JP6514622B2 - 射出成形機の成形支援方法 - Google Patents

射出成形機の成形支援方法Info

- Publication number

- JP6514622B2 JP6514622B2 JP2015214086A JP2015214086A JP6514622B2 JP 6514622 B2 JP6514622 B2 JP 6514622B2 JP 2015214086 A JP2015214086 A JP 2015214086A JP 2015214086 A JP2015214086 A JP 2015214086A JP 6514622 B2 JP6514622 B2 JP 6514622B2

- Authority

- JP

- Japan

- Prior art keywords

- molding

- data

- conditions

- function

- molding machine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000465 moulding Methods 0.000 title claims description 171

- 238000000034 method Methods 0.000 title claims description 99

- 238000001746 injection moulding Methods 0.000 title claims description 49

- 230000006870 function Effects 0.000 claims description 94

- 238000012545 processing Methods 0.000 claims description 65

- 238000005457 optimization Methods 0.000 claims description 43

- 239000011347 resin Substances 0.000 claims description 42

- 229920005989 resin Polymers 0.000 claims description 42

- 230000008569 process Effects 0.000 claims description 32

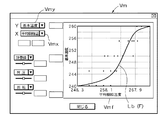

- 238000013528 artificial neural network Methods 0.000 claims description 24

- 238000012886 linear function Methods 0.000 claims description 8

- 238000004519 manufacturing process Methods 0.000 description 27

- 238000010438 heat treatment Methods 0.000 description 24

- 238000002347 injection Methods 0.000 description 20

- 239000007924 injection Substances 0.000 description 20

- 230000008859 change Effects 0.000 description 14

- 238000005259 measurement Methods 0.000 description 13

- 238000007493 shaping process Methods 0.000 description 6

- 230000008901 benefit Effects 0.000 description 5

- 239000012778 molding material Substances 0.000 description 3

- 230000009467 reduction Effects 0.000 description 3

- 230000006641 stabilisation Effects 0.000 description 3

- 238000011105 stabilization Methods 0.000 description 3

- 238000004891 communication Methods 0.000 description 2

- 230000002950 deficient Effects 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 238000000265 homogenisation Methods 0.000 description 2

- 230000006872 improvement Effects 0.000 description 2

- 238000003909 pattern recognition Methods 0.000 description 2

- 239000008188 pellet Substances 0.000 description 2

- 238000005070 sampling Methods 0.000 description 2

- 239000000243 solution Substances 0.000 description 2

- 238000012360 testing method Methods 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 1

- 230000000593 degrading effect Effects 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000005265 energy consumption Methods 0.000 description 1

- 239000004973 liquid crystal related substance Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 238000010926 purge Methods 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 238000004088 simulation Methods 0.000 description 1

- 238000005496 tempering Methods 0.000 description 1

- 238000012549 training Methods 0.000 description 1

- 230000009466 transformation Effects 0.000 description 1

Images

Landscapes

- Injection Moulding Of Plastics Or The Like (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015214086A JP6514622B2 (ja) | 2015-10-30 | 2015-10-30 | 射出成形機の成形支援方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015214086A JP6514622B2 (ja) | 2015-10-30 | 2015-10-30 | 射出成形機の成形支援方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2017081071A JP2017081071A (ja) | 2017-05-18 |

| JP2017081071A5 JP2017081071A5 (enExample) | 2018-03-08 |

| JP6514622B2 true JP6514622B2 (ja) | 2019-05-15 |

Family

ID=58712361

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2015214086A Active JP6514622B2 (ja) | 2015-10-30 | 2015-10-30 | 射出成形機の成形支援方法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP6514622B2 (enExample) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3437825B1 (en) * | 2017-08-02 | 2020-09-30 | Fundació Eurecat | A computer implemented method for generating a mold model for production predictive control and computer program products thereof |

| US12202184B2 (en) * | 2018-09-20 | 2025-01-21 | Jtekt Corporation | Device for assisting molding condition determination and injection molding apparatus |

| US11403535B2 (en) * | 2018-12-21 | 2022-08-02 | Industrial Technology Research Institute | Model-based machine learning system |

| JP6868652B2 (ja) * | 2019-02-21 | 2021-05-12 | 日精樹脂工業株式会社 | 射出成形機の成形支援装置 |

| JP7291532B2 (ja) * | 2019-05-10 | 2023-06-15 | ポリプラスチックス株式会社 | 成形教育装置、成形教育方法および成形教育プログラム |

