KR20180089515A - 전구체 화합물을 직접 재활용하는 dli-mocvd에 의한 코팅의 증착 공정 - Google Patents

전구체 화합물을 직접 재활용하는 dli-mocvd에 의한 코팅의 증착 공정 Download PDFInfo

- Publication number

- KR20180089515A KR20180089515A KR1020187020519A KR20187020519A KR20180089515A KR 20180089515 A KR20180089515 A KR 20180089515A KR 1020187020519 A KR1020187020519 A KR 1020187020519A KR 20187020519 A KR20187020519 A KR 20187020519A KR 20180089515 A KR20180089515 A KR 20180089515A

- Authority

- KR

- South Korea

- Prior art keywords

- precursor

- deposition

- transition metal

- reactor

- mother liquor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 239000002243 precursor Substances 0.000 title claims abstract description 150

- 238000000034 method Methods 0.000 title claims abstract description 107

- 238000000151 deposition Methods 0.000 title claims abstract description 96

- 230000008021 deposition Effects 0.000 title claims abstract description 94

- 230000008569 process Effects 0.000 title claims abstract description 63

- 150000001875 compounds Chemical class 0.000 title claims description 30

- 238000002488 metal-organic chemical vapour deposition Methods 0.000 title claims description 30

- 238000000576 coating method Methods 0.000 title description 45

- 239000011248 coating agent Substances 0.000 title description 26

- 238000004064 recycling Methods 0.000 title description 19

- 239000002904 solvent Substances 0.000 claims abstract description 55

- 150000003624 transition metals Chemical class 0.000 claims abstract description 55

- 229910052723 transition metal Inorganic materials 0.000 claims abstract description 54

- 239000012452 mother liquor Substances 0.000 claims abstract description 51

- 239000000758 substrate Substances 0.000 claims abstract description 39

- 238000006243 chemical reaction Methods 0.000 claims abstract description 28

- 239000007789 gas Substances 0.000 claims abstract description 28

- 239000006227 byproduct Substances 0.000 claims abstract description 21

- 239000011253 protective coating Substances 0.000 claims abstract description 21

- 238000005229 chemical vapour deposition Methods 0.000 claims abstract description 18

- 125000003118 aryl group Chemical group 0.000 claims abstract description 17

- 239000011241 protective layer Substances 0.000 claims abstract description 16

- 229930195733 hydrocarbon Natural products 0.000 claims abstract description 12

- 239000003112 inhibitor Substances 0.000 claims abstract description 10

- 238000010348 incorporation Methods 0.000 claims abstract description 9

- 239000004215 Carbon black (E152) Substances 0.000 claims abstract description 7

- 238000001704 evaporation Methods 0.000 claims abstract description 7

- 125000004430 oxygen atom Chemical group O* 0.000 claims abstract description 7

- 239000000243 solution Substances 0.000 claims description 73

- 239000011651 chromium Substances 0.000 claims description 63

- 229910052751 metal Inorganic materials 0.000 claims description 49

- 239000002184 metal Substances 0.000 claims description 45

- UHOVQNZJYSORNB-UHFFFAOYSA-N Benzene Chemical group C1=CC=CC=C1 UHOVQNZJYSORNB-UHFFFAOYSA-N 0.000 claims description 39

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Natural products CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 claims description 38

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 claims description 34

- 229910045601 alloy Inorganic materials 0.000 claims description 32

- 239000000956 alloy Substances 0.000 claims description 32

- 238000005137 deposition process Methods 0.000 claims description 31

- 229910052804 chromium Inorganic materials 0.000 claims description 29

- 150000004945 aromatic hydrocarbons Chemical class 0.000 claims description 28

- 239000000203 mixture Substances 0.000 claims description 21

- 238000000354 decomposition reaction Methods 0.000 claims description 20

- 239000000463 material Substances 0.000 claims description 20

- 230000001681 protective effect Effects 0.000 claims description 17

- 239000007788 liquid Substances 0.000 claims description 16

- 238000002347 injection Methods 0.000 claims description 15

- 239000007924 injection Substances 0.000 claims description 15

- 229910052786 argon Inorganic materials 0.000 claims description 14

- 229910052799 carbon Inorganic materials 0.000 claims description 13

- 239000000654 additive Substances 0.000 claims description 12

- 230000000996 additive effect Effects 0.000 claims description 12

- 238000009833 condensation Methods 0.000 claims description 12

- 230000005494 condensation Effects 0.000 claims description 12

- 230000003647 oxidation Effects 0.000 claims description 11

- 238000007254 oxidation reaction Methods 0.000 claims description 11

- 229910052720 vanadium Inorganic materials 0.000 claims description 11

- 150000002902 organometallic compounds Chemical class 0.000 claims description 10

- 239000010410 layer Substances 0.000 claims description 9

- 239000000460 chlorine Substances 0.000 claims description 7

- 229910052750 molybdenum Inorganic materials 0.000 claims description 7

- 229910052758 niobium Inorganic materials 0.000 claims description 7

- 239000010955 niobium Substances 0.000 claims description 7

- 230000008016 vaporization Effects 0.000 claims description 7

- 239000000919 ceramic Substances 0.000 claims description 6

- 229910052801 chlorine Inorganic materials 0.000 claims description 6

- 229910052748 manganese Inorganic materials 0.000 claims description 6

- ZAMOUSCENKQFHK-UHFFFAOYSA-N Chlorine atom Chemical compound [Cl] ZAMOUSCENKQFHK-UHFFFAOYSA-N 0.000 claims description 5

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 claims description 5

- 238000009835 boiling Methods 0.000 claims description 5

- 230000008020 evaporation Effects 0.000 claims description 5

- 229910052717 sulfur Inorganic materials 0.000 claims description 5

- 239000011593 sulfur Substances 0.000 claims description 5

- 125000001495 ethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 claims description 4

- 229910052735 hafnium Inorganic materials 0.000 claims description 4

- 125000001449 isopropyl group Chemical group [H]C([H])([H])C([H])(*)C([H])([H])[H] 0.000 claims description 4

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 claims description 4

- 239000010413 mother solution Substances 0.000 claims description 4

- 125000001997 phenyl group Chemical group [H]C1=C([H])C([H])=C(*)C([H])=C1[H] 0.000 claims description 4

- 229910052721 tungsten Inorganic materials 0.000 claims description 4

- -1 mono-cyclic aromatic hydrocarbon Chemical class 0.000 claims description 3

- 229910052710 silicon Inorganic materials 0.000 claims description 3

- 239000010703 silicon Substances 0.000 claims description 3

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 claims description 2

- 125000000217 alkyl group Chemical group 0.000 claims description 2

- 150000001555 benzenes Chemical group 0.000 claims description 2

- 239000007791 liquid phase Substances 0.000 claims description 2

- 239000011733 molybdenum Substances 0.000 claims description 2

- GUCVJGMIXFAOAE-UHFFFAOYSA-N niobium atom Chemical compound [Nb] GUCVJGMIXFAOAE-UHFFFAOYSA-N 0.000 claims description 2

- 230000000717 retained effect Effects 0.000 claims description 2

- 125000003396 thiol group Chemical group [H]S* 0.000 claims description 2

- 125000001309 chloro group Chemical group Cl* 0.000 claims 1

- AUHZEENZYGFFBQ-UHFFFAOYSA-N mesitylene Substances CC1=CC(C)=CC(C)=C1 AUHZEENZYGFFBQ-UHFFFAOYSA-N 0.000 claims 1

- 125000001827 mesitylenyl group Chemical group [H]C1=C(C(*)=C(C([H])=C1C([H])([H])[H])C([H])([H])[H])C([H])([H])[H] 0.000 claims 1

- 125000003944 tolyl group Chemical group 0.000 claims 1

- GPPXJZIENCGNKB-UHFFFAOYSA-N vanadium Chemical compound [V]#[V] GPPXJZIENCGNKB-UHFFFAOYSA-N 0.000 claims 1

- 239000012808 vapor phase Substances 0.000 claims 1

- 150000002430 hydrocarbons Chemical class 0.000 abstract description 10

- 230000000694 effects Effects 0.000 abstract description 3

- 150000001361 allenes Chemical class 0.000 abstract description 2

- 239000011550 stock solution Substances 0.000 abstract description 2

- 239000012224 working solution Substances 0.000 abstract 1

- 208000037998 chronic venous disease Diseases 0.000 description 39

- 239000003446 ligand Substances 0.000 description 17

- 239000000376 reactant Substances 0.000 description 14

- 239000000126 substance Substances 0.000 description 13

- 150000002739 metals Chemical class 0.000 description 11

- 230000008901 benefit Effects 0.000 description 10

- UFGZSIPAQKLCGR-UHFFFAOYSA-N chromium carbide Chemical compound [Cr]#C[Cr]C#[Cr] UFGZSIPAQKLCGR-UHFFFAOYSA-N 0.000 description 10

- 239000010408 film Substances 0.000 description 10

- 150000001247 metal acetylides Chemical class 0.000 description 10

- 125000002524 organometallic group Chemical group 0.000 description 10

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 9

- 229910003470 tongbaite Inorganic materials 0.000 description 9

- 239000012159 carrier gas Substances 0.000 description 8

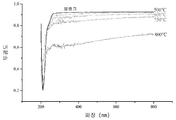

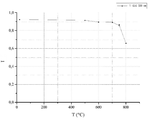

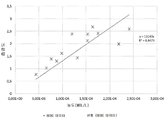

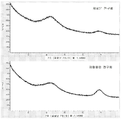

- 238000002835 absorbance Methods 0.000 description 7

- 230000008859 change Effects 0.000 description 7

- 230000007613 environmental effect Effects 0.000 description 7

- 238000004519 manufacturing process Methods 0.000 description 7

- 230000007246 mechanism Effects 0.000 description 7

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 6

- 238000005516 engineering process Methods 0.000 description 6

- 238000005259 measurement Methods 0.000 description 6

- RMVRSNDYEFQCLF-UHFFFAOYSA-N thiophenol Chemical group SC1=CC=CC=C1 RMVRSNDYEFQCLF-UHFFFAOYSA-N 0.000 description 6

- 238000009834 vaporization Methods 0.000 description 6

- 229910000599 Cr alloy Inorganic materials 0.000 description 5

- 238000004458 analytical method Methods 0.000 description 5

- 150000004820 halides Chemical class 0.000 description 5

- 238000001228 spectrum Methods 0.000 description 5

- 241001120493 Arene Species 0.000 description 4

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 4

- 229910000756 V alloy Inorganic materials 0.000 description 4

- 238000005260 corrosion Methods 0.000 description 4

- 230000007797 corrosion Effects 0.000 description 4

- 238000002474 experimental method Methods 0.000 description 4

- 239000012535 impurity Substances 0.000 description 4

- 238000011084 recovery Methods 0.000 description 4

- 238000003860 storage Methods 0.000 description 4

- 238000002834 transmittance Methods 0.000 description 4

- LEONUFNNVUYDNQ-UHFFFAOYSA-N vanadium atom Chemical compound [V] LEONUFNNVUYDNQ-UHFFFAOYSA-N 0.000 description 4

- 229910003902 SiCl 4 Inorganic materials 0.000 description 3

- 238000002441 X-ray diffraction Methods 0.000 description 3

- 150000001336 alkenes Chemical class 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 3

- SLLGVCUQYRMELA-UHFFFAOYSA-N chlorosilicon Chemical compound Cl[Si] SLLGVCUQYRMELA-UHFFFAOYSA-N 0.000 description 3

- 238000010586 diagram Methods 0.000 description 3

- 238000004453 electron probe microanalysis Methods 0.000 description 3

- 230000006870 function Effects 0.000 description 3

- 150000004767 nitrides Chemical class 0.000 description 3

- 229910052757 nitrogen Inorganic materials 0.000 description 3

- 239000012071 phase Substances 0.000 description 3

- 229910021420 polycrystalline silicon Inorganic materials 0.000 description 3

- 239000000843 powder Substances 0.000 description 3

- 239000000047 product Substances 0.000 description 3

- 239000010453 quartz Substances 0.000 description 3

- 239000000523 sample Substances 0.000 description 3

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 3

- 239000002356 single layer Substances 0.000 description 3

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 2

- YNQLUTRBYVCPMQ-UHFFFAOYSA-N Ethylbenzene Chemical compound CCC1=CC=CC=C1 YNQLUTRBYVCPMQ-UHFFFAOYSA-N 0.000 description 2

- 229910001257 Nb alloy Inorganic materials 0.000 description 2

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 2

- 150000001338 aliphatic hydrocarbons Chemical class 0.000 description 2

- 150000001491 aromatic compounds Chemical class 0.000 description 2

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 2

- 230000009286 beneficial effect Effects 0.000 description 2

- IWCQVOVBDXJJDF-UHFFFAOYSA-N benzene;chromium;cyclohexane Chemical compound [Cr].[CH-]1[CH-][CH-][CH-][CH-][CH-]1.C1=CC=CC=C1 IWCQVOVBDXJJDF-UHFFFAOYSA-N 0.000 description 2

- 230000000711 cancerogenic effect Effects 0.000 description 2

- 210000004027 cell Anatomy 0.000 description 2

- 239000007795 chemical reaction product Substances 0.000 description 2

- CICKSZMRNUBQQF-UHFFFAOYSA-N chromium ethylbenzene Chemical compound [Cr].CCc1ccccc1.CCc1ccccc1 CICKSZMRNUBQQF-UHFFFAOYSA-N 0.000 description 2

- 238000004140 cleaning Methods 0.000 description 2

- 238000011109 contamination Methods 0.000 description 2

- RWGFKTVRMDUZSP-UHFFFAOYSA-N cumene Chemical compound CC(C)C1=CC=CC=C1 RWGFKTVRMDUZSP-UHFFFAOYSA-N 0.000 description 2

- 230000001747 exhibiting effect Effects 0.000 description 2

- 239000012634 fragment Substances 0.000 description 2

- 238000010438 heat treatment Methods 0.000 description 2

- 150000004678 hydrides Chemical class 0.000 description 2

- 239000011261 inert gas Substances 0.000 description 2

- 238000004377 microelectronic Methods 0.000 description 2

- 229910052575 non-oxide ceramic Inorganic materials 0.000 description 2

- 150000002894 organic compounds Chemical class 0.000 description 2

- 239000001301 oxygen Substances 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- 230000001105 regulatory effect Effects 0.000 description 2

- 238000004626 scanning electron microscopy Methods 0.000 description 2

- 238000006467 substitution reaction Methods 0.000 description 2

- 238000012360 testing method Methods 0.000 description 2

- 239000012855 volatile organic compound Substances 0.000 description 2

- 239000002699 waste material Substances 0.000 description 2

- WZEYZMKZKQPXSX-UHFFFAOYSA-N 1,3,5-trimethylbenzene Chemical compound CC1=CC(C)=CC(C)=C1.CC1=CC(C)=CC(C)=C1 WZEYZMKZKQPXSX-UHFFFAOYSA-N 0.000 description 1

- VEXZGXHMUGYJMC-UHFFFAOYSA-M Chloride anion Chemical compound [Cl-] VEXZGXHMUGYJMC-UHFFFAOYSA-M 0.000 description 1

- 239000005046 Chlorosilane Substances 0.000 description 1

- XDTMQSROBMDMFD-UHFFFAOYSA-N Cyclohexane Chemical compound C1CCCCC1 XDTMQSROBMDMFD-UHFFFAOYSA-N 0.000 description 1

- VEXZGXHMUGYJMC-UHFFFAOYSA-N Hydrochloric acid Chemical compound Cl VEXZGXHMUGYJMC-UHFFFAOYSA-N 0.000 description 1

- 229910001182 Mo alloy Inorganic materials 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 229910021536 Zeolite Inorganic materials 0.000 description 1

- 238000005299 abrasion Methods 0.000 description 1

- 238000011481 absorbance measurement Methods 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 239000000443 aerosol Substances 0.000 description 1

- 150000001335 aliphatic alkanes Chemical class 0.000 description 1

- 125000001931 aliphatic group Chemical group 0.000 description 1

- 229910021417 amorphous silicon Inorganic materials 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 239000003849 aromatic solvent Substances 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- 239000010953 base metal Substances 0.000 description 1

- 230000008033 biological extinction Effects 0.000 description 1

- 230000033228 biological regulation Effects 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- 125000004432 carbon atom Chemical group C* 0.000 description 1

- 239000002041 carbon nanotube Substances 0.000 description 1

- 229910021393 carbon nanotube Inorganic materials 0.000 description 1

- 231100000357 carcinogen Toxicity 0.000 description 1

- 239000003183 carcinogenic agent Substances 0.000 description 1

- 230000003197 catalytic effect Effects 0.000 description 1

- 239000004568 cement Substances 0.000 description 1

- 238000005524 ceramic coating Methods 0.000 description 1

- 229910010293 ceramic material Inorganic materials 0.000 description 1

- 229910052729 chemical element Inorganic materials 0.000 description 1

- KOPOQZFJUQMUML-UHFFFAOYSA-N chlorosilane Chemical compound Cl[SiH3] KOPOQZFJUQMUML-UHFFFAOYSA-N 0.000 description 1

- 150000001845 chromium compounds Chemical class 0.000 description 1

- JOPOVCBBYLSVDA-UHFFFAOYSA-N chromium(6+) Chemical compound [Cr+6] JOPOVCBBYLSVDA-UHFFFAOYSA-N 0.000 description 1

- 230000001112 coagulating effect Effects 0.000 description 1

- 238000004737 colorimetric analysis Methods 0.000 description 1

- 230000000536 complexating effect Effects 0.000 description 1

- 238000004590 computer program Methods 0.000 description 1

- 239000000356 contaminant Substances 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 238000005336 cracking Methods 0.000 description 1

- 230000006837 decompression Effects 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 230000001066 destructive effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 238000003745 diagnosis Methods 0.000 description 1

- HNPSIPDUKPIQMN-UHFFFAOYSA-N dioxosilane;oxo(oxoalumanyloxy)alumane Chemical compound O=[Si]=O.O=[Al]O[Al]=O HNPSIPDUKPIQMN-UHFFFAOYSA-N 0.000 description 1

- 238000001928 direct liquid injection chemical vapour deposition Methods 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 238000010494 dissociation reaction Methods 0.000 description 1

- 230000005593 dissociations Effects 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000005323 electroforming Methods 0.000 description 1

- 238000009713 electroplating Methods 0.000 description 1

- 238000000724 energy-dispersive X-ray spectrum Methods 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 230000004992 fission Effects 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 210000000540 fraction c Anatomy 0.000 description 1

- 229910021389 graphene Inorganic materials 0.000 description 1

- 229910001385 heavy metal Inorganic materials 0.000 description 1

- 239000001307 helium Substances 0.000 description 1

- 229910052734 helium Inorganic materials 0.000 description 1

- SWQJXJOGLNCZEY-UHFFFAOYSA-N helium atom Chemical compound [He] SWQJXJOGLNCZEY-UHFFFAOYSA-N 0.000 description 1

- CKAPSXZOOQJIBF-UHFFFAOYSA-N hexachlorobenzene Chemical compound ClC1=C(Cl)C(Cl)=C(Cl)C(Cl)=C1Cl CKAPSXZOOQJIBF-UHFFFAOYSA-N 0.000 description 1

- 231100000086 high toxicity Toxicity 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 238000007373 indentation Methods 0.000 description 1

- 238000009776 industrial production Methods 0.000 description 1

- 239000012705 liquid precursor Substances 0.000 description 1

- 238000004518 low pressure chemical vapour deposition Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 150000002736 metal compounds Chemical class 0.000 description 1

- 238000005272 metallurgy Methods 0.000 description 1

- FXNGWBDIVIGISM-UHFFFAOYSA-N methylidynechromium Chemical compound [Cr]#[C] FXNGWBDIVIGISM-UHFFFAOYSA-N 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 230000007935 neutral effect Effects 0.000 description 1

- 229910000510 noble metal Inorganic materials 0.000 description 1

- 239000011225 non-oxide ceramic Substances 0.000 description 1

- 229910052755 nonmetal Inorganic materials 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 239000013110 organic ligand Substances 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 238000005240 physical vapour deposition Methods 0.000 description 1

- 229910052697 platinum Inorganic materials 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 238000010926 purge Methods 0.000 description 1

- 238000000746 purification Methods 0.000 description 1

- 238000000197 pyrolysis Methods 0.000 description 1

- 238000004445 quantitative analysis Methods 0.000 description 1

- 239000012495 reaction gas Substances 0.000 description 1

- 239000011541 reaction mixture Substances 0.000 description 1

- 230000009257 reactivity Effects 0.000 description 1

- 238000006722 reduction reaction Methods 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 238000005070 sampling Methods 0.000 description 1

- 229920006395 saturated elastomer Polymers 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

- 238000004088 simulation Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000002798 spectrophotometry method Methods 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 238000000859 sublimation Methods 0.000 description 1

- 230000008022 sublimation Effects 0.000 description 1

- 125000001424 substituent group Chemical group 0.000 description 1

- 238000004381 surface treatment Methods 0.000 description 1

- 238000001308 synthesis method Methods 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 231100000331 toxic Toxicity 0.000 description 1

- 230000002588 toxic effect Effects 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- 230000009466 transformation Effects 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 238000000411 transmission spectrum Methods 0.000 description 1

- 238000002371 ultraviolet--visible spectrum Methods 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 239000006200 vaporizer Substances 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

- 239000010457 zeolite Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/448—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for generating reactive gas streams, e.g. by evaporation or sublimation of precursor materials

- C23C16/4486—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for generating reactive gas streams, e.g. by evaporation or sublimation of precursor materials by producing an aerosol and subsequent evaporation of the droplets or particles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D5/00—Condensation of vapours; Recovering volatile solvents by condensation

- B01D5/0057—Condensation of vapours; Recovering volatile solvents by condensation in combination with other processes

- B01D5/006—Condensation of vapours; Recovering volatile solvents by condensation in combination with other processes with evaporation or distillation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D8/00—Cold traps; Cold baffles

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/06—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of metallic material

- C23C16/18—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of metallic material from metallo-organic compounds

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/30—Deposition of compounds, mixtures or solid solutions, e.g. borides, carbides, nitrides

- C23C16/32—Carbides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/4412—Details relating to the exhausts, e.g. pumps, filters, scrubbers, particle traps

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/448—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for generating reactive gas streams, e.g. by evaporation or sublimation of precursor materials

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/453—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating passing the reaction gases through burners or torches, e.g. atmospheric pressure CVD

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Inorganic Chemistry (AREA)

- Dispersion Chemistry (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Chemical Vapour Deposition (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR1562862 | 2015-12-18 | ||

| FR1562862A FR3045673B1 (fr) | 2015-12-18 | 2015-12-18 | Procede de depot d'un revetement par dli-mocvd avec recyclage du compose precurseur |

| PCT/FR2016/053541 WO2017103546A1 (fr) | 2015-12-18 | 2016-12-17 | Procede de depot d'un revetement par dli-mocvd avec recyclage direct du compose precurseur |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20180089515A true KR20180089515A (ko) | 2018-08-08 |

Family

ID=55948887

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020187020519A Ceased KR20180089515A (ko) | 2015-12-18 | 2016-12-17 | 전구체 화합물을 직접 재활용하는 dli-mocvd에 의한 코팅의 증착 공정 |

Country Status (7)

| Country | Link |

|---|---|

| US (2) | US20190003048A1 (enExample) |

| EP (1) | EP3390686B1 (enExample) |

| JP (1) | JP6997711B2 (enExample) |

| KR (1) | KR20180089515A (enExample) |

| FR (1) | FR3045673B1 (enExample) |

| RU (1) | RU2699126C1 (enExample) |

| WO (1) | WO2017103546A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2020050974A1 (en) * | 2018-09-03 | 2020-03-12 | Applied Materials, Inc. | Direct liquid injection system for thin film deposition |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2827830T3 (es) | 2016-09-28 | 2021-05-24 | Commissariat Energie Atomique | Componente nuclear con sustrato metálico, procedimiento de fabricación mediante DLI-MOCVD y usos contra la oxidación/hidruración |

| US11715572B2 (en) | 2016-09-28 | 2023-08-01 | Commissariat A L'energie Atomique Et Aux Energies Alternatives | Composite nuclear component, DLI-MOCVD method for producing same, and uses for controlling oxidation/hydridation |

| WO2018060642A1 (fr) | 2016-09-28 | 2018-04-05 | Commissariat A L'energie Atomique Et Aux Energies Alternatives | Composant nucléaire avec revetement de crc amorphe, procédé de fabrication par dli-mocvd et utilisations contre l'oxydation/hydruration |

| EP3520118B1 (fr) | 2016-09-28 | 2020-08-05 | Commissariat à l'Énergie Atomique et aux Énergies Alternatives | Composant nucléaire avec revetement de cr metastable, procédé de fabrication par dli-mocvd et utilisations contre l'oxydation/hydruration |

| US11560625B2 (en) * | 2018-01-19 | 2023-01-24 | Entegris, Inc. | Vapor deposition of molybdenum using a bis(alkyl-arene) molybdenum precursor |

| FR3114588B1 (fr) * | 2020-09-29 | 2023-08-11 | Safran Ceram | Procédé de fabrication d’une barrière environnementale |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SU1453950A1 (ru) * | 1987-01-07 | 1994-06-30 | А.И. Костылев | Парогазовая смесь для пиролитического нанесения защитных покрытий на основе хрома |

| FR2643071B1 (fr) * | 1989-02-16 | 1993-05-07 | Unirec | Procede de depot en phase vapeur a basse temperature d'un revetement ceramique du type nitrure ou carbonitrure metallique |

| SU1759958A1 (ru) * | 1990-04-19 | 1992-09-07 | Дзержинский филиал Ленинградского научно-исследовательского и конструкторского института химического машиностроения | Способ нанесени пиролитического карбидохромового покрыти на металлические поверхности |

| JPH0412525A (ja) * | 1990-05-02 | 1992-01-17 | Babcock Hitachi Kk | 有機金属化学気相成長装置 |

| WO2005028704A1 (en) * | 2003-09-19 | 2005-03-31 | Akzo Nobel N.V. | Metallization of substrate (s) by a liquid/vapor deposition process |

| KR101388817B1 (ko) * | 2006-03-14 | 2014-04-23 | 프랙스에어 테크놀로지, 인코포레이티드 | 증착 방법을 위한 온도 제어 콜드 트랩 및 그의 용도 |

| FR2904007B1 (fr) | 2006-07-21 | 2008-11-21 | Toulouse Inst Nat Polytech | Procede de depot de revetements ceramiques non oxydes. |

| FR2904006B1 (fr) * | 2006-07-21 | 2008-10-31 | Toulouse Inst Nat Polytech | Procede de depot de revetements metalliques durs |

| JP5277784B2 (ja) * | 2008-08-07 | 2013-08-28 | 東京エレクトロン株式会社 | 原料回収方法、トラップ機構、排気系及びこれを用いた成膜装置 |

| RU2513496C2 (ru) * | 2012-05-31 | 2014-04-20 | Федеральное государственное унитарное предприятие "Научно-производственное объединение "Радиевый институт имени В.Г. Хлопина" | Износостойкое металлическое покрытие на основе хрома и способ его нанесения |

| WO2014074589A1 (en) * | 2012-11-06 | 2014-05-15 | Applied Materials, Inc. | Apparatus for spatial atomic layer deposition with recirculation and methods of use |

| JP6101958B2 (ja) * | 2013-02-13 | 2017-03-29 | 日本パイオニクス株式会社 | アンモニア及び水素の回収方法及び再利用方法 |

| JP2015151564A (ja) * | 2014-02-13 | 2015-08-24 | 東洋製罐グループホールディングス株式会社 | 原子層堆積成膜装置 |

-

2015

- 2015-12-18 FR FR1562862A patent/FR3045673B1/fr active Active

-

2016

- 2016-12-17 US US16/063,405 patent/US20190003048A1/en not_active Abandoned

- 2016-12-17 RU RU2018125304A patent/RU2699126C1/ru not_active IP Right Cessation

- 2016-12-17 EP EP16831495.3A patent/EP3390686B1/fr active Active

- 2016-12-17 WO PCT/FR2016/053541 patent/WO2017103546A1/fr not_active Ceased

- 2016-12-17 JP JP2018531355A patent/JP6997711B2/ja active Active

- 2016-12-17 KR KR1020187020519A patent/KR20180089515A/ko not_active Ceased

-

2019

- 2019-10-31 US US16/669,854 patent/US11142822B2/en active Active

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2020050974A1 (en) * | 2018-09-03 | 2020-03-12 | Applied Materials, Inc. | Direct liquid injection system for thin film deposition |

| US11180849B2 (en) | 2018-09-03 | 2021-11-23 | Applied Materials, Inc. | Direct liquid injection system for thin film deposition |

| EP3847294A4 (en) * | 2018-09-03 | 2022-06-01 | Applied Materials, Inc. | DIRECT LIQUID INJECTION SYSTEM FOR THIN FILM DEPOSITION |

Also Published As

| Publication number | Publication date |

|---|---|

| US20190003048A1 (en) | 2019-01-03 |

| EP3390686A1 (fr) | 2018-10-24 |

| FR3045673A1 (fr) | 2017-06-23 |

| WO2017103546A1 (fr) | 2017-06-22 |

| RU2699126C1 (ru) | 2019-09-03 |

| JP6997711B2 (ja) | 2022-02-04 |

| US20200123655A1 (en) | 2020-04-23 |

| EP3390686B1 (fr) | 2019-11-20 |

| JP2019502023A (ja) | 2019-01-24 |

| FR3045673B1 (fr) | 2020-02-28 |

| US11142822B2 (en) | 2021-10-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US11142822B2 (en) | Method for depositing a coating by DLI-MOCVD with direct recycling of the precursor compound | |

| Carlsson et al. | Chemical vapor deposition | |

| Thurier et al. | Platinum OMCVD processes and precursor chemistry | |

| US8431190B2 (en) | Method for depositing hard metallic coatings | |

| US8343582B2 (en) | Process for deposition of non-oxide ceramic coatings | |

| Gebhard et al. | An efficient PE-ALD process for TiO 2 thin films employing a new Ti-precursor | |

| JP2019537704A (ja) | アモルファスCrC被覆を有する原子炉コンポーネント、DLI−MOCVDによる製造方法および酸化/水素化に対する使用 | |

| Pedersen et al. | Low Temperature CVD of Thin, Amorphous Boron‐Carbon Films for Neutron Detectors | |

| Carta et al. | CVD of MgO thin films from bis (methylcyclopentadienyl) magnesium | |

| KR102721931B1 (ko) | 탄화수소 중 알킬-인듐 화합물의 용액을 사용하는 유기금속 기상 증착 방법 | |

| WO2007106462A2 (en) | Temperature controlled cold trap for a vapour deposition process and uses thereof | |

| Douard et al. | Nanocrystalline chromium-based coatings deposited by DLI-MOCVD under atmospheric pressure from Cr (CO) 6 | |

| Liu et al. | Etching effect on metal‐organic molecular‐beam epitaxy growth of GaSb using triethylgallium and trisdimethylaminoantimony | |

| Bystrov et al. | Plasmachemical synthesis of titanium carbide on copper substrates | |

| Fainer et al. | Preparation of nanocrystalline titanium carbonitride coatings using Ti (N (Et) 2) 4 | |

| Boisselier et al. | Growth of chromium carbide in a hot wall DLICVD reactor | |

| Lee | The Preparation of Titanium‐Based Thin Film by CVD Using Titanium Chlorides as Precursors | |

| Kim et al. | Precise Thickness Controlled Growth of Al2O3 Thin Film Using Ecofriendly Direct Liquid Injection-Based Low Pressure Chemical Vapor Deposition (DLI-LPCVD) | |

| Kreinin et al. | Rapid thermal two-stage metal-organic chemical vapor deposition growth of epitaxial BaTiO3 thin films | |

| Schulz et al. | Single source precursor-based HV-MOCVD deposition of binary group 13-antimonide thin films | |

| Makarevich et al. | Low-temperature MOCVD of epitaxial CaF2 and SrF2 films | |

| Maury et al. | Low‐temperature MOCVD of chromium carbonitride coatings from tetrakis (diethylamido) chromium and pyrolysis mechanism of this single‐source precursor | |

| Blakeney et al. | A volatile dialane complex from ring-expansion of an N-heterocyclic carbene and its use in atomic layer deposition of aluminum metal films | |

| Hobbs et al. | Plasma-assisted deposition of BN thin films from B (N3) 3 | |

| Schulz | CVD Deposition of Binary AlSb and GaSb Material Films--a Single-Source Approach |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20180717 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| A201 | Request for examination | ||

| A302 | Request for accelerated examination | ||

| PA0201 | Request for examination |

Patent event code: PA02012R01D Patent event date: 20180719 Comment text: Request for Examination of Application |

|

| PA0302 | Request for accelerated examination |

Patent event date: 20180719 Patent event code: PA03022R01D Comment text: Request for Accelerated Examination |

|

| PG1501 | Laying open of application | ||

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20181204 Patent event code: PE09021S01D |

|

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20190625 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20181204 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |