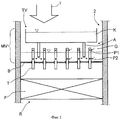

RU2466784C2 - Реактор для проведения трехфазной реакции жидкой и газообразной фаз в неподвижном слое катализатора - Google Patents

Реактор для проведения трехфазной реакции жидкой и газообразной фаз в неподвижном слое катализатора Download PDFInfo

- Publication number

- RU2466784C2 RU2466784C2 RU2010101601/05A RU2010101601A RU2466784C2 RU 2466784 C2 RU2466784 C2 RU 2466784C2 RU 2010101601/05 A RU2010101601/05 A RU 2010101601/05A RU 2010101601 A RU2010101601 A RU 2010101601A RU 2466784 C2 RU2466784 C2 RU 2466784C2

- Authority

- RU

- Russia

- Prior art keywords

- reactor

- distribution plate

- holes

- liquid phase

- liquid

- Prior art date

Links

- 239000007788 liquid Substances 0.000 title claims abstract description 33

- 239000003054 catalyst Substances 0.000 title claims abstract description 30

- 238000006243 chemical reaction Methods 0.000 title claims abstract description 22

- 230000003068 static effect Effects 0.000 title description 5

- 239000007791 liquid phase Substances 0.000 claims abstract description 75

- 239000012071 phase Substances 0.000 claims abstract description 17

- 238000009826 distribution Methods 0.000 claims description 97

- 239000007792 gaseous phase Substances 0.000 claims description 48

- KAKZBPTYRLMSJV-UHFFFAOYSA-N Butadiene Chemical compound C=CC=C KAKZBPTYRLMSJV-UHFFFAOYSA-N 0.000 claims description 16

- 239000007789 gas Substances 0.000 claims description 13

- 150000002430 hydrocarbons Chemical class 0.000 claims description 12

- 229930195733 hydrocarbon Natural products 0.000 claims description 11

- 239000004215 Carbon black (E152) Substances 0.000 claims description 10

- 238000005984 hydrogenation reaction Methods 0.000 claims description 9

- 125000004432 carbon atom Chemical group C* 0.000 claims description 8

- 238000000034 method Methods 0.000 claims description 8

- VXNZUUAINFGPBY-UHFFFAOYSA-N 1-Butene Chemical class CCC=C VXNZUUAINFGPBY-UHFFFAOYSA-N 0.000 claims description 5

- 239000000203 mixture Substances 0.000 claims description 5

- 238000000197 pyrolysis Methods 0.000 claims description 2

- 238000011144 upstream manufacturing Methods 0.000 claims 2

- 238000009827 uniform distribution Methods 0.000 abstract description 5

- 239000000126 substance Substances 0.000 abstract description 3

- 230000000694 effects Effects 0.000 abstract description 2

- 239000012530 fluid Substances 0.000 abstract description 2

- 230000009466 transformation Effects 0.000 abstract 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- 238000005516 engineering process Methods 0.000 description 2

- 125000000383 tetramethylene group Chemical class [H]C([H])([*:1])C([H])([H])C([H])([H])C([H])([H])[*:2] 0.000 description 2

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 1

- HSFWRNGVRCDJHI-UHFFFAOYSA-N alpha-acetylene Natural products C#C HSFWRNGVRCDJHI-UHFFFAOYSA-N 0.000 description 1

- 239000001273 butane Substances 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 150000001993 dienes Chemical class 0.000 description 1

- 125000002534 ethynyl group Chemical group [H]C#C* 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- IJDNQMDRQITEOD-UHFFFAOYSA-N n-butane Chemical compound CCCC IJDNQMDRQITEOD-UHFFFAOYSA-N 0.000 description 1

- OFBQJSOFQDEBGM-UHFFFAOYSA-N n-pentane Natural products CCCCC OFBQJSOFQDEBGM-UHFFFAOYSA-N 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 239000007858 starting material Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/008—Details of the reactor or of the particulate material; Processes to increase or to retard the rate of reaction

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/02—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds

- B01J8/0242—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid flow within the bed being predominantly vertical

- B01J8/025—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid flow within the bed being predominantly vertical in a cylindrical shaped bed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/02—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds

- B01J8/0278—Feeding reactive fluids

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/02—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds

- B01J8/04—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds

- B01J8/0446—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds the flow within the beds being predominantly vertical

- B01J8/0449—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds the flow within the beds being predominantly vertical in two or more cylindrical beds

- B01J8/0453—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds the flow within the beds being predominantly vertical in two or more cylindrical beds the beds being superimposed one above the other

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/02—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds

- B01J8/04—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds

- B01J8/0492—Feeding reactive fluids

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C7/00—Purification; Separation; Use of additives

- C07C7/148—Purification; Separation; Use of additives by treatment giving rise to a chemical modification of at least one compound

- C07C7/163—Purification; Separation; Use of additives by treatment giving rise to a chemical modification of at least one compound by hydrogenation

- C07C7/167—Purification; Separation; Use of additives by treatment giving rise to a chemical modification of at least one compound by hydrogenation for removal of compounds containing a triple carbon-to-carbon bond

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2208/00—Processes carried out in the presence of solid particles; Reactors therefor

- B01J2208/00008—Controlling the process

- B01J2208/00548—Flow

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10G—CRACKING HYDROCARBON OILS; PRODUCTION OF LIQUID HYDROCARBON MIXTURES, e.g. BY DESTRUCTIVE HYDROGENATION, OLIGOMERISATION, POLYMERISATION; RECOVERY OF HYDROCARBON OILS FROM OIL-SHALE, OIL-SAND, OR GASES; REFINING MIXTURES MAINLY CONSISTING OF HYDROCARBONS; REFORMING OF NAPHTHA; MINERAL WAXES

- C10G2400/00—Products obtained by processes covered by groups C10G9/00 - C10G69/14

- C10G2400/20—C2-C4 olefins

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- General Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Analytical Chemistry (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Water Supply & Treatment (AREA)

- Devices And Processes Conducted In The Presence Of Fluids And Solid Particles (AREA)

- Organic Low-Molecular-Weight Compounds And Preparation Thereof (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US94546107P | 2007-06-21 | 2007-06-21 | |

| US60/945,461 | 2007-06-21 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| RU2010101601A RU2010101601A (ru) | 2011-07-27 |

| RU2466784C2 true RU2466784C2 (ru) | 2012-11-20 |

Family

ID=39712175

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| RU2010101601/05A RU2466784C2 (ru) | 2007-06-21 | 2008-06-20 | Реактор для проведения трехфазной реакции жидкой и газообразной фаз в неподвижном слое катализатора |

Country Status (12)

| Country | Link |

|---|---|

| US (1) | US9011790B2 (enExample) |

| EP (1) | EP2170494B1 (enExample) |

| JP (1) | JP5276098B2 (enExample) |

| KR (1) | KR101509274B1 (enExample) |

| CN (1) | CN101778666B (enExample) |

| AT (1) | ATE520455T1 (enExample) |

| BR (1) | BRPI0812907A2 (enExample) |

| CA (1) | CA2691642C (enExample) |

| MY (1) | MY147674A (enExample) |

| RU (1) | RU2466784C2 (enExample) |

| TW (1) | TWI458553B (enExample) |

| WO (1) | WO2008155399A1 (enExample) |

Families Citing this family (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2274343A1 (en) * | 2008-05-02 | 2011-01-19 | Basf Se | Process and apparatus for continuously polymerizing cationically polymerizable monomers |

| EP2274339B1 (de) | 2008-05-02 | 2015-11-11 | Basf Se | Verfahren und vorrichtung zur kontinuierlichen herstellung von polymerisaten durch radikalische polymerisation |

| US8177198B2 (en) * | 2008-06-26 | 2012-05-15 | Uop Llc | Quench zone design using spray nozzles |

| EP2476482B2 (en) * | 2011-01-18 | 2020-05-13 | Neste Oyj | Method and arrangement for feeding heat-sensitive materials to fixed-bed reactors |

| CN103084121B (zh) * | 2011-10-27 | 2014-09-17 | 中国科学院大连化学物理研究所 | 一种气-液-固三相反应器及其应用 |

| CN102442874B (zh) * | 2011-10-28 | 2015-02-25 | 山东华懋新材料有限公司 | 恒温固定床丁烯氧化脱氢制备丁二烯的方法 |

| FR2987280B1 (fr) * | 2012-02-24 | 2014-02-28 | IFP Energies Nouvelles | Reacteur catalytique avec systeme de distribution a caissons |

| FR3006599B1 (fr) * | 2013-06-10 | 2015-05-29 | IFP Energies Nouvelles | Plateau distributeur pour colonne de contact gaz/liquide avec systeme de distribution secondaire |

| KR102186555B1 (ko) | 2013-07-12 | 2020-12-04 | 삼성전자주식회사 | 전자장치 및 전자장치의 정보 처리방법 |

| EP2918332A1 (en) * | 2014-03-14 | 2015-09-16 | Morten Müller Ltd., ApS | Scale collection and predistribution tray for vessel with downwards two-phase flow |

| CN105561887A (zh) * | 2014-10-10 | 2016-05-11 | 天津汇康源科技有限公司 | 化工反应釜的催化反应结构 |

| CN106554806B (zh) * | 2015-09-25 | 2018-08-10 | 中国石油天然气股份有限公司 | 膨松床反应器及重油轻质化方法 |

| CN105664805A (zh) * | 2016-01-15 | 2016-06-15 | 中航黎明锦西化工机械(集团)有限责任公司 | 滴流床反应器分布器 |

| CN106000242B (zh) * | 2016-06-23 | 2018-08-24 | 中国船舶重工集团公司第七一八研究所 | 一种具有自适应进气功能的催化床结构 |

| US10441932B2 (en) * | 2017-06-28 | 2019-10-15 | Uop Llc | Apparatus for vapor-liquid distribution |

| FR3072306B1 (fr) * | 2017-10-12 | 2019-10-18 | IFP Energies Nouvelles | Dispositif de melange et de distribution avec ouverture longitudinale |

| US11224849B2 (en) * | 2017-12-21 | 2022-01-18 | Uop Llc | Scale collection device for downflow reactors |

| US10556212B2 (en) * | 2017-12-21 | 2020-02-11 | Uop Llc | Scale collection device for downflow reactors |

| DE102018005694A1 (de) * | 2018-07-19 | 2020-01-23 | Linde Aktiengesellschaft | Stoff- und/oder Wärmeaustauschkolonne und Verfahren zur Behandlung eines ersten Fluids und eines zweiten Fluids unter Verwendung einer Stoff- und/oder Wärmeaustauschkolonne |

| EP3604261A1 (de) | 2018-08-02 | 2020-02-05 | Omv Refining & Marketing Gmbh | Verfahren zur aufreinigung von isobuten aus einem c4-strom und verfahrenstechnische anlage dafür |

| CN109200952B (zh) * | 2018-11-15 | 2021-04-27 | 中石化炼化工程(集团)股份有限公司 | 一种气液混合组件及用于反应器的催化剂床层结构 |

| US11298670B2 (en) * | 2020-04-24 | 2022-04-12 | Uop Llc | Compact quench zone reactor internals |

| CN114452901B (zh) * | 2020-10-21 | 2023-03-07 | 中国石油化工股份有限公司 | 催化反应单元以及反应蒸馏塔 |

| CN112387219A (zh) * | 2020-11-13 | 2021-02-23 | 华东理工大学 | 一种用于碳酸乙烯酯加氢的气化-反应一体化多段反应器 |

| CN116351234B (zh) * | 2023-03-23 | 2023-10-20 | 汇舸(南通)环保设备有限公司 | 烟气留驻时间延长装置及采用该装置的船用脱硫塔 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6669915B1 (en) * | 1999-07-13 | 2003-12-30 | Exxonmobil Research And Engineering Company | Gas-liquid inlet nozzle for cocurrent downflow reactors |

| RU2005112896A (ru) * | 2004-04-29 | 2006-11-10 | Оксено Олефинхеми Гмбх (De) | Способ и реактор для проведения каталитических реакций жидкостей с газами и распределительная тарелка для реаторов |

