JP7067242B2 - 塗液の製造方法 - Google Patents

塗液の製造方法 Download PDFInfo

- Publication number

- JP7067242B2 JP7067242B2 JP2018084884A JP2018084884A JP7067242B2 JP 7067242 B2 JP7067242 B2 JP 7067242B2 JP 2018084884 A JP2018084884 A JP 2018084884A JP 2018084884 A JP2018084884 A JP 2018084884A JP 7067242 B2 JP7067242 B2 JP 7067242B2

- Authority

- JP

- Japan

- Prior art keywords

- coating liquid

- vacuum

- container

- degree

- coating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000007788 liquid Substances 0.000 title claims description 140

- 238000000576 coating method Methods 0.000 title claims description 136

- 239000011248 coating agent Substances 0.000 title claims description 133

- 238000004519 manufacturing process Methods 0.000 title claims description 18

- 238000003756 stirring Methods 0.000 claims description 44

- 238000000034 method Methods 0.000 claims description 26

- 239000005871 repellent Substances 0.000 claims description 18

- 239000002245 particle Substances 0.000 claims description 16

- 239000011347 resin Substances 0.000 claims description 13

- 229920005989 resin Polymers 0.000 claims description 13

- 230000007246 mechanism Effects 0.000 claims description 6

- 210000002784 stomach Anatomy 0.000 claims 1

- 239000000758 substrate Substances 0.000 description 35

- 238000009792 diffusion process Methods 0.000 description 26

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 26

- 239000000463 material Substances 0.000 description 23

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 22

- 229910052799 carbon Inorganic materials 0.000 description 16

- 230000006837 decompression Effects 0.000 description 15

- 239000004094 surface-active agent Substances 0.000 description 13

- 239000003054 catalyst Substances 0.000 description 9

- 239000002270 dispersing agent Substances 0.000 description 9

- 239000006185 dispersion Substances 0.000 description 9

- 239000000446 fuel Substances 0.000 description 9

- 229920000049 Carbon (fiber) Polymers 0.000 description 8

- 239000004917 carbon fiber Substances 0.000 description 8

- 230000000694 effects Effects 0.000 description 8

- 239000010419 fine particle Substances 0.000 description 8

- 238000005245 sintering Methods 0.000 description 8

- 238000001035 drying Methods 0.000 description 7

- 229920001343 polytetrafluoroethylene Polymers 0.000 description 6

- 239000004810 polytetrafluoroethylene Substances 0.000 description 6

- 239000002562 thickening agent Substances 0.000 description 6

- 230000000052 comparative effect Effects 0.000 description 5

- 230000007547 defect Effects 0.000 description 5

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 5

- 230000002093 peripheral effect Effects 0.000 description 5

- 239000011148 porous material Substances 0.000 description 5

- 230000002940 repellent Effects 0.000 description 5

- 238000011282 treatment Methods 0.000 description 5

- 239000006229 carbon black Substances 0.000 description 4

- 239000002537 cosmetic Substances 0.000 description 4

- 230000007423 decrease Effects 0.000 description 4

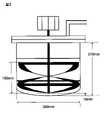

- 238000010586 diagram Methods 0.000 description 4

- 239000002612 dispersion medium Substances 0.000 description 4

- 239000006260 foam Substances 0.000 description 4

- 239000012528 membrane Substances 0.000 description 4

- 239000002184 metal Substances 0.000 description 4

- 239000005518 polymer electrolyte Substances 0.000 description 4

- 239000006230 acetylene black Substances 0.000 description 3

- 238000000354 decomposition reaction Methods 0.000 description 3

- 239000003792 electrolyte Substances 0.000 description 3

- 230000007613 environmental effect Effects 0.000 description 3

- 238000011156 evaluation Methods 0.000 description 3

- 239000004744 fabric Substances 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 238000012545 processing Methods 0.000 description 3

- 239000000047 product Substances 0.000 description 3

- 239000002904 solvent Substances 0.000 description 3

- 229920002799 BoPET Polymers 0.000 description 2

- 102100030695 Electron transfer flavoprotein subunit alpha, mitochondrial Human genes 0.000 description 2

- 101001010541 Homo sapiens Electron transfer flavoprotein subunit alpha, mitochondrial Proteins 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 239000000835 fiber Substances 0.000 description 2

- 238000007654 immersion Methods 0.000 description 2

- 230000014759 maintenance of location Effects 0.000 description 2

- 238000005259 measurement Methods 0.000 description 2

- 239000002609 medium Substances 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 229920002620 polyvinyl fluoride Polymers 0.000 description 2

- 238000002360 preparation method Methods 0.000 description 2

- 238000005070 sampling Methods 0.000 description 2

- 238000010008 shearing Methods 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 239000007921 spray Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 1

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 1

- 239000005977 Ethylene Substances 0.000 description 1

- YCKRFDGAMUMZLT-UHFFFAOYSA-N Fluorine atom Chemical compound [F] YCKRFDGAMUMZLT-UHFFFAOYSA-N 0.000 description 1

- 239000002033 PVDF binder Substances 0.000 description 1

- 239000002202 Polyethylene glycol Substances 0.000 description 1

- 229920006361 Polyflon Polymers 0.000 description 1

- 239000004372 Polyvinyl alcohol Substances 0.000 description 1

- 239000004809 Teflon Substances 0.000 description 1

- 229920006362 Teflon® Polymers 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- HSFWRNGVRCDJHI-UHFFFAOYSA-N alpha-acetylene Natural products C#C HSFWRNGVRCDJHI-UHFFFAOYSA-N 0.000 description 1

- 238000009835 boiling Methods 0.000 description 1

- HXNZTJULPKRNPR-UHFFFAOYSA-N borinine Chemical compound B1=CC=CC=C1 HXNZTJULPKRNPR-UHFFFAOYSA-N 0.000 description 1

- 230000009172 bursting Effects 0.000 description 1

- 239000002134 carbon nanofiber Substances 0.000 description 1

- 229910021393 carbon nanotube Inorganic materials 0.000 description 1

- 239000002041 carbon nanotube Substances 0.000 description 1

- 239000005539 carbonized material Substances 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 238000012790 confirmation Methods 0.000 description 1

- 229920001577 copolymer Polymers 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 230000005611 electricity Effects 0.000 description 1

- 238000003487 electrochemical reaction Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 125000002573 ethenylidene group Chemical group [*]=C=C([H])[H] 0.000 description 1

- 229920001038 ethylene copolymer Polymers 0.000 description 1

- 125000000816 ethylene group Chemical group [H]C([H])([*:1])C([H])([H])[*:2] 0.000 description 1

- 125000002534 ethynyl group Chemical group [H]C#C* 0.000 description 1

- 238000007667 floating Methods 0.000 description 1

- 229910052731 fluorine Inorganic materials 0.000 description 1

- 239000011737 fluorine Substances 0.000 description 1

- 238000005187 foaming Methods 0.000 description 1

- 238000007429 general method Methods 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 229910021389 graphene Inorganic materials 0.000 description 1

- 229910002804 graphite Inorganic materials 0.000 description 1

- 239000010439 graphite Substances 0.000 description 1

- 238000007646 gravure printing Methods 0.000 description 1

- 230000002209 hydrophobic effect Effects 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 238000010348 incorporation Methods 0.000 description 1

- 229920000609 methyl cellulose Polymers 0.000 description 1

- 239000001923 methylcellulose Substances 0.000 description 1

- 235000010981 methylcellulose Nutrition 0.000 description 1

- 239000004745 nonwoven fabric Substances 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 238000005325 percolation Methods 0.000 description 1

- 230000035699 permeability Effects 0.000 description 1

- 239000012466 permeate Substances 0.000 description 1

- 229920001223 polyethylene glycol Polymers 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- -1 polytetrafluoroethylene Polymers 0.000 description 1

- 229920002451 polyvinyl alcohol Polymers 0.000 description 1

- 229920002981 polyvinylidene fluoride Polymers 0.000 description 1

- 238000010248 power generation Methods 0.000 description 1

- 238000007639 printing Methods 0.000 description 1

- 230000001846 repelling effect Effects 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 238000010022 rotary screen printing Methods 0.000 description 1

- 238000007650 screen-printing Methods 0.000 description 1

- 238000002791 soaking Methods 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 238000004544 sputter deposition Methods 0.000 description 1

- 230000003746 surface roughness Effects 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- GPRLSGONYQIRFK-MNYXATJNSA-N triton Chemical compound [3H+] GPRLSGONYQIRFK-MNYXATJNSA-N 0.000 description 1

- 238000004804 winding Methods 0.000 description 1

- 239000002759 woven fabric Substances 0.000 description 1

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/30—Hydrogen technology

- Y02E60/50—Fuel cells

Landscapes

- Degasification And Air Bubble Elimination (AREA)

- Paints Or Removers (AREA)

- Inert Electrodes (AREA)

- Fuel Cell (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018084884A JP7067242B2 (ja) | 2018-04-26 | 2018-04-26 | 塗液の製造方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018084884A JP7067242B2 (ja) | 2018-04-26 | 2018-04-26 | 塗液の製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2019189766A JP2019189766A (ja) | 2019-10-31 |

| JP2019189766A5 JP2019189766A5 (enExample) | 2021-06-10 |

| JP7067242B2 true JP7067242B2 (ja) | 2022-05-16 |

Family

ID=68388545

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2018084884A Active JP7067242B2 (ja) | 2018-04-26 | 2018-04-26 | 塗液の製造方法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP7067242B2 (enExample) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2022182299A (ja) * | 2021-05-28 | 2022-12-08 | 東レ株式会社 | ガス拡散電極の製造方法、ガス拡散電極、およびガス拡散電極ロール状物 |

| CN118768135B (zh) * | 2024-09-05 | 2024-11-22 | 新乡市阳光电源制造有限公司 | 一种锂电池涂布机的涂布机构及其涂布方法 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003059505A (ja) | 2001-08-10 | 2003-02-28 | Matsushita Electric Ind Co Ltd | 燃料電池の製造方法 |

| JP2003100305A (ja) | 2001-09-19 | 2003-04-04 | Matsushita Electric Ind Co Ltd | 燃料電池用電極の製造方法 |

| JP2006316086A (ja) | 2005-05-10 | 2006-11-24 | Kyocera Chemical Corp | 金属製セパレータ被覆用液状導電性樹脂組成物 |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS551633A (en) * | 1978-06-20 | 1980-01-08 | Hitachi Maxell Ltd | Production of magnetic recording medium |

-

2018

- 2018-04-26 JP JP2018084884A patent/JP7067242B2/ja active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003059505A (ja) | 2001-08-10 | 2003-02-28 | Matsushita Electric Ind Co Ltd | 燃料電池の製造方法 |

| JP2003100305A (ja) | 2001-09-19 | 2003-04-04 | Matsushita Electric Ind Co Ltd | 燃料電池用電極の製造方法 |

| JP2006316086A (ja) | 2005-05-10 | 2006-11-24 | Kyocera Chemical Corp | 金属製セパレータ被覆用液状導電性樹脂組成物 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2019189766A (ja) | 2019-10-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6637556B2 (ja) | アルカリ水電解用隔膜、アルカリ水電解装置、水素の製造方法及びアルカリ水電解用隔膜の製造方法 | |

| TWI658637B (zh) | 氣體擴散電極及其製造方法 | |

| TWI644478B (zh) | Gas diffusion electrode substrate, manufacturing method and application thereof | |

| US20150064606A1 (en) | Assembly of a porous metal diffusion substrate and a polymeric separator membrane | |

| TWI743027B (zh) | 氣體擴散電極基材及氣體擴散電極基材之製造方法 | |

| TW201801384A (zh) | 氣體擴散電極及其製造方法 | |

| JP6596289B2 (ja) | ポリフェニレン共重合体を含む微多孔膜、及びその製造方法 | |

| JP7151193B2 (ja) | 分散液体の脱泡方法及び塗液の製造方法 | |

| TW201801382A (zh) | 氣體擴散電極 | |

| TW201806739A (zh) | 氣體擴散電極基材、積層體及燃料電池 | |

| JP2016015216A (ja) | ガス拡散電極、その製造方法および製造装置 | |

| TW201547097A (zh) | 氣體擴散電極基材以及具備其之膜電極接合體及燃料電池 | |

| JP7067242B2 (ja) | 塗液の製造方法 | |

| TWI703765B (zh) | 氣體擴散電極 | |

| US20200287220A1 (en) | Method for producing gas diffusion electrode substrate and fuel cell | |

| JP7119607B2 (ja) | 塗液の製造方法 | |

| JP2015191826A (ja) | ガス拡散電極の製造方法および製造装置 | |

| CN108137419B (zh) | 碳片、气体扩散电极基材、卷绕体和燃料电池 | |

| JP2019216060A (ja) | ガス拡散電極の微多孔層を形成するための塗液の製造方法 | |

| US20120312696A1 (en) | Method of manufacturing proton-conducting membranes | |

| JP6291962B2 (ja) | ガス拡散電極の製造方法および製造装置 | |

| JP2022182299A (ja) | ガス拡散電極の製造方法、ガス拡散電極、およびガス拡散電極ロール状物 | |

| JP4817622B2 (ja) | 固体高分子型燃料電池用ガス拡散電極の製造方法 | |

| CN112771699B (zh) | 气体扩散电极基材及其制造方法、固体高分子型燃料电池 | |

| JP2010255096A (ja) | イオン透過性隔膜の製造装置及び製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20210421 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20210421 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20211025 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20211102 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20211210 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20220329 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20220411 |

|

| R151 | Written notification of patent or utility model registration |

Ref document number: 7067242 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R151 |