KR20130124152A - 철강 분말 야금 - Google Patents

철강 분말 야금 Download PDFInfo

- Publication number

- KR20130124152A KR20130124152A KR1020127030327A KR20127030327A KR20130124152A KR 20130124152 A KR20130124152 A KR 20130124152A KR 1020127030327 A KR1020127030327 A KR 1020127030327A KR 20127030327 A KR20127030327 A KR 20127030327A KR 20130124152 A KR20130124152 A KR 20130124152A

- Authority

- KR

- South Korea

- Prior art keywords

- steel

- production

- powder

- steel powder

- production process

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

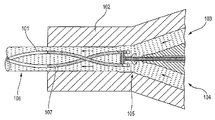

- B22F3/20—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces by extruding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F1/00—Metallic powder; Treatment of metallic powder, e.g. to facilitate working or to improve properties

- B22F1/10—Metallic powder containing lubricating or binding agents; Metallic powder containing organic material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/12—Both compacting and sintering

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F5/00—Manufacture of workpieces or articles from metallic powder characterised by the special shape of the product

- B22F5/10—Manufacture of workpieces or articles from metallic powder characterised by the special shape of the product of articles with cavities or holes, not otherwise provided for in the preceding subgroups

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F5/00—Manufacture of workpieces or articles from metallic powder characterised by the special shape of the product

- B22F5/10—Manufacture of workpieces or articles from metallic powder characterised by the special shape of the product of articles with cavities or holes, not otherwise provided for in the preceding subgroups

- B22F5/106—Tube or ring forms

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C33/00—Making ferrous alloys

- C22C33/02—Making ferrous alloys by powder metallurgy

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C33/00—Making ferrous alloys

- C22C33/02—Making ferrous alloys by powder metallurgy

- C22C33/0257—Making ferrous alloys by powder metallurgy characterised by the range of the alloying elements

- C22C33/0278—Making ferrous alloys by powder metallurgy characterised by the range of the alloying elements with at least one alloying element having a minimum content above 5%

- C22C33/0285—Making ferrous alloys by powder metallurgy characterised by the range of the alloying elements with at least one alloying element having a minimum content above 5% with Cr, Co, or Ni having a minimum content higher than 5%

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/22—Ferrous alloys, e.g. steel alloys containing chromium with molybdenum or tungsten

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Powder Metallurgy (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102010019599A DE102010019599A1 (de) | 2010-05-05 | 2010-05-05 | Pulvermetallurgischer Stahl |

| DE102010019599.5 | 2010-05-05 | ||

| PCT/EP2011/057257 WO2011138422A2 (de) | 2010-05-05 | 2011-05-05 | Pulvermetallurgischer stahl |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20130124152A true KR20130124152A (ko) | 2013-11-13 |

Family

ID=44201069

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020127030327A Ceased KR20130124152A (ko) | 2010-05-05 | 2011-05-05 | 철강 분말 야금 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20130136647A1 (enExample) |

| EP (1) | EP2566640A2 (enExample) |

| JP (1) | JP5940058B2 (enExample) |

| KR (1) | KR20130124152A (enExample) |

| DE (1) | DE102010019599A1 (enExample) |

| WO (1) | WO2011138422A2 (enExample) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104972127B (zh) * | 2015-07-02 | 2017-03-08 | 东睦新材料集团股份有限公司 | 一种粉末冶金打击块的制备方法 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2422994A (en) | 1944-01-03 | 1947-06-24 | Carboloy Company Inc | Twist drill |

| JPS61223102A (ja) * | 1985-03-29 | 1986-10-03 | Hitachi Metals Ltd | 中空孔を有する焼結鋼部材の製造方法 |

| DE3600681A1 (de) | 1985-10-31 | 1987-05-07 | Krupp Gmbh | Hartmetall- oder keramikbohrerrohling sowie verfahren und strangpresswerkzeug zu seiner herstellung |

| DE3601385A1 (de) | 1986-01-18 | 1987-07-23 | Krupp Gmbh | Verfahren zur herstellung von sinterkoerpern mit inneren kanaelen, strangpresswerkzeug zur durchfuehrung des verfahrens und bohrwerkzeug |

| DE3814687A1 (de) | 1988-04-30 | 1989-11-09 | Krupp Widia Gmbh | Strangpresswerkzeug |

| JPH0317203A (ja) * | 1989-06-15 | 1991-01-25 | Kawasaki Steel Corp | 粉末冶金製品の製造方法 |

| AT398286B (de) * | 1990-05-22 | 1994-11-25 | Boehlerit Gmbh & Co Kg | Hartmetall- oder keramikrohling sowie verfahren und werkzeug zur herstellung desselben |

| DE4120165C2 (de) * | 1990-07-05 | 1995-01-26 | Friedrichs Konrad Kg | Strangpreßwerkzeug zur Herstellung eines Hartmetall- oder Keramikstabes |

| JPH04235203A (ja) * | 1991-01-08 | 1992-08-24 | Hitachi Metals Ltd | エジェクタスリーブの製造方法 |

| DE4120166C2 (de) | 1991-06-19 | 1994-10-06 | Friedrichs Konrad Kg | Strangpreßwerkzeug zur Herstellung eines Hartmetall- oder Keramikstabes mit gedrallten Innenbohrungen |

| JPH055104A (ja) * | 1991-06-25 | 1993-01-14 | Daido Steel Co Ltd | 高速度鋼合金粉末の押出し成形体とその焼結品 |

| DE19644447C2 (de) | 1996-10-25 | 2001-10-18 | Friedrichs Konrad Kg | Verfahren und Vorrichtung zur kontinuierlichen Extrusion von mit einem wendelförmigen Innenkanal ausgestatteten Stäben aus plastischem Rohmaterial |

-

2010

- 2010-05-05 DE DE102010019599A patent/DE102010019599A1/de not_active Withdrawn

-

2011

- 2011-05-05 KR KR1020127030327A patent/KR20130124152A/ko not_active Ceased

- 2011-05-05 JP JP2013508514A patent/JP5940058B2/ja active Active

- 2011-05-05 EP EP11719228A patent/EP2566640A2/de not_active Withdrawn

- 2011-05-05 WO PCT/EP2011/057257 patent/WO2011138422A2/de not_active Ceased

-

2012

- 2012-11-01 US US13/666,164 patent/US20130136647A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| JP2013528705A (ja) | 2013-07-11 |

| WO2011138422A3 (de) | 2012-03-15 |

| EP2566640A2 (de) | 2013-03-13 |

| JP5940058B2 (ja) | 2016-06-29 |

| US20130136647A1 (en) | 2013-05-30 |

| DE102010019599A1 (de) | 2011-11-10 |

| WO2011138422A2 (de) | 2011-11-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP7116495B2 (ja) | 高炭素コバルト系合金 | |

| EP2242606B1 (de) | Verfahren und vorrichtung zur herstellung von ringförmigen, rotationssymmetrischen werkstücken aus metall- und/oder keramikpulver unter verwendung von metall- und/oder keramikpulvern und einem laserstrahl | |

| CN105081330B (zh) | 一种大长径比的超细晶硬质合金台阶状棒材及制备方法 | |

| CN111386164B (zh) | 高硬度3d打印钢产品 | |

| JP2025011174A (ja) | 3d印刷高炭素含有鋼およびそれを作製する方法 | |

| Choudhari et al. | Additive manufacturing of AISI M2 tool steel by binder jetting (BJ): Investigation of microstructural and mechanical properties | |

| CN101537559B (zh) | 一种金刚石工具的制造方法 | |

| US20250339900A1 (en) | Process of forming a cutting tool with additively deposited cutting edge | |

| KR20130124152A (ko) | 철강 분말 야금 | |

| JP7221028B2 (ja) | 焼結歯車の製造方法 | |

| CN104760088B (zh) | 一种激光熔覆直接成型的旋转模切模辊 | |

| EP4414106A1 (en) | 3d printed metal with controlled carbide size and method of producing the same | |

| CN102230173B (zh) | 平行双螺杆挤出机用全披覆熔覆性螺纹元件 | |

| JP2007211259A (ja) | 金属粉末の成形法及び同成形法で成形した加工工具 | |

| WO2020226111A1 (ja) | 焼結歯車の製造方法 | |

| CN114749666B (zh) | 一种多台阶异型硬质合金棒料的生产方法 | |

| JPWO2020149787A5 (enExample) | ||

| Tanoe | Introduction of advanced technology in the processes of cutting tools manufacturing | |

| WO2024170447A1 (en) | 3d printed metal with controlled carbide size and method of producing the same | |

| EP4665524A1 (en) | 3d printed metal with controlled carbide size and method of producing the same | |

| WO2020171787A1 (en) | A ceramic/carbide socket cutting insert with high-toughness and manufacturing method thereof | |

| CN107774978A (zh) | 粉末冶金方法 | |

| JP2013528705A5 (enExample) | ||

| CN106756403A (zh) | 一种精密复合拉刀加工工艺 | |

| HK1114814A1 (en) | Composite cutting inserts and methods of making the same |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20121120 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| A201 | Request for examination | ||

| PA0201 | Request for examination |

Patent event code: PA02012R01D Patent event date: 20160321 Comment text: Request for Examination of Application |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20170227 Patent event code: PE09021S01D |

|

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20170502 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20170227 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |