KR20180098684A - 에디 전류 테스트 프로브의 자동 위치잡기를 위한 장치 - Google Patents

에디 전류 테스트 프로브의 자동 위치잡기를 위한 장치 Download PDFInfo

- Publication number

- KR20180098684A KR20180098684A KR1020187024283A KR20187024283A KR20180098684A KR 20180098684 A KR20180098684 A KR 20180098684A KR 1020187024283 A KR1020187024283 A KR 1020187024283A KR 20187024283 A KR20187024283 A KR 20187024283A KR 20180098684 A KR20180098684 A KR 20180098684A

- Authority

- KR

- South Korea

- Prior art keywords

- tube

- gripper

- grippers

- robot

- housing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66C—CRANES; LOAD-ENGAGING ELEMENTS OR DEVICES FOR CRANES, CAPSTANS, WINCHES, OR TACKLES

- B66C1/00—Load-engaging elements or devices attached to lifting or lowering gear of cranes or adapted for connection therewith for transmitting lifting forces to articles or groups of articles

- B66C1/10—Load-engaging elements or devices attached to lifting or lowering gear of cranes or adapted for connection therewith for transmitting lifting forces to articles or groups of articles by mechanical means

- B66C1/42—Gripping members engaging only the external or internal surfaces of the articles

- B66C1/44—Gripping members engaging only the external or internal surfaces of the articles and applying frictional forces

- B66C1/54—Internally-expanding grippers for handling hollow articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25J—MANIPULATORS; CHAMBERS PROVIDED WITH MANIPULATION DEVICES

- B25J15/00—Gripping heads and other end effectors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66C—CRANES; LOAD-ENGAGING ELEMENTS OR DEVICES FOR CRANES, CAPSTANS, WINCHES, OR TACKLES

- B66C1/00—Load-engaging elements or devices attached to lifting or lowering gear of cranes or adapted for connection therewith for transmitting lifting forces to articles or groups of articles

- B66C1/10—Load-engaging elements or devices attached to lifting or lowering gear of cranes or adapted for connection therewith for transmitting lifting forces to articles or groups of articles by mechanical means

- B66C1/42—Gripping members engaging only the external or internal surfaces of the articles

- B66C1/44—Gripping members engaging only the external or internal surfaces of the articles and applying frictional forces

- B66C1/54—Internally-expanding grippers for handling hollow articles

- B66C1/56—Internally-expanding grippers for handling hollow articles for handling tubes

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F22—STEAM GENERATION

- F22B—METHODS OF STEAM GENERATION; STEAM BOILERS

- F22B37/00—Component parts or details of steam boilers

- F22B37/002—Component parts or details of steam boilers specially adapted for nuclear steam generators, e.g. maintenance, repairing or inspecting equipment not otherwise provided for

- F22B37/003—Maintenance, repairing or inspecting equipment positioned in or via the headers

- F22B37/005—Positioning apparatus specially adapted therefor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F22—STEAM GENERATION

- F22B—METHODS OF STEAM GENERATION; STEAM BOILERS

- F22B37/00—Component parts or details of steam boilers

- F22B37/002—Component parts or details of steam boilers specially adapted for nuclear steam generators, e.g. maintenance, repairing or inspecting equipment not otherwise provided for

- F22B37/006—Walking equipment, e.g. walking platforms suspended at the tube sheet

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01D—MEASURING NOT SPECIALLY ADAPTED FOR A SPECIFIC VARIABLE; ARRANGEMENTS FOR MEASURING TWO OR MORE VARIABLES NOT COVERED IN A SINGLE OTHER SUBCLASS; TARIFF METERING APPARATUS; MEASURING OR TESTING NOT OTHERWISE PROVIDED FOR

- G01D11/00—Component parts of measuring arrangements not specially adapted for a specific variable

- G01D11/30—Supports specially adapted for an instrument; Supports specially adapted for a set of instruments

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01M—TESTING STATIC OR DYNAMIC BALANCE OF MACHINES OR STRUCTURES; TESTING OF STRUCTURES OR APPARATUS, NOT OTHERWISE PROVIDED FOR

- G01M5/00—Investigating the elasticity of structures, e.g. deflection of bridges or air-craft wings

- G01M5/0025—Investigating the elasticity of structures, e.g. deflection of bridges or air-craft wings of elongated objects, e.g. pipes, masts, towers or railways

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01M—TESTING STATIC OR DYNAMIC BALANCE OF MACHINES OR STRUCTURES; TESTING OF STRUCTURES OR APPARATUS, NOT OTHERWISE PROVIDED FOR

- G01M5/00—Investigating the elasticity of structures, e.g. deflection of bridges or air-craft wings

- G01M5/0033—Investigating the elasticity of structures, e.g. deflection of bridges or air-craft wings by determining damage, crack or wear

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01M—TESTING STATIC OR DYNAMIC BALANCE OF MACHINES OR STRUCTURES; TESTING OF STRUCTURES OR APPARATUS, NOT OTHERWISE PROVIDED FOR

- G01M5/00—Investigating the elasticity of structures, e.g. deflection of bridges or air-craft wings

- G01M5/0091—Investigating the elasticity of structures, e.g. deflection of bridges or air-craft wings by using electromagnetic excitation or detection

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N27/00—Investigating or analysing materials by the use of electric, electrochemical, or magnetic means

- G01N27/72—Investigating or analysing materials by the use of electric, electrochemical, or magnetic means by investigating magnetic variables

- G01N27/82—Investigating or analysing materials by the use of electric, electrochemical, or magnetic means by investigating magnetic variables for investigating the presence of flaws

- G01N27/90—Investigating or analysing materials by the use of electric, electrochemical, or magnetic means by investigating magnetic variables for investigating the presence of flaws using eddy currents

- G01N27/9013—Arrangements for scanning

- G01N27/902—Arrangements for scanning by moving the sensors

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/51—Plural diverse manufacturing apparatus including means for metal shaping or assembling

- Y10T29/5199—Work on tubes

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- General Physics & Mathematics (AREA)

- Aviation & Aerospace Engineering (AREA)

- Chemical & Material Sciences (AREA)

- High Energy & Nuclear Physics (AREA)

- Thermal Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Electrochemistry (AREA)

- Immunology (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Pathology (AREA)

- Electromagnetism (AREA)

- Robotics (AREA)

- Manipulator (AREA)

- Investigating Or Analyzing Materials By The Use Of Magnetic Means (AREA)

- Monitoring And Testing Of Nuclear Reactors (AREA)

Abstract

Description

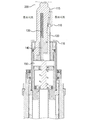

도 1은, 자동 포지셔너의 예시적인 설계가 도시된 등축도이다.

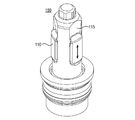

도 2는, 튜브 그리퍼 헤드의 등축도이다.

도 3은, 튜브 안에 삽입된 예시적인 튜브 그리퍼의 단면도이다.

도 4는, 예시적인 튜브 그리퍼의 확대도이다.

30: 슬라이딩 몸체 부분 40: 회전 그리퍼 포드

50: 그리퍼 60: 도구 헤드 커플링

61: 도구 헤드 잠금장치 63: 머신 비전 조명장치

64: 머신 비전 카메라 100: 그리퍼 헤드

110: 그리핑 고정부 115: 경사면

120: 밀대 130: 스프링

140: 회복 핀 150: 플레이트

200: 튜브 벽

Claims (5)

- 튜브의 내부 벽에 장비를 고정하기 위한 장치를 조절하는 방법으로서,

상기 장치는:

삽입 엑츄에이터,

그리퍼 고정부들,

그리퍼 고정부 엑츄에이터, 및

위치 센서를 가지고,

상기 방법은:

상기 장비가 상기 튜브 안에 삽입되는 제1 시간 간격 동안 상기 엑츄에이터를 가동시키는 단계;

제2 시간 간격 동안 상기 그리퍼 고정부 엑츄에이터를 가동시키는 단계;

상기 튜브 안에서 상기 장치의 위치를 감지하는 단계; 및

상기 제1 및 제2 시간 간격들 중 적어도 하나에 대하여 다른 값들을 가지고, 상기 장치를 끌어당기고 상기 장치를 재삽입하는 것에 의해 상기 튜브 안에서 상기 엑츄에이터의 위치를 조정하는 단계를 포함하는 방법.

- 복수의 튜브 개구부를 가지는 튜브 어레이 안에 테스트 및 수리 장비(equipment)를 위치시키기 위한 로봇 도구 포지셔너에 있어서,

상기 포지셔너는,

a) 하우징;

b) 튜브에 결합되기 위해 하우징으로부터 연장되며 튜브 개구부 개별적으로 연장되는 모든 그리퍼를 갖추고, 모든 그리퍼가 또한 하우징을 향해 개별적으로 다시 끌어당겨질 수 있는(retractable back) 적어도 네 개의 그리퍼; 및

c) 상기 적어도 네 개의 그리퍼 중 적어도 세 개의 그리퍼가 튜브와 결합되고 그리퍼 중 적어도 하나가 또 다른 튜브로부터 끌어당겨질 때 이동가능하여, 하우징이 이동에 의해서 튜브 어레이에 대해 이동되고 재위치될 수 있는 하우징을 포함하는 로봇 도구 포지셔너.

- 제2 항에 있어서,

모든 그리퍼가 슬라이드식으로(slidably) 연장가능하며 슬라이드식으로 끌어당겨질 수 있는 로봇 도구 포지셔너.

- 제2 항에 있어서,

하우징이 그리퍼 중 적어도 하나에 대해서 이동가능한 로봇 도구 포지셔너.

- 제2 항에 있어서,

적어도 네 개의 그리퍼 중 네 개의 그리퍼가 튜브에 결합될 때 하우징이 그리퍼 중 적어도 하나에 대해서 이동가능한 로봇 도구 포지셔너.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US14562909P | 2009-01-19 | 2009-01-19 | |

| US61/145,629 | 2009-01-19 | ||

| PCT/US2010/021407 WO2010083521A2 (en) | 2009-01-19 | 2010-01-19 | Apparatus for automated positioning of eddy current test probe |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020117019217A Division KR101894596B1 (ko) | 2009-01-19 | 2010-01-19 | 에디 전류 테스트 프로브의 자동 위치잡기를 위한 장치 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR20180098684A true KR20180098684A (ko) | 2018-09-04 |

| KR102081528B1 KR102081528B1 (ko) | 2020-02-25 |

Family

ID=42336330

Family Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020117019217A Active KR101894596B1 (ko) | 2009-01-19 | 2010-01-19 | 에디 전류 테스트 프로브의 자동 위치잡기를 위한 장치 |

| KR1020187024283A Active KR102081528B1 (ko) | 2009-01-19 | 2010-01-19 | 에디 전류 테스트 프로브의 자동 위치잡기를 위한 장치 |

| KR1020177009662A Active KR102110018B1 (ko) | 2009-01-19 | 2010-01-19 | 에디 전류 테스트 프로브의 자동 위치잡기를 위한 장치 |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020117019217A Active KR101894596B1 (ko) | 2009-01-19 | 2010-01-19 | 에디 전류 테스트 프로브의 자동 위치잡기를 위한 장치 |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020177009662A Active KR102110018B1 (ko) | 2009-01-19 | 2010-01-19 | 에디 전류 테스트 프로브의 자동 위치잡기를 위한 장치 |

Country Status (9)

| Country | Link |

|---|---|

| US (3) | US8746089B2 (ko) |

| EP (2) | EP2389538B1 (ko) |

| JP (1) | JP5676479B2 (ko) |

| KR (3) | KR101894596B1 (ko) |

| CN (1) | CN102388266B (ko) |

| CA (2) | CA2750221C (ko) |

| ES (2) | ES2728721T3 (ko) |

| SI (2) | SI2389538T1 (ko) |

| WO (1) | WO2010083521A2 (ko) |

Families Citing this family (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012042185A (ja) * | 2010-08-23 | 2012-03-01 | Mitsubishi Heavy Ind Ltd | クランパおよび水室内作業装置 |

| US8278779B2 (en) | 2011-02-07 | 2012-10-02 | General Electric Company | System and method for providing redundant power to a device |

| CN102649274A (zh) * | 2011-02-25 | 2012-08-29 | 富泰华工业(深圳)有限公司 | 机器人手爪及采用该机器人手爪的机器人 |

| GB2522472B (en) * | 2014-01-27 | 2017-09-06 | Epsilon Optics Aerospace Ltd | A method and apparatus for a structural monitoring device adapted to be locatable within a tubular structure |

| CN104249368B (zh) * | 2014-09-09 | 2016-06-01 | 上海交通大学 | 双柱形自重构模块化机器人 |

| WO2016083897A2 (en) * | 2014-11-24 | 2016-06-02 | Kitov Systems Ltd. | Automated inspection |

| US9961194B1 (en) * | 2016-04-05 | 2018-05-01 | State Farm Mutual Automobile Insurance Company | Systems and methods for authenticating a caller at a call center |

| CN105945962B (zh) * | 2016-05-19 | 2018-01-30 | 哈尔滨工业大学 | 用于蒸汽发生器热管检测的关节式爬行机器人 |

| DE102016013245B4 (de) | 2016-11-08 | 2025-10-16 | Westinghouse Electric Germany Gmbh | Bohrgerät für das Bearbeiten von Rohren in radioaktiver Umgebung |

| DE102016013247A1 (de) * | 2016-11-08 | 2018-05-09 | Westinghouse Electric Germany Gmbh | Bohrvorrichtung für das Bearbeiten von Rohren an Rohrböden in radioaktiver Umgebung |

| EP3592493A4 (en) * | 2017-03-08 | 2020-12-02 | BWXT Nuclear Energy, Inc. | PARTITION BOLT REPAIR APPARATUS AND METHOD |

| CN106970146B (zh) * | 2017-03-28 | 2020-02-21 | 哈尔滨工业大学 | 一种蒸汽发生器传热管检测设备定位连接机构 |

| US11112382B2 (en) * | 2018-03-21 | 2021-09-07 | Infrastructure Preservation Corporation | Robotic magnetic flux inspection system for bridge wire rope suspender cables |

| US20220260529A1 (en) * | 2019-03-21 | 2022-08-18 | Infrastructure Preservation Corporation | Robotic magnetic flux inspection system for broadcast tower support cables |

| FR3095274B1 (fr) * | 2019-04-19 | 2021-04-02 | Framatome Sa | Dispositif de contrôle d’une soudure d’un élément tubulaire longitudinal creux |

| CN112066158A (zh) * | 2019-12-10 | 2020-12-11 | 天目爱视(北京)科技有限公司 | 一种智能管道机器人 |

| CN111717609A (zh) * | 2020-05-13 | 2020-09-29 | 中核武汉核电运行技术股份有限公司 | 用于蒸汽发生器管板检修的运载平台及控制方法 |

| CN111458404A (zh) * | 2020-05-20 | 2020-07-28 | 四川纽赛特工业机器人制造有限公司 | 一种自动化管件测试中心 |

| CN112945507B (zh) * | 2021-02-03 | 2023-05-19 | 中国空气动力研究与发展中心高速空气动力研究所 | 一种高超声速风洞轴对称喷管 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20050029231A (ko) * | 2002-07-22 | 2005-03-24 | 웨스팅하우스 일레트릭 캄파니 엘엘씨 | 튜브 보수용 조종기 |

Family Cites Families (45)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2865640A (en) * | 1955-12-21 | 1958-12-23 | Exxon Research Engineering Co | Tube holding apparatus |

| DE1627286C3 (de) * | 1967-09-14 | 1973-01-18 | Schmid & Wezel | Handgeraet mit hin- und hergehendem Werkzeug |

| US3495546A (en) * | 1967-11-03 | 1970-02-17 | American Mach & Foundry | Speed control device for pipeline inspection apparatus |

| US3889820A (en) * | 1973-08-01 | 1975-06-17 | Combustion Eng | Method and apparatus for suspendedly supporting a platform |

| US3913752A (en) | 1973-08-01 | 1975-10-21 | Combustion Eng | Remotely movable platform |

| JPS5157489A (en) * | 1974-11-15 | 1976-05-19 | Mitsubishi Heavy Ind Ltd | Jidokensasochino kontorooruhoho |

| FR2309314A1 (fr) | 1974-12-05 | 1976-11-26 | Framatome Sa | Dispositif de positionnement selectif d'un organe sur une plaque tubulaire |

| CA1014724A (en) | 1975-03-11 | 1977-08-02 | Peter D. Stevens-Guille | Locating test probes in heat exchanger tubes |

| US4018345A (en) * | 1975-11-18 | 1977-04-19 | Combustion Engineering, Inc. | Surface traversing apparatus |

| US4018346A (en) * | 1975-11-18 | 1977-04-19 | Combustion Engineering, Inc. | Mounting arrangement for anchor fingers on a surface traversing apparatus |

| US4074814A (en) | 1976-03-26 | 1978-02-21 | Combustion Engineering, Inc. | Method and apparatus for controlling surface traversing device |

| US4193735A (en) | 1978-04-24 | 1980-03-18 | Combustion Engineering, Inc. | Work table for a stepped platform |

| GB2039268B (en) * | 1978-12-15 | 1983-01-19 | Exxon Research Engineering Co | Metal extraction by solid-liquid agglomerates |

| FR2448143A1 (fr) | 1979-02-05 | 1980-08-29 | Intercontrole Sa | Procede et dispositif pour retirer un porte-sonde de la chambre inferieure d'un echangeur de chaleur tubulaire verticale |

| FR2503920B1 (fr) | 1981-04-08 | 1987-08-21 | Intercontrole Sa | Dispositif pour le positionnement d'un organe en vis-a-vis des perforations d'une plaque |

| FR2503921A1 (fr) * | 1981-04-10 | 1982-10-15 | Commissariat Energie Atomique | Dispositif pour le positionnement d'un organe en vis-a-vis des perforations d'une plaque et procede de montage a distance d'un tel dispositif |

| FR2513927A1 (fr) * | 1981-10-05 | 1983-04-08 | Framatome Sa | Tele-manipulateur d'intervention dans une boite a eau de generateur de vapeur |

| US4449599A (en) | 1982-09-27 | 1984-05-22 | Combustion Engineering, Inc. | Finger walker for tube sheet |

| JPS5997864A (ja) | 1982-11-29 | 1984-06-05 | 三菱重工業株式会社 | 作業用間欠移動装置 |

| US4688327A (en) * | 1983-10-03 | 1987-08-25 | Westinghouse Electric Corp. | Sleeving of tubes of steam generator |

| US4597294A (en) | 1984-06-25 | 1986-07-01 | Westinghouse Electric Corp. | Ultrasonic nondestructive tubing inspection system |

| DE3509177C1 (de) * | 1985-03-14 | 1986-10-02 | Brown Boveri Reaktor GmbH, 6800 Mannheim | Einrichtung zum Einbringen eines zylindrischen Koerpers,insbesondere einer Huelse,in ein Rohr eines Dampferzeugers |

| JPH086894B2 (ja) | 1985-03-22 | 1996-01-29 | 株式会社日立製作所 | 熱交換器水室内作業ロボツトの移動・保持装置 |

| US4702878A (en) * | 1986-01-15 | 1987-10-27 | Westinghouse Electric Corp. | Search and retrieval device |

| JPS6344162A (ja) * | 1986-08-11 | 1988-02-25 | Kubota Ltd | サクシヨンロ−ルシエル亀裂検出装置 |

| US4720902A (en) * | 1986-12-22 | 1988-01-26 | Carrier Corporation | One step tension expander and method of using |

| US4829648A (en) | 1987-01-27 | 1989-05-16 | Westinghouse Electric Corp. | Apparatus and method for simultaneously loading a reinforcing sleeve and mandrel into a tube |

| JPH073333B2 (ja) * | 1988-01-28 | 1995-01-18 | 住友ゴム工業株式会社 | 弾性体シートのジョイント部の不良検出方法および装置 |

| US4872524A (en) * | 1988-04-13 | 1989-10-10 | Oconnor Chadwell | Wheel-less walking dolly |

| FR2644568B1 (fr) | 1989-03-16 | 1991-07-05 | Intercontrole Sa | Dispositif d'intervention, notamment pour le controle, l'inspection et la maintenance des echangeurs de chaleur |

| FR2645328B1 (fr) | 1989-04-04 | 1991-07-19 | Framatome Sa | Dispositif de centrage d'un outil d'intervention dans un tube de generateur de vapeur |

| JPH0333651A (ja) * | 1989-06-30 | 1991-02-13 | Chubu Electric Power Co Inc | 自動検査装置 |

| US5355063A (en) * | 1990-11-01 | 1994-10-11 | Westinghouse Electric Corp. | Robotic system for servicing the heat exchanger tubes of a nuclear steam generator |

| FR2674938B1 (fr) | 1991-04-05 | 1993-07-30 | Barras Provence | Vehicule d'exploration et de maintenance d'un reseau de tubes d'un generateur de vapeur. |

| US6672257B1 (en) * | 1994-05-06 | 2004-01-06 | Foster-Miller, Inc. | Upper bundle steam generator cleaning system and method |

| US5890553A (en) * | 1996-08-01 | 1999-04-06 | California Institute Of Technology | Multifunction automated crawling system |

| DE29700027U1 (de) | 1997-01-02 | 1998-04-30 | Siemens AG, 80333 München | Prüfmanipulator zur Wirbelstrom- und Ultraschallprüfung von hohlzylindrischen Kernreaktorbauteilen, insbesondere von Steuerstabantriebsgehäusen |

| AUPO724797A0 (en) * | 1997-06-06 | 1997-07-03 | Down Hole Technologies Pty Ltd | Retrieval head for a drill bit composed of a plurality of bit segments |

| JPH11174032A (ja) * | 1997-12-10 | 1999-07-02 | Toshiba Corp | 中間熱交換器の検査装置およびその方法 |

| TW463028B (en) * | 1998-04-21 | 2001-11-11 | Hitachi Shipbuilding Eng Co | Working robot for heat exchangers and operating method thereof |

| US6450104B1 (en) | 2000-04-28 | 2002-09-17 | North Carolina State University | Modular observation crawler and sensing instrument and method for operating same |

| WO2006116870A1 (en) | 2005-05-03 | 2006-11-09 | Noetic Engineering Inc. | Gripping tool |

| JP2008089328A (ja) * | 2006-09-29 | 2008-04-17 | Hitachi Ltd | 渦電流探傷装置及び渦電流探傷方法 |

| US7775572B2 (en) | 2007-12-10 | 2010-08-17 | Noetic Technologies Inc. | Gripping tool with fluid grip activation |

| US8317455B2 (en) * | 2009-11-11 | 2012-11-27 | Peinemann Equipment B.V. | Device and method for removing a bundle from a heat exchanger |

-

2010

- 2010-01-14 US US12/687,261 patent/US8746089B2/en active Active

- 2010-01-19 EP EP10700929.2A patent/EP2389538B1/en active Active

- 2010-01-19 KR KR1020117019217A patent/KR101894596B1/ko active Active

- 2010-01-19 KR KR1020187024283A patent/KR102081528B1/ko active Active

- 2010-01-19 CN CN201080011051.4A patent/CN102388266B/zh active Active

- 2010-01-19 ES ES16183475T patent/ES2728721T3/es active Active

- 2010-01-19 EP EP16183475.9A patent/EP3163161B1/en active Active

- 2010-01-19 WO PCT/US2010/021407 patent/WO2010083521A2/en not_active Ceased

- 2010-01-19 ES ES10700929.2T patent/ES2605227T3/es active Active

- 2010-01-19 CA CA2750221A patent/CA2750221C/en active Active

- 2010-01-19 SI SI201031325A patent/SI2389538T1/sl unknown

- 2010-01-19 CA CA2967589A patent/CA2967589C/en active Active

- 2010-01-19 JP JP2011546426A patent/JP5676479B2/ja active Active

- 2010-01-19 SI SI201031881T patent/SI3163161T1/sl unknown

- 2010-01-19 KR KR1020177009662A patent/KR102110018B1/ko active Active

-

2013

- 2013-08-09 US US13/963,630 patent/US9273985B2/en active Active

-

2016

- 2016-02-26 US US15/055,178 patent/US20160176685A1/en not_active Abandoned

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20050029231A (ko) * | 2002-07-22 | 2005-03-24 | 웨스팅하우스 일레트릭 캄파니 엘엘씨 | 튜브 보수용 조종기 |

Also Published As

| Publication number | Publication date |

|---|---|

| SI3163161T1 (sl) | 2019-08-30 |

| ES2605227T3 (es) | 2017-03-13 |

| JP5676479B2 (ja) | 2015-02-25 |

| KR102110018B1 (ko) | 2020-05-13 |

| SI2389538T1 (sl) | 2017-04-26 |

| KR102081528B1 (ko) | 2020-02-25 |

| US9273985B2 (en) | 2016-03-01 |

| KR101894596B1 (ko) | 2018-10-04 |

| CA2750221A1 (en) | 2010-07-22 |

| CA2967589A1 (en) | 2010-07-22 |

| EP2389538B1 (en) | 2016-08-10 |

| EP3163161A3 (en) | 2017-06-21 |

| JP2012515895A (ja) | 2012-07-12 |

| CN102388266B (zh) | 2014-12-03 |

| ES2728721T3 (es) | 2019-10-28 |

| US20160176685A1 (en) | 2016-06-23 |

| US8746089B2 (en) | 2014-06-10 |

| CA2967589C (en) | 2019-06-25 |

| CN102388266A (zh) | 2012-03-21 |

| EP3163161B1 (en) | 2019-03-13 |

| US20100181791A1 (en) | 2010-07-22 |

| WO2010083521A3 (en) | 2011-09-29 |

| KR20110121687A (ko) | 2011-11-08 |

| WO2010083521A2 (en) | 2010-07-22 |

| CA2750221C (en) | 2017-07-04 |

| KR20170045358A (ko) | 2017-04-26 |

| EP3163161A2 (en) | 2017-05-03 |

| US20140033837A1 (en) | 2014-02-06 |

| EP2389538A2 (en) | 2011-11-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR101894596B1 (ko) | 에디 전류 테스트 프로브의 자동 위치잡기를 위한 장치 | |

| EP1523395B1 (en) | Miniature manipulator for servicing the interior of nuclear steam generator tubes | |

| US20080107239A1 (en) | Collimator changer | |

| CN110769959B (zh) | 用于挡板螺栓修理的设备和方法 | |

| EP0979512A2 (en) | Inspection device | |

| EP0836694B1 (en) | Movable robot for internal inspection of pipes | |

| JP2012515895A5 (ko) | ||

| WO2018013899A1 (en) | Tube sheet inspection robot | |

| US20060017237A1 (en) | Bayonet collet pickup tool for agile fixturing | |

| US12202126B2 (en) | Articulated manipulator for navigating and servicing a heat exchanger | |

| CN108146529B (zh) | 多通道悬伸驱动装置 | |

| Qiu et al. | Research on the Automatic Exchange Technology for Space Robot Manipulators |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A107 | Divisional application of patent | ||

| A201 | Request for examination | ||

| PA0104 | Divisional application for international application |

Comment text: Divisional Application for International Patent Patent event code: PA01041R01D Patent event date: 20180823 Application number text: 1020117019217 Filing date: 20110818 |

|

| PA0201 | Request for examination | ||

| PG1501 | Laying open of application | ||

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20181010 Patent event code: PE09021S01D |

|

| AMND | Amendment | ||

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20190716 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20181010 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |

|

| X091 | Application refused [patent] | ||

| AMND | Amendment | ||

| PX0901 | Re-examination |

Patent event code: PX09011S01I Patent event date: 20190716 Comment text: Decision to Refuse Application Patent event code: PX09012R01I Patent event date: 20190308 Comment text: Amendment to Specification, etc. |

|

| PX0701 | Decision of registration after re-examination |

Patent event date: 20191119 Comment text: Decision to Grant Registration Patent event code: PX07013S01D Patent event date: 20191014 Comment text: Amendment to Specification, etc. Patent event code: PX07012R01I Patent event date: 20190716 Comment text: Decision to Refuse Application Patent event code: PX07011S01I Patent event date: 20190308 Comment text: Amendment to Specification, etc. Patent event code: PX07012R01I |

|

| X701 | Decision to grant (after re-examination) | ||

| GRNT | Written decision to grant | ||

| PR0701 | Registration of establishment |

Comment text: Registration of Establishment Patent event date: 20200219 Patent event code: PR07011E01D Comment text: Amendment to Specification, etc. Patent event date: 20191014 Patent event code: PX07012R01I Comment text: Decision to Refuse Application Patent event date: 20190716 Patent event code: PX07011S01I Comment text: Amendment to Specification, etc. Patent event date: 20190308 Patent event code: PX07012R01I |

|

| PR1002 | Payment of registration fee |

Payment date: 20200219 End annual number: 3 Start annual number: 1 |

|

| PG1601 | Publication of registration | ||

| PR1001 | Payment of annual fee |

Payment date: 20230217 Start annual number: 4 End annual number: 4 |

|

| PR1001 | Payment of annual fee |

Payment date: 20240207 Start annual number: 5 End annual number: 5 |

|

| PR1001 | Payment of annual fee |

Payment date: 20250212 Start annual number: 6 End annual number: 6 |