KR20120089749A - 파이프 섹션 접합 - Google Patents

파이프 섹션 접합 Download PDFInfo

- Publication number

- KR20120089749A KR20120089749A KR1020127015312A KR20127015312A KR20120089749A KR 20120089749 A KR20120089749 A KR 20120089749A KR 1020127015312 A KR1020127015312 A KR 1020127015312A KR 20127015312 A KR20127015312 A KR 20127015312A KR 20120089749 A KR20120089749 A KR 20120089749A

- Authority

- KR

- South Korea

- Prior art keywords

- key

- pipe section

- key groove

- pipe

- recesses

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000005304 joining Methods 0.000 title abstract description 10

- 229920000431 shape-memory polymer Polymers 0.000 claims abstract description 91

- 238000000034 method Methods 0.000 claims abstract description 35

- 230000008878 coupling Effects 0.000 claims abstract description 21

- 238000010168 coupling process Methods 0.000 claims abstract description 21

- 238000005859 coupling reaction Methods 0.000 claims abstract description 21

- 230000007704 transition Effects 0.000 claims description 37

- 229920000642 polymer Polymers 0.000 claims description 22

- 238000010438 heat treatment Methods 0.000 claims description 14

- 238000001816 cooling Methods 0.000 claims description 11

- 238000003303 reheating Methods 0.000 claims description 5

- 238000002407 reforming Methods 0.000 claims description 2

- 230000000712 assembly Effects 0.000 abstract 1

- 238000000429 assembly Methods 0.000 abstract 1

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 12

- 239000000463 material Substances 0.000 description 12

- 230000004913 activation Effects 0.000 description 10

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 9

- 229910052802 copper Inorganic materials 0.000 description 9

- 239000010949 copper Substances 0.000 description 9

- 229920002635 polyurethane Polymers 0.000 description 8

- 239000004814 polyurethane Substances 0.000 description 8

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 6

- 229920001577 copolymer Polymers 0.000 description 6

- 229910052757 nitrogen Inorganic materials 0.000 description 6

- 239000011541 reaction mixture Substances 0.000 description 6

- 239000004676 acrylonitrile butadiene styrene Substances 0.000 description 5

- 239000000853 adhesive Substances 0.000 description 5

- 230000001070 adhesive effect Effects 0.000 description 5

- 239000012530 fluid Substances 0.000 description 5

- 230000002441 reversible effect Effects 0.000 description 5

- 239000012781 shape memory material Substances 0.000 description 5

- HECLRDQVFMWTQS-RGOKHQFPSA-N 1755-01-7 Chemical compound C1[C@H]2[C@@H]3CC=C[C@@H]3[C@@H]1C=C2 HECLRDQVFMWTQS-RGOKHQFPSA-N 0.000 description 4

- YRKCREAYFQTBPV-UHFFFAOYSA-N acetylacetone Chemical compound CC(=O)CC(C)=O YRKCREAYFQTBPV-UHFFFAOYSA-N 0.000 description 4

- XECAHXYUAAWDEL-UHFFFAOYSA-N acrylonitrile butadiene styrene Chemical compound C=CC=C.C=CC#N.C=CC1=CC=CC=C1 XECAHXYUAAWDEL-UHFFFAOYSA-N 0.000 description 4

- 229920000122 acrylonitrile butadiene styrene Polymers 0.000 description 4

- 238000005516 engineering process Methods 0.000 description 4

- 239000000203 mixture Substances 0.000 description 4

- 239000000126 substance Substances 0.000 description 4

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 4

- 239000004698 Polyethylene Substances 0.000 description 3

- 230000008901 benefit Effects 0.000 description 3

- 239000003054 catalyst Substances 0.000 description 3

- PBAYDYUZOSNJGU-UHFFFAOYSA-N chelidonic acid Natural products OC(=O)C1=CC(=O)C=C(C(O)=O)O1 PBAYDYUZOSNJGU-UHFFFAOYSA-N 0.000 description 3

- -1 polysiloxane Polymers 0.000 description 3

- 230000009467 reduction Effects 0.000 description 3

- OJOWICOBYCXEKR-KRXBUXKQSA-N (5e)-5-ethylidenebicyclo[2.2.1]hept-2-ene Chemical compound C1C2C(=C/C)/CC1C=C2 OJOWICOBYCXEKR-KRXBUXKQSA-N 0.000 description 2

- 239000004721 Polyphenylene oxide Substances 0.000 description 2

- BGYHLZZASRKEJE-UHFFFAOYSA-N [3-[3-(3,5-ditert-butyl-4-hydroxyphenyl)propanoyloxy]-2,2-bis[3-(3,5-ditert-butyl-4-hydroxyphenyl)propanoyloxymethyl]propyl] 3-(3,5-ditert-butyl-4-hydroxyphenyl)propanoate Chemical compound CC(C)(C)C1=C(O)C(C(C)(C)C)=CC(CCC(=O)OCC(COC(=O)CCC=2C=C(C(O)=C(C=2)C(C)(C)C)C(C)(C)C)(COC(=O)CCC=2C=C(C(O)=C(C=2)C(C)(C)C)C(C)(C)C)COC(=O)CCC=2C=C(C(O)=C(C=2)C(C)(C)C)C(C)(C)C)=C1 BGYHLZZASRKEJE-UHFFFAOYSA-N 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 239000002131 composite material Substances 0.000 description 2

- 238000005520 cutting process Methods 0.000 description 2

- 239000007789 gas Substances 0.000 description 2

- 230000009477 glass transition Effects 0.000 description 2

- 238000003780 insertion Methods 0.000 description 2

- 230000037431 insertion Effects 0.000 description 2

- 230000009878 intermolecular interaction Effects 0.000 description 2

- 238000002844 melting Methods 0.000 description 2

- 230000008018 melting Effects 0.000 description 2

- 230000003446 memory effect Effects 0.000 description 2

- 229920003229 poly(methyl methacrylate) Polymers 0.000 description 2

- 229920000636 poly(norbornene) polymer Polymers 0.000 description 2

- 229920000570 polyether Polymers 0.000 description 2

- 229920001195 polyisoprene Polymers 0.000 description 2

- 238000006116 polymerization reaction Methods 0.000 description 2

- 239000004926 polymethyl methacrylate Substances 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- 238000010926 purge Methods 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 238000010008 shearing Methods 0.000 description 2

- 229910000679 solder Inorganic materials 0.000 description 2

- 238000003860 storage Methods 0.000 description 2

- 229920001169 thermoplastic Polymers 0.000 description 2

- 239000004416 thermosoftening plastic Substances 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- OJOWICOBYCXEKR-APPZFPTMSA-N (1S,4R)-5-ethylidenebicyclo[2.2.1]hept-2-ene Chemical compound CC=C1C[C@@H]2C[C@@H]1C=C2 OJOWICOBYCXEKR-APPZFPTMSA-N 0.000 description 1

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 1

- 101000632994 Homo sapiens Somatostatin Proteins 0.000 description 1

- JVTAAEKCZFNVCJ-REOHCLBHSA-N L-lactic acid Chemical compound C[C@H](O)C(O)=O JVTAAEKCZFNVCJ-REOHCLBHSA-N 0.000 description 1

- IGFHQQFPSIBGKE-UHFFFAOYSA-N Nonylphenol Natural products CCCCCCCCCC1=CC=C(O)C=C1 IGFHQQFPSIBGKE-UHFFFAOYSA-N 0.000 description 1

- 229920002292 Nylon 6 Polymers 0.000 description 1

- 108091034117 Oligonucleotide Proteins 0.000 description 1

- 229920005689 PLLA-PGA Polymers 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 229920002614 Polyether block amide Polymers 0.000 description 1

- 239000004793 Polystyrene Substances 0.000 description 1

- 238000012356 Product development Methods 0.000 description 1

- 102100029563 Somatostatin Human genes 0.000 description 1

- 239000004433 Thermoplastic polyurethane Substances 0.000 description 1

- 244000000188 Vaccinium ovalifolium Species 0.000 description 1

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 1

- 230000004075 alteration Effects 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 239000000987 azo dye Substances 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 229920001400 block copolymer Polymers 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 239000003638 chemical reducing agent Substances 0.000 description 1

- 238000002788 crimping Methods 0.000 description 1

- 239000004703 cross-linked polyethylene Substances 0.000 description 1

- 229920003020 cross-linked polyethylene Polymers 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- YNLAOSYQHBDIKW-UHFFFAOYSA-M diethylaluminium chloride Chemical compound CC[Al](Cl)CC YNLAOSYQHBDIKW-UHFFFAOYSA-M 0.000 description 1

- 229920001971 elastomer Polymers 0.000 description 1

- 239000000806 elastomer Substances 0.000 description 1

- 150000002148 esters Chemical class 0.000 description 1

- SJMLNDPIJZBEKY-UHFFFAOYSA-N ethyl 2,2,2-trichloroacetate Chemical compound CCOC(=O)C(Cl)(Cl)Cl SJMLNDPIJZBEKY-UHFFFAOYSA-N 0.000 description 1

- 229920002457 flexible plastic Polymers 0.000 description 1

- 125000000524 functional group Chemical group 0.000 description 1

- 229920000578 graft copolymer Polymers 0.000 description 1

- 229920001903 high density polyethylene Polymers 0.000 description 1

- 239000004700 high-density polyethylene Substances 0.000 description 1

- 229920001684 low density polyethylene Polymers 0.000 description 1

- 239000004702 low-density polyethylene Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000008204 material by function Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 239000011325 microbead Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000000178 monomer Substances 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 229920006030 multiblock copolymer Polymers 0.000 description 1

- SNQQPOLDUKLAAF-UHFFFAOYSA-N nonylphenol Chemical compound CCCCCCCCCC1=CC=CC=C1O SNQQPOLDUKLAAF-UHFFFAOYSA-N 0.000 description 1

- 239000002530 phenolic antioxidant Substances 0.000 description 1

- 239000008029 phthalate plasticizer Substances 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920000773 poly(2-methyl-2-oxazoline) polymer Polymers 0.000 description 1

- 229920001432 poly(L-lactide) Polymers 0.000 description 1

- 229920000058 polyacrylate Polymers 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920001610 polycaprolactone Polymers 0.000 description 1

- 229920000515 polycarbonate Polymers 0.000 description 1

- 239000004417 polycarbonate Substances 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 229920000139 polyethylene terephthalate Polymers 0.000 description 1

- 229920001296 polysiloxane Polymers 0.000 description 1

- 229920002223 polystyrene Polymers 0.000 description 1

- 229920000909 polytetrahydrofuran Polymers 0.000 description 1

- 239000011118 polyvinyl acetate Substances 0.000 description 1

- 229920002689 polyvinyl acetate Polymers 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 238000004064 recycling Methods 0.000 description 1

- 230000008439 repair process Effects 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 229910001285 shape-memory alloy Inorganic materials 0.000 description 1

- 238000005476 soldering Methods 0.000 description 1

- 229920003048 styrene butadiene rubber Polymers 0.000 description 1

- 230000000930 thermomechanical effect Effects 0.000 description 1

- 229920002803 thermoplastic polyurethane Polymers 0.000 description 1

- 229920001187 thermosetting polymer Polymers 0.000 description 1

- 229920000428 triblock copolymer Polymers 0.000 description 1

- 239000003039 volatile agent Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

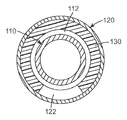

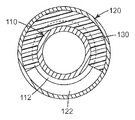

- F16L21/00—Joints with sleeve or socket

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16B—DEVICES FOR FASTENING OR SECURING CONSTRUCTIONAL ELEMENTS OR MACHINE PARTS TOGETHER, e.g. NAILS, BOLTS, CIRCLIPS, CLAMPS, CLIPS OR WEDGES; JOINTS OR JOINTING

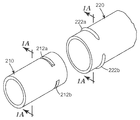

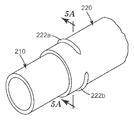

- F16B3/00—Key-type connections; Keys

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L21/00—Joints with sleeve or socket

- F16L21/02—Joints with sleeve or socket with elastic sealing rings between pipe and sleeve or between pipe and socket, e.g. with rolling or other prefabricated profiled rings

- F16L21/03—Joints with sleeve or socket with elastic sealing rings between pipe and sleeve or between pipe and socket, e.g. with rolling or other prefabricated profiled rings placed in the socket before connection

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L47/00—Connecting arrangements or other fittings specially adapted to be made of plastics or to be used with pipes made of plastics

- F16L47/20—Connecting arrangements or other fittings specially adapted to be made of plastics or to be used with pipes made of plastics based principally on specific properties of plastics

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L55/00—Devices or appurtenances for use in, or in connection with, pipes or pipe systems

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16B—DEVICES FOR FASTENING OR SECURING CONSTRUCTIONAL ELEMENTS OR MACHINE PARTS TOGETHER, e.g. NAILS, BOLTS, CIRCLIPS, CLAMPS, CLIPS OR WEDGES; JOINTS OR JOINTING

- F16B2200/00—Constructional details of connections not covered for in other groups of this subclass

- F16B2200/77—Use of a shape-memory material

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49826—Assembling or joining

- Y10T29/49863—Assembling or joining with prestressing of part

- Y10T29/49865—Assembling or joining with prestressing of part by temperature differential [e.g., shrink fit]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49826—Assembling or joining

- Y10T29/49908—Joining by deforming

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Lining Or Joining Of Plastics Or The Like (AREA)

- Quick-Acting Or Multi-Walled Pipe Joints (AREA)

- Mutual Connection Of Rods And Tubes (AREA)

- Joints With Sleeves (AREA)

- Rigid Pipes And Flexible Pipes (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US26159509P | 2009-11-16 | 2009-11-16 | |

| US61/261,595 | 2009-11-16 | ||

| PCT/US2010/056377 WO2011060167A2 (en) | 2009-11-16 | 2010-11-11 | Pipe section joining |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20120089749A true KR20120089749A (ko) | 2012-08-13 |

Family

ID=43992401

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020127015312A Ceased KR20120089749A (ko) | 2009-11-16 | 2010-11-11 | 파이프 섹션 접합 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US8870236B2 (enExample) |

| EP (1) | EP2501976B1 (enExample) |

| JP (1) | JP5907878B2 (enExample) |

| KR (1) | KR20120089749A (enExample) |

| CN (1) | CN102686928B (enExample) |

| WO (1) | WO2011060167A2 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20160071540A (ko) * | 2014-12-11 | 2016-06-22 | 하대환 | 필라멘트 와인딩용 파이프 연결구조 |

Families Citing this family (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8047844B2 (en) | 2009-07-16 | 2011-11-01 | Rodo Medical, Inc. | Dental rentention systems |

| FR2963654B1 (fr) * | 2010-08-06 | 2013-12-13 | Saipem Sa | Conduite comportant un chemisage interne et un manchon tubulaire de jonction en matiere plastique |

| EP2481966A1 (en) * | 2011-02-01 | 2012-08-01 | Uponor Innovation AB | Clamping ring |

| US9168111B2 (en) * | 2011-02-04 | 2015-10-27 | Rodo Medical, Inc. | Abutment devices and methods for natural teeth |

| US9623813B2 (en) * | 2013-11-14 | 2017-04-18 | GM Global Technology Operations LLC | Fit and finish methods |

| US9719536B2 (en) * | 2014-07-03 | 2017-08-01 | The Boeing Company | Assemblies including shape memory alloy fittings and composite structural members |

| DE102014010899A1 (de) * | 2014-07-24 | 2016-01-28 | Wabco Gmbh | Drehbare axial sichernde und druckfeste Leitungsverbindung |

| US10927987B2 (en) * | 2015-09-22 | 2021-02-23 | Raytheon Company | Duct with shape memory material, and installation method |

| US20180038400A1 (en) * | 2016-08-08 | 2018-02-08 | GM Global Technology Operations LLC | Coupling system |

| CN107687178A (zh) * | 2017-09-04 | 2018-02-13 | 滨州学院 | 一种抗地基不均匀沉降的预制拼装综合管廊结构 |

| US11267236B2 (en) * | 2018-03-16 | 2022-03-08 | Divergent Technologies, Inc. | Single shear joint for node-to-node connections |

| CN111219555A (zh) * | 2020-03-12 | 2020-06-02 | 岳阳长岭凯美特气体有限公司 | 一种防止槽车的物料充装软管被拉断的钥匙保存装置 |

| CN112096978A (zh) * | 2020-09-26 | 2020-12-18 | 中国石油天然气集团有限公司 | 一种薄壁管连接结构 |

| CN114001225B (zh) * | 2021-09-13 | 2023-06-16 | 安徽省宏忆新型材料有限公司 | 一种复合材料沟槽密封用镶嵌套件及其使用方法 |

| US12473999B1 (en) * | 2024-08-06 | 2025-11-18 | Richard Di Loreto | Selectable length conduits |

Family Cites Families (47)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB650573A (en) | 1947-02-20 | 1951-02-28 | Motor Columbus Ag Fuer Elek Sc | Improvements in and relating to rigid pipe connections |

| SE428596B (sv) | 1975-04-09 | 1983-07-11 | Raychem Corp | Anordning for hopkoppling av substrat exv ror omfattande ett organ av minnesmetall |

| US4426761A (en) * | 1981-05-21 | 1984-01-24 | Mcinerney Spring And Wire Company | Pipe clamp and method of clamping |

| US4436858A (en) | 1982-05-14 | 1984-03-13 | Hercules Incorporated | Plasticized polydicyclopentadiene and a method for making the same |

| US4650228A (en) * | 1983-09-14 | 1987-03-17 | Raychem Corporation | Heat-recoverable coupling assembly |

| JPS6081572A (ja) | 1983-10-07 | 1985-05-09 | Hitachi Tokyo Electronics Co Ltd | シ−ル構造 |

| US5506300A (en) | 1985-01-04 | 1996-04-09 | Thoratec Laboratories Corporation | Compositions that soften at predetermined temperatures and the method of making same |

| US4832382A (en) | 1987-02-19 | 1989-05-23 | Raychem Corporation | Coupling device |

| US4872713A (en) | 1987-02-19 | 1989-10-10 | Raychem Corporation | Coupling device |

| JPS63152996U (enExample) * | 1987-03-27 | 1988-10-06 | ||

| FR2616197B1 (fr) | 1987-06-05 | 1989-10-13 | Hutchinson | Dispositif de connexion d'un tube, soufflet ou analogue a un embout a l'aide d'un organe en alliage a memoire de forme et procede pour son montage |

| JP2502132B2 (ja) | 1988-09-30 | 1996-05-29 | 三菱重工業株式会社 | 形状記憶ポリウレタンエラストマ―成形体 |

| JPH02121907A (ja) | 1988-10-31 | 1990-05-09 | Mitsubishi Heavy Ind Ltd | 人用化粧料 |

| JP2959775B2 (ja) | 1988-11-11 | 1999-10-06 | 日本ゼオン株式会社 | 形状記憶成形体用材料 |

| JPH02158483A (ja) * | 1988-12-09 | 1990-06-18 | Matsushita Electric Ind Co Ltd | 自転車フレーム |

| JPH02163594A (ja) | 1988-12-19 | 1990-06-22 | Mitsubishi Heavy Ind Ltd | 形状記憶性ポリマを用いた配管接続方法 |

| US4934743A (en) | 1989-02-07 | 1990-06-19 | Raychem Corporation | Assembly for forming a mechanical connection to an object |

| JP2505568B2 (ja) | 1989-02-27 | 1996-06-12 | 積水化学工業株式会社 | ライニング鋼管の接続構造 |

| KR910004768Y1 (ko) * | 1989-07-05 | 1991-07-04 | 최의영 | 강파이프 이음관 |

| JPH03265784A (ja) | 1990-03-12 | 1991-11-26 | Sekisui Chem Co Ltd | 管継手 |

| GB9007284D0 (en) | 1990-03-31 | 1990-05-30 | Ciba Geigy Ag | Production of pigments |

| US5665822A (en) | 1991-10-07 | 1997-09-09 | Landec Corporation | Thermoplastic Elastomers |

| JPH04282093A (ja) | 1991-03-06 | 1992-10-07 | Maezawa Kiyuusou Kogyo Kk | 管の接続方法 |

| JPH053776U (ja) * | 1991-07-04 | 1993-01-22 | 株式会社クボタ | 管継手用挿口リング |

| JPH05133488A (ja) * | 1991-11-08 | 1993-05-28 | Furukawa Electric Co Ltd:The | 形状記憶合金を使用する管継手用ライナ |

| JPH0784913B2 (ja) * | 1993-01-22 | 1995-09-13 | 岩谷産業株式会社 | 金属管接続方法 |

| JPH07126125A (ja) | 1993-11-08 | 1995-05-16 | Mitsubishi Heavy Ind Ltd | メイクアップ化粧料 |

| JP3265784B2 (ja) | 1993-12-24 | 2002-03-18 | 日本油脂株式会社 | セメント用添加剤 |

| US5989353A (en) | 1996-10-11 | 1999-11-23 | Mallinckrodt Baker, Inc. | Cleaning wafer substrates of metal contamination while maintaining wafer smoothness |

| JP3028215B2 (ja) | 1997-07-02 | 2000-04-04 | 日本鋼管株式会社 | 差込み型継手 |

| US6240630B1 (en) * | 1997-12-03 | 2001-06-05 | The Regents Of The University Of California | Apparatus for loading shape memory gripper mechanisms |

| AU751861B2 (en) | 1998-02-23 | 2002-08-29 | Massachusetts Institute Of Technology | Biodegradable shape memory polymers |

| AU758800B2 (en) | 1998-02-23 | 2003-03-27 | Gkss-Forschungszentrum Geesthacht Gmbh | Shape memory polymers |

| KR100282510B1 (ko) | 1998-05-14 | 2001-02-15 | 박실조 | 파이프 연결구조 및 그 연결방법 |

| US6511253B1 (en) * | 1998-11-16 | 2003-01-28 | Steve Grimes | Method for mounting a housing to an object and devices related thereto |

| AU2003227596A1 (en) | 2002-04-10 | 2003-10-20 | Mnemoscience Gmbh | Method for the generation of memory effects on hair |

| US20040030062A1 (en) | 2002-05-02 | 2004-02-12 | Mather Patrick T. | Castable shape memory polymers |

| WO2004033553A1 (en) | 2002-10-11 | 2004-04-22 | University Of Connecticut | Crosslinked polycyclooctene |

| CN2596155Y (zh) * | 2003-01-29 | 2003-12-31 | 中国科学院金属研究所 | 形状记忆合金管接头 |

| KR20030066472A (ko) | 2003-04-28 | 2003-08-09 | 김수근 | 밸브 턱 파이프 연결장치 |

| US7516990B2 (en) | 2003-05-15 | 2009-04-14 | Mueller Industries, Inc. | Fluid conduit system and fittings therefor |

| DE10334784A1 (de) | 2003-07-30 | 2005-03-03 | Mnemoscience Gmbh | Kosmetische Zusammensetzung mit Polyol/Polyester Blockpolymeren |

| JP2006242285A (ja) | 2005-03-03 | 2006-09-14 | Toyota Motor Corp | 配管継手部のシール構造 |

| DE202005009018U1 (de) * | 2005-06-09 | 2006-10-19 | Voss Automotive Gmbh | Anschlussvorrichtung mit Medienleitungen |

| US8083268B2 (en) | 2005-10-21 | 2011-12-27 | Mueller Industries, Inc. | Coupling, joint and method for fixedly and sealingly securing components to one another |

| EP1930605A1 (de) * | 2006-12-06 | 2008-06-11 | Uponor Innovation Ab | Fitting für ein Rohr, insbesondere ein Kunststoffrohr oder ein Kunststoff-/Metallverbundrohr |

| CN101126473A (zh) * | 2007-07-30 | 2008-02-20 | 天力管件有限公司 | 金属管与形状记忆合金管接头的连接方法 |

-

2010

- 2010-11-11 CN CN201080051859.5A patent/CN102686928B/zh not_active Expired - Fee Related

- 2010-11-11 EP EP10830730.7A patent/EP2501976B1/en not_active Not-in-force

- 2010-11-11 JP JP2012538981A patent/JP5907878B2/ja not_active Expired - Fee Related

- 2010-11-11 US US13/504,532 patent/US8870236B2/en not_active Expired - Fee Related

- 2010-11-11 KR KR1020127015312A patent/KR20120089749A/ko not_active Ceased

- 2010-11-11 WO PCT/US2010/056377 patent/WO2011060167A2/en not_active Ceased

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20160071540A (ko) * | 2014-12-11 | 2016-06-22 | 하대환 | 필라멘트 와인딩용 파이프 연결구조 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2501976A4 (en) | 2014-04-02 |

| JP2013511010A (ja) | 2013-03-28 |

| WO2011060167A2 (en) | 2011-05-19 |

| EP2501976A2 (en) | 2012-09-26 |

| WO2011060167A3 (en) | 2011-09-22 |

| EP2501976B1 (en) | 2017-10-04 |

| US8870236B2 (en) | 2014-10-28 |

| CN102686928A (zh) | 2012-09-19 |

| US20120211119A1 (en) | 2012-08-23 |

| CN102686928B (zh) | 2016-03-23 |

| JP5907878B2 (ja) | 2016-04-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2501976B1 (en) | Pipe section joining | |

| US4469357A (en) | Composite coupling | |

| EP2815164B1 (en) | Pipe, pipe connection and pipeline system | |

| US4874193A (en) | Heat-recoverable composition coupling device | |

| US4379575A (en) | Composite coupling | |

| US20120280488A1 (en) | Part for connecting pipes including an internal liner, a covering method, and a method of assembly | |

| US9080702B2 (en) | Method for the highly-thick thermal coating of joints by using electrofusion in pipes used for conducting fluids, made of steel tubes externally coated with polyolefins | |

| SG183753A1 (en) | Conduit, manufacture thereof and fusion process therefor | |

| EP1741968A1 (en) | Clamping ring | |

| GB2149468A (en) | Heat shrinkable pipe coupling | |

| WO2020117638A1 (en) | Apparatus and method for joining molecularly oriented pipe | |

| WO2008042945A2 (en) | Wellbore casing and method of forming same | |

| EP2205428A1 (en) | Welding of ptfe parts | |

| CN105339717B (zh) | 用于联结件的加强套筒,加强套筒和联结件的组件,将例如多层管道焊接至组件的方法 | |

| AU2007254617B2 (en) | A coupling system for polymeric pipes | |

| KR100625895B1 (ko) | 열수축성관 | |

| CN111578008B (zh) | 具有高分子材料内衬的由壬连接结构及其装配方法 | |

| WO1999022170A1 (en) | Pipe joints | |

| CN118998484B (zh) | 一种便于管道连接的高密封性接头及其装配方法 | |

| EP1040293B1 (en) | Connector for thermoplastic pipe | |

| RU2527282C2 (ru) | Способ наружной изоляции соединений трубопроводов из стальных труб с наружным покрытием | |

| RU2225562C1 (ru) | Способ соединения стальных труб с внутренней пластмассовой облицовкой | |

| JP2000199594A (ja) | 樹脂製継手 | |

| CN112610782B (zh) | 一种用于抑菌型衬塑复合钢管的全防腐连接结构及其施工方法 | |

| JP2001009917A (ja) | 熱可塑性樹脂管状体の接合方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20120613 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| A201 | Request for examination | ||

| PA0201 | Request for examination |

Patent event code: PA02012R01D Patent event date: 20151110 Comment text: Request for Examination of Application |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20170418 Patent event code: PE09021S01D |

|

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20171030 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20170418 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |