JP7586840B2 - 反ったワークピースのための吸着グリッパ - Google Patents

反ったワークピースのための吸着グリッパ Download PDFInfo

- Publication number

- JP7586840B2 JP7586840B2 JP2021567842A JP2021567842A JP7586840B2 JP 7586840 B2 JP7586840 B2 JP 7586840B2 JP 2021567842 A JP2021567842 A JP 2021567842A JP 2021567842 A JP2021567842 A JP 2021567842A JP 7586840 B2 JP7586840 B2 JP 7586840B2

- Authority

- JP

- Japan

- Prior art keywords

- gripper

- suction

- opening

- workpiece

- openings

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25J—MANIPULATORS; CHAMBERS PROVIDED WITH MANIPULATION DEVICES

- B25J11/00—Manipulators not otherwise provided for

- B25J11/0095—Manipulators transporting wafers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25J—MANIPULATORS; CHAMBERS PROVIDED WITH MANIPULATION DEVICES

- B25J15/00—Gripping heads and other end effectors

- B25J15/0014—Gripping heads and other end effectors having fork, comb or plate shaped means for engaging the lower surface on a object to be transported

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25J—MANIPULATORS; CHAMBERS PROVIDED WITH MANIPULATION DEVICES

- B25J15/00—Gripping heads and other end effectors

- B25J15/0052—Gripping heads and other end effectors multiple gripper units or multiple end effectors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25J—MANIPULATORS; CHAMBERS PROVIDED WITH MANIPULATION DEVICES

- B25J15/00—Gripping heads and other end effectors

- B25J15/0052—Gripping heads and other end effectors multiple gripper units or multiple end effectors

- B25J15/0061—Gripping heads and other end effectors multiple gripper units or multiple end effectors mounted on a modular gripping structure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25J—MANIPULATORS; CHAMBERS PROVIDED WITH MANIPULATION DEVICES

- B25J15/00—Gripping heads and other end effectors

- B25J15/06—Gripping heads and other end effectors with vacuum or magnetic holding means

- B25J15/0616—Gripping heads and other end effectors with vacuum or magnetic holding means with vacuum

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25J—MANIPULATORS; CHAMBERS PROVIDED WITH MANIPULATION DEVICES

- B25J15/00—Gripping heads and other end effectors

- B25J15/06—Gripping heads and other end effectors with vacuum or magnetic holding means

- B25J15/0616—Gripping heads and other end effectors with vacuum or magnetic holding means with vacuum

- B25J15/0625—Gripping heads and other end effectors with vacuum or magnetic holding means with vacuum provided with a valve

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25J—MANIPULATORS; CHAMBERS PROVIDED WITH MANIPULATION DEVICES

- B25J15/00—Gripping heads and other end effectors

- B25J15/06—Gripping heads and other end effectors with vacuum or magnetic holding means

- B25J15/0616—Gripping heads and other end effectors with vacuum or magnetic holding means with vacuum

- B25J15/0683—Details of suction cup structure, e.g. grooves or ridges

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/6838—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping with gripping and holding devices using a vacuum; Bernoulli devices

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/687—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches

- H01L21/68707—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a robot blade, or gripped by a gripper for conveyance

Landscapes

- Engineering & Computer Science (AREA)

- Robotics (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Manipulator (AREA)

- Container, Conveyance, Adherence, Positioning, Of Wafer (AREA)

Description

Claims (16)

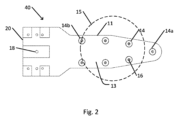

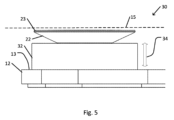

- ワークピースを把持するグリッパであって、前記グリッパは、平らなグリッパ表面を有する本体と、少なくとも1つの流量制限器と、を備え、

前記グリッパ表面は、前記グリッパ表面上に分配された複数の開口部を含み、前記開口部のそれぞれは、吸着源に接続可能であり、

前記少なくとも1つの流量制限器は、前記複数の開口部と、前記吸着源への前記グリッパのコネクタと、の間に配置され、前記複数の開口部のそれぞれの開口部を通じた流入を制限し、吸着が前記複数の開口部に行われ、ワークピース表面の一部が、前記複数の開口部のうちの少なくとも1つの開口部を覆い、別の開口部が覆われていないままであるとき、覆われた開口部での吸着力が、前記ワークピース表面を把持するのに十分な強さであり、

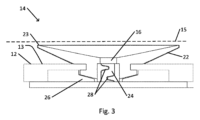

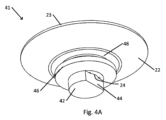

前記複数の開口部の開口部は、弾性シール構造を含み、前記弾性シール構造は、前記ワークピース表面が前記弾性シール構造と接触しているときに、吸着がその開口部に行われたときに、その開口部と前記ワークピース表面との間にシールを形成するように構成され、

前記弾性シール構造は、前記複数の開口部の前記開口部に挿入可能なステムを介して、前記グリッパ表面に接続可能であり、

前記ステムは、平らな側面を形成するように横方向に切り落とされたシリンダの形であり、

前記少なくとも1つの流量制限器は、前記側面と、前記ステムを取り囲む円筒面と、の間の空間に配置される、グリッパ。 - 請求項1に記載のグリッパであって、前記本体は、単一の基部から延びる複数のアームを備える、グリッパ。

- 請求項2に記載のグリッパであって、前記コネクタから前記複数の開口部の開口部への導管は、前記複数のアームのアームに沿って延びる、グリッパ。

- 請求項1に記載のグリッパであって、前記グリッパ表面は連続している、グリッパ。

- 請求項1から4のいずれか1項に記載のグリッパであって、前記少なくとも1つの流量制限器は、前記複数の開口部の開口部と、その開口部と前記コネクタとの間の流体接続を形成する導管と、の間に配置される、グリッパ。

- 請求項1から5のいずれか1項に記載のグリッパであって、前記流量制限器は、複数のバッフルを備える、グリッパ。

- 請求項6に記載のグリッパであって、前記流量制限器は、内部に取り付けられた千鳥状の対向フィンを有する自己適応型セグメント化オリフィス(SASO)を備える、グリッパ。

- 請求項1から5のいずれか1項に記載のグリッパであって、前記流量制限器は、狭窄部を備える、グリッパ。

- 請求項8に記載のグリッパであって、前記流量制限器は、ニードル弁を備える、グリッパ。

- 請求項9に記載のグリッパであって、前記弾性シール構造は、弾性カップを備える、グリッパ。

- 請求項9に記載のグリッパであって、前記弾性シール構造は、パッドまたはガスケットを備える、グリッパ。

- 請求項9から11のいずれか1項に記載のグリッパであって、前記弾性シール構造は、ポリマーを備える、グリッパ。

- 請求項12に記載のグリッパであって、前記ポリマーは、シリコーンを備える、グリッパ。

- 請求項1から13のいずれか1項に記載のグリッパであって、前記複数の開口部の開口部は、その開口部を前記グリッパ表面から前記ワークピース表面に向かって外側に伸長する伸長機構を備える、グリッパ。

- 請求項14に記載のグリッパであって、前記伸長機構は、前記開口部が前記ワークピース表面と接触していないときに、前記開口部を外側に延ばすように構成される、グリッパ。

- 請求項15に記載のグリッパであって、前記伸長機構は、吸着が前記開口部に行われ、前記開口部が前記ワークピースの表面と接触しているときに、吸着力が前記開口部を前記グリッパ表面の方へ引き寄せることを可能にするように構成される、グリッパ。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201962848601P | 2019-05-16 | 2019-05-16 | |

| US62/848,601 | 2019-05-16 | ||

| PCT/IL2020/050514 WO2020230125A1 (en) | 2019-05-16 | 2020-05-13 | Suction gripper for warped workpiece |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2022532720A JP2022532720A (ja) | 2022-07-19 |

| JP7586840B2 true JP7586840B2 (ja) | 2024-11-19 |

Family

ID=73288861

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2021567842A Active JP7586840B2 (ja) | 2019-05-16 | 2020-05-13 | 反ったワークピースのための吸着グリッパ |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US12327753B2 (ja) |

| EP (1) | EP3969400A4 (ja) |

| JP (1) | JP7586840B2 (ja) |

| KR (1) | KR102867740B1 (ja) |

| CN (1) | CN113853348B (ja) |

| TW (1) | TWI875759B (ja) |

| WO (1) | WO2020230125A1 (ja) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4275094A1 (en) * | 2021-01-11 | 2023-11-15 | ASML Netherlands B.V. | Gripper and lithographic apparatus comprising the gripper |

| JP7641187B2 (ja) * | 2021-06-23 | 2025-03-06 | 株式会社ダイヘン | ワーク搬送用ハンド |

| CN114131621B (zh) * | 2021-10-29 | 2024-12-24 | 赛莱克斯微系统科技(北京)有限公司 | 一种晶圆运输机械手 |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002517088A (ja) | 1998-05-27 | 2002-06-11 | バリアン・セミコンダクター・エクイップメント・アソシエイツ・インコーポレイテッド | 半導体ウエハハンドリング用バッチ式エンドエフェクタ |

| JP2003509227A (ja) | 1999-08-25 | 2003-03-11 | コア フロー リミテッド | 系を握持している自動適応真空 |

| JP2004119488A (ja) | 2002-09-24 | 2004-04-15 | Tokyo Electron Ltd | 真空吸着装置、基板搬送装置及び基板処理装置 |

| US20060054774A1 (en) | 2001-12-27 | 2006-03-16 | Yuval Yassour | High-performance non-contact support platforms |

| JP2011211119A (ja) | 2010-03-30 | 2011-10-20 | Fuji Electric Co Ltd | ウェハ搬送装置およびウェハ搬送方法 |

| JP5379589B2 (ja) | 2009-07-24 | 2013-12-25 | 東京エレクトロン株式会社 | 真空吸着パッド、搬送アーム及び基板搬送装置 |

| JP2018140445A (ja) | 2015-07-20 | 2018-09-13 | ライフロボティクス株式会社 | ロボット装置 |

| JP2018157221A (ja) | 2014-03-06 | 2018-10-04 | カスケード マイクロテック インコーポレイテッドCascade Microtech,Incorporated | ウェーハ‐ハンドリング・エンドエフェクタ |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IL131589A (en) | 1999-08-25 | 2007-05-15 | Yuval Yassour | Device for creating forces by injecting liquid |

| US6467824B2 (en) * | 2001-03-13 | 2002-10-22 | Data I/O Corporation | Floating seal pick and place system and unit therefor |

| JP2004119448A (ja) | 2002-09-24 | 2004-04-15 | Nec Kyushu Ltd | プラズマエッチング装置およびプラズマエッチング方法 |

| US7055875B2 (en) * | 2003-07-11 | 2006-06-06 | Asyst Technologies, Inc. | Ultra low contact area end effector |

| US8382174B2 (en) * | 2009-10-08 | 2013-02-26 | University Of Maryland | System, method, and apparatus for suction gripping |

| CN102782829B (zh) * | 2011-02-28 | 2015-04-01 | 晟碟半导体(上海)有限公司 | 具有非均匀真空分布的裸芯安装端部 |

| US9401296B2 (en) * | 2011-11-29 | 2016-07-26 | Persimmon Technologies Corporation | Vacuum robot adapted to grip and transport a substrate and method thereof with passive bias |

| DE102011056029A1 (de) * | 2011-12-05 | 2013-06-06 | Rehau Ag + Co | Transportverfahren zur Ablage von Fasermatten, Transportvorrichtung sowie eine Vorrichtung zum Greifen eines flächigen Halbzeugs |

| US8864202B1 (en) * | 2013-04-12 | 2014-10-21 | Varian Semiconductor Equipment Associates, Inc. | Spring retained end effector contact pad |

| JP5861677B2 (ja) * | 2013-07-08 | 2016-02-16 | 株式会社安川電機 | 吸着構造、ロボットハンドおよびロボット |

| JP6224437B2 (ja) * | 2013-11-26 | 2017-11-01 | 東京エレクトロン株式会社 | 基板搬送装置 |

| US9415519B2 (en) * | 2014-07-01 | 2016-08-16 | Varian Semiconductor Equipment Associates, Inc. | Composite end effector and method of making a composite end effector |

| CA2996868C (en) * | 2015-08-26 | 2021-02-16 | Berkshire Grey, Inc. | Systems and methods for providing vacuum valve assemblies for end effectors |

| CN105552016A (zh) * | 2015-12-23 | 2016-05-04 | 苏州工业园区纳米产业技术研究院有限公司 | 一种适用于翘曲晶圆的涂布机台机械手的结构改造及改造方法 |

| KR101820722B1 (ko) | 2016-05-17 | 2018-01-24 | 금오공과대학교 산학협력단 | 평패널용 진공 흡착 장치 |

| US9975255B1 (en) | 2016-12-15 | 2018-05-22 | Jabil Inc. | Apparatus, system and method for providing a conformable vacuum cup for an end effector |

| JP6442563B1 (ja) * | 2017-05-30 | 2018-12-19 | キヤノン株式会社 | 搬送ハンド、搬送装置、リソグラフィ装置、物品の製造方法及び保持機構 |

-

2020

- 2020-05-13 CN CN202080036144.6A patent/CN113853348B/zh active Active

- 2020-05-13 US US17/607,029 patent/US12327753B2/en active Active

- 2020-05-13 WO PCT/IL2020/050514 patent/WO2020230125A1/en not_active Ceased

- 2020-05-13 KR KR1020217041171A patent/KR102867740B1/ko active Active

- 2020-05-13 TW TW109115930A patent/TWI875759B/zh active

- 2020-05-13 EP EP20805594.7A patent/EP3969400A4/en not_active Withdrawn

- 2020-05-13 JP JP2021567842A patent/JP7586840B2/ja active Active

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002517088A (ja) | 1998-05-27 | 2002-06-11 | バリアン・セミコンダクター・エクイップメント・アソシエイツ・インコーポレイテッド | 半導体ウエハハンドリング用バッチ式エンドエフェクタ |

| JP2003509227A (ja) | 1999-08-25 | 2003-03-11 | コア フロー リミテッド | 系を握持している自動適応真空 |

| US20060054774A1 (en) | 2001-12-27 | 2006-03-16 | Yuval Yassour | High-performance non-contact support platforms |

| JP2004119488A (ja) | 2002-09-24 | 2004-04-15 | Tokyo Electron Ltd | 真空吸着装置、基板搬送装置及び基板処理装置 |

| JP5379589B2 (ja) | 2009-07-24 | 2013-12-25 | 東京エレクトロン株式会社 | 真空吸着パッド、搬送アーム及び基板搬送装置 |

| JP2011211119A (ja) | 2010-03-30 | 2011-10-20 | Fuji Electric Co Ltd | ウェハ搬送装置およびウェハ搬送方法 |

| JP2018157221A (ja) | 2014-03-06 | 2018-10-04 | カスケード マイクロテック インコーポレイテッドCascade Microtech,Incorporated | ウェーハ‐ハンドリング・エンドエフェクタ |

| JP2018140445A (ja) | 2015-07-20 | 2018-09-13 | ライフロボティクス株式会社 | ロボット装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20220216090A1 (en) | 2022-07-07 |

| EP3969400A4 (en) | 2023-06-14 |

| EP3969400A1 (en) | 2022-03-23 |

| WO2020230125A1 (en) | 2020-11-19 |

| US12327753B2 (en) | 2025-06-10 |

| KR20220008899A (ko) | 2022-01-21 |

| CN113853348A (zh) | 2021-12-28 |

| KR102867740B1 (ko) | 2025-10-13 |

| CN113853348B (zh) | 2025-02-21 |

| TWI875759B (zh) | 2025-03-11 |

| JP2022532720A (ja) | 2022-07-19 |

| TW202101660A (zh) | 2021-01-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP7586840B2 (ja) | 反ったワークピースのための吸着グリッパ | |

| US10946532B2 (en) | Gripping tool and gripping system | |

| US20090142169A1 (en) | Vacuum Assisted Manipulation of Objects | |

| US10875196B2 (en) | Gripping device and industrial robot | |

| WO2018088046A1 (ja) | 把持ツールおよび把持システム | |

| EP3434428B1 (en) | Robot hand apparatus, robot hand system, and holding method | |

| KR20190138447A (ko) | 소프트 그리퍼 유닛 및 이를 포함하는 소프트 로봇 장치 | |

| CN110877344A (zh) | 一种多自由度气动柔性机械手 | |

| US20220250168A1 (en) | Chuck for acquiring a warped workpiece | |

| US11267137B1 (en) | Controlling end effector suction area using expandable bladder | |

| CN117157162A (zh) | 用于捕获翘曲工件的卡盘 | |

| JP3917528B2 (ja) | 吸着パッド | |

| CN115052720A (zh) | 末端执行器、可编程运动装置和操作可编程运动装置的方法 | |

| JP2012009751A (ja) | 真空ピンセット | |

| US10625428B2 (en) | End effector with selectively deformable interface | |

| CN117597772A (zh) | 用于获取翘曲工件的卡盘 | |

| JP2012009540A (ja) | 真空ピンセット | |

| CN109817561B (zh) | 机械手指、晶片传输方法及机械手 | |

| US20240181655A1 (en) | Variable friction finger assembly | |

| JP2012033723A (ja) | 真空ピンセット及び真空吸着方法 | |

| CN120641250A (zh) | 用于改进对物体的抓握的抓持器模块 | |

| KR20250006291A (ko) | 도어 개스킷을 갖는 기판 용기 | |

| JP2018122408A (ja) | 把持装置 | |

| JP2000312428A (ja) | ケーブルガイド装置 | |

| KR20030055663A (ko) | 웨이퍼 이송용 트위저 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20230511 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20240531 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20240625 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20240920 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20241008 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20241107 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 7586840 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |