JP6117237B2 - 常温収縮チューブのための支持コア - Google Patents

常温収縮チューブのための支持コア Download PDFInfo

- Publication number

- JP6117237B2 JP6117237B2 JP2014549198A JP2014549198A JP6117237B2 JP 6117237 B2 JP6117237 B2 JP 6117237B2 JP 2014549198 A JP2014549198 A JP 2014549198A JP 2014549198 A JP2014549198 A JP 2014549198A JP 6117237 B2 JP6117237 B2 JP 6117237B2

- Authority

- JP

- Japan

- Prior art keywords

- support core

- ribbon

- length

- core

- tubular support

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 229920001971 elastomer Polymers 0.000 claims 1

- 239000000806 elastomer Substances 0.000 claims 1

- 230000008878 coupling Effects 0.000 description 12

- 238000010168 coupling process Methods 0.000 description 12

- 238000005859 coupling reaction Methods 0.000 description 12

- 238000000034 method Methods 0.000 description 12

- 238000003466 welding Methods 0.000 description 11

- 239000000853 adhesive Substances 0.000 description 10

- 230000001070 adhesive effect Effects 0.000 description 10

- 239000000463 material Substances 0.000 description 9

- 238000000926 separation method Methods 0.000 description 5

- 239000007787 solid Substances 0.000 description 5

- 230000008569 process Effects 0.000 description 4

- 230000008901 benefit Effects 0.000 description 3

- 239000004020 conductor Substances 0.000 description 3

- 230000007246 mechanism Effects 0.000 description 3

- 239000012815 thermoplastic material Substances 0.000 description 3

- KAKZBPTYRLMSJV-UHFFFAOYSA-N Butadiene Chemical compound C=CC=C KAKZBPTYRLMSJV-UHFFFAOYSA-N 0.000 description 2

- 239000004721 Polyphenylene oxide Substances 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 230000007423 decrease Effects 0.000 description 2

- 239000003292 glue Substances 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 229920006380 polyphenylene oxide Polymers 0.000 description 2

- 239000002904 solvent Substances 0.000 description 2

- NLHHRLWOUZZQLW-UHFFFAOYSA-N Acrylonitrile Chemical compound C=CC#N NLHHRLWOUZZQLW-UHFFFAOYSA-N 0.000 description 1

- 229920000122 acrylonitrile butadiene styrene Polymers 0.000 description 1

- 230000006978 adaptation Effects 0.000 description 1

- 230000000712 assembly Effects 0.000 description 1

- 238000000429 assembly Methods 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000013521 mastic Substances 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 229920000098 polyolefin Polymers 0.000 description 1

- 229920005672 polyolefin resin Polymers 0.000 description 1

- 230000002028 premature Effects 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 238000011084 recovery Methods 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920001897 terpolymer Polymers 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B1/00—Layered products having a non-planar shape

- B32B1/08—Tubular products

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02G—INSTALLATION OF ELECTRIC CABLES OR LINES, OR OF COMBINED OPTICAL AND ELECTRIC CABLES OR LINES

- H02G15/00—Cable fittings

- H02G15/08—Cable junctions

- H02G15/18—Cable junctions protected by sleeves, e.g. for communication cable

- H02G15/182—Cable junctions protected by sleeves, e.g. for communication cable held in expanded condition in radial direction prior to installation

- H02G15/1826—Cable junctions protected by sleeves, e.g. for communication cable held in expanded condition in radial direction prior to installation on a removable hollow core, e.g. a tube

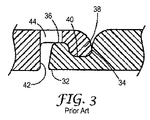

- H02G15/1833—Cable junctions protected by sleeves, e.g. for communication cable held in expanded condition in radial direction prior to installation on a removable hollow core, e.g. a tube formed of helically wound strip with adjacent windings, which are removable by applying a pulling force to a strip end

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/13—Hollow or container type article [e.g., tube, vase, etc.]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/13—Hollow or container type article [e.g., tube, vase, etc.]

- Y10T428/1328—Shrinkable or shrunk [e.g., due to heat, solvent, volatile agent, restraint removal, etc.]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/13—Hollow or container type article [e.g., tube, vase, etc.]

- Y10T428/1352—Polymer or resin containing [i.e., natural or synthetic]

- Y10T428/139—Open-ended, self-supporting conduit, cylinder, or tube-type article

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/13—Hollow or container type article [e.g., tube, vase, etc.]

- Y10T428/1352—Polymer or resin containing [i.e., natural or synthetic]

- Y10T428/139—Open-ended, self-supporting conduit, cylinder, or tube-type article

- Y10T428/1393—Multilayer [continuous layer]

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Cable Accessories (AREA)

- Shaping Of Tube Ends By Bending Or Straightening (AREA)

- Storage Of Web-Like Or Filamentary Materials (AREA)

- Package Frames And Binding Bands (AREA)

Description

「結合」とは、材料の2つの部品が互いに取り付けられる位置を意味する。

「結合強度」とは、取り付けられた区分を分離するために必要な力の相対的な量により判定される、2つの隣接するリボンの区分が互いに取り付けられた度合いを意味する。

「接続部」とは、支持コアの2つの隣接するリボン区分が互いに取り付けられる、別個の点又は領域を意味する。

「シーム」とは、支持コアの2つの隣接するリボン区分の連続的な付加物を意味する。

「螺旋状の巻かれたリボン」とは、支持コアが、剛性の支持コアを形成するように巻かれ、固定された材料の長く細いバンドから形成されているか、又は支持コアが中実のチューブ内に形成された溝又は他の分離手段を有する中実のチューブから形成されているかにかかわらず、支持コアの一般的構造を形成する、材料の連続的なバンドを指す。

Claims (3)

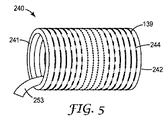

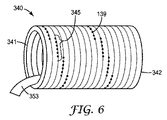

- 管状支持コアを形成する螺旋状に巻かれたリボンであって、前記リボンは、第1縁部及び第2縁部を有し、隣接する第1縁部及び第2縁部は、前記管状支持コアの長さに沿って1つ以上の結合部を含む、リボンを含み、

前記1つ以上の結合部の強度が、前記管状支持コアの前記長さに沿って変化し、

前記結合強度が、前記管状支持コアの前記長さに沿って規則的な反復パターンで変化している、物品。 - 中空の管状支持コアの長さ上で、大きく伸張した状態で支持されたエラストマースリーブと、

前記管状支持コアを形成する螺旋状に巻かれたリボンであって、前記リボンは第1縁部及び第2縁部を有し、隣接する第1縁部及び第2縁部は、前記管状支持コアの前記長さに沿って1つ以上の結合部を含む、リボンと、を有し、

前記1つ以上の結合部の強度が、前記管状支持コアの前記長さに沿って変化し、

前記結合強度が、前記管状支持コアの前記長さに沿って規則的な反復パターンで変化している、物品。 - 前記結合強度パターンが、弱い結合部の区分と交互の強い結合部の区分を含む、請求項1又は2に記載の物品。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201161579315P | 2011-12-22 | 2011-12-22 | |

| US61/579,315 | 2011-12-22 | ||

| PCT/US2012/070303 WO2013096287A2 (en) | 2011-12-22 | 2012-12-18 | Support core for cold shrink tube |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2015503892A JP2015503892A (ja) | 2015-02-02 |

| JP2015503892A5 JP2015503892A5 (ja) | 2016-02-04 |

| JP6117237B2 true JP6117237B2 (ja) | 2017-04-19 |

Family

ID=47604089

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014549198A Active JP6117237B2 (ja) | 2011-12-22 | 2012-12-18 | 常温収縮チューブのための支持コア |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US8709557B2 (ja) |

| EP (1) | EP2795754B1 (ja) |

| JP (1) | JP6117237B2 (ja) |

| CN (1) | CN104040814B (ja) |

| BR (1) | BR112014014961B1 (ja) |

| ES (1) | ES2675243T3 (ja) |

| MX (1) | MX2014007432A (ja) |

| TW (1) | TWI537987B (ja) |

| WO (1) | WO2013096287A2 (ja) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6128996B2 (ja) * | 2013-06-28 | 2017-05-17 | スリーエム イノベイティブ プロパティズ カンパニー | 紐状体及び被覆処理具 |

| CN103594959A (zh) * | 2013-12-05 | 2014-02-19 | 深圳市沃尔核材股份有限公司 | 一种适于冷缩工艺的支撑条 |

| US10148077B2 (en) * | 2014-04-08 | 2018-12-04 | Te Connectivity Corporation | Sealing systems and methods for elongate members |

| EP3880342B1 (en) | 2018-11-16 | 2024-06-12 | Corning Incorporated | Cordierite-containing ceramic bodies, batch composition mixtures, and methods of manufacturing cordierite-containing ceramic bodies |

| WO2020208440A1 (en) | 2019-04-09 | 2020-10-15 | 3M Innovative Properties Company | Support core for an elastic sleeve |

| CN110001096A (zh) * | 2019-04-18 | 2019-07-12 | 山东华凌电缆有限公司 | 一种冷缩管的制备方法 |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3562082A (en) * | 1967-10-27 | 1971-02-09 | Uniroyal Inc | Flexible high-stretch laminate with surface skins and coiled-filament non-woven fabric spacer |

| US3515798A (en) * | 1968-12-06 | 1970-06-02 | Minnesota Mining & Mfg | Elastic cover and removable cone assembly |

| AU6219890A (en) | 1989-10-16 | 1991-04-18 | Minnesota Mining And Manufacturing Company | Elastomeric covering having conformable interior |

| JP2697392B2 (ja) | 1991-07-30 | 1998-01-14 | ソニー株式会社 | 相補型半導体装置の製造方法 |

| IT1252219B (it) * | 1991-12-16 | 1995-06-05 | Pirelli Cavi Spa | Complesso di rivestimento di elementi cilindrici allungati quali giunti di cavi elettrici. |

| US5925427A (en) | 1995-02-06 | 1999-07-20 | Minnesota Mining And Manufacturing Company | Support core ribbon for cold-shrink tube |

| US5670223A (en) | 1995-02-06 | 1997-09-23 | Minnesota Mining And Manufacturing Company | Support core ribbon for cold-shrink tube |

| US5670233A (en) * | 1995-06-29 | 1997-09-23 | The United States Of America As Represented By The Secretary Of The Navy | Acoustic window and method for making the same |

| JP2000102156A (ja) | 1998-09-21 | 2000-04-07 | Fujikura Ltd | 常温収縮チューブ用の拡径保持スペーサ |

| US6138439A (en) * | 1999-05-21 | 2000-10-31 | Illinois Tool Works Inc. | Methods of making slide-zippered reclosable packages on horizontal form-fill-seal machines |

| JP4690559B2 (ja) * | 2000-02-17 | 2011-06-01 | 古河電気工業株式会社 | 拡径支持筒付絶縁筒体 |

| JP3946035B2 (ja) | 2001-11-28 | 2007-07-18 | スリーエム イノベイティブ プロパティズ カンパニー | 引裂き可能なコア部材及びそのコア部材を有する常温収縮管装置 |

| US20050069657A1 (en) * | 2001-11-28 | 2005-03-31 | Shigeru Suzuki | Tearable core member and cold-shrink tube device having the same |

| ATE442878T1 (de) * | 2002-09-03 | 2009-10-15 | Clean Cut Technologies Llc | Vorrichtung zur verpackung von länglichen chirurgischen vorrichtungen |

| US6838959B2 (en) * | 2003-04-14 | 2005-01-04 | Agilent Technologies, Inc. | Longitudinal electromagnetic latching relay |

| US7744977B2 (en) | 2006-05-24 | 2010-06-29 | Tyco Electronics Raychem Gmbh | Support coil comprising a mechanical locking means and method for the production thereof |

| US20090056101A1 (en) * | 2007-08-29 | 2009-03-05 | Standard Aero Limited | Method for securing a threaded insert in a threaded opening |

| DE102008023963A1 (de) * | 2008-05-16 | 2009-12-10 | Tyco Electronics Raychem Gmbh | Laserstrahl absorbierende Stützwendel sowie Verfahren und Vorrichtung zur Herstellung derselben |

-

2012

- 2012-12-18 CN CN201280063688.7A patent/CN104040814B/zh active Active

- 2012-12-18 EP EP12818718.4A patent/EP2795754B1/en active Active

- 2012-12-18 JP JP2014549198A patent/JP6117237B2/ja active Active

- 2012-12-18 BR BR112014014961-5A patent/BR112014014961B1/pt active IP Right Grant

- 2012-12-18 WO PCT/US2012/070303 patent/WO2013096287A2/en active Application Filing

- 2012-12-18 US US13/718,201 patent/US8709557B2/en active Active

- 2012-12-18 MX MX2014007432A patent/MX2014007432A/es active IP Right Grant

- 2012-12-18 ES ES12818718.4T patent/ES2675243T3/es active Active

- 2012-12-21 TW TW101149154A patent/TWI537987B/zh not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| MX2014007432A (es) | 2014-07-28 |

| EP2795754B1 (en) | 2018-04-11 |

| EP2795754A2 (en) | 2014-10-29 |

| BR112014014961B1 (pt) | 2021-01-26 |

| WO2013096287A3 (en) | 2014-01-03 |

| TW201342395A (zh) | 2013-10-16 |

| US8709557B2 (en) | 2014-04-29 |

| WO2013096287A2 (en) | 2013-06-27 |

| BR112014014961A2 (pt) | 2017-06-13 |

| CN104040814A (zh) | 2014-09-10 |

| ES2675243T3 (es) | 2018-07-09 |

| JP2015503892A (ja) | 2015-02-02 |

| US20130164475A1 (en) | 2013-06-27 |

| CN104040814B (zh) | 2017-07-11 |

| TWI537987B (zh) | 2016-06-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6117237B2 (ja) | 常温収縮チューブのための支持コア | |

| CA2172683C (en) | Elastic sleeve support | |

| CA2211178C (en) | Support core ribbon for cold-shrink tube | |

| US5844170A (en) | Closure with flowable material and reinforcing core | |

| EP0117092B1 (en) | Plastic core for an elastically shrinkable tubular cover | |

| JP2014097390A5 (ja) | ||

| CN110192137B (zh) | 两件式铠装光学电缆 | |

| JP6562937B2 (ja) | 螺旋状にラップされた不織スリーブおよびその製造方法 | |

| PT1835591E (pt) | Suporte helicoidal e método para a produção do mesmo | |

| EP3289271B1 (en) | Joining method | |

| EP2317203A1 (en) | Method for coating a joint between two pipes | |

| JP3118582B2 (ja) | 樹脂管 | |

| US8192816B2 (en) | Support coil with mechanical locking device and method for its manufacture | |

| JP2000102156A (ja) | 常温収縮チューブ用の拡径保持スペーサ | |

| KR20150005067A (ko) | 나선파형관의 연결구조 | |

| KR200344542Y1 (ko) | 관이음구 | |

| KR200347803Y1 (ko) | 관이음구 | |

| JP3873244B2 (ja) | 糸条巻取筒 | |

| CA2245653C (en) | Closure with flowable material and reinforcing core | |

| EP3155307B1 (en) | A device for connecting plastic pipes as well as a method for the arrangement of a welding ring in a groove of a plastic pipe | |

| JPWO2004101416A1 (ja) | 熱可塑性樹脂紐の巻体の製造方法 | |

| DE102012109796A1 (de) | Ortungshilfe zum Aufspüren von Kunststoffrohren | |

| JPH11173484A (ja) | エレクトロフュージョン継手 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20151211 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20151211 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20161109 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20161122 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20170222 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170224 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20170307 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20170322 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6117237 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |