KR860000484B1 - 금속제 용기의 제조 방법 - Google Patents

금속제 용기의 제조 방법 Download PDFInfo

- Publication number

- KR860000484B1 KR860000484B1 KR1019810002611A KR810002611A KR860000484B1 KR 860000484 B1 KR860000484 B1 KR 860000484B1 KR 1019810002611 A KR1019810002611 A KR 1019810002611A KR 810002611 A KR810002611 A KR 810002611A KR 860000484 B1 KR860000484 B1 KR 860000484B1

- Authority

- KR

- South Korea

- Prior art keywords

- roller

- seam

- winding

- end plate

- flange

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D7/00—Containers having bodies formed by interconnecting or uniting two or more rigid, or substantially rigid, components made wholly or mainly of metal

- B65D7/12—Containers having bodies formed by interconnecting or uniting two or more rigid, or substantially rigid, components made wholly or mainly of metal characterised by wall construction or by connections between walls

- B65D7/34—Containers having bodies formed by interconnecting or uniting two or more rigid, or substantially rigid, components made wholly or mainly of metal characterised by wall construction or by connections between walls with permanent connections between walls

- B65D7/36—Containers having bodies formed by interconnecting or uniting two or more rigid, or substantially rigid, components made wholly or mainly of metal characterised by wall construction or by connections between walls with permanent connections between walls formed by rolling, or by rolling and pressing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D39/00—Application of procedures in order to connect objects or parts, e.g. coating with sheet metal otherwise than by plating; Tube expanders

- B21D39/02—Application of procedures in order to connect objects or parts, e.g. coating with sheet metal otherwise than by plating; Tube expanders of sheet metal by folding, e.g. connecting edges of a sheet to form a cylinder

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D51/00—Making hollow objects

- B21D51/16—Making hollow objects characterised by the use of the objects

- B21D51/26—Making hollow objects characterised by the use of the objects cans or tins; Closing same in a permanent manner

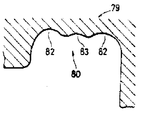

- B21D51/30—Folding the circumferential seam

- B21D51/32—Folding the circumferential seam by rolling

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Rigid Containers With Two Or More Constituent Elements (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP63986 | 1981-04-30 | ||

| JP56063986A JPS57183947A (en) | 1981-04-30 | 1981-04-30 | Vessel made of metal, its manufacture and its device |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR830005921A KR830005921A (ko) | 1983-09-14 |

| KR860000484B1 true KR860000484B1 (ko) | 1986-04-30 |

Family

ID=13245108

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1019810002611A Expired KR860000484B1 (ko) | 1981-04-30 | 1981-07-18 | 금속제 용기의 제조 방법 |

Country Status (6)

| Country | Link |

|---|---|

| JP (1) | JPS57183947A (enExample) |

| KR (1) | KR860000484B1 (enExample) |

| AU (1) | AU542114B2 (enExample) |

| GB (1) | GB2097748B (enExample) |

| IN (1) | IN152442B (enExample) |

| PH (1) | PH18088A (enExample) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4952271A (en) * | 1989-06-26 | 1990-08-28 | Signode Corporation | Apparatus for forming an offset joint in flexible thermoplastic strap |

| KR970707018A (ko) * | 1994-11-14 | 1997-12-01 | 리터 하르트무트, 배제 헬가 | 캔(can)용 계단 외형구조의 씨임(seam)(STEPPED FOLD FOR A CAN) |

| KR20010100516A (ko) * | 2000-05-03 | 2001-11-14 | 조광범 | 금속제 바구니의 제조방법 및 그 바구니 |

| JP2002168577A (ja) * | 2000-12-05 | 2002-06-14 | Furukawa Electric Co Ltd:The | ヒートパイプの製造方法 |

| JP4908788B2 (ja) * | 2005-06-30 | 2012-04-04 | トヨタ自動車株式会社 | 管状部材の製造方法及び製造装置 |

| JP5377471B2 (ja) * | 2010-10-14 | 2013-12-25 | ユニバーサル製缶株式会社 | 缶の二重巻締め部構造 |

| JP2011073065A (ja) * | 2011-01-17 | 2011-04-14 | Toyota Motor Corp | 管状部材の製造方法及び製造装置 |

| CN107900235B (zh) * | 2017-11-24 | 2023-09-08 | 安徽鲲鹏装备模具制造有限公司 | 一种用于冷柜内胆底板圆角铆接的铆接机构 |

| CN107900236B (zh) * | 2017-11-24 | 2023-10-20 | 安徽鲲鹏装备模具制造有限公司 | 一种冷柜内胆的底板四圆角铆接设备 |

| CN109013796B (zh) * | 2018-09-30 | 2024-05-24 | 凯龙高科技股份有限公司 | 一种管材卷边装置 |

-

1981

- 1981-04-30 JP JP56063986A patent/JPS57183947A/ja active Granted

- 1981-06-25 AU AU72140/81A patent/AU542114B2/en not_active Ceased

- 1981-07-18 KR KR1019810002611A patent/KR860000484B1/ko not_active Expired

- 1981-07-30 PH PH25984A patent/PH18088A/en unknown

- 1981-09-30 IN IN1097/CAL/81A patent/IN152442B/en unknown

- 1981-12-31 GB GB8139178A patent/GB2097748B/en not_active Expired

Also Published As

| Publication number | Publication date |

|---|---|

| GB2097748A (en) | 1982-11-10 |

| GB2097748B (en) | 1985-10-02 |

| JPS627056B2 (enExample) | 1987-02-14 |

| IN152442B (enExample) | 1984-01-14 |

| JPS57183947A (en) | 1982-11-12 |

| PH18088A (en) | 1985-03-20 |

| AU7214081A (en) | 1982-11-04 |

| KR830005921A (ko) | 1983-09-14 |

| AU542114B2 (en) | 1985-02-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3960709B2 (ja) | ダブルシームが施された複合材コンテナ | |

| KR860000484B1 (ko) | 금속제 용기의 제조 방법 | |

| JP5021859B2 (ja) | 強化した側壁を有する缶端部およびそれを作る装置と方法 | |

| US5911551A (en) | Containers | |

| AU2004278366B2 (en) | Can shell and double-seamed can end | |

| US4578007A (en) | Reforming necked-in portions of can bodies | |

| EP0365063B1 (en) | Method of manufacturing a seam connection | |

| CN1321862C (zh) | 罐壳以及双重卷边的罐端 | |

| EP1603802B1 (en) | Seaming apparatus and method for cans | |

| JPH05177285A (ja) | 耐圧性の板金製端末閉鎖部材 | |

| JP2004514561A (ja) | 缶ふた及びその二重継ぎ目を形成する方法 | |

| EP1907287B1 (en) | Can lid closure and method of joining a can lid closure to a can body | |

| JP2003520135A (ja) | 缶閉鎖ふたと缶閉鎖ふたを缶本体に接合する方法 | |

| CN1606521A (zh) | 再成型的罐端部及其制造方法 | |

| AU2002354810A1 (en) | Can shell and double-seamed can end | |

| US4626158A (en) | Container seam and a process for forming a container seam | |

| ZA200602202B (en) | Can shell and double seamed can end | |

| EP0243107B1 (en) | Bottom seam for a pail | |

| US4540323A (en) | Metal containers and their manufacturing method and apparatus | |

| GB2166410A (en) | Seaming ends to containers | |

| US4543025A (en) | Metal containers - their manufacturing methods | |

| WO1997023312A1 (en) | Containers | |

| JPH032745B2 (enExample) | ||

| JPS6058336A (ja) | 金属製容器およびその製造方法 | |

| JPH0343349A (ja) | 角缶多重巻締方法及び缶 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0109 | Patent application |

St.27 status event code: A-0-1-A10-A12-nap-PA0109 |

|

| PG1501 | Laying open of application |

St.27 status event code: A-1-1-Q10-Q12-nap-PG1501 |

|

| R17-X000 | Change to representative recorded |

St.27 status event code: A-3-3-R10-R17-oth-X000 |

|

| PE0902 | Notice of grounds for rejection |

St.27 status event code: A-1-2-D10-D21-exm-PE0902 |

|

| T11-X000 | Administrative time limit extension requested |

St.27 status event code: U-3-3-T10-T11-oth-X000 |

|

| P11-X000 | Amendment of application requested |

St.27 status event code: A-2-2-P10-P11-nap-X000 |

|

| P13-X000 | Application amended |

St.27 status event code: A-2-2-P10-P13-nap-X000 |

|

| PE0902 | Notice of grounds for rejection |

St.27 status event code: A-1-2-D10-D21-exm-PE0902 |

|

| R17-X000 | Change to representative recorded |

St.27 status event code: A-3-3-R10-R17-oth-X000 |

|

| T11-X000 | Administrative time limit extension requested |

St.27 status event code: U-3-3-T10-T11-oth-X000 |

|

| P11-X000 | Amendment of application requested |

St.27 status event code: A-2-2-P10-P11-nap-X000 |

|

| P13-X000 | Application amended |

St.27 status event code: A-2-2-P10-P13-nap-X000 |

|

| PE0902 | Notice of grounds for rejection |

St.27 status event code: A-1-2-D10-D21-exm-PE0902 |

|

| T11-X000 | Administrative time limit extension requested |

St.27 status event code: U-3-3-T10-T11-oth-X000 |

|

| PG1605 | Publication of application before grant of patent |

St.27 status event code: A-2-2-Q10-Q13-nap-PG1605 |

|

| PE0701 | Decision of registration |

St.27 status event code: A-1-2-D10-D22-exm-PE0701 |

|

| PR0701 | Registration of establishment |

St.27 status event code: A-2-4-F10-F11-exm-PR0701 |

|

| PR1002 | Payment of registration fee |

St.27 status event code: A-2-2-U10-U11-oth-PR1002 Fee payment year number: 1 |

|

| PC1903 | Unpaid annual fee |

St.27 status event code: A-4-4-U10-U13-oth-PC1903 Not in force date: 19890501 Payment event data comment text: Termination Category : DEFAULT_OF_REGISTRATION_FEE |

|

| PC1903 | Unpaid annual fee |

St.27 status event code: N-4-6-H10-H13-oth-PC1903 Ip right cessation event data comment text: Termination Category : DEFAULT_OF_REGISTRATION_FEE Not in force date: 19890501 |