PRODUCING SEAMLESS COLD DRAWN PIPES OF 325x8-14 mm SIZE MADE OF STEEL OF "08Х18Н10Т-Ш" GRADE | |

| RU2542139C1 (en) | Method of manufacturing of pipes "t=279(36" and "t=346(40" mm out of "08-18=10t-+" grade steel for nuclear power facilities | |

| RU2613817C1 (en) | METHOD FOR PRODUCING SEAMLESS PIPES OF 377×8-13 mm SIZE MADE OF STEEL OF "08Х18Н10Т-Ш" GRADE | |

| RU2613813C1 (en) | METHOD OF PRODUCING COLD-DEFORMED COUPLING PIPES OF 108×18 mm SIZE FROM CORROSION-RESISTANT ALLOY OF "ХН30МДБ" GRADE | |

| RU2642998C1 (en) | Method of production of seamless cold-formed pipes 08h18n10t-sh of size 426x14-19 mm | |

| RU2523399C1 (en) | Production of rerolled long-sized pipes from iron-nickel- and nickel-based alloys at pru with pilger mills | |

| RU2614478C1 (en) | METHOD OF MANUFACTURING SEAMLESS PIPES OF SIZE 426 × 17-19 mm FOR NUCLEAR POWER FACILITIES OF STEEL OF "08X18Н10-Ш" GRADE | |

| RU2613811C1 (en) | METHOD OF MANUFACTURING SEAMLESS PIPES OF SIZE 377×8-18 mm FOR NUCLEAR POWER FACILITIES OF STEEL OF 08X18H10T-W GRADE | |

| RU2615928C1 (en) | METHOD OF PRODUCING SEAMLESS MACHINED PIPES WITH 530x13-18 mm SIZE FROM STEEL OF "08Х18Н10Т-Ш" GRADE | |

| RU2615394C1 (en) | METHOD FOR PRODUCING SEAMLESS PIPES OF 325×8-14 mm SIZE MADE OF STEEL OF "08X18Н10Т-Ш" GRADE | |

| RU2613812C1 (en) | METHOD FOR PRODUCING SEAMLESS PIPES WITH DIAMETER 377 mm AND WALL THICKNESS 14-18 mm OF STEEL OF "08Х18Н10Т-Ш" GRADE | |

| RU2613822C1 (en) | METHOD FOR PRODUCING SEAMLESS PIPES OF 325×8-14 mm SIZE MADE OF STEEL OF "08Х18Н10Т-Ш" GRADE | |

| RU2620204C1 (en) | METHOD OF PRODUCING SEAMLESS MACHINED PIPES WITH 530 × 13-18 mm SIZE FROM STEEL OF "08Х18Н10-Ш" GRADE | |

| RU2615922C1 (en) | METHOD FOR PRODUCING SEAMLESS PIPES OF 377x8-18 mm SIZE MADE OF STEEL OF "08Х18Н10Т-Ш" GRADE | |

| RU2618686C1 (en) | METHOD FOR PRODUCING SEAMLESS PIPES OF 426×8-13 mm SIZE MADE OF STEEL MARK "08Х18Н10Т-Ш" | |

| RU2613815C1 (en) | METHOD FOR PRODUCING SEAMLESS PIPES WITH DIAMETER OF 426×8-10 mm SIZE FOR NUCLEAR POWER FACILITIES OF STEEL OF "08Х18Н10-Ш" GRADE | |

| RU2620205C1 (en) | METHOD OF PRODUCING SEAMLESS MACHINED PIPES WITH 530 ×19-24 mm SIZE FROM STEEL OF "08Х18Н10-Ш" GRADE | |

| RU2386499C2 (en) | Method for production of ship lengthy hollow shafts of large and medium diametre from low-magnetic corrosion-resistant steels |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| MM4A | The patent is invalid due to non-payment of fees |

Effective date: 20180717 |