KR20180098138A - 기존 토포그래피 위에 평탄화된 에칭 마스크 구조를 형성하는 방법 - Google Patents

기존 토포그래피 위에 평탄화된 에칭 마스크 구조를 형성하는 방법 Download PDFInfo

- Publication number

- KR20180098138A KR20180098138A KR1020180017407A KR20180017407A KR20180098138A KR 20180098138 A KR20180098138 A KR 20180098138A KR 1020180017407 A KR1020180017407 A KR 1020180017407A KR 20180017407 A KR20180017407 A KR 20180017407A KR 20180098138 A KR20180098138 A KR 20180098138A

- Authority

- KR

- South Korea

- Prior art keywords

- layer

- feature

- substrate

- stack

- features

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- H10P76/4085—

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/027—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34

- H01L21/033—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34 comprising inorganic layers

- H01L21/0334—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34 comprising inorganic layers characterised by their size, orientation, disposition, behaviour, shape, in horizontal or vertical plane

- H01L21/0337—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34 comprising inorganic layers characterised by their size, orientation, disposition, behaviour, shape, in horizontal or vertical plane characterised by the process involved to create the mask, e.g. lift-off masks, sidewalls, or to modify the mask, e.g. pre-treatment, post-treatment

-

- H10P50/692—

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/0002—Lithographic processes using patterning methods other than those involving the exposure to radiation, e.g. by stamping

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/027—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34

- H01L21/0271—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34 comprising organic layers

- H01L21/0273—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34 comprising organic layers characterised by the treatment of photoresist layers

- H01L21/0274—Photolithographic processes

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/71—Manufacture of specific parts of devices defined in group H01L21/70

- H01L21/768—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics

- H01L21/76801—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the dielectrics, e.g. smoothing

- H01L21/76802—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the dielectrics, e.g. smoothing by forming openings in dielectrics

- H01L21/76816—Aspects relating to the layout of the pattern or to the size of vias or trenches

-

- H10P14/6342—

-

- H10P14/6902—

-

- H10P50/283—

-

- H10P50/695—

-

- H10P50/696—

-

- H10P76/204—

-

- H10P76/2041—

-

- H10P76/405—

-

- H10P95/06—

-

- H10W20/089—

Landscapes

- Engineering & Computer Science (AREA)

- General Physics & Mathematics (AREA)

- Physics & Mathematics (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Chemical & Material Sciences (AREA)

- Inorganic Chemistry (AREA)

- Exposure Of Semiconductors, Excluding Electron Or Ion Beam Exposure (AREA)

- Drying Of Semiconductors (AREA)

- Laminated Bodies (AREA)

- Shaping Of Tube Ends By Bending Or Straightening (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

Abstract

Description

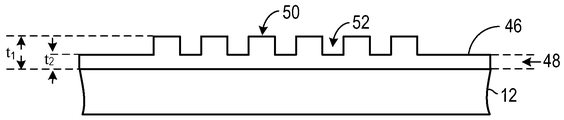

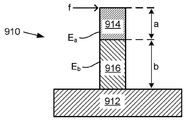

도 2는 고화된 패터닝된 층이 그 위에 형성된, 도 1에 도시된 기판의 단순화된 도면.

도 3은 도 2의 것과 유사한 패터닝된 층의 100nm 미만 피쳐의 기계적 강성도(영 모듈러스)의 단순화된 플롯.

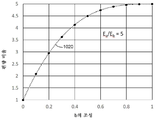

도 4는 피쳐 종횡비의 함수로서 100nm 미만 피쳐를 지지하는데 필요한 기계적 강성도(영 모듈러스)의 단순화된 플롯.

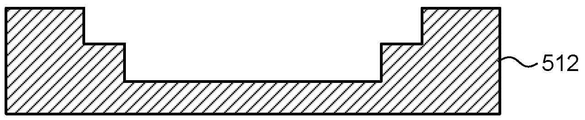

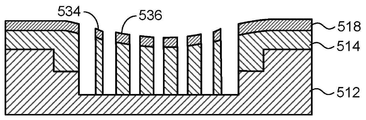

또한, 도 5a 내지 도 5h는 다층 레지스트 스택 내로 그리고 그후 기판 내로의 패턴 전사 시퀀스의 단순화된 도면.

또한, 도 6a 내지 도 6i는 본 발명의 일 실시예에 따른 다층 레지스트 스택 내로의 그리고 그후 기판으로의 패턴 전사 시퀀스의 단순화된 도면.

도 7은 도 6g에 도시된 것과 유사한 다층 레지스트 스택에 형성된 피쳐의 단순화된 도면.

도 8은 그 재료 조성의 함수로서 도 7의 피쳐와 유사한 피쳐의 편향 비율의 단순화된 플롯.

도 9는 상이한 다층 레지스트 스택에 형성된 피쳐의 단순화된 도면.

도 10은 그 재료 조성의 함수로서의 도 9의 피쳐의 편향의 단순화된 플롯.

Claims (13)

- 비-평면(non-planar) 표면 변화가 있는 표면을 갖는 기판을 제공하는 단계;

상기 기판 위에 제1 기저층을 부착하는 단계로서, 형성되는 상기 제1 기저층이 아래에 있는 상기 기판의 비-평면 표면 변화에 대응하는 비평면 표면 변화를 갖는, 제1 기저층을 부착하는 단계, 및

상기 제1 기저층 위에 제2 평탄화층을 부착하는 단계

에 의해, 상기 기판 상에 다층 스택을 형성하는 단계;

상기 다층 스택 상에 하드 마스크를 피착하는 단계; 및

상기 하드 마스크 상에 패터닝된 층을 형성하는 단계를 포함하고,

형성된 상기 패터닝된 층은 피쳐(features)를 갖고,

상기 다층 스택은, 50nm 이하의 피쳐 치수 및 2.5:1 이상의 종횡비를 갖는 하나 이상의 에칭된 피쳐를 최소 피쳐 압궤(collapse)로 유지하는 데 충분한 복합 유효 기계적 강성도(Eeff)를 갖는, 방법. - 제1항에 있어서, 상기 하나 이상의 에칭된 피쳐는 5:1 이상의 종횡비를 갖는, 방법.

- 제1항에 있어서, 상기 다층 스택의 하나 이상의 에칭된 피쳐의 피쳐 압궤는, 동일한 조건 하에서 전체적으로 제2 평탄화 재료로 형성된 층으로 에칭된 동일한 피쳐와 비교하여 감소되는, 방법.

- 제3항에 있어서, 제2 평탄화 재료의 에칭 내성은 상기 제1 기저층의 에칭 내성의 30 % 이내인, 방법.

- 제1항에 있어서, 상기 패터닝된 층의 피쳐는 특정 임계 치수(CD)를 가지며, 상기 다층 스택의 에칭된 피쳐는 전체적으로 제1 기저층 재료로 형성된 층으로 에칭된 동일한 피쳐와 비교하여 더 높은 임계 치수(CD) 균일성을 유지하는, 방법.

- 제1항에 있어서, 상기 다층 스택은 피쳐 압궤없이 상기 하나 이상의 에칭된 피쳐를 유지하는 데 충분한 복합 유효 기계적 강성도(Eeff)를 가지는, 방법.

- 제1항 내지 제6항 중 어느 한 항에 있어서, 상기 형성된 패터닝된 층의 피쳐를 상기 다층 스택으로 에칭하는 하나 이상의 에칭 단계를 수행하는 단계를 더 포함하는, 방법.

- 제7항에 있어서, 상기 형성된 패터닝된 층의 피쳐를 상기 기판으로 전사하기 위해 하나 이상의 추가 에칭 단계를 수행하는 단계를 더 포함하는, 방법.

- 다층 스택이며,

비-평면 표면 변화가 있는 표면을 갖는 기판;

상기 기판의 표면 위에 형성되고, 상기 기판 표면의 비-평면 표면 변화에 대응하는 비-평면 표면 변화를 갖는 제1 탄소 층; 및

상기 제1 탄소 층 위에 형성되고 평면 표면을 갖는 제2 평탄화 층을 포함하며,

다층 스택은 2.5:1 이상의 종횡비에서 50nm 이하의 피쳐를 최소 피쳐 압궤로 유지하는 데 충분한 복합 유효 기계적 강성도(Eeff)를 갖는, 다층 스택. - 제9항에 있어서, 상기 다층 스택은, 5:1 이상의 종횡비에서 50nm 이하의 피쳐를 최소 피쳐 압궤로 유지하는 데 충분한 복합 유효 기계적 강성도(Eeff)를 갖는, 다층 스택.

- 제9항에 있어서, 상기 제2 평탄화 층의 에칭 내성은 제1 탄소 층의 에칭 내성의 30 % 이내인, 다층 스택.

- 디바이스를 제조하는 방법이며,

제8항의 방법에 따라 형성된 패터닝된 층의 피쳐를 기판으로 전사하는 단계, 및

상기 기판을 처리하여 디바이스를 제조하는 단계를 포함하는, 방법. - 제12항에 있어서, 상기 기판은 반도체 웨이퍼를 더 포함하며, 제조된 상기 디바이스는 반도체 디바이스인, 방법.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US15/441,381 US10079152B1 (en) | 2017-02-24 | 2017-02-24 | Method for forming planarized etch mask structures over existing topography |

| US15/441,381 | 2017-02-24 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR20180098138A true KR20180098138A (ko) | 2018-09-03 |

| KR102253295B1 KR102253295B1 (ko) | 2021-05-20 |

Family

ID=63246983

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020180017407A Active KR102253295B1 (ko) | 2017-02-24 | 2018-02-13 | 기존 토포그래피 위에 평탄화된 에칭 마스크 구조를 형성하는 방법 |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US10079152B1 (ko) |

| JP (1) | JP7222606B2 (ko) |

| KR (1) | KR102253295B1 (ko) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20210080218A (ko) * | 2019-12-20 | 2021-06-30 | 캐논 가부시끼가이샤 | 임프린트 시스템 내의 왜곡의 보정을 갖는 나노제조 방법 |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7403961B2 (ja) * | 2019-03-19 | 2023-12-25 | キオクシア株式会社 | インプリント方法および半導体装置の製造方法 |

| JP7336303B2 (ja) * | 2019-07-31 | 2023-08-31 | キヤノン株式会社 | 物品製造方法、膜形成方法、型製造方法、物品製造システム、情報処理方法およびプログラム |

| US11656546B2 (en) | 2020-02-27 | 2023-05-23 | Canon Kabushiki Kaisha | Exposure apparatus for uniform light intensity and methods of using the same |

| US11349061B2 (en) * | 2020-06-08 | 2022-05-31 | International Business Machines Corporation | Glassy carbon mask for immersion implant and selective laser anneal |

| US11443940B2 (en) * | 2020-06-24 | 2022-09-13 | Canon Kabushiki Kaisha | Apparatus for uniform light intensity and methods of using the same |

| US20250013153A1 (en) * | 2023-07-06 | 2025-01-09 | Tokyo Electron Limited | Method of preventing pattern collapse |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20050184637A1 (en) * | 2004-01-29 | 2005-08-25 | Asahi Glass Company, Limited | Envelope for a flat panel display and flat panel display employing the envelope |

| US20130068720A1 (en) * | 2011-09-16 | 2013-03-21 | Shuichi Taniguchi | Pattern forming method |

| US20140227887A1 (en) * | 2011-09-06 | 2014-08-14 | Dongjin Semichem Co., Ltd. | Phenol-based self-crosslinking polymer and resist underlayer film composition including same |

| US20170003568A1 (en) * | 2014-01-30 | 2017-01-05 | Sony Corporation | Display unit and electronic apparatus |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6873087B1 (en) | 1999-10-29 | 2005-03-29 | Board Of Regents, The University Of Texas System | High precision orientation alignment and gap control stages for imprint lithography processes |

| US7077992B2 (en) | 2002-07-11 | 2006-07-18 | Molecular Imprints, Inc. | Step and repeat imprint lithography processes |

| US6932934B2 (en) | 2002-07-11 | 2005-08-23 | Molecular Imprints, Inc. | Formation of discontinuous films during an imprint lithography process |

| US7179396B2 (en) | 2003-03-25 | 2007-02-20 | Molecular Imprints, Inc. | Positive tone bi-layer imprint lithography method |

| US7396475B2 (en) | 2003-04-25 | 2008-07-08 | Molecular Imprints, Inc. | Method of forming stepped structures employing imprint lithography |

| US7157036B2 (en) | 2003-06-17 | 2007-01-02 | Molecular Imprints, Inc | Method to reduce adhesion between a conformable region and a pattern of a mold |

| US7790231B2 (en) | 2003-07-10 | 2010-09-07 | Brewer Science Inc. | Automated process and apparatus for planarization of topographical surfaces |

| US8076386B2 (en) | 2004-02-23 | 2011-12-13 | Molecular Imprints, Inc. | Materials for imprint lithography |

| US7998651B2 (en) | 2006-05-15 | 2011-08-16 | Asml Netherlands B.V. | Imprint lithography |

| EP2249204A4 (en) * | 2008-02-18 | 2012-01-11 | Nissan Chemical Ind Ltd | SILICULAR RESISTANT LAYERING COMPOSITION COMPOSITION CONTAINING A CYCLIC AMINO GROUP |

| US8071275B2 (en) | 2008-04-10 | 2011-12-06 | Lexmark International, Inc. | Methods for planarizing unevenness on surface of wafer photoresist layer and wafers produced by the methods |

| KR101653195B1 (ko) | 2008-06-09 | 2016-09-01 | 보드 오브 리전츠 더 유니버시티 오브 텍사스 시스템 | 적응적 나노토포그래피 형상제작 |

| EP2805347B1 (en) * | 2012-01-19 | 2018-03-07 | Brewer Science, Inc. | Nonpolymeric antireflection compositions containing adamantyl groups |

| SG11201601162TA (en) | 2013-08-19 | 2016-03-30 | Univ Texas | Programmable deposition of thin films of a user-defined profile with nanometer scale accuracy |

| JP6323456B2 (ja) * | 2013-09-11 | 2018-05-16 | Jsr株式会社 | 多層レジストプロセス用無機膜形成組成物及びパターン形成方法 |

-

2017

- 2017-02-24 US US15/441,381 patent/US10079152B1/en active Active

-

2018

- 2018-02-13 KR KR1020180017407A patent/KR102253295B1/ko active Active

- 2018-02-19 JP JP2018027233A patent/JP7222606B2/ja active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20050184637A1 (en) * | 2004-01-29 | 2005-08-25 | Asahi Glass Company, Limited | Envelope for a flat panel display and flat panel display employing the envelope |

| US20140227887A1 (en) * | 2011-09-06 | 2014-08-14 | Dongjin Semichem Co., Ltd. | Phenol-based self-crosslinking polymer and resist underlayer film composition including same |

| US20130068720A1 (en) * | 2011-09-16 | 2013-03-21 | Shuichi Taniguchi | Pattern forming method |

| JP2013065725A (ja) * | 2011-09-16 | 2013-04-11 | Toshiba Corp | パターン形成方法 |

| US20170003568A1 (en) * | 2014-01-30 | 2017-01-05 | Sony Corporation | Display unit and electronic apparatus |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20210080218A (ko) * | 2019-12-20 | 2021-06-30 | 캐논 가부시끼가이샤 | 임프린트 시스템 내의 왜곡의 보정을 갖는 나노제조 방법 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2018142701A (ja) | 2018-09-13 |

| US20180247823A1 (en) | 2018-08-30 |

| US10079152B1 (en) | 2018-09-18 |

| KR102253295B1 (ko) | 2021-05-20 |

| JP7222606B2 (ja) | 2023-02-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR102253295B1 (ko) | 기존 토포그래피 위에 평탄화된 에칭 마스크 구조를 형성하는 방법 | |

| US8012394B2 (en) | Template pattern density doubling | |

| US7960090B2 (en) | Pattern forming method, pattern formed thereby, mold, processing apparatus, and processing method | |

| US8961852B2 (en) | Templates having high contrast alignment marks | |

| US7140861B2 (en) | Compliant hard template for UV imprinting | |

| US7357876B2 (en) | Eliminating printability of sub-resolution defects in imprint lithography | |

| JP5404654B2 (ja) | テンプレート形成時の限界寸法制御 | |

| US10211051B2 (en) | Method of reverse tone patterning | |

| CN108020986B (zh) | 从形成在衬底上的固化图案层分离纳米压印模板的设备和方法 | |

| KR102379626B1 (ko) | 차광 재료를 구비한 나노임프린트 템플릿 및 제작 방법 | |

| JP2009182075A (ja) | インプリントによる構造体の製造方法 | |

| CN114097062B (zh) | 用于调整衬底上膜的应力过渡的方法 | |

| US8935981B2 (en) | High contrast alignment marks through multiple stage imprinting | |

| US7985530B2 (en) | Etch-enhanced technique for lift-off patterning | |

| JP5848386B2 (ja) | インサイチュ嵌込み構造物形成方法 | |

| US20100095862A1 (en) | Double Sidewall Angle Nano-Imprint Template | |

| KR20210080218A (ko) | 임프린트 시스템 내의 왜곡의 보정을 갖는 나노제조 방법 | |

| KR20220034874A (ko) | 스핀-온 및 cvd 증착된 유기 막의 평탄화를 위한 방법 | |

| TW202400507A (zh) | 用於製造壓印微影模板的方法、用於製造光學部件的方法以及用於製造光學元件的方法 | |

| US20230205080A1 (en) | Template, method of forming a template, apparatus and method of manufacturing an article |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0109 | Patent application |

St.27 status event code: A-0-1-A10-A12-nap-PA0109 |

|

| PG1501 | Laying open of application |

St.27 status event code: A-1-1-Q10-Q12-nap-PG1501 |

|

| A201 | Request for examination | ||

| PA0201 | Request for examination |

St.27 status event code: A-1-2-D10-D11-exm-PA0201 |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

St.27 status event code: A-1-2-D10-D21-exm-PE0902 |

|

| E13-X000 | Pre-grant limitation requested |

St.27 status event code: A-2-3-E10-E13-lim-X000 |

|

| P11-X000 | Amendment of application requested |

St.27 status event code: A-2-2-P10-P11-nap-X000 |

|

| P13-X000 | Application amended |

St.27 status event code: A-2-2-P10-P13-nap-X000 |

|

| E701 | Decision to grant or registration of patent right | ||

| PE0701 | Decision of registration |

St.27 status event code: A-1-2-D10-D22-exm-PE0701 |

|

| GRNT | Written decision to grant | ||

| PR0701 | Registration of establishment |

St.27 status event code: A-2-4-F10-F11-exm-PR0701 |

|

| PR1002 | Payment of registration fee |

St.27 status event code: A-2-2-U10-U11-oth-PR1002 Fee payment year number: 1 |

|

| PG1601 | Publication of registration |

St.27 status event code: A-4-4-Q10-Q13-nap-PG1601 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 4 |

|

| P22-X000 | Classification modified |

St.27 status event code: A-4-4-P10-P22-nap-X000 |