RU2392449C2 - Турбина, содержащая сменные носители истираемого уплотнения для создания уплотнения между вращающимся и стационарным компонентами турбины - Google Patents

Турбина, содержащая сменные носители истираемого уплотнения для создания уплотнения между вращающимся и стационарным компонентами турбины Download PDFInfo

- Publication number

- RU2392449C2 RU2392449C2 RU2005140142/06A RU2005140142A RU2392449C2 RU 2392449 C2 RU2392449 C2 RU 2392449C2 RU 2005140142/06 A RU2005140142/06 A RU 2005140142/06A RU 2005140142 A RU2005140142 A RU 2005140142A RU 2392449 C2 RU2392449 C2 RU 2392449C2

- Authority

- RU

- Russia

- Prior art keywords

- diaphragm

- sealing

- seal

- sealing surface

- turbine

- Prior art date

Links

- 238000007789 sealing Methods 0.000 title claims abstract description 63

- 239000000969 carrier Substances 0.000 title description 7

- 239000000463 material Substances 0.000 claims abstract description 25

- 238000005299 abrasion Methods 0.000 claims description 6

- 238000000605 extraction Methods 0.000 claims 1

- 239000003566 sealing material Substances 0.000 claims 1

- 230000003247 decreasing effect Effects 0.000 abstract 1

- 230000000694 effects Effects 0.000 abstract 1

- 239000000126 substance Substances 0.000 abstract 1

- 239000003082 abrasive agent Substances 0.000 description 3

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- 229910052582 BN Inorganic materials 0.000 description 1

- PZNSFCLAULLKQX-UHFFFAOYSA-N Boron nitride Chemical compound N#B PZNSFCLAULLKQX-UHFFFAOYSA-N 0.000 description 1

- HOXABWNBYWQOAK-UHFFFAOYSA-N [Cr]=[Y] Chemical compound [Cr]=[Y] HOXABWNBYWQOAK-UHFFFAOYSA-N 0.000 description 1

- 230000000712 assembly Effects 0.000 description 1

- 238000000429 assembly Methods 0.000 description 1

- 238000005219 brazing Methods 0.000 description 1

- 229910017052 cobalt Inorganic materials 0.000 description 1

- 239000010941 cobalt Substances 0.000 description 1

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000013011 mating Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 238000005192 partition Methods 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 230000003252 repetitive effect Effects 0.000 description 1

- 230000001052 transient effect Effects 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

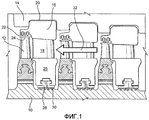

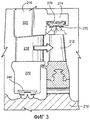

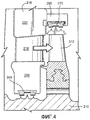

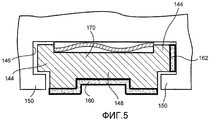

- F01D11/00—Preventing or minimising internal leakage of working-fluid, e.g. between stages

- F01D11/08—Preventing or minimising internal leakage of working-fluid, e.g. between stages for sealing space between rotor blade tips and stator

- F01D11/12—Preventing or minimising internal leakage of working-fluid, e.g. between stages for sealing space between rotor blade tips and stator using a rubstrip, e.g. erodible. deformable or resiliently-biased part

- F01D11/122—Preventing or minimising internal leakage of working-fluid, e.g. between stages for sealing space between rotor blade tips and stator using a rubstrip, e.g. erodible. deformable or resiliently-biased part with erodable or abradable material

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D11/00—Preventing or minimising internal leakage of working-fluid, e.g. between stages

- F01D11/001—Preventing or minimising internal leakage of working-fluid, e.g. between stages for sealing space between stator blade and rotor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/22—Blade-to-blade connections, e.g. for damping vibrations

- F01D5/225—Blade-to-blade connections, e.g. for damping vibrations by shrouding

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/017,661 | 2004-12-22 | ||

| US11/017,661 US7287956B2 (en) | 2004-12-22 | 2004-12-22 | Removable abradable seal carriers for sealing between rotary and stationary turbine components |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| RU2005140142A RU2005140142A (ru) | 2007-06-27 |

| RU2392449C2 true RU2392449C2 (ru) | 2010-06-20 |

Family

ID=36585717

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| RU2005140142/06A RU2392449C2 (ru) | 2004-12-22 | 2005-12-21 | Турбина, содержащая сменные носители истираемого уплотнения для создания уплотнения между вращающимся и стационарным компонентами турбины |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US7287956B2 (enExample) |

| JP (1) | JP4740730B2 (enExample) |

| CN (1) | CN1800589B (enExample) |

| FR (1) | FR2879649B1 (enExample) |

| IT (1) | ITMI20052424A1 (enExample) |

| RU (1) | RU2392449C2 (enExample) |

Families Citing this family (57)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10348290A1 (de) * | 2003-10-17 | 2005-05-12 | Mtu Aero Engines Gmbh | Dichtungsanordnung für eine Gasturbine |

| DE102004044803A1 (de) * | 2004-09-16 | 2006-03-30 | WINKLER + DüNNEBIER AG | Sich selbst einstellende Spaltdichtung zwischen zwei sich gegeneinander beweglicher Bauteile |

| US20070132193A1 (en) * | 2005-12-13 | 2007-06-14 | Wolfe Christopher E | Compliant abradable sealing system and method for rotary machines |

| US20070248452A1 (en) * | 2006-04-25 | 2007-10-25 | Brisson Bruce W | Retractable compliant abradable sealing system and method for rotary machines |

| US20080050222A1 (en) * | 2006-08-23 | 2008-02-28 | General Electric Company | Singlet welded nozzle hybrid design for a turbine |

| JP2008169705A (ja) * | 2007-01-09 | 2008-07-24 | Toshiba Corp | 蒸気タービン |

| US7713024B2 (en) * | 2007-02-09 | 2010-05-11 | General Electric Company | Bling nozzle/carrier interface design for a steam turbine |

| US8038388B2 (en) * | 2007-03-05 | 2011-10-18 | United Technologies Corporation | Abradable component for a gas turbine engine |

| CN101328815B (zh) * | 2007-06-22 | 2011-09-21 | 齐传正 | 一种自由环接触式无间隙密封结构 |

| US20090053042A1 (en) * | 2007-08-22 | 2009-02-26 | General Electric Company | Method and apparatus for clearance control of turbine blade tip |

| JP4668976B2 (ja) * | 2007-12-04 | 2011-04-13 | 株式会社日立製作所 | 蒸気タービンのシール構造 |

| US8257015B2 (en) * | 2008-02-14 | 2012-09-04 | General Electric Company | Apparatus for cooling rotary components within a steam turbine |

| US20090206554A1 (en) * | 2008-02-18 | 2009-08-20 | Mark Kevin Bowen | Steam turbine engine and method of assembling same |

| JP2009236038A (ja) * | 2008-03-27 | 2009-10-15 | Toshiba Corp | 蒸気タービン |

| RU2403418C2 (ru) * | 2008-05-27 | 2010-11-10 | Закрытое акционерное общество "Уральский турбинный завод" | Уплотнение статора турбины |

| US9004495B2 (en) * | 2008-09-15 | 2015-04-14 | Stein Seal Company | Segmented intershaft seal assembly |

| US8052380B2 (en) * | 2008-10-29 | 2011-11-08 | General Electric Company | Thermally-activated clearance reduction for a steam turbine |

| US8021103B2 (en) * | 2008-10-29 | 2011-09-20 | General Electric Company | Pressure activated flow path seal for a steam turbine |

| DE102008060706A1 (de) * | 2008-12-05 | 2010-06-10 | Man Turbo Ag | Düsensegment für eine Dampfturbine |

| US8262349B2 (en) * | 2008-12-22 | 2012-09-11 | General Electric Company | Adaptive compliant plate seal assemblies and methods |

| JP5411569B2 (ja) * | 2009-05-01 | 2014-02-12 | 株式会社日立製作所 | シール構造とその制御方法 |

| US8172519B2 (en) * | 2009-05-06 | 2012-05-08 | General Electric Company | Abradable seals |

| EP2444701B1 (en) * | 2009-06-16 | 2020-07-01 | Mitsubishi Hitachi Power Systems, Ltd. | Shaft seal device |

| JP5210984B2 (ja) * | 2009-06-29 | 2013-06-12 | 株式会社日立製作所 | タービン用高信頼性メタルシール材 |

| US20110070072A1 (en) * | 2009-09-23 | 2011-03-24 | General Electric Company | Rotary machine tip clearance control mechanism |

| KR101016210B1 (ko) | 2009-10-27 | 2011-02-25 | 조정봉 | 스팀 터빈 및 스팀 터빈용 펌프 씰 |

| IT1397706B1 (it) | 2009-12-22 | 2013-01-24 | Nuovo Pignone Spa | Tenuta che si puo' abradere con spostamento assiale. |