Family Cites Families (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2898292A (en) * | 1957-11-05 | 1959-08-04 | Socony Mobil Oil Co Inc | Method for distributing a vapor-liquid feed and apparatus therefor |

| US3146189A (en) * | 1960-12-06 | 1964-08-25 | Shell Oil Co | Distributing vapor-liquid feed to beds |

| US3502445A (en) * | 1966-11-02 | 1970-03-24 | Union Oil Co | Apparatus for mixing fluids in concurrent downflow relationship |

| US3541000A (en) * | 1968-08-27 | 1970-11-17 | Mobil Oil Corp | Method and means for treating mixed phase vapor and liquid reactants under exothermic reaction conditions and temperature control |

| CH658198A5 (de) * | 1983-01-04 | 1986-10-31 | Sulzer Ag | Fluessigkeitsverteiler in einer stoff- und waermeaustauschkolonne. |

| US4937051A (en) * | 1985-11-07 | 1990-06-26 | Mobil Oil Corporation | Catalytic reactor with liquid recycle |

| US4836989A (en) * | 1987-07-02 | 1989-06-06 | Mobil Oil Corporation | Distribution system for downflow reactors |

| US4808350A (en) * | 1987-08-26 | 1989-02-28 | The Dow Chemical Company | Liquid distributor apparatus for high turndown ratios and minimum fouling |

| US5246568A (en) * | 1989-06-01 | 1993-09-21 | Mobil Oil Corporation | Catalytic dewaxing process |

| US5232283A (en) * | 1992-10-13 | 1993-08-03 | The M. W. Kellogg Company | Apparatus for mixing concurrently, downwardly flowing fluids |

| US5484518A (en) * | 1994-03-04 | 1996-01-16 | Shipley Company Inc. | Electroplating process |

| US5484578A (en) * | 1994-06-20 | 1996-01-16 | Mobil Oil Corporation | Two-phase distributor system for downflow reactors |

| US5635145A (en) * | 1994-08-23 | 1997-06-03 | Shell Oil Company | Multi-bed downflow reactor |

| FR2724390B1 (fr) * | 1994-09-08 | 1996-12-13 | Inst Francais Du Petrole | Hydrogenation selective de coupes hydrocarbonees renfermant des hydrocarbures monoinsatures et polyinsatures |

| FR2807673B1 (fr) * | 2000-04-17 | 2003-07-04 | Inst Francais Du Petrole | Dispositif de distribution d'un melange polyphasique sur un lit de solide granulaire comportant un element brise-jet poreux |

| WO2002048286A1 (en) * | 2000-12-11 | 2002-06-20 | Shell Internationale Research Maatschappij B.V. | Mixing device comprising a swirl chamber for mixing liquid |

| US7112312B2 (en) * | 2001-04-02 | 2006-09-26 | Tai-Sheng Chou | Quench box for a multi-bed, mixed-phase cocurrent downflow fixed-bed reactor |

| FR2832075B1 (fr) * | 2001-11-09 | 2005-02-04 | Inst Francais Du Petrole | Dispositif de distribution d'un melange polyphasique sur un lit de solide granulaire comportant un element brise jet poreux a rebords |

| FR2842435B1 (fr) * | 2002-07-16 | 2004-09-24 | Inst Francais Du Petrole | Dispositif de melange et de distribution d'un fluide dense et d'un fluide leger place en amont d'un lit granulaire et son utilisation en ecoulement descendant |

| US7506861B2 (en) | 2005-01-21 | 2009-03-24 | Morten Muller Ltd. Aps | Distribution device for two-phase concurrent downflow vessels |

| FR2883200B1 (fr) * | 2005-03-17 | 2007-05-11 | Inst Francais Du Petrole | Dispositif pour le melange et la repartition d'un gaz et d' un liquide en amont d'un lit granulaire |

| CN2834690Y (zh) * | 2005-11-14 | 2006-11-08 | 中国石油化工集团公司 | 并流气液分配器 |

-

2008

- 2008-06-20 CN CN200880025631.1A patent/CN101778666B/zh active Active

- 2008-06-20 MY MYPI20095479A patent/MY147674A/en unknown

- 2008-06-20 TW TW097123243A patent/TWI458553B/zh active

- 2008-06-20 BR BRPI0812907-0A2A patent/BRPI0812907A2/pt active IP Right Grant

- 2008-06-20 AT AT08774160T patent/ATE520455T1/de active

- 2008-06-20 JP JP2010512698A patent/JP5276098B2/ja active Active

- 2008-06-20 KR KR1020107001360A patent/KR101509274B1/ko active Active

- 2008-06-20 US US12/665,533 patent/US9011790B2/en active Active

- 2008-06-20 WO PCT/EP2008/057832 patent/WO2008155399A1/de not_active Ceased

- 2008-06-20 CA CA2691642A patent/CA2691642C/en active Active

- 2008-06-20 RU RU2010101601/05A patent/RU2466784C2/ru not_active IP Right Cessation

- 2008-06-20 EP EP08774160A patent/EP2170494B1/de active Active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6669915B1 (en) * | 1999-07-13 | 2003-12-30 | Exxonmobil Research And Engineering Company | Gas-liquid inlet nozzle for cocurrent downflow reactors |

| RU2005112896A (ru) * | 2004-04-29 | 2006-11-10 | Оксено Олефинхеми Гмбх (De) | Способ и реактор для проведения каталитических реакций жидкостей с газами и распределительная тарелка для реаторов |

Also Published As

| Publication number | Publication date |

|---|---|

| BRPI0812907A2 (pt) | 2014-12-09 |

| ATE520455T1 (de) | 2011-09-15 |

| MY147674A (en) | 2012-12-31 |

| CA2691642A1 (en) | 2008-12-24 |

| TWI458553B (zh) | 2014-11-01 |

| CA2691642C (en) | 2015-12-22 |

| KR101509274B1 (ko) | 2015-04-06 |

| JP5276098B2 (ja) | 2013-08-28 |

| EP2170494A1 (de) | 2010-04-07 |

| WO2008155399A1 (de) | 2008-12-24 |

| JP2010530804A (ja) | 2010-09-16 |

| EP2170494B1 (de) | 2011-08-17 |

| RU2010101601A (ru) | 2011-07-27 |

| KR20100053503A (ko) | 2010-05-20 |

| TW200916192A (en) | 2009-04-16 |

| CN101778666A (zh) | 2010-07-14 |

| CN101778666B (zh) | 2012-10-10 |

| US9011790B2 (en) | 2015-04-21 |

| US20100185032A1 (en) | 2010-07-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| RU2466784C2 (ru) | Реактор для проведения трехфазной реакции жидкой и газообразной фаз в неподвижном слое катализатора | |

| RU2542248C2 (ru) | Устройство распределения потока текучей среды для каталитических реакторов с нисходящим потоком | |

| JP2010530804A5 (enExample) | ||

| CN100584442C (zh) | 下降流催化反应器 | |

| EP2767333B1 (en) | Mixing device with tangential inlets for two-phase concurrent vessels | |

| CN101391197B (zh) | 一种物流混合分配系统 | |

| JP4741237B2 (ja) | 2相並流用ベッセルに用いられるミキシング・デバイス | |

| JP5615812B2 (ja) | スプレーノズルを使用した改善された急冷ゾーン設計 | |

| CA2595478C (en) | Distribution device for two-phase concurrent downflow vessels | |

| CA2431271A1 (en) | Multiple bed downflow reactor | |

| MX2008013006A (es) | Bandeja de distribucion de fluido y metodo de distribucion de fluido de dispersion elevada a traves de un lecho de material de contacto. | |

| KR101608988B1 (ko) | 입상 베드를 구비하고 이 베드를 통해 본질적 액상 및 본질적 기상이 흐르는 처리 또는 수소화 처리용 반응기 | |

| JP2002172321A (ja) | 多相混合を行って同時に分配しうる2つの連続床の間に配置される流体の注入装置 | |

| CN105582857B (zh) | 一种气液固三相反应器及其应用方法 | |

| JP2004130301A (ja) | 粒状床の上流に配置される濃い流体と軽い流体との混合および分配装置、ならびに下降流における該装置の使用 | |

| KR20130112807A (ko) | 접선방향으로 급냉 유체가 주입되는 급냉 장치를 구비하는 촉매 반응기 | |

| CA1288374C (en) | Apparatus for mixing dispersed flows prior to their entry into a catalyst bed | |

| TW201628710A (zh) | 薄型流體混合裝置 | |

| RU53589U1 (ru) | Распределитель жидкости для колонн | |

| CN109985575A (zh) | 具有减冲组件的加氢反应器 | |

| TW314479B (enExample) | ||

| JP2023544287A (ja) | 化学原料分配器及びそれを使用する方法 | |

| BRPI0812907B1 (pt) | Reactor and process to perform a three-phase reaction of a liquid phase and a gaseous phase on a fixed-lay catalyst, and, using the reactor. | |

| KR20200068648A (ko) | 종방향 개구를 갖는 혼합 및 분배 디바이스 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| MM4A | The patent is invalid due to non-payment of fees |

Effective date: 20170621 |