JP6802075B2 - ハニカム構造体 - Google Patents

ハニカム構造体 Download PDFInfo

- Publication number

- JP6802075B2 JP6802075B2 JP2017008903A JP2017008903A JP6802075B2 JP 6802075 B2 JP6802075 B2 JP 6802075B2 JP 2017008903 A JP2017008903 A JP 2017008903A JP 2017008903 A JP2017008903 A JP 2017008903A JP 6802075 B2 JP6802075 B2 JP 6802075B2

- Authority

- JP

- Japan

- Prior art keywords

- honeycomb

- segment

- honeycomb structure

- segments

- bonding layer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000002093 peripheral effect Effects 0.000 claims description 38

- 238000007789 sealing Methods 0.000 claims description 22

- 238000005192 partition Methods 0.000 claims description 20

- 238000005304 joining Methods 0.000 claims description 12

- 239000012530 fluid Substances 0.000 claims description 8

- 239000010410 layer Substances 0.000 description 170

- 230000000052 comparative effect Effects 0.000 description 41

- 238000011156 evaluation Methods 0.000 description 30

- 239000007789 gas Substances 0.000 description 24

- 239000000463 material Substances 0.000 description 22

- 230000035939 shock Effects 0.000 description 14

- 238000000034 method Methods 0.000 description 11

- MWUXSHHQAYIFBG-UHFFFAOYSA-N nitrogen oxide Inorganic materials O=[N] MWUXSHHQAYIFBG-UHFFFAOYSA-N 0.000 description 9

- 230000007423 decrease Effects 0.000 description 8

- 230000008646 thermal stress Effects 0.000 description 8

- 238000005259 measurement Methods 0.000 description 7

- 238000010586 diagram Methods 0.000 description 6

- 238000010304 firing Methods 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 6

- 229910052751 metal Inorganic materials 0.000 description 6

- 239000002184 metal Substances 0.000 description 6

- 125000006850 spacer group Chemical group 0.000 description 6

- 230000035882 stress Effects 0.000 description 6

- 239000000919 ceramic Substances 0.000 description 5

- 239000004927 clay Substances 0.000 description 5

- 239000000567 combustion gas Substances 0.000 description 5

- 238000006073 displacement reaction Methods 0.000 description 5

- 239000013618 particulate matter Substances 0.000 description 5

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 5

- 239000004071 soot Substances 0.000 description 5

- 229910000505 Al2TiO5 Inorganic materials 0.000 description 4

- ATUOYWHBWRKTHZ-UHFFFAOYSA-N Propane Chemical compound CCC ATUOYWHBWRKTHZ-UHFFFAOYSA-N 0.000 description 4

- 239000003054 catalyst Substances 0.000 description 4

- 239000011248 coating agent Substances 0.000 description 4

- 238000000576 coating method Methods 0.000 description 4

- 239000000446 fuel Substances 0.000 description 4

- AABBHSMFGKYLKE-SNAWJCMRSA-N propan-2-yl (e)-but-2-enoate Chemical compound C\C=C\C(=O)OC(C)C AABBHSMFGKYLKE-SNAWJCMRSA-N 0.000 description 4

- 238000000746 purification Methods 0.000 description 4

- 238000010008 shearing Methods 0.000 description 4

- 229910010271 silicon carbide Inorganic materials 0.000 description 4

- 238000012360 testing method Methods 0.000 description 4

- 238000001816 cooling Methods 0.000 description 3

- 238000005516 engineering process Methods 0.000 description 3

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 description 3

- 229910052753 mercury Inorganic materials 0.000 description 3

- 239000002994 raw material Substances 0.000 description 3

- 239000002002 slurry Substances 0.000 description 3

- 229910052581 Si3N4 Inorganic materials 0.000 description 2

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 2

- 239000012298 atmosphere Substances 0.000 description 2

- 239000011230 binding agent Substances 0.000 description 2

- 239000011247 coating layer Substances 0.000 description 2

- 238000002485 combustion reaction Methods 0.000 description 2

- 229910052878 cordierite Inorganic materials 0.000 description 2

- 230000006866 deterioration Effects 0.000 description 2

- JSKIRARMQDRGJZ-UHFFFAOYSA-N dimagnesium dioxido-bis[(1-oxido-3-oxo-2,4,6,8,9-pentaoxa-1,3-disila-5,7-dialuminabicyclo[3.3.1]nonan-7-yl)oxy]silane Chemical compound [Mg++].[Mg++].[O-][Si]([O-])(O[Al]1O[Al]2O[Si](=O)O[Si]([O-])(O1)O2)O[Al]1O[Al]2O[Si](=O)O[Si]([O-])(O1)O2 JSKIRARMQDRGJZ-UHFFFAOYSA-N 0.000 description 2

- KZHJGOXRZJKJNY-UHFFFAOYSA-N dioxosilane;oxo(oxoalumanyloxy)alumane Chemical compound O=[Si]=O.O=[Si]=O.O=[Al]O[Al]=O.O=[Al]O[Al]=O.O=[Al]O[Al]=O KZHJGOXRZJKJNY-UHFFFAOYSA-N 0.000 description 2

- 238000002347 injection Methods 0.000 description 2

- 239000007924 injection Substances 0.000 description 2

- 239000011812 mixed powder Substances 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 229910052863 mullite Inorganic materials 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 229920003023 plastic Polymers 0.000 description 2

- 239000001294 propane Substances 0.000 description 2

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 2

- 238000000638 solvent extraction Methods 0.000 description 2

- 238000010998 test method Methods 0.000 description 2

- 238000009423 ventilation Methods 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 229910002060 Fe-Cr-Al alloy Inorganic materials 0.000 description 1

- 238000009825 accumulation Methods 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 239000012300 argon atmosphere Substances 0.000 description 1

- 230000033228 biological regulation Effects 0.000 description 1

- 238000009924 canning Methods 0.000 description 1

- 229910010293 ceramic material Inorganic materials 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- -1 corderite Chemical compound 0.000 description 1

- 238000005238 degreasing Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 230000020169 heat generation Effects 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 229910052575 non-oxide ceramic Inorganic materials 0.000 description 1

- 239000011225 non-oxide ceramic Substances 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 229910052574 oxide ceramic Inorganic materials 0.000 description 1

- 239000011224 oxide ceramic Substances 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 230000008929 regeneration Effects 0.000 description 1

- 238000011069 regeneration method Methods 0.000 description 1

- 239000000565 sealant Substances 0.000 description 1

- SBEQWOXEGHQIMW-UHFFFAOYSA-N silicon Chemical compound [Si].[Si] SBEQWOXEGHQIMW-UHFFFAOYSA-N 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 239000011863 silicon-based powder Substances 0.000 description 1

- 229910052596 spinel Inorganic materials 0.000 description 1

- 239000011029 spinel Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 239000002341 toxic gas Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/24—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies

- B01D46/2403—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies characterised by the physical shape or structure of the filtering element

- B01D46/2418—Honeycomb filters

- B01D46/2451—Honeycomb filters characterized by the geometrical structure, shape, pattern or configuration or parameters related to the geometry of the structure

- B01D46/2455—Honeycomb filters characterized by the geometrical structure, shape, pattern or configuration or parameters related to the geometry of the structure of the whole honeycomb or segments

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/24—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies

- B01D46/2403—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies characterised by the physical shape or structure of the filtering element

- B01D46/2418—Honeycomb filters

- B01D46/2451—Honeycomb filters characterized by the geometrical structure, shape, pattern or configuration or parameters related to the geometry of the structure

- B01D46/2466—Honeycomb filters characterized by the geometrical structure, shape, pattern or configuration or parameters related to the geometry of the structure of the adhesive layers, i.e. joints between segments

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/24—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies

- B01D46/2403—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies characterised by the physical shape or structure of the filtering element

- B01D46/2418—Honeycomb filters

- B01D46/2451—Honeycomb filters characterized by the geometrical structure, shape, pattern or configuration or parameters related to the geometry of the structure

- B01D46/247—Honeycomb filters characterized by the geometrical structure, shape, pattern or configuration or parameters related to the geometry of the structure of the cells

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/24—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies

- B01D46/2403—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies characterised by the physical shape or structure of the filtering element

- B01D46/2418—Honeycomb filters

- B01D46/2451—Honeycomb filters characterized by the geometrical structure, shape, pattern or configuration or parameters related to the geometry of the structure

- B01D46/2476—Monolithic structures

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/24—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies

- B01D46/2403—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies characterised by the physical shape or structure of the filtering element

- B01D46/2418—Honeycomb filters

- B01D46/2451—Honeycomb filters characterized by the geometrical structure, shape, pattern or configuration or parameters related to the geometry of the structure

- B01D46/2478—Structures comprising honeycomb segments

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/24—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies

- B01D46/2403—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies characterised by the physical shape or structure of the filtering element

- B01D46/2418—Honeycomb filters

- B01D46/2451—Honeycomb filters characterized by the geometrical structure, shape, pattern or configuration or parameters related to the geometry of the structure

- B01D46/2482—Thickness, height, width, length or diameter

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/24—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies

- B01D46/2403—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies characterised by the physical shape or structure of the filtering element

- B01D46/2418—Honeycomb filters

- B01D46/2451—Honeycomb filters characterized by the geometrical structure, shape, pattern or configuration or parameters related to the geometry of the structure

- B01D46/2484—Cell density, area or aspect ratio

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/24—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies

- B01D46/2403—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies characterised by the physical shape or structure of the filtering element

- B01D46/2418—Honeycomb filters

- B01D46/2451—Honeycomb filters characterized by the geometrical structure, shape, pattern or configuration or parameters related to the geometry of the structure

- B01D46/2486—Honeycomb filters characterized by the geometrical structure, shape, pattern or configuration or parameters related to the geometry of the structure characterised by the shapes or configurations

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J35/00—Catalysts, in general, characterised by their form or physical properties

- B01J35/50—Catalysts, in general, characterised by their form or physical properties characterised by their shape or configuration

- B01J35/56—Foraminous structures having flow-through passages or channels, e.g. grids or three-dimensional monoliths

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/01—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on oxide ceramics

- C04B35/46—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on oxide ceramics based on titanium oxides or titanates

- C04B35/462—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on oxide ceramics based on titanium oxides or titanates based on titanates

- C04B35/478—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on oxide ceramics based on titanium oxides or titanates based on titanates based on aluminium titanates

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/515—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on non-oxide ceramics

- C04B35/56—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on non-oxide ceramics based on carbides or oxycarbides

- C04B35/565—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on non-oxide ceramics based on carbides or oxycarbides based on silicon carbide

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/622—Forming processes; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/622—Forming processes; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/626—Preparing or treating the powders individually or as batches ; preparing or treating macroscopic reinforcing agents for ceramic products, e.g. fibres; mechanical aspects section B

- C04B35/63—Preparing or treating the powders individually or as batches ; preparing or treating macroscopic reinforcing agents for ceramic products, e.g. fibres; mechanical aspects section B using additives specially adapted for forming the products, e.g.. binder binders

- C04B35/632—Organic additives

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/622—Forming processes; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/626—Preparing or treating the powders individually or as batches ; preparing or treating macroscopic reinforcing agents for ceramic products, e.g. fibres; mechanical aspects section B

- C04B35/63—Preparing or treating the powders individually or as batches ; preparing or treating macroscopic reinforcing agents for ceramic products, e.g. fibres; mechanical aspects section B using additives specially adapted for forming the products, e.g.. binder binders

- C04B35/638—Removal thereof

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B37/00—Joining burned ceramic articles with other burned ceramic articles or other articles by heating

- C04B37/003—Joining burned ceramic articles with other burned ceramic articles or other articles by heating by means of an interlayer consisting of a combination of materials selected from glass, or ceramic material with metals, metal oxides or metal salts

- C04B37/005—Joining burned ceramic articles with other burned ceramic articles or other articles by heating by means of an interlayer consisting of a combination of materials selected from glass, or ceramic material with metals, metal oxides or metal salts consisting of glass or ceramic material

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B38/00—Porous mortars, concrete, artificial stone or ceramic ware; Preparation thereof

- C04B38/0006—Honeycomb structures

- C04B38/0012—Honeycomb structures characterised by the material used for sealing or plugging (some of) the channels of the honeycombs

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/02—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust

- F01N3/021—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust by means of filters

- F01N3/022—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust by means of filters characterised by specially adapted filtering structure, e.g. honeycomb, mesh or fibrous

- F01N3/0222—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust by means of filters characterised by specially adapted filtering structure, e.g. honeycomb, mesh or fibrous the structure being monolithic, e.g. honeycombs

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/24—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by constructional aspects of converting apparatus

- F01N3/28—Construction of catalytic reactors

- F01N3/2803—Construction of catalytic reactors characterised by structure, by material or by manufacturing of catalyst support

- F01N3/2825—Ceramics

- F01N3/2828—Ceramic multi-channel monoliths, e.g. honeycombs

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/42—Non metallic elements added as constituents or additives, e.g. sulfur, phosphor, selenium or tellurium

- C04B2235/428—Silicon

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/60—Aspects relating to the preparation, properties or mechanical treatment of green bodies or pre-forms

- C04B2235/606—Drying

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2237/00—Aspects relating to ceramic laminates or to joining of ceramic articles with other articles by heating

- C04B2237/30—Composition of layers of ceramic laminates or of ceramic or metallic articles to be joined by heating, e.g. Si substrates

- C04B2237/32—Ceramic

- C04B2237/36—Non-oxidic

- C04B2237/365—Silicon carbide

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2237/00—Aspects relating to ceramic laminates or to joining of ceramic articles with other articles by heating

- C04B2237/50—Processing aspects relating to ceramic laminates or to the joining of ceramic articles with other articles by heating

- C04B2237/70—Forming laminates or joined articles comprising layers of a specific, unusual thickness

- C04B2237/708—Forming laminates or joined articles comprising layers of a specific, unusual thickness of one or more of the interlayers

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2237/00—Aspects relating to ceramic laminates or to joining of ceramic articles with other articles by heating

- C04B2237/50—Processing aspects relating to ceramic laminates or to the joining of ceramic articles with other articles by heating

- C04B2237/78—Side-way connecting, e.g. connecting two plates through their sides

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2330/00—Structure of catalyst support or particle filter

- F01N2330/02—Metallic plates or honeycombs, e.g. superposed or rolled-up corrugated or otherwise deformed sheet metal

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2330/00—Structure of catalyst support or particle filter

- F01N2330/06—Ceramic, e.g. monoliths

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2330/00—Structure of catalyst support or particle filter

- F01N2330/30—Honeycomb supports characterised by their structural details

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/10—Internal combustion engine [ICE] based vehicles

- Y02T10/12—Improving ICE efficiencies

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Geometry (AREA)

- Physics & Mathematics (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Ceramic Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Organic Chemistry (AREA)

- Materials Engineering (AREA)

- Structural Engineering (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Inorganic Chemistry (AREA)

- Toxicology (AREA)

- Health & Medical Sciences (AREA)

- Filtering Materials (AREA)

- Catalysts (AREA)

- Processes For Solid Components From Exhaust (AREA)

- Filtering Of Dispersed Particles In Gases (AREA)

- Ceramic Products (AREA)

Description

複数個の前記ハニカムセグメントの側面同士を互いに接合する接合層と、を備え、

複数個の前記ハニカムセグメントは、前記セルの延びる方向に直交する断面の形状が同一の完全セグメント、及び前記断面の形状が前記完全セグメントの一部の形状である不完全セグメントを、それぞれ複数個含み、

前記完全セグメントの全体形状が、前記流入端面と前記流出端面の形状及び大きさが同一の四角柱状であり、

前記接合層は、前記セルの延びる方向に直交する断面において、対向配置された2つの前記ハニカムセグメントの相互間に配置された部分接合層の複数個が、前記ハニカムセグメントの接合体の周縁の一の点から他の点まで延びるように配列した複数の列を有し、

それぞれの前記列の前記接合層は、一の方向に配列した複数個の前記部分接合層のうち、前記断面における最外周に配置された最外周部分接合層と、当該一の方向に配列した他の前記部分接合層のうちの少なく1つとが、当該一の方向の延長線上において相互に重ならないように配置されており、

複数個の前記ハニカムセグメントのそれぞれは、隣り合う前記ハニカムセグメント同士の互いに対向する側面のずれ量が、前記完全セグメントの側面の1辺の長さに対して、1.4%以上、10%以下である、ハニカム構造体。

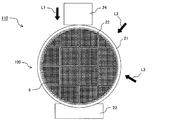

本発明のハニカム構造体の第一実施形態は、図1〜図5に示すように、複数個の角柱状のハニカムセグメント4と、接合層6と、を備えた、ハニカム構造体100である。本実施形態のハニカム構造体100は、所謂、セグメント構造のハニカム構造体である。ハニカム構造体100の外周には、複数個のハニカムセグメント4を囲繞するように配設された外壁8を更に備えている。本実施形態のハニカム構造体100は、排ガス中に含まれる粒子状物質を除去するための捕集フィルタとして好適に利用することができる。

次に、本発明のハニカム構造体を製造する方法について説明する。なお、本発明のハニカム構造体を製造する方法については、以下に説明する製造方法に限定されることはない。

まず、炭化珪素粉末を80質量部と、Si粉末を20質量部とを混合して、混合粉末を得た。この混合粉末に、バインダ、造孔材、及び水を添加して、混合、混練して坏土を調製した。

接合層の列の配置を、表2に示すように変更して、実施例2及び3のハニカム構造体を作製した。実施例2のハニカム構造体は、接合層の列の配置が、a、及びbのうちのいずれかの配置であった。実施例3のハニカム構造体は、接合層の列の配置が、b、及びcのうちのいずれかの配置であった。隣り合うハニカムセグメント同士の互いに対向する側面の最大ずれ量YMAXは、実施例2のハニカム構造体が、2.5mmで、実施例3のハニカム構造体が、1mmであった。

実施例4〜12においては、表1のセル構造の欄に示されるようなハニカムセグメントを複数個作製し、作製したハニカムセグメントを用いてハニカム構造体を作製した。各実施例において、表1の「セグメント数」の欄に示すような個数のハニカムセグメントを用いた。得られたハニカム構造体の「接合層の列の配置」、及び「隣り合うセグメントの最大ずれ量YMAX」、及び「最大ずれ比率」を表2に示す。

表3に示すようなセル構造のハニカムセグメントを作製し、接合層の列の配置を、表4に示すように変更して、比較例1〜12のハニカム構造体を作製した。接合層の列の配置において、パターンd、又はパターンeが含まれている場合は、最外周部分接合層と、他の部分接合層とが、一の方向の延長線上において相互に重なっている接合層を含むこととなる。また、「最大ずれ比率」が10%を超えている場合は、隣り合うハニカムセグメント同士の互いに対向する側面の最大ずれ量YMAXが、完全セグメントの側面の1辺の長さZに対して、10%を超えることとなる。

耐熱衝撃性(1)の評価として、ハニカム構造体に以下に記載する試験を行い、試験後のハニカム構造体におけるクラックの発生の有無により、ハニカム構造体のロバスト(robust)性を評価するものとした。具体的には、2.2Lディーゼルエンジンを搭載するエンジンベンチにて、エンジン回転数2000rpm、エンジントルク60Nmの運転条件にて、2〜12g/Lの煤を、各実施例及び比較例のハニカム構造体の内部に堆積させた。その後、ポストインジェクションによる再生処理を行い、ハニカム構造体の入口ガス温度を上昇させ、ハニカム構造体の前後の圧損が低下し始めたところでポストインジェクションを切り、エンジンをアイドル状態に切り替えた。このときの煤堆積量は、実施例の各水準において、流出側端面の中央部における最高温度が1000℃となるようにし、実施例と比較例の同じ番号は同一煤量となる条件で試験を実施した。そして、ハニカム構造体の流出端面側及び流入端面側におけるクラックの有無を、それぞれ目視にて観察した。クラックが確認されない場合を合格とし、クラックが確認された場合を不合格として、流出端面側及び流入端面側のそれぞれの結果に基づいて、以下の評価基準により、耐熱衝撃性(1)の評価を行った。耐熱衝撃性(1)の評価において、流入端面側及び流出端面側が共に「合格」の場合を、評価Aとした。耐熱衝撃性(1)の評価において、流入端面側及び流出端面側の少なくとも一方が「不合格」の場合を、評価Cとした。評価結果を表2及び表4に示す。

図14に示すせん断強度試験機110を用い、実施例1〜12及び比較例1〜12のハニカム構造体に対してせん断強度の評価を行った。具体的には、まず、各ハニカム構造体100の外壁8の周りに緩衝用のマット22を巻き付けた。次に、緩衝用のマット22を巻き付けた状態のハニカム構造体100を、金属製の缶体21内に挿入し、せん断強度測定用の測定試料とした。マット22としては、三菱樹脂製のセラミックマット(商品名:マフテック OBM−P)を用いた。使用したマット22は、単位面積当たりの質量が1000〜1200g/m2であり、その厚さが、4.0〜5.0mmであった。このようにして作製した測定試料に対して、第一荷重方向L1、第二荷重方向L2、及び第三荷重方向L3のそれぞれから荷重を負荷し、ハニカム構造体100にせん断が発生する強度を測定した。各荷重の負荷は、ダイヤルゲージ(Dial gauge)を取り付けた荷重供給部24を、測定試料とした缶体21の一方の端面近傍の端部に押し付けることによって行った。測定試料に負荷する荷重は、せん断強度試験の負荷荷重を読み取ることによって確認した。測定試料に負荷する荷重を徐々に大きくしていき、ハニカム構造体100にせん断が発生した際の荷重を、ハニカム構造体100のせん断強度とした。

