JP6629751B2 - 繊維強化複合材料積層体、及びこれから作製された物品 - Google Patents

繊維強化複合材料積層体、及びこれから作製された物品 Download PDFInfo

- Publication number

- JP6629751B2 JP6629751B2 JP2016559535A JP2016559535A JP6629751B2 JP 6629751 B2 JP6629751 B2 JP 6629751B2 JP 2016559535 A JP2016559535 A JP 2016559535A JP 2016559535 A JP2016559535 A JP 2016559535A JP 6629751 B2 JP6629751 B2 JP 6629751B2

- Authority

- JP

- Japan

- Prior art keywords

- fabric

- fibers

- poly

- fiber

- woven fabric

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/22—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed

- B32B5/24—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer

- B32B5/245—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer another layer next to it being a foam layer

-

- A—HUMAN NECESSITIES

- A45—HAND OR TRAVELLING ARTICLES

- A45C—PURSES; LUGGAGE; HAND CARRIED BAGS

- A45C11/00—Receptacles for purposes not provided for in groups A45C1/00-A45C9/00

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/022—Non-woven fabric

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/024—Woven fabric

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/12—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer characterised by the relative arrangement of fibres or filaments of different layers, e.g. the fibres or filaments being parallel or perpendicular to each other

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/22—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed

- B32B5/24—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer

- B32B5/26—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer another layer next to it also being fibrous or filamentary

-

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F1/00—Details not covered by groups G06F3/00 - G06F13/00 and G06F21/00

- G06F1/16—Constructional details or arrangements

- G06F1/1613—Constructional details or arrangements for portable computers

- G06F1/1628—Enclosures for carrying portable computers with peripheral devices, e.g. cases for a laptop and a printer

-

- A—HUMAN NECESSITIES

- A45—HAND OR TRAVELLING ARTICLES

- A45C—PURSES; LUGGAGE; HAND CARRIED BAGS

- A45C11/00—Receptacles for purposes not provided for in groups A45C1/00-A45C9/00

- A45C11/001—Receptacles for purposes not provided for in groups A45C1/00-A45C9/00 for storing portable audio devices, e.g. headphones or digital music players

-

- A—HUMAN NECESSITIES

- A45—HAND OR TRAVELLING ARTICLES

- A45C—PURSES; LUGGAGE; HAND CARRIED BAGS

- A45C11/00—Receptacles for purposes not provided for in groups A45C1/00-A45C9/00

- A45C11/002—Receptacles for purposes not provided for in groups A45C1/00-A45C9/00 for storing portable handheld communication devices, e.g. pagers or smart phones

-

- A—HUMAN NECESSITIES

- A45—HAND OR TRAVELLING ARTICLES

- A45C—PURSES; LUGGAGE; HAND CARRIED BAGS

- A45C11/00—Receptacles for purposes not provided for in groups A45C1/00-A45C9/00

- A45C11/003—Receptacles for purposes not provided for in groups A45C1/00-A45C9/00 for storing portable computing devices, e.g. laptops, tablets or calculators

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/20—All layers being fibrous or filamentary

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2260/00—Layered product comprising an impregnated, embedded, or bonded layer wherein the layer comprises an impregnation, embedding, or binder material

- B32B2260/02—Composition of the impregnated, bonded or embedded layer

- B32B2260/021—Fibrous or filamentary layer

- B32B2260/023—Two or more layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2260/00—Layered product comprising an impregnated, embedded, or bonded layer wherein the layer comprises an impregnation, embedding, or binder material

- B32B2260/04—Impregnation, embedding, or binder material

- B32B2260/046—Synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0261—Polyamide fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0261—Polyamide fibres

- B32B2262/0269—Aromatic polyamide fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/50—Properties of the layers or laminate having particular mechanical properties

- B32B2307/546—Flexural strength; Flexion stiffness

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/71—Resistive to light or to UV

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/718—Weight, e.g. weight per square meter

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/732—Dimensional properties

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2439/00—Containers; Receptacles

- B32B2439/02—Open containers

- B32B2439/06—Bags, sacks, sachets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2439/00—Containers; Receptacles

- B32B2439/40—Closed containers

- B32B2439/46—Bags

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2457/00—Electrical equipment

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2571/00—Protective equipment

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Theoretical Computer Science (AREA)

- Computer Hardware Design (AREA)

- Human Computer Interaction (AREA)

- Physics & Mathematics (AREA)

- General Engineering & Computer Science (AREA)

- General Physics & Mathematics (AREA)

- Laminated Bodies (AREA)

- Reinforced Plastic Materials (AREA)

Description

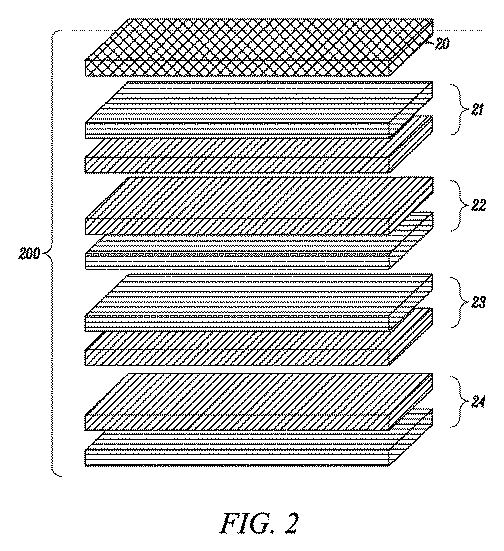

(a)上部層である織布の層と、

(b)一方向性布地の少なくとも1つの層と、

から本質的になる複合材料積層体を提供し、

複合材料積層体は、0.1mm〜2mmの総厚さを有し、

織布(a)は、ポリ(p−フェニレンテレフタルアミド)ホモポリマー、ポリ(p−フェニレンテレフタルアミド)コポリマー、ポリ(m−フェニレンイソフタルアミド)ホモポリマー、ポリ(m−フェニレンイソフタルアミド)コポリマー、ポリスルホンアミドホモポリマー、ポリスルホンアミドコポリマー、及びそれらの混合物から生成される繊維を含み、

一方向性布地(b)は、ポリ(p−フェニレンテレフタルアミド)ホモポリマー又はポリ(p−フェニレンテレフタルアミド)コポリマーから生成される高弾性率繊維を含み、繊維は、少なくとも100GPaの引張り弾性率を有し、

織布(a)及び一方向性布地(b)は、それぞれ独立して、エポキシ、ポリイミド、及びそれらの混合物から選択される熱硬化性樹脂を含む。

本発明においては、織布(a)及び一方向性布地(b)において使用されるのに適切な繊維は、芳香族ポリアミド(「アラミド」とも略記される)繊維である。アラミド繊維は、アラミド分子の構造に起因する、耐熱性、耐化学薬品性、及び難燃特性を有する。アラミドは、アミド(−CO−NH−)結合の少なくとも85%が2つの芳香環に直接結合していることを含む。

より微細な繊維は、製造及び製織により費用がかかるが、単位重量当たりにおいてより大きな効果を生むことができる。効果及び費用を考慮し、複数の繊維を含むそれぞれの糸条は、約200デニール(220dtex)〜約3,000デニール(3300dtex)、より好ましくは約400デニール(440dtex)〜約2,400デニール(2640dtex)、最も好ましくは約1,000デニール(1100dtex)〜約2,000デニール(2200dtex)の好ましい線密度を有する。

本発明においては、一方向性布地(b)において使用されるのに適切な繊維は、ポリ(p−フェニレンテレフタルアミド)又はポリ(p−フェニレンテレフタルアミド)コポリマーから生成される高弾性率繊維である。

適切な構造堅固性及び剛性性能を有する本発明の複合材料積層体を提供するために、織布(a)及びUD布地(b)は、マトリックスとしての熱硬化性樹脂にそれぞれ独立して包埋される。本発明の複合材料積層体の主要な用途は、携帯電子機器のためのハウジング又は保護カバーであり、従って、堅固性及び剛性の優れた組合せが必要である(曲げ弾性率によって特徴づけられるように)。また、マトリックスとしての高い引張り弾性率の樹脂は、より高い堅固性複合材料を産生する際に役に立つことが知られている。

織布(a)、及びUD布地(b)の複数の層を圧密化して複合材料積層体を形成する方法は、周知である。

織布(a1):縦糸であるblack Kevlar(登録商標)K29 1500デニール(1670dtex、DuPontから入手可能)、及び、横糸であるgray Technora(登録商標)1500デニール(1670dtex、帝人株式会社から入手可能)である、ポリ(p−フェニレンテレフタルアミド)糸条から作製された綾織布地。織布は、7×7エンド/cm2で作製し、含浸前の目付は、約225g/m2であった。エポキシ樹脂で含浸した後、製織されたp−アラミドプリプレグ(a1)の目付は、約368g/m2であり、Xin Xiu Electronics Co.,Ltd.から購入した。樹脂含有量は、製織されたp−アラミドプリプレグ(a1)の総重量の約39重量%であった。

実施例1〜5及び比較例1〜6の複合材料積層体を、圧縮成形法によって調製した。

硬化した積層体それぞれを、レーザー裁断機(Han’s Laser Co.,model:P060)によって50.8mm×12.7mmの長方形を有する6つの試験片に切断した。

2織布は、「w」によって表され、一方、UD布地層のそれぞれのプライの繊維配向は、複合材料積層体の縦軸に対して、度の単位で角度の数によって表される。

即ち、本明細書に開示した本発明の修正と等価物が日常の実験以上のものを要することなく当業者には明かであり、すべてのかかる修正と均等物は以下の特許請求の範囲に記載の本発明の趣旨及び範囲に属すると考えられる。

次に、本発明の好ましい態様を示す。

1. (a)上部層である織布の層と、

(b)一方向性布地の少なくとも1つの層と、

から本質的になる複合材料積層体であって、

前記複合材料積層体は、0.1mm〜2mmの総厚さを有し、

前記織布(a)は、ポリ(p−フェニレンテレフタルアミド)ホモポリマー、ポリ(p−フェニレンテレフタルアミド)コポリマー、ポリ(m−フェニレンイソフタルアミド)ホモポリマー、ポリ(m−フェニレンイソフタルアミド)コポリマー、ポリスルホンアミドホモポリマー、ポリスルホンアミドコポリマー、及びそれらの混合物から生成される繊維を含み、

前記一方向性布地(b)は、ポリ(p−フェニレンテレフタルアミド)ホモポリマー又はポリ(p−フェニレンテレフタルアミド)コポリマーから生成される高弾性率繊維を含み、前記繊維は、少なくとも100GPaの引張り弾性率を有し、

前記織布(a)及び前記一方向性布地(b)は、それぞれ独立して、エポキシ、ポリイミド、及びそれらの混合物から選択される熱硬化性樹脂を含む、複合材料積層体。

2. 前記一方向性布地(b)は、層当たり2つ又は3つの撚りを含み、且つ、これらの撚りは、前記複合材料積層体の縦軸に対して、[0/90]又は[0/90/0]である配向角度でそれぞれ直交に重ねられる、上記1に記載の複合材料積層体。

3. 前記熱硬化性樹脂は、フェノールグリシジルエーテル、芳香族グリシジルエーテル、グリセロールポリグリシジルエーテル、グリシジルアミン、及び環状脂肪族からなる群から選択されるエポキシ樹脂である、上記1に記載の複合材料積層体。

4. 織布(a)の目付は、30g/m 2 〜660g/m 2 である、上記1に記載の複合材料積層体。

5. 前記一方向性布地(b)の目付は、20g/m 2 〜660g/m 2 である、上記1に記載の複合材料積層体。

6. 前記織布(a)は、前記織布(a)と樹脂の組み合わされた重量に基づいて、20重量%〜80重量%の量の熱硬化性樹脂で含浸される、上記1に記載の複合材料積層体。

7. 前記一方向性布地(b)は、前記一方向性布地(b)と樹脂の組み合わされた重量に基づいて、20重量%〜80重量%の量の熱硬化性樹脂で含浸される、上記1に記載の複合材料積層体。

8. 携帯電子機器のためのハウジング又は保護カバーである、上記1に記載の複合材料積層体を含む物品。

9. 前記携帯電子機器は、携帯型コンピューター、タブレット型コンピューター、携帯電話、電子書籍端末、携帯用ゲーム装置、携帯メディアプレーヤー、又はディジタルカメラである、上記8に記載の物品。

Claims (2)

- (a)唯一の織布の層が最上部層である織布の層と、

(b)一方向性布地の少なくとも1つの層と、

から本質的になる複合材料積層体であって、

前記複合材料積層体は、0.1mm〜2mmの総厚さを有し、

前記織布(a)は、ポリ(p−フェニレンテレフタルアミド)ホモポリマー、ポリ(p−フェニレンテレフタルアミド)コポリマー、ポリ(m−フェニレンイソフタルアミド)ホモポリマー、ポリ(m−フェニレンイソフタルアミド)コポリマー、ポリスルホンアミドホモポリマー、ポリスルホンアミドコポリマー、及びそれらの混合物から生成される繊維を含み、

前記一方向性布地(b)は、ポリ(p−フェニレンテレフタルアミド)ホモポリマー又はポリ(p−フェニレンテレフタルアミド)コポリマーから生成される高弾性率繊維を含み、前記繊維は、少なくとも100GPaの引張り弾性率を有し、

前記織布(a)及び前記一方向性布地(b)は、それぞれ独立して、エポキシ、ポリイミド、及びそれらの混合物から選択される熱硬化性樹脂を含む、複合材料積層体。 - 携帯電子機器のためのハウジング又は保護カバーである、請求項1に記載の複合材料積層体を含む物品。

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201420147328.1 | 2014-03-28 | ||

| CN201410122526.7 | 2014-03-28 | ||

| CN201420147328.1U CN203994940U (zh) | 2014-03-28 | 2014-03-28 | 纤维增强的复合层合体和由其制成的制品 |

| CN201410122526.7A CN104943289B (zh) | 2014-03-28 | 2014-03-28 | 纤维增强的复合层合体和由其制成的制品 |

| PCT/US2015/023315 WO2015149063A1 (en) | 2014-03-28 | 2015-03-30 | Fiber-reinforced composite laminate and articles made therefrom |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2017511268A JP2017511268A (ja) | 2017-04-20 |

| JP2017511268A5 JP2017511268A5 (ja) | 2018-05-17 |

| JP6629751B2 true JP6629751B2 (ja) | 2020-01-15 |

Family

ID=52829439

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016559535A Active JP6629751B2 (ja) | 2014-03-28 | 2015-03-30 | 繊維強化複合材料積層体、及びこれから作製された物品 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US20170087806A1 (ja) |

| EP (1) | EP3122551B1 (ja) |

| JP (1) | JP6629751B2 (ja) |

| WO (1) | WO2015149063A1 (ja) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6563793B2 (ja) * | 2015-11-30 | 2019-08-21 | ダイハツ工業株式会社 | 加飾シート |

| JP6563794B2 (ja) * | 2015-11-30 | 2019-08-21 | ダイハツ工業株式会社 | 加飾方法、加飾シート、成形シートおよびその製造方法 |

| IT201900004301A1 (it) * | 2019-03-25 | 2020-09-25 | Composite Mat Italy Srl | Composito comprendente preimpregnati prodotti mediante processo a solvente e preimpregnati hot-melt, e stampo formato dal composito stesso |

| CN113635621A (zh) * | 2021-07-30 | 2021-11-12 | 歌尔光学科技有限公司 | 碳纤维预浸料的铺层方法、碳纤维预制品和可穿戴设备 |

| CN115723390A (zh) * | 2022-11-14 | 2023-03-03 | 天津航空机电有限公司 | 一种基于镍铬合金丝纬编结构的电热复合材料及制备方法 |

Family Cites Families (37)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3063966A (en) | 1958-02-05 | 1962-11-13 | Du Pont | Process of making wholly aromatic polyamides |

| US3094511A (en) | 1958-11-17 | 1963-06-18 | Du Pont | Wholly aromatic polyamides |

| US3227793A (en) | 1961-01-23 | 1966-01-04 | Celanese Corp | Spinning of a poly(polymethylene) terephthalamide |

| US3414645A (en) | 1964-06-19 | 1968-12-03 | Monsanto Co | Process for spinning wholly aromatic polyamide fibers |

| US3287324A (en) | 1965-05-07 | 1966-11-22 | Du Pont | Poly-meta-phenylene isophthalamides |

| US3354127A (en) | 1966-04-18 | 1967-11-21 | Du Pont | Aromatic copolyamides |

| US3819587A (en) | 1969-05-23 | 1974-06-25 | Du Pont | Wholly aromatic carbocyclic polycarbonamide fiber having orientation angle of less than about 45{20 |

| US3673143A (en) | 1970-06-24 | 1972-06-27 | Du Pont | Optically anisotropic spinning dopes of polycarbonamides |

| US3869429A (en) | 1971-08-17 | 1975-03-04 | Du Pont | High strength polyamide fibers and films |

| US3869430A (en) | 1971-08-17 | 1975-03-04 | Du Pont | High modulus, high tenacity poly(p-phenylene terephthalamide) fiber |

| US3767756A (en) | 1972-06-30 | 1973-10-23 | Du Pont | Dry jet wet spinning process |

| JPS53294A (en) | 1976-06-23 | 1978-01-05 | Teijin Ltd | Preparation of aromatic polyamide with high degree of polymerization |

| US4457985A (en) | 1982-03-19 | 1984-07-03 | Allied Corporation | Ballistic-resistant article |

| US4403012A (en) | 1982-03-19 | 1983-09-06 | Allied Corporation | Ballistic-resistant article |

| US4623574A (en) | 1985-01-14 | 1986-11-18 | Allied Corporation | Ballistic-resistant composite article |

| US4748064A (en) | 1985-01-14 | 1988-05-31 | Allied Corporation | Ballistic-resistant composite article |

| US4737402A (en) | 1985-02-28 | 1988-04-12 | Allied Corporation | Complex composite article having improved impact resistance |

| US4916000A (en) * | 1987-07-13 | 1990-04-10 | Allied-Signal Inc. | Ballistic-resistant composite article |

| US5436301A (en) * | 1988-05-09 | 1995-07-25 | Teijin Limited | Epoxy resin-impregnated prepreg |

| AT396240B (de) | 1990-06-13 | 1993-07-26 | Isovolta | Prepreg verfahren zu seiner herstellung und seine verwendung |

| US5733643A (en) * | 1995-10-11 | 1998-03-31 | P.G. Products, Inc. | Physical barrier composite material |

| US5667743A (en) | 1996-05-21 | 1997-09-16 | E. I. Du Pont De Nemours And Company | Wet spinning process for aramid polymer containing salts |

| JP3896559B2 (ja) * | 1997-11-21 | 2007-03-22 | 東レ・デュポン株式会社 | コンクリート構造物の補強・補修方法 |

| JPH11230698A (ja) * | 1998-02-18 | 1999-08-27 | Sumitomo Bakelite Co Ltd | 防護板 |

| JP2000033617A (ja) * | 1998-07-16 | 2000-02-02 | Shinto Paint Co Ltd | 補強材及び補強工法 |

| JP2000248689A (ja) * | 1999-03-03 | 2000-09-12 | Shinto Paint Co Ltd | 補強材及び補強工法 |

| JP2000297540A (ja) * | 1999-04-14 | 2000-10-24 | Shinto Paint Co Ltd | 補強工法 |

| CN1176256C (zh) | 2002-07-16 | 2004-11-17 | 上海纺织控股(集团)公司 | 芳香族聚砜酰胺纤维的制造方法 |

| US7288307B2 (en) | 2004-01-12 | 2007-10-30 | Honeywell International Inc. | Hybrid laminated fiber sheets |

| CN1264896C (zh) | 2004-11-19 | 2006-07-19 | 上海市合成纤维研究所 | 连续化双螺杆制备聚砜酰胺纺丝溶液的方法 |

| JP4613298B2 (ja) * | 2004-12-01 | 2011-01-12 | 東邦テナックス株式会社 | 複合シートとそれを用いた平滑な表面を有する複合材料 |

| DE102008014657B4 (de) | 2008-03-17 | 2015-08-20 | Airbus Defence and Space GmbH | Verfahren zur Herstellung von Faserverbundbauteilen |

| US20120189804A1 (en) * | 2009-04-06 | 2012-07-26 | E.I.Du Pont De Nemours And Company | Ballistic resistant armor articles |

| US20110312238A1 (en) * | 2009-12-29 | 2011-12-22 | E.I. Du Pont De Nemours And Company | Enhanced lightweight ballistic materials |

| US20130284004A1 (en) * | 2011-10-17 | 2013-10-31 | E I Du Pont De Nemours And Company | Composite material; a ballistic resistant article made from same and method of making the article |

| TWI488025B (zh) * | 2012-08-31 | 2015-06-11 | Quanta Comp Inc | 電子裝置之殼體及其製法 |

| US20140082808A1 (en) * | 2012-09-21 | 2014-03-27 | E I Du Pont De Nemours And Company | Ballistic resistant body armor articles |

-

2015

- 2015-03-30 US US15/127,950 patent/US20170087806A1/en not_active Abandoned

- 2015-03-30 EP EP15716328.8A patent/EP3122551B1/en active Active

- 2015-03-30 JP JP2016559535A patent/JP6629751B2/ja active Active

- 2015-03-30 WO PCT/US2015/023315 patent/WO2015149063A1/en not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| EP3122551B1 (en) | 2021-04-21 |

| EP3122551A1 (en) | 2017-02-01 |

| JP2017511268A (ja) | 2017-04-20 |

| US20170087806A1 (en) | 2017-03-30 |

| WO2015149063A1 (en) | 2015-10-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6629751B2 (ja) | 繊維強化複合材料積層体、及びこれから作製された物品 | |

| EP3442787B1 (en) | Blister free composite materials molding | |

| CN102762949B (zh) | 防弹制品 | |

| JP5535307B2 (ja) | 耐弾道性防護具物品 | |

| CN104943289B (zh) | 纤维增强的复合层合体和由其制成的制品 | |

| JP5241732B2 (ja) | 剛性防護具用途に好適なコーティング布及びラミネート並びにそれらの製造方法 | |

| KR101398748B1 (ko) | 방탄용 복합재료 및 이를 이용하여 제조된 방탄용 헬멧 | |

| JP2018500189A (ja) | 熱可塑性複合材料積層体及びそれから製造される物品 | |

| JP2016520446A (ja) | 高強度繊維複合材、その製造方法及びこれを用いたヘルメット | |

| EP3071922B1 (en) | Composites and ballistic resistant armor articles containing the composites | |

| KR102626083B1 (ko) | 열가소성 복합 라미네이트 및 이로부터 제조된 물품 | |

| AU2021242887A1 (en) | Stitched reinforcing-fiber base material, preform material, fiber-reinforced composite material, and production method for stitched reinforcing-fiber base material, preform material, and fiber-reinforced composite material | |

| JP2007063710A (ja) | 薄葉織物、それを用いた積層体、プリプレグ、繊維強化樹脂組成物成形品及び防護具 | |

| JP2007063710A5 (ja) | ||

| EP2121299A1 (en) | Flexible ballistic fabric and articles made therefrom | |

| KR102327592B1 (ko) | 아라미드 복합재 및 이로 제조된 헬멧 | |

| KR101458665B1 (ko) | 방탄 헬멧용 복합재 및 그 제조방법 | |

| CN203994940U (zh) | 纤维增强的复合层合体和由其制成的制品 | |

| KR101397247B1 (ko) | 아라미드 복합재 및 그 제조방법 | |

| JP5280982B2 (ja) | 繊維強化複合材料 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20180329 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20180329 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20190225 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20190322 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190618 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20191107 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20191205 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6629751 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313113 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |