JP6256994B2 - 導電体とコンタクト部材を備える導電体装置 - Google Patents

導電体とコンタクト部材を備える導電体装置 Download PDFInfo

- Publication number

- JP6256994B2 JP6256994B2 JP2015501907A JP2015501907A JP6256994B2 JP 6256994 B2 JP6256994 B2 JP 6256994B2 JP 2015501907 A JP2015501907 A JP 2015501907A JP 2015501907 A JP2015501907 A JP 2015501907A JP 6256994 B2 JP6256994 B2 JP 6256994B2

- Authority

- JP

- Japan

- Prior art keywords

- region

- conductor

- contact

- contact member

- sheath

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000004020 conductor Substances 0.000 title claims description 192

- 238000002788 crimping Methods 0.000 claims description 77

- 238000007789 sealing Methods 0.000 claims description 69

- 230000007704 transition Effects 0.000 claims description 27

- 238000000034 method Methods 0.000 claims description 16

- 239000000463 material Substances 0.000 claims description 8

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims description 4

- 229910052802 copper Inorganic materials 0.000 claims description 4

- 239000010949 copper Substances 0.000 claims description 4

- 238000005520 cutting process Methods 0.000 claims description 4

- 229910052782 aluminium Inorganic materials 0.000 claims description 3

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 3

- 238000006073 displacement reaction Methods 0.000 claims description 3

- 230000007797 corrosion Effects 0.000 description 5

- 238000005260 corrosion Methods 0.000 description 5

- 229910052751 metal Inorganic materials 0.000 description 4

- 239000002184 metal Substances 0.000 description 4

- 238000003825 pressing Methods 0.000 description 4

- 230000006835 compression Effects 0.000 description 3

- 238000007906 compression Methods 0.000 description 3

- 239000004800 polyvinyl chloride Substances 0.000 description 3

- 239000000654 additive Substances 0.000 description 2

- 230000000996 additive effect Effects 0.000 description 2

- 230000035515 penetration Effects 0.000 description 2

- 229920000915 polyvinyl chloride Polymers 0.000 description 2

- 239000000565 sealant Substances 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000004519 grease Substances 0.000 description 1

- 239000011810 insulating material Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000013011 mating Effects 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- 229910000679 solder Inorganic materials 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/58—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation characterised by the form or material of the contacting members

- H01R4/62—Connections between conductors of different materials; Connections between or with aluminium or steel-core aluminium conductors

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/70—Insulation of connections

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R43/00—Apparatus or processes specially adapted for manufacturing, assembling, maintaining, or repairing of line connectors or current collectors or for joining electric conductors

- H01R43/28—Apparatus or processes specially adapted for manufacturing, assembling, maintaining, or repairing of line connectors or current collectors or for joining electric conductors for wire processing before connecting to contact members, not provided for in groups H01R43/02 - H01R43/26

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/10—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation effected solely by twisting, wrapping, bending, crimping, or other permanent deformation

- H01R4/18—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation effected solely by twisting, wrapping, bending, crimping, or other permanent deformation by crimping

- H01R4/183—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation effected solely by twisting, wrapping, bending, crimping, or other permanent deformation by crimping for cylindrical elongated bodies, e.g. cables having circular cross-section

- H01R4/184—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation effected solely by twisting, wrapping, bending, crimping, or other permanent deformation by crimping for cylindrical elongated bodies, e.g. cables having circular cross-section comprising a U-shaped wire-receiving portion

- H01R4/185—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation effected solely by twisting, wrapping, bending, crimping, or other permanent deformation by crimping for cylindrical elongated bodies, e.g. cables having circular cross-section comprising a U-shaped wire-receiving portion combined with a U-shaped insulation-receiving portion

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Connections Effected By Soldering, Adhesion, Or Permanent Deformation (AREA)

- Manufacturing Of Electrical Connectors (AREA)

- Coupling Device And Connection With Printed Circuit (AREA)

Description

Claims (12)

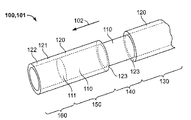

- コンタクト部材(210,310)を取り付ける方法であって、

導電性の心線(110)と絶縁性のシース(120)を備える導電体(100)を提供する工程と、

前記導電体(100)の端部領域(101)における前記シース(120)のシース部(121)を取り外す工程と、

前記シース部(121)が前記心線(110)の長手方向端部(111)を超えて突出するように、前記心線(110)に対して前記シース部(121)を変位する工程と、

前記シース部(121)の少なくとも一部が、前記コンタクト部材(210,310)と前記心線(110)との間に包囲されるように、前記導電体(100)の前記端部領域(101)にコンタクト部材(210,310)を圧着する工程を含み、

前記心線(110)は、前記シース部(121)の前記変位によって露出され、

前記コンタクト部材(210,310)の圧着領域(212,312,312b)は、導電体側封止領域(130,330)において前記圧着領域(212,312,312b)が前記シース(120)を包囲するように、且つ、前記導電体(100)の接触領域(140,340)において前記圧着領域(212,312,312b)が前記心線(110)と直接接触するように圧着され、

前記コンタクト部材(210,310)は、前記圧着領域に続く移行領域(211,311)、及び前記移行領域(211,311)に続く接触部材をさらに有し、

前記導電体側封止領域(330)及び前記接触領域(340)の間、並びに前記接触領域(340)と前記心線(110)の前記長手方向端部(111)との間に配置されたコンタクト側封止領域(350)及び前記接触領域(340)の間には、長手方向に対して傾斜する移行領域(335,345)が形成される方法。 - 前記シース部(121)の取り外しが切断によって行われる請求項1に記載の方法。

- 前記シース部(121)の、前記長手方向端部(111)より突出する突出部分(122)は、前記圧着時に前記心線(110)の前記長手方向端部(111)の周囲を完全に包囲する請求項1及び2のいずれか一項に記載の方法。

- 前記圧着前の前記コンタクト部材(210)が、スリーブ状の部分を有し、

前記導電体の前記端部領域(101)が、前記圧着前に前記スリーブ状の部分に挿入される請求項1乃至3のいずれか一項に記載の方法。 - 導電体(100)内に導電性の心線(110)と絶縁性のシース(120)を備え、且つコンタクト部材(210,310)を備える導電体装置(200,300)であって、

前記心線(110)は、前記導電体(100)の端部領域(101)において長手方向端部(111)を有し、

前記コンタクト部材(210,310)は、前記導電体(100)の前記端部領域(101)において前記導電体(100)に対して圧着され、

前記コンタクト部材(210,310)と前記心線(110)との間に、前記シース(120)の一部(121)が配置され、

前記一部(121)は、前記シース(120)の残余の領域から取り外されており、

前記コンタクト部材(210,310)は、前記導電体が圧着される圧着領域(212,312)に続く移行領域(211,311)、及び前記移行領域(211,311)に続く接触部材をさらに有し、

当該導電体装置(200,300)は、接触領域(240,340)を有し、

前記接触領域(240,340)には、前記コンタクト部材(210,310)と前記心線(110)との間に導電性接触部が存在し、

当該導電体装置(200,300)は、コンタクト側封止領域(250,350)を有し、

前記コンタクト側封止領域(250,350)は、前記接触領域(240,340)と前記心線(110)の前記長手方向端部(111)との間に配置され、

前記シース(120)の前記切り離された部分(121)は、前記コンタクト側封止領域(250,350)に配置され、

当該導電体装置(200,300)は、導電体側封止領域(230,330)を有し、

前記接触領域(240,340)は、前記コンタクト側封止領域(250,350)と前記導電体側封止領域(230,330)との間に配置され、

前記導電体側封止領域(230,330)において、前記コンタクト部材(210,310)と前記心線(110)との間に前記シース(120)の前記残余の領域が配置され、

前記導電体側封止領域(330)及び前記接触領域(340)の間、並びに前記コンタクト側封止領域(350)及び前記接触領域(340)の間には、長手方向に対して傾斜する移行領域(335,345)を有する導電体装置(200)。 - 前記シース(120)の前記切り離された部分(121)は、前記心線(110)の前記長手方向端部(111)を超えて突出する請求項5に記載の導電体装置(200)。

- 前記切り離された部分(121)の、前記長手方向端部(111)より突出する突出部分(122)が、前記心線(110)の前記長手方向端部(111)の周囲を完全に包囲する請求項6に記載の導電体装置(200)。

- 前記コンタクト部材(210,310)は、第2の圧着領域(312b)を含み、

前記導電体(100)の接触領域(140)において、前記コンタクト部材(210,310)の前記第2の圧着領域(312b)は、当該導電体装置(200,300)の前記接触領域(240,340)を少なくとも部分的に形成する請求項7に記載の導電体装置(200,300)。 - 前記コンタクト部材(210,310)は、前記導電体(100)の前記端部領域(101)において前記導電体(100)に圧着される第1の圧着領域(312a)を更に含み、

前記第1の圧着領域(312a)と前記第2の圧着領域(312b)は、個別の部品や、個別に圧着される圧着領域である請求項8に記載の導電体装置(200,300)。 - 前記心線(110)は、アルミニウムを有する請求項5乃至9のいずれか一項に記載の導電体装置(200)。

- 前記シース(120)は、PVCを有する請求項5乃至10のいずれか一項に記載の導電体装置(200)。

- 前記コンタクト部材(210)は、銅材料を有する請求項5乃至11のいずれか一項に記載の導電体装置(200)。

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102012204578 | 2012-03-22 | ||

| DE102012204578.3 | 2012-03-22 | ||

| USPCT/US2013/027604 | 2013-02-25 | ||

| USPCT/US2013/027604 | 2013-02-25 | ||

| PCT/US2013/033263 WO2013142666A1 (en) | 2012-03-22 | 2013-03-21 | Conductor arrangement with conductor and contact element |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2015511062A JP2015511062A (ja) | 2015-04-13 |

| JP2015511062A5 JP2015511062A5 (ja) | 2016-03-17 |

| JP6256994B2 true JP6256994B2 (ja) | 2018-01-10 |

Family

ID=48050954

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2015501907A Expired - Fee Related JP6256994B2 (ja) | 2012-03-22 | 2013-03-21 | 導電体とコンタクト部材を備える導電体装置 |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP2828933B1 (ja) |

| JP (1) | JP6256994B2 (ja) |

| WO (1) | WO2013142666A1 (ja) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102014204358A1 (de) | 2014-03-10 | 2015-09-10 | Te Connectivity Germany Gmbh | Kontaktelement und Kontaktanordnung mit Frontschutz sowie Verfahren zu deren Herstellung |

| WO2019167714A1 (ja) | 2018-03-02 | 2019-09-06 | 日本航空電子工業株式会社 | 電線、端子付き電線、ハーネス、電線の製造方法、端子付き電線の製造方法 |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5567187A (en) * | 1994-06-16 | 1996-10-22 | Belden Wire & Cable Company | Reverse insulation grip blade |

| JP4031288B2 (ja) * | 2002-05-20 | 2008-01-09 | 矢崎総業株式会社 | 被覆電線を端子に溶接するための接合方法 |

| JP2008235130A (ja) * | 2007-03-23 | 2008-10-02 | Furukawa Electric Co Ltd:The | 電線の端子接続構造体及びその端子接続方法 |

| GB2453360A (en) | 2007-10-04 | 2009-04-08 | Deutsch Uk | A wire crimp,a crimping tool and a crimping method |

| FR2928039B1 (fr) | 2008-02-25 | 2010-03-12 | Leoni Wiring Systems France | Assemblage formant liaison electrique par sertissage. |

| US8360803B2 (en) * | 2009-09-18 | 2013-01-29 | Delphi Technologies, Inc. | Electrical terminal connection with molded seal |

| JP5418332B2 (ja) * | 2010-03-17 | 2014-02-19 | 株式会社オートネットワーク技術研究所 | 端子金具付き電線 |

| JP5557378B2 (ja) * | 2010-03-23 | 2014-07-23 | 矢崎総業株式会社 | 圧着端子および圧着端子の電線に対する圧着構造 |

| JP5606127B2 (ja) * | 2010-04-01 | 2014-10-15 | 矢崎総業株式会社 | 圧着端子の電線に対する接続構造 |

| JP5902924B2 (ja) * | 2011-11-11 | 2016-04-13 | 矢崎総業株式会社 | コネクタ端子の接続構造及び接続方法 |

-

2013

- 2013-03-21 WO PCT/US2013/033263 patent/WO2013142666A1/en active Application Filing

- 2013-03-21 EP EP13715087.6A patent/EP2828933B1/en not_active Not-in-force

- 2013-03-21 JP JP2015501907A patent/JP6256994B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| EP2828933B1 (en) | 2016-05-18 |

| EP2828933A1 (en) | 2015-01-28 |

| WO2013142666A8 (en) | 2014-10-09 |

| WO2013142666A1 (en) | 2013-09-26 |

| JP2015511062A (ja) | 2015-04-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US9543689B2 (en) | Terminal crimped wire | |

| JP5884986B2 (ja) | 圧着端子付きアルミ電線 | |

| JP6020436B2 (ja) | 電線接続用の端子および該端子の電線接続構造 | |

| KR101481003B1 (ko) | 접속 구조체, 커넥터, 및 접속 구조체의 제조방법 | |

| JP5909336B2 (ja) | コネクタ端子の製造方法 | |

| JP5864280B2 (ja) | フラット回路体と端子金具との接続方法 | |

| JP5920284B2 (ja) | 端子付電線 | |

| WO2014014105A1 (ja) | 圧着端子、接続構造体、コネクタ及び圧着端子の圧着方法 | |

| WO2013175902A1 (ja) | 端子付き電線およびその製造方法、ならびに治具 | |

| WO2014129227A1 (ja) | 接続構造体の製造方法、接続構造体、ワイヤーハーネス、圧着部材、及び圧着装置 | |

| KR20130085437A (ko) | 커넥터 단자의 전선접속구조 및 그 제조방법 | |

| CN110323581B (zh) | 带端子的电线 | |

| JP5995799B2 (ja) | 接続構造体、コネクタ、及び接続方法 | |

| CN103620871A (zh) | 包括边界压接部的电连接端子 | |

| US11791599B2 (en) | Electric cable with terminal and method for manufacturing electric cable with terminal | |

| CN105765789B (zh) | 具有端子的电线和具有端子的电线的制造方法 | |

| JP6256994B2 (ja) | 導電体とコンタクト部材を備える導電体装置 | |

| CN109417261B (zh) | 电连接组件的制造方法 | |

| US9825450B2 (en) | Conductor arrangement with conductor and contact element | |

| JP2011150841A (ja) | 端子付きケーブル | |

| KR102382776B1 (ko) | 모터의 스테이터 조립방법, 모터의 스테이터 구조, 및 압착단자 | |

| WO2016186021A1 (ja) | 端子、及び端子付き電線 | |

| JP2015511062A5 (ja) | ||

| KR20130004633U (ko) | 전기 커넥터 | |

| JP6615064B2 (ja) | 端子付き電線の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160125 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20160125 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20161209 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20161214 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170314 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20170824 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20171117 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20171130 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20171130 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6256994 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |