KR20150126668A - 선형상 지재, 브러시형상 지석 및 선형상 지재의 제조방법 - Google Patents

선형상 지재, 브러시형상 지석 및 선형상 지재의 제조방법 Download PDFInfo

- Publication number

- KR20150126668A KR20150126668A KR1020157027806A KR20157027806A KR20150126668A KR 20150126668 A KR20150126668 A KR 20150126668A KR 1020157027806 A KR1020157027806 A KR 1020157027806A KR 20157027806 A KR20157027806 A KR 20157027806A KR 20150126668 A KR20150126668 A KR 20150126668A

- Authority

- KR

- South Korea

- Prior art keywords

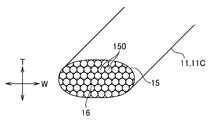

- linear

- sectional shape

- cross

- yarn

- resin binder

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D3/00—Preparing, i.e. Manufacturing brush bodies

- A46D3/005—Preparing, i.e. Manufacturing brush bodies by moulding or casting a body around bristles or tufts of bristles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D13/00—Wheels having flexibly-acting working parts, e.g. buffing wheels; Mountings therefor

- B24D13/02—Wheels having flexibly-acting working parts, e.g. buffing wheels; Mountings therefor acting by their periphery

- B24D13/10—Wheels having flexibly-acting working parts, e.g. buffing wheels; Mountings therefor acting by their periphery comprising assemblies of brushes

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D1/00—Bristles; Selection of materials for bristles

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D1/00—Bristles; Selection of materials for bristles

- A46D1/04—Preparing bristles

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D3/00—Preparing, i.e. Manufacturing brush bodies

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D13/00—Wheels having flexibly-acting working parts, e.g. buffing wheels; Mountings therefor

- B24D13/14—Wheels having flexibly-acting working parts, e.g. buffing wheels; Mountings therefor acting by the front face

- B24D13/145—Wheels having flexibly-acting working parts, e.g. buffing wheels; Mountings therefor acting by the front face having a brush-like working surface

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D18/00—Manufacture of grinding tools or other grinding devices, e.g. wheels, not otherwise provided for

- B24D18/0027—Manufacture of grinding tools or other grinding devices, e.g. wheels, not otherwise provided for by impregnation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D3/00—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents

- B24D3/02—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents the constituent being used as bonding agent

- B24D3/20—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents the constituent being used as bonding agent and being essentially organic

- B24D3/28—Resins or natural or synthetic macromolecular compounds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D3/00—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents

- B24D3/34—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents characterised by additives enhancing special physical properties, e.g. wear resistance, electric conductivity, self-cleaning properties

- B24D3/342—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents characterised by additives enhancing special physical properties, e.g. wear resistance, electric conductivity, self-cleaning properties incorporated in the bonding agent

- B24D3/344—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents characterised by additives enhancing special physical properties, e.g. wear resistance, electric conductivity, self-cleaning properties incorporated in the bonding agent the bonding agent being organic

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46B—BRUSHES

- A46B2200/00—Brushes characterized by their functions, uses or applications

- A46B2200/30—Brushes for cleaning or polishing

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46B—BRUSHES

- A46B2200/00—Brushes characterized by their functions, uses or applications

- A46B2200/30—Brushes for cleaning or polishing

- A46B2200/3093—Brush with abrasive properties, e.g. wire bristles

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Polishing Bodies And Polishing Tools (AREA)

- Brushes (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013046982A JP6325195B2 (ja) | 2013-03-08 | 2013-03-08 | ブラシ状砥石の製造方法、線状砥材およびブラシ状砥石 |

| JPJP-P-2013-046982 | 2013-03-08 | ||

| PCT/JP2014/056028 WO2014136954A1 (ja) | 2013-03-08 | 2014-03-07 | 線状砥材、ブラシ状砥石および線状砥材の製造方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20150126668A true KR20150126668A (ko) | 2015-11-12 |

Family

ID=51491461

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020157027806A Ceased KR20150126668A (ko) | 2013-03-08 | 2014-03-07 | 선형상 지재, 브러시형상 지석 및 선형상 지재의 제조방법 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US20160016293A1 (enExample) |

| EP (1) | EP2965866B1 (enExample) |

| JP (1) | JP6325195B2 (enExample) |

| KR (1) | KR20150126668A (enExample) |

| CN (1) | CN105026108A (enExample) |

| BR (1) | BR112015021636B1 (enExample) |

| MX (1) | MX2015011248A (enExample) |

| WO (1) | WO2014136954A1 (enExample) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2015166679A1 (ja) * | 2014-05-01 | 2015-11-05 | 株式会社ジーベックテクノロジー | 回転工具、研磨工具および加工方法 |

| DE112015002410T5 (de) * | 2014-05-22 | 2017-02-02 | Taimei Chemicals Co., Ltd | Werkzeughalter, Polierwerkzeug, Polierwerkzeugeinheit und Verfahren zum Einstellen des Überstands eines Schleifelements |

| US10332151B2 (en) * | 2014-05-28 | 2019-06-25 | Blake F. Megdal | Method and system for using media points to influence content delivery |

| DE112014007101T5 (de) * | 2014-10-27 | 2017-07-20 | Taimei Chemicals Co., Ltd | Schleifbürste |

| JP2017055785A (ja) * | 2015-09-14 | 2017-03-23 | 正雄 西木 | 研掃ブラシ |

| JP6786075B2 (ja) | 2016-07-15 | 2020-11-18 | 大明化学工業株式会社 | ホイールブラシおよび砥材束ホルダ |

| JP1567542S (enExample) * | 2016-07-15 | 2017-01-23 | ||

| JP1567543S (enExample) * | 2016-07-15 | 2017-01-23 | ||

| JP1567544S (enExample) * | 2016-07-15 | 2017-01-23 | ||

| CN108555733A (zh) * | 2018-06-08 | 2018-09-21 | 辽宁科技大学 | 用于精磨医用注射器针头内表面的装置 |

| US10675728B2 (en) * | 2018-10-29 | 2020-06-09 | Shin-Yain Industrial Co., Ltd. | Cutter holder capable of polishing |

| US20230157481A1 (en) * | 2021-11-22 | 2023-05-25 | Steven Monti | Multi-purpose espresso machine group head cleaning tool |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0584670A (ja) * | 1991-09-27 | 1993-04-06 | Mazda Motor Corp | 研磨糸を有してなる研磨具 |

| JP3114311B2 (ja) * | 1991-12-20 | 2000-12-04 | 株式会社神戸製鋼所 | 繊維強化樹脂ストランドの製造方法 |

| US5609398A (en) * | 1994-10-20 | 1997-03-11 | Jason Incorporated | Twisted stem abrading tool and method of making |

| JPH08309669A (ja) * | 1995-05-15 | 1996-11-26 | Mazda Motor Corp | 研磨工具 |

| JPH09216166A (ja) * | 1996-02-08 | 1997-08-19 | Souwa Kasei Kk | Frp製研磨体とその製造方法 |

| JP2002210662A (ja) | 2001-01-16 | 2002-07-30 | Xebec Technology Co Ltd | ブラシ状砥石、バリ取り並びに研磨方法 |

| JP2002219656A (ja) * | 2001-01-23 | 2002-08-06 | Xebec Technology Co Ltd | ブラシ状砥石、バリ取り並びに研磨方法 |

| JP3819286B2 (ja) * | 2001-12-12 | 2006-09-06 | 株式会社神戸製鋼所 | 長繊維強化熱可塑性樹脂ストランドの製造装置および製造方法 |

| EP1543924B1 (en) * | 2002-07-22 | 2010-02-17 | Xebec Technology Co., Ltd. | Polisher brush |

| GB0305257D0 (en) * | 2003-03-07 | 2003-04-09 | Exchem Plc | A cleaning brush |

| JP2007075954A (ja) * | 2005-09-14 | 2007-03-29 | Xebec Technology Co Ltd | ブラシ状砥石 |

| WO2007097115A1 (ja) * | 2006-02-20 | 2007-08-30 | Xebec Technology Co., Ltd. | ブラシ状砥石 |

| WO2007119747A1 (ja) * | 2006-04-13 | 2007-10-25 | Toyo Boseki Kabushiki Kaisha | 微細炭素繊維撚糸を連続的に製造する方法、装置、及び該方法によって製造された微細炭素繊維撚糸 |

| JP4871175B2 (ja) * | 2007-03-12 | 2012-02-08 | 株式会社神戸製鋼所 | 長繊維強化熱可塑性樹脂ペレットの製造方法 |

| JP5306619B2 (ja) * | 2007-09-06 | 2013-10-02 | スリーエム イノベイティブ プロパティズ カンパニー | 線形研磨ブラシ部材、線形研磨ブラシ部材の製造方法、及び研磨ブラシ |

| JP2011218526A (ja) * | 2010-04-14 | 2011-11-04 | Toray Monofilament Co Ltd | 研磨ブラシ用毛材および研磨ブラシ |

-

2013

- 2013-03-08 JP JP2013046982A patent/JP6325195B2/ja active Active

-

2014

- 2014-03-07 BR BR112015021636-6A patent/BR112015021636B1/pt active IP Right Grant

- 2014-03-07 US US14/773,307 patent/US20160016293A1/en not_active Abandoned

- 2014-03-07 WO PCT/JP2014/056028 patent/WO2014136954A1/ja not_active Ceased

- 2014-03-07 KR KR1020157027806A patent/KR20150126668A/ko not_active Ceased

- 2014-03-07 EP EP14759583.9A patent/EP2965866B1/en active Active

- 2014-03-07 MX MX2015011248A patent/MX2015011248A/es unknown

- 2014-03-07 CN CN201480012744.3A patent/CN105026108A/zh active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| EP2965866A1 (en) | 2016-01-13 |

| BR112015021636A2 (pt) | 2020-01-28 |

| BR112015021636B1 (pt) | 2021-11-23 |

| EP2965866A4 (en) | 2016-11-02 |

| MX2015011248A (es) | 2016-03-04 |

| WO2014136954A1 (ja) | 2014-09-12 |

| EP2965866B1 (en) | 2020-04-22 |

| JP6325195B2 (ja) | 2018-05-16 |

| CN105026108A (zh) | 2015-11-04 |

| US20160016293A1 (en) | 2016-01-21 |

| JP2014172126A (ja) | 2014-09-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20150126668A (ko) | 선형상 지재, 브러시형상 지석 및 선형상 지재의 제조방법 | |

| JP2014172126A5 (enExample) | ||

| CN100396439C (zh) | 一种研磨机用刷 | |

| JP5238488B2 (ja) | ブラシ状砥石 | |

| CN105492168A (zh) | 研磨方法、刷状磨石、研磨刷以及线材集合体 | |

| JP6786075B2 (ja) | ホイールブラシおよび砥材束ホルダ | |

| JP3932487B2 (ja) | トーションレース機に使用される付属品 | |

| CN209970411U (zh) | 一种金刚线多线切割辅助辊 | |

| JP2002219656A (ja) | ブラシ状砥石、バリ取り並びに研磨方法 | |

| JP5959284B2 (ja) | 曲面研磨方法および研磨装置 | |

| JP6022686B2 (ja) | フライス切削と後続のブラッシングとによって原材料を加工する方法 | |

| JP2002210662A (ja) | ブラシ状砥石、バリ取り並びに研磨方法 | |

| JP7239951B1 (ja) | スティック砥石および研磨方法 | |

| JP2000094344A (ja) | ブラシ状砥石並びにバリ取り、研磨方法 | |

| JP7117702B1 (ja) | 研磨ブラシ用線状砥材、および研磨ブラシ | |

| JP2002210661A (ja) | ブラシ状砥石、バリ取り並びに研磨方法 | |

| KR20250047278A (ko) | 스틱 지석 및 연마 방법 | |

| WO2016166852A1 (ja) | 砥材および回転研磨工具 | |

| JP2005138221A (ja) | バリ取り工具 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| PA0105 | International application |

Patent event date: 20151006 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PA0201 | Request for examination | ||

| PG1501 | Laying open of application | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20161130 Patent event code: PE09021S01D |

|

| AMND | Amendment | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20170630 Patent event code: PE09021S01D |

|

| PE0601 | Decision on rejection of patent |

Patent event date: 20180131 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20170630 Comment text: Notification of reason for refusal Patent event code: PE06011S01I Patent event date: 20161130 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |

|

| AMND | Amendment | ||

| PX0901 | Re-examination |

Patent event code: PX09011S01I Patent event date: 20180131 Comment text: Decision to Refuse Application Patent event code: PX09012R01I Patent event date: 20170109 Comment text: Amendment to Specification, etc. |

|

| PX0601 | Decision of rejection after re-examination |

Comment text: Decision to Refuse Application Patent event code: PX06014S01D Patent event date: 20180502 Comment text: Amendment to Specification, etc. Patent event code: PX06012R01I Patent event date: 20180330 Comment text: Decision to Refuse Application Patent event code: PX06011S01I Patent event date: 20180131 Comment text: Notification of reason for refusal Patent event code: PX06013S01I Patent event date: 20170630 Comment text: Amendment to Specification, etc. Patent event code: PX06012R01I Patent event date: 20170109 Comment text: Notification of reason for refusal Patent event code: PX06013S01I Patent event date: 20161130 |