実施例1〜12のハニカム構造体は、耐熱衝撃性(1)及びせん断強度の評価において、共に良好な結果を得ることができた。一方、比較例1、3〜8、10及び12のハニカム構造体は、せん断強度の評価において、大きなせん断強度の低下が認められた。比較例1、3〜8、10及び12のハニカム構造体は、接合層の列の配置において、パターンd、又はパターンeが含まれているものであった。また、比較例2、5、7、9、11及び12のハニカム構造体は、耐熱衝撃性(1)の評価において、流入端面側及び流出端面側の少なくとも一方が「不合格」であった。比較例2、5、7、9、11及び12のハニカム構造体は、「最大ずれ比率」が10%を超えているものであった。

実施例13〜24においては、表5のセル構造の欄に示されるようなハニカムセグメントを複数個作製し、作製したハニカムセグメントを用いてハニカム構造体を作製した。なお、実施例13〜24においては、作製したハニカムセグメントの各セルに目封止部を配設しない状態で、ハニカム構造体を作製した。なお、実施例13のハニカム構造体は、目封止部を有していないこと以外は、実施例1のハニカム構造体と同様に構成されたものである。同様に、実施例14〜24のハニカム構造体も、その順番に、実施例2〜12のハニカム構造体と同様に構成されたものである。

比較例13〜24においては、表7のセル構造の欄に示されるようなハニカムセグメントを複数個作製し、作製したハニカムセグメントを用いてハニカム構造体を作製した。なお、比較例13〜24においては、作製したハニカムセグメントの各セルに目封止部を配設しない状態で、ハニカム構造体を作製した。なお、比較例13のハニカム構造体は、目封止部を有していないこと以外は、比較例1のハニカム構造体と同様に構成されたものである。同様に、比較例14〜24のハニカム構造体も、その順番に、比較例2〜12のハニカム構造体と同様に構成されたものである。

ハニカム構造体を収納する缶体内に加熱ガスを供給することができる「プロパンガスバーナー装置」を用いて、ハニカム構造体の耐熱衝撃性(2)の評価を行った。具体的には、各実施例のハニカム構造体を缶体内に収納(キャニング)し、その缶体を、上記プロパンガスバーナー装置に設置した。次に、ハニカム構造体に燃焼ガスを流した。燃焼ガスは、まず、流量60NL/minで10分間流した。ハニカム構造体の前方10mm位置での中央部のガス温度は、10分後に1100℃であった。その後、燃焼ガスの通気を停止し、燃焼ガスの代わりに冷却エアーを、流量250NL/minで10分間流した。冷却エアーを流すことにより、10分後、ハニカム構造体の前方10mm位置での中央部のガス温度は、100℃であった。このような、燃焼ガスと冷却エアーの通気を1サイクル(cycle)とし、これを20サイクル実施した。その後、ハニカム構造体の流出端面側及び流入端面側におけるクラックの有無を、それぞれ目視にて観察した。クラックが確認されない場合を合格とし、クラックが確認された場合を不合格として、流出端面側及び流入端面側のそれぞれの結果に基づいて、以下の評価基準により、耐熱衝撃性(2)の評価を行った。耐熱衝撃性(2)の評価において、流入端面側及び流出端面側が共に「合格」の場合を、評価Aとした。耐熱衝撃性(2)の評価において、流入端面側及び流出端面側の少なくとも一方が「不合格」の場合を、評価Cとした。

実施例13〜24のハニカム構造体は、耐熱衝撃性(2)及びせん断強度の評価において、共に良好な結果を得ることができた。一方、比較例13、15〜20、22及び24のハニカム構造体は、せん断強度の評価において、大きなせん断強度の低下が認められた。比較例13、15〜20、22及び24のハニカム構造体は、接合層の列の配置において、パターンd、又はパターンeが含まれているものであった。また、比較例14、17、19、21、23及び24のハニカム構造体は、耐熱衝撃性(2)の評価において、流入端面側及び流出端面側の少なくとも一方が「不合格」であった。比較例14、17、19、21、23及び24のハニカム構造体は、「最大ずれ比率」が10%を超えているものであった。

Claims (3)

- 流体が流入する流入端面から流体が流出する流出端面まで延びる複数のセルを区画形成する多孔質の隔壁、及び最外周に配設されたセグメント外周壁を有する、複数個の角柱状のハニカムセグメントと、

複数個の前記ハニカムセグメントの側面同士を互いに接合する接合層と、を備え、

複数個の前記ハニカムセグメントは、前記セルの延びる方向に直交する断面の形状が同一の完全セグメント、及び前記断面の形状が前記完全セグメントの一部の形状である不完全セグメントを、それぞれ複数個含み、

前記完全セグメントの全体形状が、前記流入端面と前記流出端面の形状及び大きさが同一の四角柱状であり、

前記接合層は、前記セルの延びる方向に直交する断面において、対向配置された2つの前記ハニカムセグメントの相互間に配置された部分接合層の複数個が、前記ハニカムセグメントの接合体の周縁の一の点から他の点まで延びるように配列した複数の列を有し、

それぞれの前記列の前記接合層は、一の方向に配列した複数個の前記部分接合層のうち、前記断面における最外周に配置された最外周部分接合層と、当該一の方向に配列した他の前記部分接合層のうちの少なく1つとが、当該一の方向の延長線上において相互に重ならないように配置されており、

複数個の前記ハニカムセグメントのそれぞれは、隣り合う前記ハニカムセグメント同士の互いに対向する側面のずれ量が、前記完全セグメントの側面の1辺の長さに対して、1.4%以上、10%以下である、ハニカム構造体。 - 前記部分接合層の幅が、0.5〜3.0mmである、請求項1に記載のハニカム構造体。

- 前記ハニカムセグメントに形成された前記セルのいずれか一方の開口部を目封止するように配設された目封止部を更に備えた、請求項1又は2に記載のハニカム構造体。

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017008903A JP6802075B2 (ja) | 2017-01-20 | 2017-01-20 | ハニカム構造体 |

| US15/854,149 US10543446B2 (en) | 2017-01-20 | 2017-12-26 | Honeycomb structure |

| CN201810003800.7A CN108331642B (zh) | 2017-01-20 | 2018-01-03 | 蜂窝结构体 |

| DE102018200762.4A DE102018200762B4 (de) | 2017-01-20 | 2018-01-18 | Wabenstruktur |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017008903A JP6802075B2 (ja) | 2017-01-20 | 2017-01-20 | ハニカム構造体 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2018114485A JP2018114485A (ja) | 2018-07-26 |

| JP2018114485A5 JP2018114485A5 (ja) | 2020-02-06 |

| JP6802075B2 true JP6802075B2 (ja) | 2020-12-16 |

Family

ID=62813091

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2017008903A Active JP6802075B2 (ja) | 2017-01-20 | 2017-01-20 | ハニカム構造体 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US10543446B2 (ja) |

| JP (1) | JP6802075B2 (ja) |

| CN (1) | CN108331642B (ja) |

| DE (1) | DE102018200762B4 (ja) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7037985B2 (ja) * | 2018-03-30 | 2022-03-17 | 日本碍子株式会社 | ハニカムフィルタ |

| JP7021704B2 (ja) * | 2018-08-23 | 2022-02-17 | 株式会社村田製作所 | 濾過フィルタ |

| WO2020045495A1 (ja) * | 2018-08-30 | 2020-03-05 | 京セラ株式会社 | セラミックス構造体 |

| JP7160741B2 (ja) * | 2019-03-28 | 2022-10-25 | 日本碍子株式会社 | ハニカム構造体 |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS535781B2 (ja) | 1973-12-25 | 1978-03-02 | ||

| DE60032391T2 (de) | 1999-09-29 | 2007-10-11 | Ibiden Co., Ltd., Ogaki | Wabenfömiger Filter und Anordnung von keramischen Filtern |

| JP4282960B2 (ja) * | 2001-08-30 | 2009-06-24 | 日本碍子株式会社 | 高強度ハニカム構造体、その成形方法及びハニカム構造コンバーター |

| JP4890857B2 (ja) | 2003-03-19 | 2012-03-07 | 日本碍子株式会社 | ハニカム構造体 |

| JP2005230680A (ja) * | 2004-02-19 | 2005-09-02 | Ngk Insulators Ltd | ハニカム構造体 |

| WO2005089901A1 (ja) * | 2004-03-23 | 2005-09-29 | Ngk Insulators, Ltd. | ハニカム構造体及びその製造方法 |

| DE102005019464A1 (de) * | 2005-04-27 | 2006-11-02 | Robert Bosch Gmbh | Filtereinrichtung, insbesondere Rußpartikelfilter, für ein Abgassystem einer Brennkraftmaschine |

| KR100884518B1 (ko) * | 2005-08-26 | 2009-02-18 | 이비덴 가부시키가이샤 | 허니컴 구조체 및 그 제조 방법 |

| US7491373B2 (en) * | 2006-11-15 | 2009-02-17 | Corning Incorporated | Flow-through honeycomb substrate and exhaust after treatment system and method |

| DE502008001738D1 (de) * | 2007-02-15 | 2010-12-23 | Mann & Hummel Gmbh | Dieselpartikelfilter mit einem keramischen Filterkörper |

| JP2009256187A (ja) * | 2008-03-24 | 2009-11-05 | Ibiden Co Ltd | ハニカム構造体及びハニカム構造体の製造方法 |

| JP2009233587A (ja) * | 2008-03-27 | 2009-10-15 | Ngk Insulators Ltd | 触媒付きディーゼルパティキュレートフィルタ及びその製造方法 |

| JP5317958B2 (ja) * | 2008-05-20 | 2013-10-16 | イビデン株式会社 | ハニカム構造体及び排ガス浄化装置 |

| JP5097237B2 (ja) | 2010-03-31 | 2012-12-12 | 日本碍子株式会社 | ハニカム構造体の製造方法 |

| JP5719645B2 (ja) * | 2011-03-10 | 2015-05-20 | 株式会社エフ・シー・シー | 排気ガス浄化装置 |

| JP6059954B2 (ja) * | 2012-10-30 | 2017-01-11 | 日本碍子株式会社 | ハニカムフィルタ |

| JP6014526B2 (ja) * | 2013-03-22 | 2016-10-25 | 日本碍子株式会社 | ハニカム構造体 |

| JP6320798B2 (ja) * | 2014-03-04 | 2018-05-09 | 日本碍子株式会社 | ハニカム構造体 |

| JP2017008903A (ja) | 2015-06-26 | 2017-01-12 | カルソニックカンセイ株式会社 | エンジンの吸気装置 |

-

2017

- 2017-01-20 JP JP2017008903A patent/JP6802075B2/ja active Active

- 2017-12-26 US US15/854,149 patent/US10543446B2/en active Active

-

2018

- 2018-01-03 CN CN201810003800.7A patent/CN108331642B/zh active Active

- 2018-01-18 DE DE102018200762.4A patent/DE102018200762B4/de active Active

Also Published As

| Publication number | Publication date |

|---|---|

| DE102018200762A1 (de) | 2018-07-26 |

| US20180207571A1 (en) | 2018-07-26 |

| DE102018200762B4 (de) | 2019-06-19 |

| CN108331642A (zh) | 2018-07-27 |

| JP2018114485A (ja) | 2018-07-26 |

| CN108331642B (zh) | 2021-05-18 |

| US10543446B2 (en) | 2020-01-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US7169203B2 (en) | Honeycomb structure | |

| JP6548528B2 (ja) | 目封止ハニカム構造体、及び目封止ハニカムセグメント | |

| US9987582B2 (en) | Plugged honeycomb structure and plugged honeycomb segment | |

| US9803596B2 (en) | Honeycomb filter | |

| US10118121B2 (en) | Plugged honeycomb structure and plugged honeycomb segment | |

| JP6802075B2 (ja) | ハニカム構造体 | |

| JP6826858B2 (ja) | 目封止ハニカム構造体 | |

| JP6169227B1 (ja) | ハニカムフィルタ | |

| KR20130135929A (ko) | 밀봉된 하니컴 구조체 | |

| CN110307060B (zh) | 蜂窝结构体 | |

| JP2014069123A (ja) | ハニカムフィルタ | |

| JP6862245B2 (ja) | ハニカムフィルタ | |

| JP2018062871A (ja) | 目封止ハニカム構造体 | |

| JP6829979B2 (ja) | 目封止ハニカム構造体 | |

| US10105696B2 (en) | Honeycomb structure | |

| JP7002377B2 (ja) | ハニカム構造体 | |

| JP2018167200A (ja) | ハニカムフィルタ | |

| US10633293B2 (en) | Honeycomb structure | |

| JP6887301B2 (ja) | ハニカムフィルタ | |

| JP7094193B2 (ja) | ハニカムフィルタ | |

| JP6802102B2 (ja) | 目封止ハニカム構造体 | |

| JP7057691B2 (ja) | ハニカム構造体 | |

| US20200308070A1 (en) | Honeycomb structure | |

| JP2017221942A (ja) | ハニカムフィルタ | |

| JP2016175789A (ja) | ハニカム構造体 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20191023 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20191219 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20200728 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20200901 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20201021 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20201117 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20201126 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6802075 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |