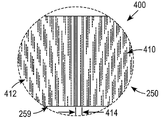

KR20150044371A - 미세-홈 형성된 비-점착성 표면을 갖는 설치 픽스처 - Google Patents

미세-홈 형성된 비-점착성 표면을 갖는 설치 픽스처 Download PDFInfo

- Publication number

- KR20150044371A KR20150044371A KR20140081147A KR20140081147A KR20150044371A KR 20150044371 A KR20150044371 A KR 20150044371A KR 20140081147 A KR20140081147 A KR 20140081147A KR 20140081147 A KR20140081147 A KR 20140081147A KR 20150044371 A KR20150044371 A KR 20150044371A

- Authority

- KR

- South Korea

- Prior art keywords

- ring

- elastomeric band

- base ring

- clamp ring

- band

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/687—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches

- H01L21/68714—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a susceptor, stage or support

- H01L21/68785—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a susceptor, stage or support characterised by the mechanical construction of the susceptor, stage or support

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67126—Apparatus for sealing, encapsulating, glassing, decapsulating or the like

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49826—Assembling or joining

- Y10T29/49863—Assembling or joining with prestressing of part

- Y10T29/4987—Elastic joining of parts

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T403/00—Joints and connections

- Y10T403/67—Thimble: screw or cam

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Container, Conveyance, Adherence, Positioning, Of Wafer (AREA)

- Drying Of Semiconductors (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US13/930,659 US9502279B2 (en) | 2013-06-28 | 2013-06-28 | Installation fixture having a micro-grooved non-stick surface |

| US13/930,659 | 2013-06-28 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20150044371A true KR20150044371A (ko) | 2015-04-24 |

Family

ID=52115739

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR20140081147A Withdrawn KR20150044371A (ko) | 2013-06-28 | 2014-06-30 | 미세-홈 형성된 비-점착성 표면을 갖는 설치 픽스처 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US9502279B2 (enExample) |

| JP (1) | JP2015029088A (enExample) |

| KR (1) | KR20150044371A (enExample) |

| CN (1) | CN104253078A (enExample) |

| TW (1) | TWI622123B (enExample) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105405797B (zh) * | 2015-12-30 | 2018-01-12 | 天津金海通自动化设备制造有限公司 | 一种给气浮动机构 |

| JP6572788B2 (ja) * | 2016-01-29 | 2019-09-11 | 住友大阪セメント株式会社 | 静電チャック装置 |

| JP7340938B2 (ja) * | 2019-02-25 | 2023-09-08 | 東京エレクトロン株式会社 | 載置台及び基板処理装置 |

| CN116845004A (zh) * | 2020-05-27 | 2023-10-03 | 北京北方华创微电子装备有限公司 | 半导体工艺设备 |

Family Cites Families (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5636098A (en) | 1994-01-06 | 1997-06-03 | Applied Materials, Inc. | Barrier seal for electrostatic chuck |

| US5740009A (en) | 1996-11-29 | 1998-04-14 | Applied Materials, Inc. | Apparatus for improving wafer and chuck edge protection |

| US6090304A (en) | 1997-08-28 | 2000-07-18 | Lam Research Corporation | Methods for selective plasma etch |

| US6364957B1 (en) | 1997-10-09 | 2002-04-02 | Applied Materials, Inc. | Support assembly with thermal expansion compensation |

| WO2002089531A1 (en) | 2001-04-30 | 2002-11-07 | Lam Research, Corporation | Method and apparatus for controlling the spatial temperature distribution across the surface of a workpiece support |

| US6771482B2 (en) | 2001-07-30 | 2004-08-03 | Unaxis Usa Inc. | Perimeter seal for backside cooling of substrates |

| JP4451098B2 (ja) * | 2002-08-22 | 2010-04-14 | 住友大阪セメント株式会社 | サセプタ装置 |

| US7252738B2 (en) | 2002-09-20 | 2007-08-07 | Lam Research Corporation | Apparatus for reducing polymer deposition on a substrate and substrate support |

| AU2003254871A1 (en) | 2002-10-25 | 2004-05-13 | Nok Corporation | Plasma resistant seal |

| US6944006B2 (en) | 2003-04-03 | 2005-09-13 | Applied Materials, Inc. | Guard for electrostatic chuck |

| US7514506B2 (en) | 2004-03-31 | 2009-04-07 | Greene, Tweed Of Delaware, Inc. | Fast curing fluoroelastomeric compositions, adhesive fluoroelastomeric compositions and methods for bonding fluoroelastomeric compositions |

| US8038796B2 (en) | 2004-12-30 | 2011-10-18 | Lam Research Corporation | Apparatus for spatial and temporal control of temperature on a substrate |

| US7319316B2 (en) | 2005-06-29 | 2008-01-15 | Lam Research Corporation | Apparatus for measuring a set of electrical characteristics in a plasma |

| US7431788B2 (en) | 2005-07-19 | 2008-10-07 | Lam Research Corporation | Method of protecting a bond layer in a substrate support adapted for use in a plasma processing system |

| JP2007207728A (ja) * | 2006-02-06 | 2007-08-16 | Aisin Seiki Co Ltd | 固体高分子型燃料電池用セパレータ及びその製造方法、並びに固体高分子型燃料電池 |

| GB0610479D0 (en) | 2006-05-26 | 2006-07-05 | Ge Healthcare Bio Sciences Ab | A method for generating metal chelating affinity ligands |

| US20090179366A1 (en) | 2008-01-16 | 2009-07-16 | Sokudo Co., Ltd. | Apparatus for supporting a substrate during semiconductor processing operations |

| CN102027574B (zh) * | 2008-02-08 | 2014-09-10 | 朗姆研究公司 | 等离子体处理室部件的保护性涂层及其使用方法 |

| CN201167837Y (zh) * | 2008-03-06 | 2008-12-24 | 浙江爱仕达电器股份有限公司 | 铝合金阳极氧化物理不粘锅 |

| US7884925B2 (en) | 2008-05-23 | 2011-02-08 | Lam Research Corporation | Electrical and optical system and methods for monitoring erosion of electrostatic chuck edge bead materials |

| JP5518071B2 (ja) | 2008-08-19 | 2014-06-11 | ラム リサーチ コーポレーション | 静電チャック用エッジリング |

| JP5635001B2 (ja) | 2008-09-26 | 2014-12-03 | ラム リサーチ コーポレーションLam Research Corporation | 結合リングをクロック回転させることによって調整可能な静電チャックとホットエッジリングとの間の熱的接触 |

| KR101624123B1 (ko) | 2008-10-31 | 2016-05-25 | 램 리써치 코포레이션 | 플라즈마 프로세싱 챔버의 하부 전극 어셈블리 |

| US20100117309A1 (en) | 2008-11-13 | 2010-05-13 | Applied Materials, Inc. | Sealing apparatus for a process chamber |

| US8409995B2 (en) | 2009-08-07 | 2013-04-02 | Tokyo Electron Limited | Substrate processing apparatus, positioning method and focus ring installation method |

| JP5291039B2 (ja) * | 2010-03-31 | 2013-09-18 | 大日本スクリーン製造株式会社 | 基板保持回転装置および基板処理装置 |

| TWM431430U (en) * | 2011-08-24 | 2012-06-11 | Wafer Works Corp | Clip board type fastening device for use in annularly etching wafer |

| US9869392B2 (en) * | 2011-10-20 | 2018-01-16 | Lam Research Corporation | Edge seal for lower electrode assembly |

| US8844106B2 (en) * | 2011-11-10 | 2014-09-30 | Lam Research Corporation | Installation fixture for elastomer bands and methods of using the same |

| US8677586B2 (en) * | 2012-04-04 | 2014-03-25 | Lam Research Corporation | Installation fixture for elastomer bands and methods of using the same |

| US9583377B2 (en) * | 2013-12-17 | 2017-02-28 | Lam Research Corporation | Installation fixture for elastomer bands |

-

2013

- 2013-06-28 US US13/930,659 patent/US9502279B2/en active Active

-

2014

- 2014-06-27 JP JP2014132168A patent/JP2015029088A/ja active Pending

- 2014-06-27 TW TW103122372A patent/TWI622123B/zh active

- 2014-06-30 CN CN201410306477.2A patent/CN104253078A/zh active Pending

- 2014-06-30 KR KR20140081147A patent/KR20150044371A/ko not_active Withdrawn

Also Published As

| Publication number | Publication date |

|---|---|

| CN104253078A (zh) | 2014-12-31 |

| TWI622123B (zh) | 2018-04-21 |

| US20150003903A1 (en) | 2015-01-01 |

| US9502279B2 (en) | 2016-11-22 |

| JP2015029088A (ja) | 2015-02-12 |

| TW201516278A (zh) | 2015-05-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR102551996B1 (ko) | 정전 척 본딩들에 대한 영구적인 2차 부식 방지 | |

| US8677586B2 (en) | Installation fixture for elastomer bands and methods of using the same | |

| TWI415165B (zh) | 保護在用於一電漿處理系統中之一基材支承內的結合層之方法 | |

| KR102282723B1 (ko) | 엘라스토머 밴드용 설치 픽스처 | |

| US10804081B2 (en) | Edge ring dimensioned to extend lifetime of elastomer seal in a plasma processing chamber | |

| CN101529558B (zh) | 具有减少微粒特性的上电极背衬构件 | |

| US9859142B2 (en) | Edge seal for lower electrode assembly | |

| US20130340942A1 (en) | Edge seal for lower electrode assembly | |

| US9355884B2 (en) | Installation fixture for elastomer bands and methods of using the same | |

| US9502279B2 (en) | Installation fixture having a micro-grooved non-stick surface |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0109 | Patent application |

Patent event code: PA01091R01D Comment text: Patent Application Patent event date: 20140630 |

|

| PG1501 | Laying open of application | ||

| PC1203 | Withdrawal of no request for examination | ||

| WITN | Application deemed withdrawn, e.g. because no request for examination was filed or no examination fee was paid |