| RU2447294C2 (ru) * | 2010-02-02 | 2012-04-10 | Сергей Владимирович Ушинин | Вставка сотового надбандажного уплотнения паровой турбины и способ установки вставок сотового надбандажного уплотнения |

| FR2961564B1 (fr) | 2010-06-17 | 2016-03-04 | Snecma | Compresseur et turbomachine a rendement optimise |

| JP5087147B2 (ja) * | 2011-01-13 | 2012-11-28 | 株式会社日立製作所 | 蒸気タービン |

| US20120195742A1 (en) * | 2011-01-28 | 2012-08-02 | Jain Sanjeev Kumar | Turbine bucket for use in gas turbine engines and methods for fabricating the same |

| DE102012005771B4 (de) | 2011-03-25 | 2022-06-30 | General Electric Technology Gmbh | Dichtvorrichtung für drehende Turbinenschaufeln |

| US9109458B2 (en) * | 2011-11-11 | 2015-08-18 | United Technologies Corporation | Turbomachinery seal |

| DE102011087207A1 (de) | 2011-11-28 | 2013-05-29 | Aktiebolaget Skf | Labyrinthdichtung mit unterschiedlich verschleißenden Labyrinthringen |

| JP5518032B2 (ja) | 2011-12-13 | 2014-06-11 | 三菱重工業株式会社 | タービン、及びシール構造 |

| US9080459B2 (en) * | 2012-01-03 | 2015-07-14 | General Electric Company | Forward step honeycomb seal for turbine shroud |

| JP5567077B2 (ja) * | 2012-08-23 | 2014-08-06 | 三菱重工業株式会社 | 回転機械 |

| US9726031B2 (en) | 2012-09-28 | 2017-08-08 | United Technologies Corporation | Piston ring coated carbon seal |

| JP5951449B2 (ja) * | 2012-11-02 | 2016-07-13 | 株式会社東芝 | 蒸気タービン |

| CZ305014B6 (cs) * | 2013-05-22 | 2015-03-25 | Doosan Ĺ koda Power s.r.o. | Uložení segmentového odtahovacího těsnění ve statoru turbíny |

| US20150040567A1 (en) * | 2013-08-08 | 2015-02-12 | General Electric Company | Systems and Methods for Reducing or Limiting One or More Flows Between a Hot Gas Path and a Wheel Space of a Turbine |

| US10119410B2 (en) | 2013-10-03 | 2018-11-06 | United Technologies Corporation | Vane seal system having spring positively locating seal member in axial direction |

| EP3052766B1 (en) | 2013-10-03 | 2019-02-27 | United Technologies Corporation | Vane seal system and seal therefor |

| US9394801B2 (en) | 2013-10-07 | 2016-07-19 | General Electric Company | Adjustable turbine seal and method of assembling same |

| US9429041B2 (en) | 2014-05-14 | 2016-08-30 | General Electric Company | Turbomachine component displacement apparatus and method of use |

| FR3047075B1 (fr) * | 2016-01-27 | 2018-02-23 | Safran Aircraft Engines | Piece de revolution pour banc d'essai de turbine ou pour turbomachine, banc d'essais de turbines comprenant ladite piece, et procede les utilisant |

| WO2016179608A2 (en) * | 2016-04-29 | 2016-11-10 | Stein Seal Company | Intershaft seal with asymmetric sealing ring |

| US10598035B2 (en) * | 2016-05-27 | 2020-03-24 | General Electric Company | Intershaft sealing systems for gas turbine engines and methods for assembling the same |

| FR3058756B1 (fr) * | 2016-11-15 | 2020-10-16 | Safran Aircraft Engines | Turbine pour turbomachine |

| FR3058755B1 (fr) * | 2016-11-15 | 2020-09-25 | Safran Aircraft Engines | Turbine pour turbomachine |

| FR3068070B1 (fr) | 2017-06-26 | 2019-07-19 | Safran Aircraft Engines | Turbine pour turbomachine |

| JP7051656B2 (ja) * | 2018-09-28 | 2022-04-11 | 三菱重工コンプレッサ株式会社 | タービンステータ、蒸気タービン、及び仕切板 |

| CN110761848A (zh) * | 2019-12-16 | 2020-02-07 | 中国船舶重工集团公司第七0三研究所 | 一种燃气轮机压气机静叶环 |

| CN112610335B (zh) * | 2020-12-21 | 2021-12-31 | 杭州汽轮动力集团有限公司 | 一种燃气轮机涡轮盘腔密封结构 |

| US11913340B2 (en) | 2022-06-17 | 2024-02-27 | Rtx Corporation | Air seal system with backside abradable layer |

| US20250264040A1 (en) * | 2024-02-20 | 2025-08-21 | Ge Infrastructure Technology Llc | Axially adjustable inserted ring and method of using same |

| JP7729967B1 (ja) * | 2024-11-18 | 2025-08-26 | 三菱重工業株式会社 | シールフィンの補修方法 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4094673A (en) * | 1974-02-28 | 1978-06-13 | Brunswick Corporation | Abradable seal material and composition thereof |

| US4897021A (en) * | 1988-06-02 | 1990-01-30 | United Technologies Corporation | Stator vane asssembly for an axial flow rotary machine |

| EP0382333A1 (en) * | 1989-01-09 | 1990-08-16 | Northern Engineering Industries Plc | Mounting arrangement of segmental members in rotary machines |

| US5501573A (en) * | 1993-01-29 | 1996-03-26 | Steam Specialties, Inc. | Segmented seal assembly and method for retrofitting the same to turbines and the like |

| RU2153112C2 (ru) * | 1998-08-25 | 2000-07-20 | Акционерное общество открытого типа "Ленинградский Металлический завод" | Сотовое уплотнение радиального зазора турбомашины |

Family Cites Families (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2044692A (en) * | 1933-11-25 | 1936-06-16 | Huhn Gustav | Packing for the shafts of steam turbines |

| US2600991A (en) * | 1949-06-14 | 1952-06-17 | Gen Electric | Labyrinth seal arrangement |

| US3501246A (en) * | 1967-12-29 | 1970-03-17 | Westinghouse Electric Corp | Axial fluid-flow machine |

| US3867060A (en) * | 1973-09-27 | 1975-02-18 | Gen Electric | Shroud assembly |

| GB1567886A (en) * | 1978-02-23 | 1980-05-21 | Mono Pumps Ltd | Bore hole pumps |

| JPS63123701A (ja) * | 1986-11-10 | 1988-05-27 | 太田 博康 | ゴミ自動パツク収容器の自動セツト用ゴミパツク製造装置 |

| US5002288A (en) * | 1988-10-13 | 1991-03-26 | General Electric Company | Positive variable clearance labyrinth seal |

| US5462403A (en) * | 1994-03-21 | 1995-10-31 | United Technologies Corporation | Compressor stator vane assembly |

| US5599026A (en) * | 1995-09-06 | 1997-02-04 | Innovative Technology, L.L.C. | Turbine seal with sealing strip and rubbing strip |

| US5785492A (en) * | 1997-03-24 | 1998-07-28 | United Technologies Corporation | Method and apparatus for sealing a gas turbine stator vane assembly |

| GB9808656D0 (en) * | 1998-04-23 | 1998-06-24 | Rolls Royce Plc | Fluid seal |

| SG72959A1 (en) * | 1998-06-18 | 2000-05-23 | United Technologies Corp | Article having durable ceramic coating with localized abradable portion |

| JP2001123803A (ja) * | 1999-10-21 | 2001-05-08 | Toshiba Corp | シール装置並びに同装置を備えた蒸気タービン及び発電プラント |

| JP3662198B2 (ja) * | 2001-02-28 | 2005-06-22 | ロナルド・イー・ブランドン | シャフト摩擦の間の力を減少させるための特別のバネを持つ流体タービン用の非伸縮式の分割されたパッキングリング |

| JP2002285802A (ja) * | 2001-03-26 | 2002-10-03 | Toshiba Corp | 回転機械のラビリンスシール装置 |

| US6547522B2 (en) * | 2001-06-18 | 2003-04-15 | General Electric Company | Spring-backed abradable seal for turbomachinery |

| JP2003214113A (ja) * | 2002-01-28 | 2003-07-30 | Toshiba Corp | 地熱タービン |

| US6655696B1 (en) * | 2002-06-28 | 2003-12-02 | General Electric Company | Seal carrier for a rotary machine and method of retrofitting |

| US6722846B2 (en) * | 2002-07-30 | 2004-04-20 | General Electric Company | Endface gap sealing of steam turbine bucket tip static seal segments and retrofitting thereof |

| JP2004332616A (ja) * | 2003-05-07 | 2004-11-25 | Toshiba Corp | 軸流型ターボ機械 |

| GB0319002D0 (en) * | 2003-05-13 | 2003-09-17 | Alstom Switzerland Ltd | Improvements in or relating to steam turbines |

| US6896482B2 (en) * | 2003-09-03 | 2005-05-24 | General Electric Company | Expanding sealing strips for steam turbines |

-

2004

- 2004-12-22 US US11/017,661 patent/US7287956B2/en not_active Expired - Lifetime

-

2005

- 2005-12-20 FR FR0512921A patent/FR2879649B1/fr not_active Expired - Fee Related

- 2005-12-20 IT IT002424A patent/ITMI20052424A1/it unknown

- 2005-12-20 JP JP2005365711A patent/JP4740730B2/ja not_active Expired - Lifetime

- 2005-12-21 RU RU2005140142/06A patent/RU2392449C2/ru active

- 2005-12-22 CN CN2005101338745A patent/CN1800589B/zh not_active Expired - Lifetime

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4094673A (en) * | 1974-02-28 | 1978-06-13 | Brunswick Corporation | Abradable seal material and composition thereof |

| US4897021A (en) * | 1988-06-02 | 1990-01-30 | United Technologies Corporation | Stator vane asssembly for an axial flow rotary machine |

| EP0382333A1 (en) * | 1989-01-09 | 1990-08-16 | Northern Engineering Industries Plc | Mounting arrangement of segmental members in rotary machines |

| US5501573A (en) * | 1993-01-29 | 1996-03-26 | Steam Specialties, Inc. | Segmented seal assembly and method for retrofitting the same to turbines and the like |

| RU2153112C2 (ru) * | 1998-08-25 | 2000-07-20 | Акционерное общество открытого типа "Ленинградский Металлический завод" | Сотовое уплотнение радиального зазора турбомашины |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1800589B (zh) | 2010-06-02 |

| FR2879649B1 (fr) | 2012-09-21 |

| CN1800589A (zh) | 2006-07-12 |

| US7287956B2 (en) | 2007-10-30 |

| FR2879649A1 (fr) | 2006-06-23 |

| JP2006177355A (ja) | 2006-07-06 |

| JP4740730B2 (ja) | 2011-08-03 |

| US20060133928A1 (en) | 2006-06-22 |

| ITMI20052424A1 (it) | 2006-06-23 |

| RU2005140142A (ru) | 2007-06-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| RU2392449C2 (ru) | Турбина, содержащая сменные носители истираемого уплотнения для создания уплотнения между вращающимся и стационарным компонентами турбины | |

| KR950006875B1 (ko) | 브러쉬 시일 | |

| KR100733175B1 (ko) | 환형 터빈 밀봉체 및 회전 기계 | |

| KR100854193B1 (ko) | 시일 및 증기 글랜드 | |

| US6790001B2 (en) | Brush seal arrangement for high pressure applications | |

| US20040239040A1 (en) | Nozzle interstage seal for steam turbines | |

| US20070245532A1 (en) | Grouped reaction nozzle tip shrouds with integrated seals | |

| US8167313B2 (en) | Seal member, assembly and method | |

| US8388310B1 (en) | Turbine disc sealing assembly | |

| CA2909467A1 (en) | Flexible film-riding seal | |

| US20080018054A1 (en) | Aspirating labyrinth seal | |

| JP2003106105A (ja) | 軸シール機構及びタービン | |

| US20130181408A1 (en) | Brush seal arrangement combined with honeycomb seal | |

| US6951339B2 (en) | Brush seal for static turbine components | |

| EP1510655A1 (en) | Brush seal support | |

| JP2004060657A (ja) | 蒸気タービンダイアフラムの段間パッキンシールのための端面間隙シール及びそれを組込む方法 | |

| CA2591249A1 (en) | Aspirating labyrinth seal | |

| US6910857B2 (en) | Seal | |

| US9103224B2 (en) | Compliant plate seal for use with rotating machines and methods of assembling a rotating machine | |

| CN102996258B (zh) | 不连续的环密封件 | |

| US20060228209A1 (en) | Abradable seal between a turbine rotor and a stationary component | |

| JP7181994B2 (ja) | 回転防止特徴を有する非接触シール | |

| US11795822B2 (en) | Rotor arrangement for a gas turbine with inclined axial contact surfaces formed on rotor segments, gas turbine and aircraft gas turbine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| QB4A | Licence on use of patent |

Free format text: LICENCE Effective date: 20130315 |

|

| QB4A | Licence on use of patent |

Free format text: LICENCE Effective date: 20140829 |