| JP7521272B2 (ja) * | 2019-09-17 | 2024-07-24 | I-Pex株式会社 | 樹脂封止方法及び樹脂封止金型 |

| CN114364502B (zh) * | 2019-09-17 | 2024-11-01 | 爱沛股份有限公司 | 树脂密封方法及树脂密封模具 |

| CN115335205A (zh) * | 2020-03-31 | 2022-11-11 | 旭化成株式会社 | 装置、方法以及程序 |

| JP7556239B2 (ja) * | 2020-09-04 | 2024-09-26 | 株式会社プロテリアル | コンピュータプログラム、不良要因分析方法及び不良要因分析装置 |

| JP7751493B2 (ja) * | 2022-01-16 | 2025-10-08 | ディムシード株式会社 | 加工機械の制御方法、制御装置及び制御プログラム |

| JP2026010982A (ja) * | 2024-07-10 | 2026-01-23 | Toyoイノベックス株式会社 | 射出成形機 |

| CN120632586A (zh) * | 2025-08-15 | 2025-09-12 | 克劳斯玛菲机械(中国)有限公司 | 螺杆最小位置与止逆环失效的预测方法及预测系统 |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4828719B2 (ja) * | 2001-04-27 | 2011-11-30 | 一般財団法人石油エネルギー技術センター | 石油コンビナートの運転条件の推定方法 |

| JP4177399B2 (ja) * | 2006-10-27 | 2008-11-05 | 日精樹脂工業株式会社 | 射出成形機の制御方法 |

-

2015

- 2015-10-30 JP JP2015214086A patent/JP6514622B2/ja active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2017081071A (ja) | 2017-05-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6514622B2 (ja) | 射出成形機の成形支援方法 | |

| JP6529183B2 (ja) | 射出成形機の成形最適化方法 | |

| JP6779316B2 (ja) | 射出成形機の成形条件推定方法 | |

| US11000982B2 (en) | Methods of setting a shaping machine | |

| CN101168282B (zh) | 注模机的支持设备 | |

| WO2019180466A1 (en) | A system and method for manufacture and material optimisation | |

| US12109748B2 (en) | Operation quantity determination device, molding apparatus system, molding machine, non-transitory computer readable recording medium, operation quantity determination method, and state display device | |

| US20230325562A1 (en) | Machine Learning Method, Non-Transitory Computer Readable Recording Medium, Machine Learning Device, and Molding Machine | |

| CN101337420A (zh) | 注塑成型机的工序时间显示装置 | |

| JPWO2018229881A1 (ja) | スクリュ形状推定装置、スクリュ形状推定方法、スクリュ形状推定プログラム | |

| EP3520987A1 (en) | Method for monitoring and control of the injection process of plastic materials | |

| CN114986833A (zh) | 一种动态调控的注塑方法、系统、装置及介质 | |

| US20240359381A1 (en) | Procedure for determining real molding fronts and aligning simulations | |

| EP4397468B1 (en) | Method for adjusting molding condition parameters, computer program, device for adjusting molding condition parameters, and molding machine | |

| CN115066324B (zh) | 注射成型辅助装置以及具备该注射成型辅助装置的注射成型机 | |

| CN118591783A (zh) | 控制塑料处理机器上的过程的方法 | |

| KR20220100577A (ko) | 사출 성형 공정을 개선시키기 위한 방법 및 시스템 | |

| JP4571044B2 (ja) | モニタリング表示装置および表示方法 | |

| EP4378658A1 (en) | Data set creation method, trained model generation method, computer program, and data set creation device | |

| EP4506138A1 (en) | Molding optimization method and device for injection molding machine | |

| JP2022052082A (ja) | 射出成形システムおよび射出成形機の設定支援方法 | |

| EP4620651A1 (en) | Molding condition correcting device, molding machine, molding condition correcting method, and computer program | |

| Mensler | A Method for Determining the Flow Front Position and Velocity of a Polymer Melt in an Injection Moulding Process | |

| Cardeal | Energy Consumption Modelling in the Injection Moulding Industry | |

| JPH06278182A (ja) | 溶融材料の金型内流動解析による評価方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20180119 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20180119 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20181225 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20190123 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190325 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20190403 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20190412 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6514622 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |