JP7262439B2 - 可変研磨剤分布を有するフロアパッド - Google Patents

可変研磨剤分布を有するフロアパッド Download PDFInfo

- Publication number

- JP7262439B2 JP7262439B2 JP2020504696A JP2020504696A JP7262439B2 JP 7262439 B2 JP7262439 B2 JP 7262439B2 JP 2020504696 A JP2020504696 A JP 2020504696A JP 2020504696 A JP2020504696 A JP 2020504696A JP 7262439 B2 JP7262439 B2 JP 7262439B2

- Authority

- JP

- Japan

- Prior art keywords

- concentration

- abrasive

- radius

- pad

- treated article

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000009826 distribution Methods 0.000 title description 53

- 239000000758 substrate Substances 0.000 claims description 65

- 239000000203 mixture Substances 0.000 claims description 46

- -1 polyethylene Polymers 0.000 claims description 26

- 238000009472 formulation Methods 0.000 claims description 21

- 239000000835 fiber Substances 0.000 claims description 16

- 229920000728 polyester Polymers 0.000 claims description 14

- 229920005989 resin Polymers 0.000 claims description 13

- 239000011347 resin Substances 0.000 claims description 13

- 239000004952 Polyamide Substances 0.000 claims description 12

- 229920002647 polyamide Polymers 0.000 claims description 12

- 238000000576 coating method Methods 0.000 claims description 11

- 239000011248 coating agent Substances 0.000 claims description 10

- 239000004698 Polyethylene Substances 0.000 claims description 9

- 239000004743 Polypropylene Substances 0.000 claims description 9

- 229920000297 Rayon Polymers 0.000 claims description 9

- 229920000573 polyethylene Polymers 0.000 claims description 9

- 229920001155 polypropylene Polymers 0.000 claims description 9

- 239000002964 rayon Substances 0.000 claims description 9

- 239000000463 material Substances 0.000 description 24

- 239000006061 abrasive grain Substances 0.000 description 17

- 239000002245 particle Substances 0.000 description 14

- 239000003082 abrasive agent Substances 0.000 description 12

- 238000005498 polishing Methods 0.000 description 11

- 229920001577 copolymer Polymers 0.000 description 10

- 238000012360 testing method Methods 0.000 description 10

- 239000002174 Styrene-butadiene Substances 0.000 description 9

- 229920003048 styrene butadiene rubber Polymers 0.000 description 9

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 8

- 239000010432 diamond Substances 0.000 description 7

- 238000004381 surface treatment Methods 0.000 description 7

- DNIAPMSPPWPWGF-UHFFFAOYSA-N Propylene glycol Chemical compound CC(O)CO DNIAPMSPPWPWGF-UHFFFAOYSA-N 0.000 description 6

- 239000000919 ceramic Substances 0.000 description 6

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 5

- 229910003460 diamond Inorganic materials 0.000 description 5

- 229920000642 polymer Polymers 0.000 description 5

- UQSXHKLRYXJYBZ-UHFFFAOYSA-N Iron oxide Chemical compound [Fe]=O UQSXHKLRYXJYBZ-UHFFFAOYSA-N 0.000 description 4

- 230000007423 decrease Effects 0.000 description 4

- 238000000034 method Methods 0.000 description 4

- 229920002994 synthetic fiber Polymers 0.000 description 4

- 239000012209 synthetic fiber Substances 0.000 description 4

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 description 4

- 229920002554 vinyl polymer Polymers 0.000 description 4

- 229920000877 Melamine resin Polymers 0.000 description 3

- 229920002396 Polyurea Polymers 0.000 description 3

- 229920001328 Polyvinylidene chloride Polymers 0.000 description 3

- DHKHKXVYLBGOIT-UHFFFAOYSA-N acetaldehyde Diethyl Acetal Natural products CCOC(C)OCC DHKHKXVYLBGOIT-UHFFFAOYSA-N 0.000 description 3

- 239000000654 additive Substances 0.000 description 3

- 239000011230 binding agent Substances 0.000 description 3

- MTAZNLWOLGHBHU-UHFFFAOYSA-N butadiene-styrene rubber Chemical compound C=CC=C.C=CC1=CC=CC=C1 MTAZNLWOLGHBHU-UHFFFAOYSA-N 0.000 description 3

- 239000000945 filler Substances 0.000 description 3

- 239000011521 glass Substances 0.000 description 3

- 238000012986 modification Methods 0.000 description 3

- 230000004048 modification Effects 0.000 description 3

- 239000003607 modifier Substances 0.000 description 3

- LGRFSURHDFAFJT-UHFFFAOYSA-N phthalic anhydride Chemical class C1=CC=C2C(=O)OC(=O)C2=C1 LGRFSURHDFAFJT-UHFFFAOYSA-N 0.000 description 3

- 239000004814 polyurethane Substances 0.000 description 3

- 229920002635 polyurethane Polymers 0.000 description 3

- 229920000915 polyvinyl chloride Polymers 0.000 description 3

- 239000004800 polyvinyl chloride Substances 0.000 description 3

- 239000005033 polyvinylidene chloride Substances 0.000 description 3

- 239000004576 sand Substances 0.000 description 3

- 238000005201 scrubbing Methods 0.000 description 3

- 239000011115 styrene butadiene Substances 0.000 description 3

- 229920001059 synthetic polymer Polymers 0.000 description 3

- 229910052580 B4C Inorganic materials 0.000 description 2

- 229910052582 BN Inorganic materials 0.000 description 2

- PZNSFCLAULLKQX-UHFFFAOYSA-N Boron nitride Chemical compound N#B PZNSFCLAULLKQX-UHFFFAOYSA-N 0.000 description 2

- VTYYLEPIZMXCLO-UHFFFAOYSA-L Calcium carbonate Chemical compound [Ca+2].[O-]C([O-])=O VTYYLEPIZMXCLO-UHFFFAOYSA-L 0.000 description 2

- 239000004971 Cross linker Substances 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 2

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 2

- MCMNRKCIXSYSNV-UHFFFAOYSA-N ZrO2 Inorganic materials O=[Zr]=O MCMNRKCIXSYSNV-UHFFFAOYSA-N 0.000 description 2

- INAHAJYZKVIDIZ-UHFFFAOYSA-N boron carbide Chemical compound B12B3B4C32B41 INAHAJYZKVIDIZ-UHFFFAOYSA-N 0.000 description 2

- CETPSERCERDGAM-UHFFFAOYSA-N ceric oxide Chemical compound O=[Ce]=O CETPSERCERDGAM-UHFFFAOYSA-N 0.000 description 2

- 229910000422 cerium(IV) oxide Inorganic materials 0.000 description 2

- 238000004140 cleaning Methods 0.000 description 2

- 230000000052 comparative effect Effects 0.000 description 2

- 229910052593 corundum Inorganic materials 0.000 description 2

- 239000010431 corundum Substances 0.000 description 2

- 238000000151 deposition Methods 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 229910001651 emery Inorganic materials 0.000 description 2

- 239000010433 feldspar Substances 0.000 description 2

- 239000006260 foam Substances 0.000 description 2

- 230000014509 gene expression Effects 0.000 description 2

- 229910052500 inorganic mineral Inorganic materials 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 239000011707 mineral Substances 0.000 description 2

- 239000004745 nonwoven fabric Substances 0.000 description 2

- 239000010449 novaculite Substances 0.000 description 2

- 239000002952 polymeric resin Substances 0.000 description 2

- 239000008262 pumice Substances 0.000 description 2

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 2

- 229910010271 silicon carbide Inorganic materials 0.000 description 2

- 239000002356 single layer Substances 0.000 description 2

- 239000007921 spray Substances 0.000 description 2

- 238000005507 spraying Methods 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 239000004575 stone Substances 0.000 description 2

- 229920003002 synthetic resin Polymers 0.000 description 2

- 238000013519 translation Methods 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 239000002023 wood Substances 0.000 description 2

- KXGFMDJXCMQABM-UHFFFAOYSA-N 2-methoxy-6-methylphenol Chemical compound [CH]OC1=CC=CC([CH])=C1O KXGFMDJXCMQABM-UHFFFAOYSA-N 0.000 description 1

- QYEXBYZXHDUPRC-UHFFFAOYSA-N B#[Ti]#B Chemical compound B#[Ti]#B QYEXBYZXHDUPRC-UHFFFAOYSA-N 0.000 description 1

- 244000025254 Cannabis sativa Species 0.000 description 1

- 235000012766 Cannabis sativa ssp. sativa var. sativa Nutrition 0.000 description 1

- 235000012765 Cannabis sativa ssp. sativa var. spontanea Nutrition 0.000 description 1

- 240000000491 Corchorus aestuans Species 0.000 description 1

- 235000011777 Corchorus aestuans Nutrition 0.000 description 1

- 235000010862 Corchorus capsularis Nutrition 0.000 description 1

- 241001465754 Metazoa Species 0.000 description 1

- 239000004677 Nylon Substances 0.000 description 1

- 229910033181 TiB2 Inorganic materials 0.000 description 1

- 240000008042 Zea mays Species 0.000 description 1

- 235000005824 Zea mays ssp. parviglumis Nutrition 0.000 description 1

- 235000002017 Zea mays subsp mays Nutrition 0.000 description 1

- 239000002318 adhesion promoter Substances 0.000 description 1

- 239000003963 antioxidant agent Substances 0.000 description 1

- JHIWVOJDXOSYLW-UHFFFAOYSA-N butyl 2,2-difluorocyclopropane-1-carboxylate Chemical compound CCCCOC(=O)C1CC1(F)F JHIWVOJDXOSYLW-UHFFFAOYSA-N 0.000 description 1

- 229910000019 calcium carbonate Inorganic materials 0.000 description 1

- 235000009120 camo Nutrition 0.000 description 1

- 239000003054 catalyst Substances 0.000 description 1

- 235000005607 chanvre indien Nutrition 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 239000008199 coating composition Substances 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 239000007859 condensation product Substances 0.000 description 1

- 230000003750 conditioning effect Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 235000005822 corn Nutrition 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- ZOCHARZZJNPSEU-UHFFFAOYSA-N diboron Chemical compound B#B ZOCHARZZJNPSEU-UHFFFAOYSA-N 0.000 description 1

- 239000003085 diluting agent Substances 0.000 description 1

- 239000002270 dispersing agent Substances 0.000 description 1

- 239000000975 dye Substances 0.000 description 1

- 239000003995 emulsifying agent Substances 0.000 description 1

- 230000007717 exclusion Effects 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 239000003063 flame retardant Substances 0.000 description 1

- 239000002223 garnet Substances 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 239000011121 hardwood Substances 0.000 description 1

- 239000011487 hemp Substances 0.000 description 1

- 239000003999 initiator Substances 0.000 description 1

- 239000010954 inorganic particle Substances 0.000 description 1

- JEIPFZHSYJVQDO-UHFFFAOYSA-N iron(III) oxide Inorganic materials O=[Fe]O[Fe]=O JEIPFZHSYJVQDO-UHFFFAOYSA-N 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- FPYJFEHAWHCUMM-UHFFFAOYSA-N maleic anhydride Chemical compound O=C1OC(=O)C=C1 FPYJFEHAWHCUMM-UHFFFAOYSA-N 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 229910044991 metal oxide Inorganic materials 0.000 description 1

- 150000004706 metal oxides Chemical class 0.000 description 1

- SNICXCGAKADSCV-UHFFFAOYSA-N nicotine Chemical compound CN1CCCC1C1=CC=CN=C1 SNICXCGAKADSCV-UHFFFAOYSA-N 0.000 description 1

- 239000002667 nucleating agent Substances 0.000 description 1

- 229920001778 nylon Polymers 0.000 description 1

- 239000003960 organic solvent Substances 0.000 description 1

- 239000003973 paint Substances 0.000 description 1

- 229920001568 phenolic resin Polymers 0.000 description 1

- 239000005011 phenolic resin Substances 0.000 description 1

- 239000000049 pigment Substances 0.000 description 1

- 239000004014 plasticizer Substances 0.000 description 1

- 229920000747 poly(lactic acid) Polymers 0.000 description 1

- 229920001225 polyester resin Polymers 0.000 description 1

- 239000004645 polyester resin Substances 0.000 description 1

- 229920000139 polyethylene terephthalate Polymers 0.000 description 1

- 239000005020 polyethylene terephthalate Substances 0.000 description 1

- 239000004626 polylactic acid Substances 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 239000000047 product Substances 0.000 description 1

- 150000003254 radicals Chemical class 0.000 description 1

- 239000006254 rheological additive Substances 0.000 description 1

- 239000010458 rotten stone Substances 0.000 description 1

- 239000003381 stabilizer Substances 0.000 description 1

- 239000007858 starting material Substances 0.000 description 1

- 239000004094 surface-active agent Substances 0.000 description 1

- 239000000454 talc Substances 0.000 description 1

- 229910052623 talc Inorganic materials 0.000 description 1

- 239000004408 titanium dioxide Substances 0.000 description 1

- 238000009827 uniform distribution Methods 0.000 description 1

- 235000013311 vegetables Nutrition 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D11/00—Constructional features of flexible abrasive materials; Special features in the manufacture of such materials

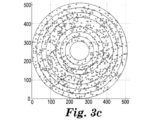

- B24D11/04—Zonally-graded surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D11/00—Constructional features of flexible abrasive materials; Special features in the manufacture of such materials

- B24D11/06—Connecting the ends of materials, e.g. for making abrasive belts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D3/00—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents

- B24D3/02—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents the constituent being used as bonding agent

- B24D3/20—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents the constituent being used as bonding agent and being essentially organic

- B24D3/28—Resins or natural or synthetic macromolecular compounds

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Polishing Bodies And Polishing Tools (AREA)

- Cleaning Implements For Floors, Carpets, Furniture, Walls, And The Like (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201762539120P | 2017-07-31 | 2017-07-31 | |

| US62/539,120 | 2017-07-31 | ||

| PCT/IB2018/055037 WO2019025883A1 (en) | 2017-07-31 | 2018-07-09 | VARIABLE ABRASIVE DISTRIBUTION FLOOR MAT |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2020529329A JP2020529329A (ja) | 2020-10-08 |

| JP2020529329A5 JP2020529329A5 (enExample) | 2021-08-19 |

| JP7262439B2 true JP7262439B2 (ja) | 2023-04-21 |

Family

ID=63143295

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2020504696A Active JP7262439B2 (ja) | 2017-07-31 | 2018-07-09 | 可変研磨剤分布を有するフロアパッド |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US11806838B2 (enExample) |

| EP (1) | EP3661697B1 (enExample) |

| JP (1) | JP7262439B2 (enExample) |

| KR (1) | KR102619228B1 (enExample) |

| CA (1) | CA3071501A1 (enExample) |

| MX (1) | MX2020001195A (enExample) |

| TW (1) | TWI826383B (enExample) |

| WO (1) | WO2019025883A1 (enExample) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115515752A (zh) * | 2020-04-07 | 2022-12-23 | 圣戈班磨料磨具有限公司 | 固结磨料抛光轮 |

| CN114378715B (zh) * | 2020-10-16 | 2023-05-30 | 万华化学集团电子材料有限公司 | 一种化学机械抛光垫及抛光方法 |

| US20240316724A1 (en) * | 2023-03-21 | 2024-09-26 | Taiwan Semiconductor Manufacturing Company, Ltd. | Multi-pattern in-pad surface for polish rate control |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007508153A (ja) | 2003-10-10 | 2007-04-05 | サンーゴバン アブレイシブズ,インコーポレイティド | 自己回避砥粒配置によって作製された研磨工具 |

| JP2008532781A (ja) | 2005-03-15 | 2008-08-21 | エイチティーシー スウェーデン エービー | 硬い表面を維持するための方法及び工具、及びかかる工具の製造方法 |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1694594C3 (de) | 1960-01-11 | 1975-05-28 | Minnesota Mining And Manufacturing Co., Saint Paul, Minn. (V.St.A.) | Reinigungs- und Polierkörper |

| US6062958A (en) | 1997-04-04 | 2000-05-16 | Micron Technology, Inc. | Variable abrasive polishing pad for mechanical and chemical-mechanical planarization |

| ES2174590T3 (es) * | 1998-03-27 | 2002-11-01 | Norton Co | Herramientas abrasivas. |

| US7201645B2 (en) | 1999-11-22 | 2007-04-10 | Chien-Min Sung | Contoured CMP pad dresser and associated methods |

| US20060059785A1 (en) * | 2002-09-24 | 2006-03-23 | Chien-Min Sung | Methods of maximizing retention of superabrasive particles in a metal matrix |

| TWI238753B (en) * | 2002-12-19 | 2005-09-01 | Miyanaga Kk | Diamond disk for grinding |

| US10065283B2 (en) * | 2005-03-15 | 2018-09-04 | Twister Cleaning Technology Ab | Method and tool for maintenance of hard surfaces, and a method for manufacturing such a tool |

| ES2286730T3 (es) * | 2005-03-15 | 2007-12-01 | Htc Sweden Ab | Procedimiento para el mantenimiento de superficies duras. |

| JP5680621B2 (ja) | 2009-04-17 | 2015-03-04 | スリーエム イノベイティブ プロパティズ カンパニー | 転写物品を使用して作製される平面状の研磨物品及びその作製方法 |

| EP2490066A4 (en) | 2009-10-15 | 2013-04-17 | Sharp Kk | LIQUID CRYSTAL DISPLAY PANEL, METHOD FOR PRODUCING THE SAME, AND LIQUID CRYSTAL DISPLAY DEVICE |

| ITMI20110850A1 (it) | 2011-05-16 | 2012-11-17 | Nicola Fiore | Utensile multi-abrasivo |

| WO2013181582A1 (en) | 2012-05-31 | 2013-12-05 | Ryan Webster | Diamond impregnated polishing pad with diamond pucks |

| TWI589404B (zh) | 2013-06-28 | 2017-07-01 | 聖高拜磨料有限公司 | 基於向日葵圖案之經塗佈的研磨製品 |

| KR102591496B1 (ko) | 2015-09-08 | 2023-10-18 | 쓰리엠 이노베이티브 프로퍼티즈 컴파니 | 연마 응집체를 가진 연마 회전 공구 |

| USD843672S1 (en) | 2017-07-31 | 2019-03-19 | 3M Innovative Properties Company | Floor pad |

| USD844272S1 (en) | 2017-08-09 | 2019-03-26 | 3M Innovative Properties Company | Floor pad |

| USD843673S1 (en) | 2017-08-09 | 2019-03-19 | 3M Innovtive Properties Company | Floor pad |

-

2018

- 2018-07-09 WO PCT/IB2018/055037 patent/WO2019025883A1/en not_active Ceased

- 2018-07-09 CA CA3071501A patent/CA3071501A1/en active Pending

- 2018-07-09 JP JP2020504696A patent/JP7262439B2/ja active Active

- 2018-07-09 MX MX2020001195A patent/MX2020001195A/es unknown

- 2018-07-09 US US16/635,332 patent/US11806838B2/en active Active

- 2018-07-09 EP EP18752261.0A patent/EP3661697B1/en active Active

- 2018-07-09 KR KR1020207005879A patent/KR102619228B1/ko active Active

- 2018-07-19 TW TW107124889A patent/TWI826383B/zh active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007508153A (ja) | 2003-10-10 | 2007-04-05 | サンーゴバン アブレイシブズ,インコーポレイティド | 自己回避砥粒配置によって作製された研磨工具 |

| JP2008532781A (ja) | 2005-03-15 | 2008-08-21 | エイチティーシー スウェーデン エービー | 硬い表面を維持するための方法及び工具、及びかかる工具の製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| BR112020002026A2 (pt) | 2020-10-06 |

| JP2020529329A (ja) | 2020-10-08 |

| KR102619228B1 (ko) | 2024-01-02 |

| TW201909828A (zh) | 2019-03-16 |

| US11806838B2 (en) | 2023-11-07 |

| EP3661697B1 (en) | 2025-02-19 |

| EP3661697A1 (en) | 2020-06-10 |

| KR20200036911A (ko) | 2020-04-07 |

| TWI826383B (zh) | 2023-12-21 |

| US20200156216A1 (en) | 2020-05-21 |

| WO2019025883A1 (en) | 2019-02-07 |

| MX2020001195A (es) | 2020-03-20 |

| CA3071501A1 (en) | 2019-02-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US20230038232A1 (en) | Floor Finish Removal Pad Assembly and Method of Removing Floor Finish | |

| US20130324021A1 (en) | Diamond impregnated polishing pad with diamond pucks | |

| JP4801116B2 (ja) | 抗目つまり処理 | |

| WO2014176108A1 (en) | Coated abrasive belt | |

| JP2012024923A (ja) | 硬い表面を維持するための方法及び工具、及びかかる工具の製造方法 | |

| US9586308B2 (en) | Abrasive product coated with agglomerated particles formed in situ and method of making the same | |

| JP2008532781A5 (enExample) | ||

| JP7262439B2 (ja) | 可変研磨剤分布を有するフロアパッド | |

| JP2005522341A (ja) | 目詰まり防止処理剤 | |

| CN101001561A (zh) | 清洁织物 | |

| KR20200083648A (ko) | 연마용 버핑 물품 | |

| CN113474122B (zh) | 磨料制品及其制备和使用方法 | |

| CN102666021B (zh) | 抗填塞磨料物品 | |

| EP3370918B1 (en) | Coated abrasive article | |

| WO2007030066A1 (en) | Grinding and/or polishing tool, and use and manufacturing thereof | |

| US20150027064A1 (en) | Aqueous Resin Composition for Abrasive Articles and Resulting Articles | |

| BR112020002026B1 (pt) | Artigo para tratamento de superfícies | |

| GB2300372A (en) | Abrasive articles | |

| US20250187145A1 (en) | Nonwoven abrasive article and methods of making the same | |

| JPH02139178A (ja) | 研摩手袋並びにその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20210707 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20210707 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20220615 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20220628 |

|

| RD03 | Notification of appointment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7423 Effective date: 20220705 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20220927 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20221111 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20230314 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20230411 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 7262439 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |