KR20140102652A - 성형 시스템용 모듈식 맨드릴 - Google Patents

성형 시스템용 모듈식 맨드릴 Download PDFInfo

- Publication number

- KR20140102652A KR20140102652A KR1020147013486A KR20147013486A KR20140102652A KR 20140102652 A KR20140102652 A KR 20140102652A KR 1020147013486 A KR1020147013486 A KR 1020147013486A KR 20147013486 A KR20147013486 A KR 20147013486A KR 20140102652 A KR20140102652 A KR 20140102652A

- Authority

- KR

- South Korea

- Prior art keywords

- connector

- segment

- mandrel

- segments

- generally

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000000465 moulding Methods 0.000 title claims abstract description 24

- 230000008859 change Effects 0.000 claims abstract description 5

- 230000003247 decreasing effect Effects 0.000 claims abstract description 3

- 238000000034 method Methods 0.000 claims description 27

- 239000000463 material Substances 0.000 description 22

- 238000004519 manufacturing process Methods 0.000 description 7

- 230000008569 process Effects 0.000 description 5

- 229910052751 metal Inorganic materials 0.000 description 4

- 239000002184 metal Substances 0.000 description 4

- 238000003466 welding Methods 0.000 description 4

- 230000007246 mechanism Effects 0.000 description 3

- 230000008439 repair process Effects 0.000 description 3

- 229910000838 Al alloy Inorganic materials 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 2

- 229910052782 aluminium Inorganic materials 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 238000004513 sizing Methods 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 230000007704 transition Effects 0.000 description 2

- 238000004026 adhesive bonding Methods 0.000 description 1

- 230000004323 axial length Effects 0.000 description 1

- 238000005219 brazing Methods 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000000737 periodic effect Effects 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 125000006850 spacer group Chemical group 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

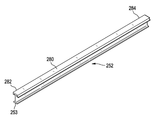

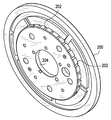

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/76—Cores

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/30—Mounting, exchanging or centering

- B29C33/301—Modular mould systems [MMS], i.e. moulds built up by stacking mould elements, e.g. plates, blocks, rods

- B29C33/302—Assembling a large number of mould elements to constitute one cavity

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/42—Moulds or cores; Details thereof or accessories therefor characterised by the shape of the moulding surface, e.g. ribs or grooves

- B29C33/424—Moulding surfaces provided with means for marking or patterning

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Moulding By Coating Moulds (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201161566830P | 2011-12-05 | 2011-12-05 | |

| US61/566,830 | 2011-12-05 | ||

| PCT/US2012/067682 WO2013085868A2 (en) | 2011-12-05 | 2012-12-04 | Modular mandrel for a molding system |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20140102652A true KR20140102652A (ko) | 2014-08-22 |

Family

ID=48571109

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020147013486A Withdrawn KR20140102652A (ko) | 2011-12-05 | 2012-12-04 | 성형 시스템용 모듈식 맨드릴 |

Country Status (11)

| Country | Link |

|---|---|

| US (1) | US20130146745A1 (cg-RX-API-DMAC7.html) |

| EP (1) | EP2788162A4 (cg-RX-API-DMAC7.html) |

| JP (1) | JP2015501741A (cg-RX-API-DMAC7.html) |

| KR (1) | KR20140102652A (cg-RX-API-DMAC7.html) |

| CN (1) | CN104125878A (cg-RX-API-DMAC7.html) |

| AR (1) | AR089089A1 (cg-RX-API-DMAC7.html) |

| AU (1) | AU2012348049A1 (cg-RX-API-DMAC7.html) |

| BR (1) | BR112014013109A2 (cg-RX-API-DMAC7.html) |

| IN (1) | IN2014MN01025A (cg-RX-API-DMAC7.html) |

| MX (1) | MX2014006651A (cg-RX-API-DMAC7.html) |

| WO (1) | WO2013085868A2 (cg-RX-API-DMAC7.html) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL2013075B1 (nl) * | 2014-06-26 | 2016-07-11 | Zamqua Holding B V | Matrijs voor het vormen van een hol lichaam en opblaasbaar lichaam. |

| NL1041749B1 (nl) * | 2016-03-08 | 2017-09-27 | Hinke Wiering Elsiena | Werkwijze waarmee grote objecten kunnen worden vervaardigd met behulp van driedimensionale apparatuur. |

| JP7585962B2 (ja) * | 2021-05-18 | 2024-11-19 | トヨタ自動車株式会社 | 成型用金型 |

| DE102023203797A1 (de) | 2023-04-25 | 2024-10-31 | Volkswagen Aktiengesellschaft | Verfahren zum automatisierten Handhaben wenigstens eines geschlossenen Riemens sowie eine Vorrichtung hierzu |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3692607A (en) * | 1970-02-09 | 1972-09-19 | Samuel M Shobert | Method and apparatus for making a reinforced plastic well screen |

| BE765040A (fr) * | 1970-04-09 | 1971-08-16 | Pirelli | Moule expansible a secteurs pour la vulcanisation de courroies |

| US3780469A (en) * | 1971-05-18 | 1973-12-25 | Hi Ho Prod Inc | Sectional creative toy |

| US4000240A (en) * | 1975-04-17 | 1976-12-28 | Teletype Corporation | Process of molding a reinforced flexible belt |

| US5176867A (en) * | 1989-08-02 | 1993-01-05 | Dayco Products, Inc. | Method of making a toothed belt construction with an endless preformed fabric sleeve |

| JP2902023B2 (ja) * | 1989-12-28 | 1999-06-07 | 横浜ゴム株式会社 | 無端ベルト用成形装置 |

| IT1240295B (it) * | 1990-04-13 | 1993-12-07 | Pirelli | Stampo e metodo per la vulcanizzazione di pneumatici e metodo per fabbricare stampi |

| CA2077400A1 (en) * | 1991-10-08 | 1993-04-09 | Mikhail Leyderman | Mandrel and a method of making a rigid tubular article |

| US5266137A (en) * | 1992-11-10 | 1993-11-30 | Hollingsworth Ritch D | Rigid segmented mandrel with inflatable support |

| JP2000280371A (ja) * | 1999-01-29 | 2000-10-10 | Mitsuboshi Belting Ltd | 両面歯付ベルトの製造方法及びそれに用いる金型装置 |

| US6712546B1 (en) * | 2001-08-08 | 2004-03-30 | John Radu, Jr. | Polymeric forms for moldable building material structures |

| JP4296077B2 (ja) * | 2003-11-18 | 2009-07-15 | 住友ゴム工業株式会社 | 弾性クローラの製造方法 |

| JP4636925B2 (ja) * | 2005-04-22 | 2011-02-23 | 住友ゴム工業株式会社 | 弾性クローラの加硫成形金型とこの金型を使用した弾性クローラの製造方法 |

| US7556752B1 (en) * | 2006-05-01 | 2009-07-07 | Gregg Hicks | Multi-sectional form for forming bases for light poles |

| JP5576650B2 (ja) * | 2009-12-25 | 2014-08-20 | 川崎重工業株式会社 | 複合材料構造物製造用成形型 |

| GB2481974A (en) * | 2010-07-12 | 2012-01-18 | Biocomposites Ltd | Bone cement pellet mould |

| US8608890B2 (en) * | 2010-11-11 | 2013-12-17 | Spirit Aerosystems, Inc. | Reconfigurable shape memory polymer tooling supports |

| US8512614B2 (en) * | 2011-06-20 | 2013-08-20 | Dayco Ip Holdings, Llc | Modular molding system |

-

2012

- 2012-12-04 MX MX2014006651A patent/MX2014006651A/es unknown

- 2012-12-04 WO PCT/US2012/067682 patent/WO2013085868A2/en not_active Ceased

- 2012-12-04 IN IN1025MUN2014 patent/IN2014MN01025A/en unknown

- 2012-12-04 BR BR112014013109A patent/BR112014013109A2/pt not_active IP Right Cessation

- 2012-12-04 CN CN201280008065.XA patent/CN104125878A/zh active Pending

- 2012-12-04 EP EP12854648.8A patent/EP2788162A4/en not_active Withdrawn

- 2012-12-04 AU AU2012348049A patent/AU2012348049A1/en not_active Abandoned

- 2012-12-04 US US13/693,480 patent/US20130146745A1/en not_active Abandoned

- 2012-12-04 JP JP2014544993A patent/JP2015501741A/ja active Pending

- 2012-12-04 KR KR1020147013486A patent/KR20140102652A/ko not_active Withdrawn

- 2012-12-05 AR ARP120104563A patent/AR089089A1/es unknown

Also Published As

| Publication number | Publication date |

|---|---|

| AR089089A1 (es) | 2014-07-30 |

| IN2014MN01025A (cg-RX-API-DMAC7.html) | 2015-05-22 |

| MX2014006651A (es) | 2014-09-04 |

| JP2015501741A (ja) | 2015-01-19 |

| WO2013085868A2 (en) | 2013-06-13 |

| US20130146745A1 (en) | 2013-06-13 |

| CN104125878A (zh) | 2014-10-29 |

| EP2788162A4 (en) | 2015-10-14 |

| EP2788162A2 (en) | 2014-10-15 |

| WO2013085868A3 (en) | 2014-10-02 |

| AU2012348049A1 (en) | 2014-06-12 |

| BR112014013109A2 (pt) | 2017-06-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| MXPA05001410A (es) | Tambor de moldeado de neumatico y metodo de moldeado de neumatico. | |

| KR101395490B1 (ko) | 맨드렐 조립체 | |

| KR102313159B1 (ko) | 가변 곡률 세그먼트를 갖는 팽창가능한 벨트 및 트레드 드럼 | |

| KR20140102652A (ko) | 성형 시스템용 모듈식 맨드릴 | |

| KR101907936B1 (ko) | 타이어 가류 성형용 금형 및 이것을 사용한 타이어의 제조 방법 | |

| US7967343B2 (en) | Adapter for clamps, particularly for welding plastic pipes | |

| US9662847B2 (en) | Tire building drum having sequenced segment expansion | |

| US20140216660A1 (en) | Transfer Ring Shoe and Transfer Ring Having Varied Shoe Profile | |

| JP4362637B2 (ja) | 複数の歯を有する駆動ベルトの製造方法 | |

| CN206579158U (zh) | 筒体材料成型装置及其芯模 | |

| US8512614B2 (en) | Modular molding system | |

| EP2313241B1 (en) | Mold having mold tooling | |

| KR102022724B1 (ko) | 휠 허브의 내부 링 상에 전방 치부를 성형하는 방법, 업셋 칼라 및 이에 따라 형성된 전방 치부를 갖는 휠 허브 | |

| CN213860802U (zh) | 一种压辊芯模及成型模具 | |

| CN102165127B (zh) | 模具的扭转锁定装置 | |

| WO2013001964A1 (ja) | 剛性中子、及びそれを用いたタイヤの製造方法 | |

| KR101883020B1 (ko) | 경사진 고정 장치에 사용하기 위한 리벳 및 그의 방법 | |

| JP4837341B2 (ja) | ゴムクローラ製造方法およびその装置 | |

| CN116261514A (zh) | 具有减少的空气滞留特征的传递环柱脚和传递环 | |

| KR20160129644A (ko) | 반전형 에어펜더및 그 제조방법 | |

| US20240328453A1 (en) | Integrated composite drive shafts | |

| TW202537814A (zh) | 具有配備軸向對應導向表面和互補耦合部分之軸向滑動內外芯軸部件的可拆卸纖維纏繞芯軸總成 | |

| CN120816638A (zh) | 软体肌肉模具 | |

| JP2007076080A (ja) | 型締めシリンダ油圧回路 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20140520 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| PC1203 | Withdrawal of no request for examination | ||

| WITN | Application deemed withdrawn, e.g. because no request for examination was filed or no examination fee was paid |