RU2213605C2 - Способ гидрообессеривания нафты в дистиляционном колонном реакторе (варианты) - Google Patents

Способ гидрообессеривания нафты в дистиляционном колонном реакторе (варианты) Download PDFInfo

- Publication number

- RU2213605C2 RU2213605C2 RU2001109433/04A RU2001109433A RU2213605C2 RU 2213605 C2 RU2213605 C2 RU 2213605C2 RU 2001109433/04 A RU2001109433/04 A RU 2001109433/04A RU 2001109433 A RU2001109433 A RU 2001109433A RU 2213605 C2 RU2213605 C2 RU 2213605C2

- Authority

- RU

- Russia

- Prior art keywords

- naphtha

- distillation column

- hydrogen

- column reactor

- boiling

- Prior art date

Links

- 238000004821 distillation Methods 0.000 title claims abstract description 138

- 238000000034 method Methods 0.000 title claims description 37

- 238000006477 desulfuration reaction Methods 0.000 title abstract description 5

- 230000023556 desulfurization Effects 0.000 title abstract description 5

- 239000001257 hydrogen Substances 0.000 claims abstract description 70

- 229910052739 hydrogen Inorganic materials 0.000 claims abstract description 70

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 claims abstract description 68

- 239000003054 catalyst Substances 0.000 claims abstract description 65

- 150000001875 compounds Chemical class 0.000 claims abstract description 29

- 238000001704 evaporation Methods 0.000 claims abstract description 27

- 230000008020 evaporation Effects 0.000 claims abstract description 25

- 125000001741 organic sulfur group Chemical group 0.000 claims abstract description 16

- 229930195733 hydrocarbon Natural products 0.000 claims abstract description 7

- 150000002430 hydrocarbons Chemical class 0.000 claims abstract description 7

- 239000004215 Carbon black (E152) Substances 0.000 claims abstract description 5

- 230000003993 interaction Effects 0.000 claims abstract 4

- 230000009834 selective interaction Effects 0.000 claims abstract 4

- 238000009835 boiling Methods 0.000 claims description 97

- 239000007788 liquid Substances 0.000 claims description 14

- 238000001556 precipitation Methods 0.000 claims description 14

- 238000010992 reflux Methods 0.000 claims description 10

- 239000002244 precipitate Substances 0.000 claims description 9

- 150000002898 organic sulfur compounds Chemical class 0.000 claims description 3

- 210000004072 lung Anatomy 0.000 claims 4

- 238000001816 cooling Methods 0.000 claims 3

- 238000004064 recycling Methods 0.000 claims 3

- 238000000926 separation method Methods 0.000 abstract description 4

- 230000000694 effects Effects 0.000 abstract description 2

- 239000000126 substance Substances 0.000 abstract description 2

- 239000003208 petroleum Substances 0.000 abstract 1

- 239000013049 sediment Substances 0.000 abstract 1

- 238000004519 manufacturing process Methods 0.000 description 39

- 239000011593 sulfur Substances 0.000 description 32

- 229910052717 sulfur Inorganic materials 0.000 description 32

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 description 31

- 238000006243 chemical reaction Methods 0.000 description 22

- 230000008569 process Effects 0.000 description 20

- 239000000047 product Substances 0.000 description 19

- 238000012545 processing Methods 0.000 description 17

- 150000001336 alkenes Chemical class 0.000 description 15

- 239000010410 layer Substances 0.000 description 14

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 12

- RWSOTUBLDIXVET-UHFFFAOYSA-N Dihydrogen sulfide Chemical compound S RWSOTUBLDIXVET-UHFFFAOYSA-N 0.000 description 11

- 238000010586 diagram Methods 0.000 description 11

- 229910052751 metal Inorganic materials 0.000 description 10

- 239000002184 metal Substances 0.000 description 10

- 239000000463 material Substances 0.000 description 9

- 239000002994 raw material Substances 0.000 description 9

- 238000009825 accumulation Methods 0.000 description 8

- 239000007789 gas Substances 0.000 description 8

- 239000003921 oil Substances 0.000 description 8

- JRZJOMJEPLMPRA-UHFFFAOYSA-N olefin Natural products CCCCCCCC=C JRZJOMJEPLMPRA-UHFFFAOYSA-N 0.000 description 7

- 239000000203 mixture Substances 0.000 description 6

- 238000000746 purification Methods 0.000 description 6

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 5

- 230000003197 catalytic effect Effects 0.000 description 5

- 238000005984 hydrogenation reaction Methods 0.000 description 5

- 150000002739 metals Chemical class 0.000 description 5

- TVMXDCGIABBOFY-UHFFFAOYSA-N octane Chemical compound CCCCCCCC TVMXDCGIABBOFY-UHFFFAOYSA-N 0.000 description 5

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 4

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 4

- 239000002245 particle Substances 0.000 description 4

- LSDPWZHWYPCBBB-UHFFFAOYSA-N Methanethiol Chemical compound SC LSDPWZHWYPCBBB-UHFFFAOYSA-N 0.000 description 3

- 230000008901 benefit Effects 0.000 description 3

- 238000004523 catalytic cracking Methods 0.000 description 3

- 150000005673 monoalkenes Chemical class 0.000 description 3

- -1 olefin compounds Chemical class 0.000 description 3

- 230000001590 oxidative effect Effects 0.000 description 3

- 239000011241 protective layer Substances 0.000 description 3

- 238000002407 reforming Methods 0.000 description 3

- 238000009423 ventilation Methods 0.000 description 3

- PMBXCGGQNSVESQ-UHFFFAOYSA-N 1-Hexanethiol Chemical compound CCCCCCS PMBXCGGQNSVESQ-UHFFFAOYSA-N 0.000 description 2

- BDFAOUQQXJIZDG-UHFFFAOYSA-N 2-methylpropane-1-thiol Chemical compound CC(C)CS BDFAOUQQXJIZDG-UHFFFAOYSA-N 0.000 description 2

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 2

- GIJGXNFNUUFEGH-UHFFFAOYSA-N Isopentyl mercaptan Chemical compound CC(C)CCS GIJGXNFNUUFEGH-UHFFFAOYSA-N 0.000 description 2

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 description 2

- KDLHZDBZIXYQEI-UHFFFAOYSA-N Palladium Chemical compound [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 description 2

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 2

- 230000009471 action Effects 0.000 description 2

- 239000002199 base oil Substances 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- LOCHFZBWPCLPAN-UHFFFAOYSA-N butane-2-thiol Chemical compound CCC(C)S LOCHFZBWPCLPAN-UHFFFAOYSA-N 0.000 description 2

- WQAQPCDUOCURKW-UHFFFAOYSA-N butanethiol Chemical compound CCCCS WQAQPCDUOCURKW-UHFFFAOYSA-N 0.000 description 2

- 229910017052 cobalt Inorganic materials 0.000 description 2

- 239000010941 cobalt Substances 0.000 description 2

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 description 2

- 238000005336 cracking Methods 0.000 description 2

- 150000002019 disulfides Chemical class 0.000 description 2

- DNJIEGIFACGWOD-UHFFFAOYSA-N ethanethiol Chemical compound CCS DNJIEGIFACGWOD-UHFFFAOYSA-N 0.000 description 2

- 239000012535 impurity Substances 0.000 description 2

- 239000007791 liquid phase Substances 0.000 description 2

- 229910052750 molybdenum Inorganic materials 0.000 description 2

- 239000011733 molybdenum Substances 0.000 description 2

- 229910052759 nickel Inorganic materials 0.000 description 2

- KJRCEJOSASVSRA-UHFFFAOYSA-N propane-2-thiol Chemical compound CC(C)S KJRCEJOSASVSRA-UHFFFAOYSA-N 0.000 description 2

- 230000001681 protective effect Effects 0.000 description 2

- 229920006395 saturated elastomer Polymers 0.000 description 2

- 239000000377 silicon dioxide Substances 0.000 description 2

- 150000003464 sulfur compounds Chemical class 0.000 description 2

- ZRKMQKLGEQPLNS-UHFFFAOYSA-N 1-Pentanethiol Chemical compound CCCCCS ZRKMQKLGEQPLNS-UHFFFAOYSA-N 0.000 description 1

- JBGWMRAMUROVND-UHFFFAOYSA-N 1-sulfanylidenethiophene Chemical class S=S1C=CC=C1 JBGWMRAMUROVND-UHFFFAOYSA-N 0.000 description 1

- QUSTYFNPKBDELJ-UHFFFAOYSA-N 2-Pentanethiol Chemical compound CCCC(C)S QUSTYFNPKBDELJ-UHFFFAOYSA-N 0.000 description 1

- BKOOMYPCSUNDGP-UHFFFAOYSA-N 2-methylbut-2-ene Chemical group CC=C(C)C BKOOMYPCSUNDGP-UHFFFAOYSA-N 0.000 description 1

- MCMNRKCIXSYSNV-UHFFFAOYSA-N ZrO2 Inorganic materials O=[Zr]=O MCMNRKCIXSYSNV-UHFFFAOYSA-N 0.000 description 1

- 150000001335 aliphatic alkanes Chemical class 0.000 description 1

- 239000003513 alkali Substances 0.000 description 1

- 229910021529 ammonia Inorganic materials 0.000 description 1

- 150000001491 aromatic compounds Chemical class 0.000 description 1

- 125000003118 aryl group Chemical group 0.000 description 1

- 239000002585 base Substances 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 238000004517 catalytic hydrocracking Methods 0.000 description 1

- 238000001833 catalytic reforming Methods 0.000 description 1

- 239000003518 caustics Substances 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- 239000003153 chemical reaction reagent Substances 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- WHDPTDWLEKQKKX-UHFFFAOYSA-N cobalt molybdenum Chemical compound [Co].[Co].[Mo] WHDPTDWLEKQKKX-UHFFFAOYSA-N 0.000 description 1

- 238000004939 coking Methods 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 239000012141 concentrate Substances 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 150000001923 cyclic compounds Chemical class 0.000 description 1

- 125000004122 cyclic group Chemical group 0.000 description 1

- 230000009849 deactivation Effects 0.000 description 1

- 150000001993 dienes Chemical class 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 230000032050 esterification Effects 0.000 description 1

- 238000005886 esterification reaction Methods 0.000 description 1

- 150000002148 esters Chemical class 0.000 description 1

- 238000011010 flushing procedure Methods 0.000 description 1

- 238000005194 fractionation Methods 0.000 description 1

- 239000007792 gaseous phase Substances 0.000 description 1

- 150000002391 heterocyclic compounds Chemical class 0.000 description 1

- ABNPJVOPTXYSQW-UHFFFAOYSA-N hexane-2-thiol Chemical compound CCCCC(C)S ABNPJVOPTXYSQW-UHFFFAOYSA-N 0.000 description 1

- VOIGMFQJDZTEKW-UHFFFAOYSA-N hexane-3-thiol Chemical compound CCCC(S)CC VOIGMFQJDZTEKW-UHFFFAOYSA-N 0.000 description 1

- 150000002431 hydrogen Chemical class 0.000 description 1

- 125000004435 hydrogen atom Chemical group [H]* 0.000 description 1

- 229910000037 hydrogen sulfide Inorganic materials 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 230000002262 irrigation Effects 0.000 description 1

- 238000003973 irrigation Methods 0.000 description 1

- 238000006317 isomerization reaction Methods 0.000 description 1

- 238000002386 leaching Methods 0.000 description 1

- 238000011068 loading method Methods 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 229910044991 metal oxide Inorganic materials 0.000 description 1

- 150000004706 metal oxides Chemical class 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- DDTIGTPWGISMKL-UHFFFAOYSA-N molybdenum nickel Chemical compound [Ni].[Mo] DDTIGTPWGISMKL-UHFFFAOYSA-N 0.000 description 1

- 230000007935 neutral effect Effects 0.000 description 1

- MOWMLACGTDMJRV-UHFFFAOYSA-N nickel tungsten Chemical compound [Ni].[W] MOWMLACGTDMJRV-UHFFFAOYSA-N 0.000 description 1

- 150000002897 organic nitrogen compounds Chemical class 0.000 description 1

- 229910052763 palladium Inorganic materials 0.000 description 1

- 239000012188 paraffin wax Substances 0.000 description 1

- WICKAMSPKJXSGN-UHFFFAOYSA-N pentane-3-thiol Chemical compound CCC(S)CC WICKAMSPKJXSGN-UHFFFAOYSA-N 0.000 description 1

- 230000000737 periodic effect Effects 0.000 description 1

- 125000003367 polycyclic group Chemical group 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 229920000098 polyolefin Polymers 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- SUVIGLJNEAMWEG-UHFFFAOYSA-N propane-1-thiol Chemical compound CCCS SUVIGLJNEAMWEG-UHFFFAOYSA-N 0.000 description 1

- 238000012552 review Methods 0.000 description 1

- 238000007086 side reaction Methods 0.000 description 1

- 235000012239 silicon dioxide Nutrition 0.000 description 1

- 239000011949 solid catalyst Substances 0.000 description 1

- 238000000638 solvent extraction Methods 0.000 description 1

- 238000004227 thermal cracking Methods 0.000 description 1

- 229930192474 thiophene Natural products 0.000 description 1

- 150000003577 thiophenes Chemical class 0.000 description 1

- 239000004408 titanium dioxide Substances 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 1

- 229910052721 tungsten Inorganic materials 0.000 description 1

- 239000010937 tungsten Substances 0.000 description 1

- 239000012808 vapor phase Substances 0.000 description 1

- 238000005406 washing Methods 0.000 description 1

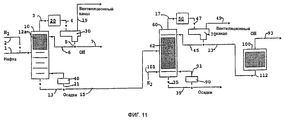

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10G—CRACKING HYDROCARBON OILS; PRODUCTION OF LIQUID HYDROCARBON MIXTURES, e.g. BY DESTRUCTIVE HYDROGENATION, OLIGOMERISATION, POLYMERISATION; RECOVERY OF HYDROCARBON OILS FROM OIL-SHALE, OIL-SAND, OR GASES; REFINING MIXTURES MAINLY CONSISTING OF HYDROCARBONS; REFORMING OF NAPHTHA; MINERAL WAXES

- C10G35/00—Reforming naphtha

- C10G35/04—Catalytic reforming

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10G—CRACKING HYDROCARBON OILS; PRODUCTION OF LIQUID HYDROCARBON MIXTURES, e.g. BY DESTRUCTIVE HYDROGENATION, OLIGOMERISATION, POLYMERISATION; RECOVERY OF HYDROCARBON OILS FROM OIL-SHALE, OIL-SAND, OR GASES; REFINING MIXTURES MAINLY CONSISTING OF HYDROCARBONS; REFORMING OF NAPHTHA; MINERAL WAXES

- C10G45/00—Refining of hydrocarbon oils using hydrogen or hydrogen-generating compounds

- C10G45/02—Refining of hydrocarbon oils using hydrogen or hydrogen-generating compounds to eliminate hetero atoms without changing the skeleton of the hydrocarbon involved and without cracking into lower boiling hydrocarbons; Hydrofinishing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D3/00—Distillation or related exchange processes in which liquids are contacted with gaseous media, e.g. stripping

- B01D3/009—Distillation or related exchange processes in which liquids are contacted with gaseous media, e.g. stripping in combination with chemical reactions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D3/00—Distillation or related exchange processes in which liquids are contacted with gaseous media, e.g. stripping

- B01D3/14—Fractional distillation or use of a fractionation or rectification column

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10G—CRACKING HYDROCARBON OILS; PRODUCTION OF LIQUID HYDROCARBON MIXTURES, e.g. BY DESTRUCTIVE HYDROGENATION, OLIGOMERISATION, POLYMERISATION; RECOVERY OF HYDROCARBON OILS FROM OIL-SHALE, OIL-SAND, OR GASES; REFINING MIXTURES MAINLY CONSISTING OF HYDROCARBONS; REFORMING OF NAPHTHA; MINERAL WAXES

- C10G2300/00—Aspects relating to hydrocarbon processing covered by groups C10G1/00 - C10G99/00

- C10G2300/40—Characteristics of the process deviating from typical ways of processing

- C10G2300/4087—Catalytic distillation

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10G—CRACKING HYDROCARBON OILS; PRODUCTION OF LIQUID HYDROCARBON MIXTURES, e.g. BY DESTRUCTIVE HYDROGENATION, OLIGOMERISATION, POLYMERISATION; RECOVERY OF HYDROCARBON OILS FROM OIL-SHALE, OIL-SAND, OR GASES; REFINING MIXTURES MAINLY CONSISTING OF HYDROCARBONS; REFORMING OF NAPHTHA; MINERAL WAXES

- C10G2400/00—Products obtained by processes covered by groups C10G9/00 - C10G69/14

- C10G2400/02—Gasoline

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Engineering & Computer Science (AREA)

- General Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Production Of Liquid Hydrocarbon Mixture For Refining Petroleum (AREA)

- Vaporization, Distillation, Condensation, Sublimation, And Cold Traps (AREA)

- Catalysts (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US09/150,573 | 1998-09-10 | ||

| US09/150,573 US6083378A (en) | 1998-09-10 | 1998-09-10 | Process for the simultaneous treatment and fractionation of light naphtha hydrocarbon streams |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| RU2001109433A RU2001109433A (ru) | 2003-09-27 |

| RU2213605C2 true RU2213605C2 (ru) | 2003-10-10 |

Family

ID=22535133

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| RU2001109433/04A RU2213605C2 (ru) | 1998-09-10 | 1999-08-10 | Способ гидрообессеривания нафты в дистиляционном колонном реакторе (варианты) |

Country Status (18)

| Country | Link |

|---|---|

| US (1) | US6083378A (enExample) |

| EP (2) | EP1119400A4 (enExample) |

| JP (1) | JP4642233B2 (enExample) |

| KR (2) | KR100650822B1 (enExample) |

| CN (1) | CN1158126C (enExample) |

| AR (1) | AR020232A1 (enExample) |

| AU (1) | AU747336B2 (enExample) |

| BR (1) | BR9913211A (enExample) |

| CA (1) | CA2343110C (enExample) |

| EG (1) | EG22245A (enExample) |

| ID (1) | ID29625A (enExample) |

| MY (1) | MY121370A (enExample) |

| RO (2) | RO123255B1 (enExample) |

| RU (1) | RU2213605C2 (enExample) |

| SA (1) | SA99200615B1 (enExample) |

| TW (1) | TW460569B (enExample) |

| WO (1) | WO2000015319A1 (enExample) |

| ZA (1) | ZA995211B (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2387696C2 (ru) * | 2005-10-31 | 2010-04-27 | Каталитик Дистиллейшн Текнолоджиз | Обработка лигроина флюид-каталитического крекинга (fcc) |

Families Citing this family (58)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7513989B1 (en) | 1997-07-15 | 2009-04-07 | Exxonmobil Research And Engineering Company | Hydrocracking process using bulk group VIII/Group VIB catalysts |

| US7232515B1 (en) | 1997-07-15 | 2007-06-19 | Exxonmobil Research And Engineering Company | Hydrofining process using bulk group VIII/Group VIB catalysts |

| US7288182B1 (en) | 1997-07-15 | 2007-10-30 | Exxonmobil Research And Engineering Company | Hydroprocessing using bulk Group VIII/Group VIB catalysts |

| US7229548B2 (en) * | 1997-07-15 | 2007-06-12 | Exxonmobil Research And Engineering Company | Process for upgrading naphtha |

| US6413413B1 (en) * | 1998-12-31 | 2002-07-02 | Catalytic Distillation Technologies | Hydrogenation process |

| US6231752B1 (en) * | 1999-09-17 | 2001-05-15 | Catalytic Distillation Technologies | Process for the removal of mercaptans |

| US6303020B1 (en) | 2000-01-07 | 2001-10-16 | Catalytic Distillation Technologies | Process for the desulfurization of petroleum feeds |

| US6946068B2 (en) * | 2000-06-09 | 2005-09-20 | Catalytic Distillation Technologies | Process for desulfurization of cracked naphtha |

| FR2811328B1 (fr) * | 2000-07-06 | 2002-08-23 | Inst Francais Du Petrole | Procede comprenant deux etapes d'hydrodesulfuration d'essence et une elimination intermediaire de l'h2s forme au cours de la premiere etape |

| US6416659B1 (en) * | 2000-08-17 | 2002-07-09 | Catalytic Distillation Technologies | Process for the production of an ultra low sulfur |

| US6495030B1 (en) * | 2000-10-03 | 2002-12-17 | Catalytic Distillation Technologies | Process for the desulfurization of FCC naphtha |

| US6416658B1 (en) | 2000-10-19 | 2002-07-09 | Catalytic Distillation Technologies | Process for simultaneous hydrotreating and splitting of naphtha streams |

| US6444118B1 (en) * | 2001-02-16 | 2002-09-03 | Catalytic Distillation Technologies | Process for sulfur reduction in naphtha streams |

| US6676830B1 (en) | 2001-09-17 | 2004-01-13 | Catalytic Distillation Technologies | Process for the desulfurization of a light FCC naphtha |

| FR2830869B1 (fr) * | 2001-10-12 | 2004-07-09 | Inst Francais Du Petrole | Procede d'hydrodesulfuration comprenant une section de stripage et une section de fractionnement sous vide |

| JP2005509727A (ja) * | 2001-11-22 | 2005-04-14 | アンスティテュ フランセ デュ ペトロール | 精留を伴うストリッピングによる中間分留を含む、中間留出物を水素化処理するための2段プロセス |

| US6913688B2 (en) * | 2001-11-30 | 2005-07-05 | Exxonmobil Research And Engineering Company | Multi-stage hydrodesulfurization of cracked naphtha streams with interstage fractionation |

| US7261809B2 (en) * | 2001-12-28 | 2007-08-28 | Catalytic Distillation Technologies | Process for ultra low sulfur gasoline |

| US7153415B2 (en) * | 2002-02-13 | 2006-12-26 | Catalytic Distillation Technologies | Process for the treatment of light naphtha hydrocarbon streams |

| US6824676B1 (en) | 2002-03-08 | 2004-11-30 | Catalytic Distillation Technologies | Process for the selective desulfurization of a mid range gasoline cut |

| US6867338B2 (en) * | 2002-03-15 | 2005-03-15 | Catalytic Distillation Technologies | Selective hydrogenation of acetylenes and dienes in a hydrocarbon stream |

| US6881324B2 (en) * | 2002-03-16 | 2005-04-19 | Catalytic Distillation Technologies | Process for the simultaneous hydrotreating and fractionation of light naphtha hydrocarbon streams |

| US7090767B2 (en) * | 2002-05-02 | 2006-08-15 | Equistar Chemicals, Lp | Hydrodesulfurization of gasoline fractions |

| US7553997B2 (en) * | 2002-08-22 | 2009-06-30 | Catalytic Distillation Technologies | Hydrogenation of olefinic feedstocks |

| US6984312B2 (en) * | 2002-11-22 | 2006-01-10 | Catalytic Distillation Technologies | Process for the desulfurization of light FCC naphtha |

| US20040129606A1 (en) * | 2003-01-07 | 2004-07-08 | Catalytic Distillation Technologies | HDS process using selected naphtha streams |

| US7722832B2 (en) * | 2003-03-25 | 2010-05-25 | Crystaphase International, Inc. | Separation method and assembly for process streams in component separation units |

| US7122114B2 (en) * | 2003-07-14 | 2006-10-17 | Christopher Dean | Desulfurization of a naphtha gasoline stream derived from a fluid catalytic cracking unit |

| US20050035026A1 (en) * | 2003-08-14 | 2005-02-17 | Conocophillips Company | Catalytic distillation hydroprocessing |

| CN1313576C (zh) * | 2003-09-15 | 2007-05-02 | 中国石油化工股份有限公司 | 一种劣质汽油加氢处理方法 |

| CN1313575C (zh) * | 2003-09-15 | 2007-05-02 | 中国石油化工股份有限公司 | 一种劣质汽油加氢改质方法 |

| US7118151B2 (en) * | 2004-05-07 | 2006-10-10 | Ford Global Technologies, Llc | Automotive wet trunk with drain |

| US7431827B2 (en) * | 2004-10-27 | 2008-10-07 | Catalytic Distillation Technologies | Process for the production of low sulfur, low olefin gasoline |

| US7638041B2 (en) * | 2005-02-14 | 2009-12-29 | Catalytic Distillation Technologies | Process for treating cracked naphtha streams |

| US20080116053A1 (en) * | 2006-11-20 | 2008-05-22 | Abb Lummus Global Inc. | Non-refluxing reactor stripper |

| AR066680A1 (es) * | 2007-05-25 | 2009-09-02 | Shell Int Research | Un proceso para remover azufre de una corriente de gas combustible, que tambien contiene dioxido de carbono y olefinas livianas |

| AR066682A1 (es) * | 2007-05-25 | 2009-09-02 | Shell Int Research | Un proceso para remover azufre a partir de sendas corrientes de gas de combustible, menos reactivas y mas reactivas que contienen azufre organico y olefinas livianas |

| AR066681A1 (es) * | 2007-05-25 | 2009-09-02 | Shell Int Research | Un proceso para remover azufre de una corriente de gas combustible |

| US7708956B2 (en) * | 2007-09-07 | 2010-05-04 | Uop Llc | Combination hot separator and reactor vessel for simultaneously desulfurizing two vapor streams |

| US8043495B2 (en) | 2008-01-25 | 2011-10-25 | Catalytic Distillation Technologies | Process to hydrodesulfurize FCC gasoline resulting in a low-mercaptan product |

| US8236172B2 (en) | 2008-01-25 | 2012-08-07 | Catalytic Distillation Technologies | Process to hydrodesulfurize FCC gasoline resulting in a low-mercaptan product |

| US7927480B2 (en) * | 2008-01-29 | 2011-04-19 | Catalytic Distillation Technologies | Process for desulfurization of cracked naphtha |

| US8357291B2 (en) * | 2008-02-11 | 2013-01-22 | Exxonmobil Upstream Research Company | Upgrading bitumen in a paraffinic froth treatment process |

| KR101133331B1 (ko) * | 2008-11-04 | 2012-04-06 | 에스케이이노베이션 주식회사 | 석유계탄화수소 유황 제거 공정의 와일드 납사 중의 황화수소 스트리핑 장치 |

| US8486258B2 (en) | 2010-04-01 | 2013-07-16 | Catalytic Distillation Technologies | Gasoline hydrodesulfurization and membrane unit to reduce mercaptan type sulfur |

| US8628656B2 (en) * | 2010-08-25 | 2014-01-14 | Catalytic Distillation Technologies | Hydrodesulfurization process with selected liquid recycle to reduce formation of recombinant mercaptans |

| US9321972B2 (en) * | 2011-05-02 | 2016-04-26 | Saudi Arabian Oil Company | Energy-efficient and environmentally advanced configurations for naptha hydrotreating process |

| FR2993569B1 (fr) * | 2012-07-17 | 2015-12-04 | IFP Energies Nouvelles | Procede de desulfuration d'une essence |

| SG11201501303XA (en) | 2012-08-21 | 2015-05-28 | Catalytic Distillation Tech | Selective hydrodesulfurization of fcc gasoline to below 10 ppm sulfur |

| US20140353209A1 (en) * | 2013-05-29 | 2014-12-04 | Uop, Llc | Process for treating a naphtha stream |

| US10144883B2 (en) | 2013-11-14 | 2018-12-04 | Uop Llc | Apparatuses and methods for desulfurization of naphtha |

| US10273420B2 (en) * | 2014-10-27 | 2019-04-30 | Uop Llc | Process for hydrotreating a hydrocarbons stream |

| US10308883B2 (en) * | 2015-10-07 | 2019-06-04 | Axens | Process for desulfurizing cracked naphtha |

| TWI746500B (zh) | 2016-01-22 | 2021-11-21 | 美商愛克瑪公司 | 使用分隔壁塔蒸餾純化硫醇或噻吩 |

| FR3056598B1 (fr) * | 2016-09-28 | 2018-10-12 | IFP Energies Nouvelles | Procede de traitement d'une essence de pyrolyse |

| CN108211403B (zh) * | 2016-12-21 | 2024-01-09 | 中国石油化工股份有限公司 | 烷基化反应产物分离装置及分离方法 |

| CN113072974A (zh) * | 2021-04-29 | 2021-07-06 | 华叙飞 | 一种石油烃加氢脱硫催化反应蒸馏工艺及设备 |

| KR102662917B1 (ko) * | 2023-06-14 | 2024-05-03 | (주)디케이유업 | 중유a 대체용 친환경 재활용유 제조방법 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4731229A (en) * | 1985-05-14 | 1988-03-15 | Sulzer Brothers Limited | Reactor and packing element for catalyzed chemical reactions |

| US5073236A (en) * | 1989-11-13 | 1991-12-17 | Gelbein Abraham P | Process and structure for effecting catalytic reactions in distillation structure |

| US5266546A (en) * | 1992-06-22 | 1993-11-30 | Chemical Research & Licensing Company | Catalytic distillation machine |

| US5431890A (en) * | 1994-01-31 | 1995-07-11 | Chemical Research & Licensing Company | Catalytic distillation structure |

| RU2074233C1 (ru) * | 1994-06-29 | 1997-02-27 | Всероссийский научно-исследовательский институт по переработке нефти | Способ получения реактивного топлива |

| US5730843A (en) * | 1995-12-29 | 1998-03-24 | Chemical Research & Licensing Company | Catalytic distillation structure |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2897141A (en) * | 1959-07-28 | Hydrodesulfurization of reformer charge | ||

| US3124526A (en) * | 1964-03-10 | Rhigh boiling | ||

| US3717571A (en) * | 1970-11-03 | 1973-02-20 | Exxon Research Engineering Co | Hydrogen purification and recycle in hydrogenating heavy mineral oils |

| US4243519A (en) * | 1979-02-14 | 1981-01-06 | Exxon Research & Engineering Co. | Hydrorefining process |

| US4246094A (en) * | 1979-06-11 | 1981-01-20 | Standard Oil Company (Indiana) | Process for upgrading naphtha hydrocarbons |

| GB8910711D0 (en) * | 1989-05-10 | 1989-06-28 | Davy Mckee London | Process |

| US5320742A (en) * | 1991-08-15 | 1994-06-14 | Mobil Oil Corporation | Gasoline upgrading process |

| JPH0734073A (ja) * | 1993-07-23 | 1995-02-03 | Jgc Corp | 石油類の水素化処理方法及び水素化処理装置 |

| US5510568A (en) * | 1994-06-17 | 1996-04-23 | Chemical Research & Licensing Company | Process for the removal of mercaptans and hydrogen sulfide from hydrocarbon streams |

| US5629451A (en) * | 1994-06-30 | 1997-05-13 | Chemical Research & Licensing Company | Reduction of nitrile contaminants by selective hydrogenation |

| US5599441A (en) * | 1995-05-31 | 1997-02-04 | Mobil Oil Corporation | Alkylation process for desulfurization of gasoline |

| US5779883A (en) * | 1995-07-10 | 1998-07-14 | Catalytic Distillation Technologies | Hydrodesulfurization process utilizing a distillation column realtor |

| US5595634A (en) * | 1995-07-10 | 1997-01-21 | Chemical Research & Licensing Company | Process for selective hydrogenation of highly unsaturated compounds and isomerization of olefins in hydrocarbon streams |

| US5597476A (en) * | 1995-08-28 | 1997-01-28 | Chemical Research & Licensing Company | Gasoline desulfurization process |

| US5877363A (en) * | 1996-09-23 | 1999-03-02 | Catalytic Distillation Technologies | Process for concurrent selective hydrogenation of acetylenes and 1,2 butadine in hydrocarbon streams |

-

1998

- 1998-09-10 US US09/150,573 patent/US6083378A/en not_active Expired - Lifetime

-

1999

- 1999-08-10 CN CNB998106623A patent/CN1158126C/zh not_active Expired - Lifetime

- 1999-08-10 CA CA002343110A patent/CA2343110C/en not_active Expired - Lifetime

- 1999-08-10 EP EP99941026A patent/EP1119400A4/en not_active Ceased

- 1999-08-10 EP EP05010905A patent/EP1579900A1/en not_active Withdrawn

- 1999-08-10 JP JP2000569899A patent/JP4642233B2/ja not_active Expired - Lifetime

- 1999-08-10 WO PCT/US1999/018148 patent/WO2000015319A1/en not_active Ceased

- 1999-08-10 ID IDW20010569A patent/ID29625A/id unknown

- 1999-08-10 RO ROA200600340A patent/RO123255B1/ro unknown

- 1999-08-10 RU RU2001109433/04A patent/RU2213605C2/ru active

- 1999-08-10 BR BR9913211-7A patent/BR9913211A/pt not_active Application Discontinuation

- 1999-08-10 KR KR1020067001981A patent/KR100650822B1/ko not_active Expired - Fee Related

- 1999-08-10 KR KR1020017002998A patent/KR100605197B1/ko not_active Expired - Fee Related

- 1999-08-10 AU AU54756/99A patent/AU747336B2/en not_active Ceased

- 1999-08-10 RO ROA200100250A patent/RO120887B1/ro unknown

- 1999-08-16 ZA ZA9905211A patent/ZA995211B/xx unknown

- 1999-08-20 AR ARP990104182A patent/AR020232A1/es active IP Right Grant

- 1999-08-26 TW TW088114614A patent/TW460569B/zh not_active IP Right Cessation

- 1999-09-04 EG EG110799A patent/EG22245A/xx active

- 1999-09-09 MY MYPI99003901A patent/MY121370A/en unknown

- 1999-09-26 SA SA99200615A patent/SA99200615B1/ar unknown

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4731229A (en) * | 1985-05-14 | 1988-03-15 | Sulzer Brothers Limited | Reactor and packing element for catalyzed chemical reactions |

| US5073236A (en) * | 1989-11-13 | 1991-12-17 | Gelbein Abraham P | Process and structure for effecting catalytic reactions in distillation structure |

| US5266546A (en) * | 1992-06-22 | 1993-11-30 | Chemical Research & Licensing Company | Catalytic distillation machine |

| US5431890A (en) * | 1994-01-31 | 1995-07-11 | Chemical Research & Licensing Company | Catalytic distillation structure |

| RU2074233C1 (ru) * | 1994-06-29 | 1997-02-27 | Всероссийский научно-исследовательский институт по переработке нефти | Способ получения реактивного топлива |

| US5730843A (en) * | 1995-12-29 | 1998-03-24 | Chemical Research & Licensing Company | Catalytic distillation structure |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2387696C2 (ru) * | 2005-10-31 | 2010-04-27 | Каталитик Дистиллейшн Текнолоджиз | Обработка лигроина флюид-каталитического крекинга (fcc) |

Also Published As

| Publication number | Publication date |

|---|---|

| ID29625A (id) | 2001-09-06 |

| EP1119400A1 (en) | 2001-08-01 |

| BR9913211A (pt) | 2001-05-22 |

| TW460569B (en) | 2001-10-21 |

| KR100605197B1 (ko) | 2006-07-28 |

| RO123255B1 (ro) | 2011-04-29 |

| CN1158126C (zh) | 2004-07-21 |

| KR20060015700A (ko) | 2006-02-17 |

| AR020232A1 (es) | 2002-05-02 |

| KR100650822B1 (ko) | 2006-11-30 |

| CA2343110A1 (en) | 2000-03-23 |

| CN1316914A (zh) | 2001-10-10 |

| RO120887B1 (ro) | 2006-09-29 |

| SA99200615B1 (ar) | 2006-09-25 |

| AU747336B2 (en) | 2002-05-16 |

| JP4642233B2 (ja) | 2011-03-02 |

| AU5475699A (en) | 2000-04-03 |

| CA2343110C (en) | 2008-06-10 |

| EP1119400A4 (en) | 2002-04-24 |

| US6083378A (en) | 2000-07-04 |

| JP2002524613A (ja) | 2002-08-06 |

| EG22245A (en) | 2002-11-30 |

| WO2000015319A1 (en) | 2000-03-23 |

| MY121370A (en) | 2006-01-28 |

| EP1579900A1 (en) | 2005-09-28 |

| ZA995211B (en) | 2000-02-18 |

| KR20010089225A (ko) | 2001-09-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| RU2213605C2 (ru) | Способ гидрообессеривания нафты в дистиляционном колонном реакторе (варианты) | |

| US7927480B2 (en) | Process for desulfurization of cracked naphtha | |

| RU2389754C2 (ru) | Способ получения бензина с низкими содержаниями серы и олефинов | |

| US8486258B2 (en) | Gasoline hydrodesulfurization and membrane unit to reduce mercaptan type sulfur | |

| RU2333934C2 (ru) | Усовершенствованный способ гидродесульфуризации с использованием выбранных потоков нафты | |

| EA017890B1 (ru) | Способ снижения содержания серы в углеводородном потоке (варианты) | |

| JP2001525007A (ja) | ベンゼンをアルキル化するための方法 | |

| WO2010027987A2 (en) | Process for ultra low benzene reformate using catalytic distillation | |

| RU2330874C2 (ru) | Способ одновременной гидроочистки и фракционирования потоков углеводородов легкой нафты | |

| US20040178123A1 (en) | Process for the hydrodesulfurization of naphtha | |

| CN100494321C (zh) | 加氢脱硫方法 | |

| RU2346976C1 (ru) | Способ переработки потоков крекированного лигроина | |

| RU2241021C2 (ru) | Способ гидродесульфуризации нефтяного сырья, способ гидродесульфуризации крекированной нафты(варианты) | |

| US7261809B2 (en) | Process for ultra low sulfur gasoline | |

| EA008904B1 (ru) | Способ десульфурации жидкой, каталитически крекированной легкой нафты |