JP6668377B2 - 低いコンプレッションハイトを有する、頑丈かつ軽量のピストンおよびその構成方法 - Google Patents

低いコンプレッションハイトを有する、頑丈かつ軽量のピストンおよびその構成方法 Download PDFInfo

- Publication number

- JP6668377B2 JP6668377B2 JP2017549779A JP2017549779A JP6668377B2 JP 6668377 B2 JP6668377 B2 JP 6668377B2 JP 2017549779 A JP2017549779 A JP 2017549779A JP 2017549779 A JP2017549779 A JP 2017549779A JP 6668377 B2 JP6668377 B2 JP 6668377B2

- Authority

- JP

- Japan

- Prior art keywords

- piston

- pin

- pin boss

- skirt

- forming

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

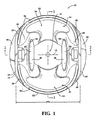

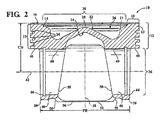

- F02F3/00—Pistons

- F02F3/26—Pistons having combustion chamber in piston head

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21K—MAKING FORGED OR PRESSED METAL PRODUCTS, e.g. HORSE-SHOES, RIVETS, BOLTS OR WHEELS

- B21K1/00—Making machine elements

- B21K1/18—Making machine elements pistons or plungers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D15/00—Casting using a mould or core of which a part significant to the process is of high thermal conductivity, e.g. chill casting; Moulds or accessories specially adapted therefor

- B22D15/02—Casting using a mould or core of which a part significant to the process is of high thermal conductivity, e.g. chill casting; Moulds or accessories specially adapted therefor of cylinders, pistons, bearing shells or like thin-walled objects

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D25/00—Special casting characterised by the nature of the product

- B22D25/02—Special casting characterised by the nature of the product by its peculiarity of shape; of works of art

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y10/00—Processes of additive manufacturing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y80/00—Products made by additive manufacturing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

- F02F3/00—Pistons

- F02F3/16—Pistons having cooling means

- F02F3/20—Pistons having cooling means the means being a fluid flowing through or along piston

- F02F3/22—Pistons having cooling means the means being a fluid flowing through or along piston the fluid being liquid

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

- F02F3/00—Pistons

- F02F2003/0007—Monolithic pistons; One piece constructions; Casting of pistons

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

- F02F2200/00—Manufacturing

- F02F2200/06—Casting

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- General Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Materials Engineering (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Pistons, Piston Rings, And Cylinders (AREA)

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201562136948P | 2015-03-23 | 2015-03-23 | |

| US62/136,948 | 2015-03-23 | ||

| US15/077,168 | 2016-03-22 | ||

| US15/077,168 US10584659B2 (en) | 2015-03-23 | 2016-03-22 | Robust, lightweight, low compression height piston and method of construction thereof |

| PCT/US2016/023653 WO2016154234A1 (en) | 2015-03-23 | 2016-03-23 | Robust, lightweight, low compression height piston and method of construction thereof |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2018510994A JP2018510994A (ja) | 2018-04-19 |

| JP2018510994A5 JP2018510994A5 (enExample) | 2019-02-28 |

| JP6668377B2 true JP6668377B2 (ja) | 2020-03-18 |

Family

ID=56974930

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2017549779A Expired - Fee Related JP6668377B2 (ja) | 2015-03-23 | 2016-03-23 | 低いコンプレッションハイトを有する、頑丈かつ軽量のピストンおよびその構成方法 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US10584659B2 (enExample) |

| EP (1) | EP3274576A1 (enExample) |

| JP (1) | JP6668377B2 (enExample) |

| KR (1) | KR20170130474A (enExample) |

| CN (1) | CN107646068B (enExample) |

| BR (1) | BR112017020371A2 (enExample) |

| WO (1) | WO2016154234A1 (enExample) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USD886155S1 (en) * | 2015-12-18 | 2020-06-02 | Mahle International Gmbh | Piston for an internal combustion engine |

| US10113503B2 (en) * | 2016-10-11 | 2018-10-30 | Caterpillar Inc. | Combustion bowl of a piston for an engine |

| BR112019021016A2 (pt) | 2017-04-19 | 2020-05-05 | Ks Kolbenschmidt Gmbh | pistão em construção estrutural |

| DE102017207005A1 (de) * | 2017-04-26 | 2018-10-31 | Federal-Mogul Nürnberg GmbH | Einteiliger, gegossener Kolben für einen Verbrennungsmotor |

| DE102017118773A1 (de) * | 2017-08-17 | 2019-02-21 | Federal-Mogul Burscheid Gmbh | Kolbenringsatz, Kolben und Verbrennungsmotor |

| CN107755699A (zh) * | 2017-11-03 | 2018-03-06 | 湖南江滨机器(集团)有限责任公司 | 一种钢活塞的制作方法 |

| US10946914B2 (en) | 2017-12-13 | 2021-03-16 | Adamant Conceptions Inc. | Chain assembly and a bicycle lock manufactured therefrom |

| WO2019143403A1 (en) | 2018-01-19 | 2019-07-25 | Cummins Inc. | Piston with insulating air gap formed by additive manufacturing |

| CN112761806A (zh) * | 2021-01-27 | 2021-05-07 | 北京理工大学 | 一种基于整体式活塞精确润滑的供油结构 |

| CN215979628U (zh) * | 2021-11-09 | 2022-03-08 | 马勒汽车技术(中国)有限公司 | 具有回油通道的活塞及发动机 |

Family Cites Families (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2153501A (en) | 1936-04-29 | 1939-04-04 | H B Motor Corp | Piston for internal combustion engines |

| US3516335A (en) | 1968-07-03 | 1970-06-23 | Caterpillar Tractor Co | Piston with heat dam |

| DE2425881A1 (de) * | 1974-05-28 | 1975-12-18 | Kloeckner Humboldt Deutz Ag | Kolben fuer hubkolben-brennkraftmaschinen |

| AU503148B2 (en) | 1975-06-16 | 1979-08-23 | Cummins Engine Company, Inc | Piston with flexible heat dam |

| JPS5924853Y2 (ja) | 1977-05-11 | 1984-07-23 | ヤンマーディーゼル株式会社 | 内燃機関用ピストン |

| IT1109578B (it) | 1978-03-22 | 1985-12-23 | Mondial Piston Galli Ercole C | Stantuffo per motori a combustione interna |

| JPS59168557U (ja) | 1983-04-28 | 1984-11-12 | 株式会社小松製作所 | 内燃機関用鋳鉄ピストン |

| GB8824222D0 (en) | 1988-10-15 | 1988-11-23 | Wellworthy Ltd | Pistons |

| DE4110306A1 (de) * | 1990-09-20 | 1992-03-26 | Mahle Gmbh | Tauchkolben aus leichtmetall fuer ottomotoren |

| DE19618625C1 (de) * | 1996-05-09 | 1997-10-23 | Daimler Benz Ag | Flüssigkeitsgekühlter Kolben für Verbrennungsmotoren |

| DE10244510A1 (de) | 2002-09-25 | 2004-04-08 | Mahle Gmbh | Einteiliger Kühlkanalkolben für einen Verbrennungsmotor |

| FR2848129B1 (fr) | 2002-12-05 | 2006-01-27 | Ascometal Sa | Procede de fabrication d'un piston pour moteur a explosion, et piston ainsi obtenu |

| JP2004285942A (ja) | 2003-03-24 | 2004-10-14 | Kubota Corp | エンジン |

| CN2623891Y (zh) | 2003-05-21 | 2004-07-07 | 中国第一汽车集团公司 | 活塞的开式内冷油道 |

| US7143685B2 (en) | 2003-11-04 | 2006-12-05 | Federal Mogul World Wide, Inc. | Monobloc piston having open floor |

| DE102004029877A1 (de) * | 2004-06-19 | 2006-01-05 | Mahle Gmbh | Gebauter Kolben für einen Verbrennungsmotor |

| US7406941B2 (en) | 2004-07-21 | 2008-08-05 | Federal - Mogul World Wide, Inc. | One piece cast steel monobloc piston |

| JP2006214298A (ja) | 2005-02-01 | 2006-08-17 | Hitachi Ltd | 内燃機関のピストン |

| DE102005037740B3 (de) | 2005-08-10 | 2006-12-21 | Federal-Mogul Nürnberg GmbH | Verfahren zur Wärmebehandlung eines Kolbens für einen Verbrennungsmotor |

| JP4333693B2 (ja) | 2006-05-22 | 2009-09-16 | トヨタ自動車株式会社 | 内燃機関用ピストンおよび内燃機関 |

| US9970384B2 (en) * | 2009-11-06 | 2018-05-15 | Federal-Mogul Llc | Steel piston with cooling gallery and method of construction thereof |

| US20110120299A1 (en) * | 2009-11-25 | 2011-05-26 | Gm Global Technology Operations, Inc. | Cast piston with pin bore lubrication and method of manufacturing same |

| US9010296B2 (en) | 2010-06-29 | 2015-04-21 | Kolbenschmidt K. K. | Piston for spark-ignition engine |

| US8876155B2 (en) * | 2011-04-20 | 2014-11-04 | Autoliv Development Ab | Curtain airbag device for vehicle |

| US10184421B2 (en) | 2012-03-12 | 2019-01-22 | Tenneco Inc. | Engine piston |

| US10738731B2 (en) | 2013-11-07 | 2020-08-11 | Tenneco Inc. | Monolithic, galleryless piston and method of construction thereof |

| EP3071823B1 (en) * | 2013-11-07 | 2021-12-22 | Federal-Mogul LLC | Monolithic, galleryless piston and method of construction thereof |

| CN107110063B (zh) | 2014-10-30 | 2019-10-22 | 天纳克公司 | 活塞 |

-

2016

- 2016-03-22 US US15/077,168 patent/US10584659B2/en active Active

- 2016-03-23 BR BR112017020371A patent/BR112017020371A2/pt not_active Application Discontinuation

- 2016-03-23 EP EP16716990.3A patent/EP3274576A1/en not_active Withdrawn

- 2016-03-23 JP JP2017549779A patent/JP6668377B2/ja not_active Expired - Fee Related

- 2016-03-23 WO PCT/US2016/023653 patent/WO2016154234A1/en not_active Ceased

- 2016-03-23 CN CN201680029794.1A patent/CN107646068B/zh active Active

- 2016-03-23 KR KR1020177029657A patent/KR20170130474A/ko not_active Withdrawn

Also Published As

| Publication number | Publication date |

|---|---|

| CN107646068A (zh) | 2018-01-30 |

| BR112017020371A2 (pt) | 2018-06-05 |

| US10584659B2 (en) | 2020-03-10 |

| CN107646068B (zh) | 2020-10-16 |

| WO2016154234A1 (en) | 2016-09-29 |

| JP2018510994A (ja) | 2018-04-19 |

| KR20170130474A (ko) | 2017-11-28 |

| US20160281635A1 (en) | 2016-09-29 |

| EP3274576A1 (en) | 2018-01-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6668377B2 (ja) | 低いコンプレッションハイトを有する、頑丈かつ軽量のピストンおよびその構成方法 | |

| US10968862B2 (en) | Monolithic, galleryless piston and method of construction thereof | |

| US10738731B2 (en) | Monolithic, galleryless piston and method of construction thereof | |

| JP2018510994A5 (enExample) | ||

| US9212621B2 (en) | Piston and method of construction thereof | |

| JP2019508624A (ja) | スロット付きリング溝を有する空洞なしのピストン | |

| US9909526B2 (en) | Monobloc piston with a low friction skirt | |

| JP2019515190A (ja) | 非対称の上部燃焼表面を有するピストンおよびその製造方法 | |

| US10352270B2 (en) | Galleryless piston with connection to pockets | |

| KR102582339B1 (ko) | 갤러리없는 모놀리식 피스톤, 및 그 제조 방법 | |

| JP5307209B2 (ja) | 内燃機関のピストン | |

| JP2019509425A (ja) | オイル排出機構を有する空洞なしのピストン |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A712 Effective date: 20181107 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190115 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20190115 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20190827 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20190828 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20191125 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20200128 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20200226 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6668377 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |