JP5875503B2 - 印字ヘッド組立体 - Google Patents

印字ヘッド組立体 Download PDFInfo

- Publication number

- JP5875503B2 JP5875503B2 JP2012251907A JP2012251907A JP5875503B2 JP 5875503 B2 JP5875503 B2 JP 5875503B2 JP 2012251907 A JP2012251907 A JP 2012251907A JP 2012251907 A JP2012251907 A JP 2012251907A JP 5875503 B2 JP5875503 B2 JP 5875503B2

- Authority

- JP

- Japan

- Prior art keywords

- adhesive

- ink

- adhesive layer

- plate

- printhead assembly

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000004593 Epoxy Substances 0.000 claims description 25

- 239000012790 adhesive layer Substances 0.000 claims description 21

- 239000000463 material Substances 0.000 claims description 16

- 239000000126 substance Substances 0.000 claims description 15

- 238000003860 storage Methods 0.000 claims description 7

- 229920006259 thermoplastic polyimide Polymers 0.000 claims description 6

- 239000003522 acrylic cement Substances 0.000 claims description 5

- 239000002184 metal Substances 0.000 claims description 5

- 229910052751 metal Inorganic materials 0.000 claims description 5

- 239000000919 ceramic Substances 0.000 claims description 2

- 239000004033 plastic Substances 0.000 claims description 2

- 229920003023 plastic Polymers 0.000 claims description 2

- 239000000853 adhesive Substances 0.000 description 66

- 230000001070 adhesive effect Effects 0.000 description 66

- 239000000976 ink Substances 0.000 description 55

- 239000010410 layer Substances 0.000 description 31

- 238000000034 method Methods 0.000 description 12

- 229920001721 polyimide Polymers 0.000 description 12

- 238000013461 design Methods 0.000 description 11

- 239000011347 resin Substances 0.000 description 11

- 229920005989 resin Polymers 0.000 description 11

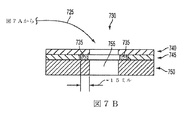

- 238000010586 diagram Methods 0.000 description 9

- 239000007788 liquid Substances 0.000 description 9

- 239000010408 film Substances 0.000 description 8

- 229910001220 stainless steel Inorganic materials 0.000 description 7

- 239000010935 stainless steel Substances 0.000 description 7

- 239000004642 Polyimide Substances 0.000 description 6

- 239000011324 bead Substances 0.000 description 5

- 238000000576 coating method Methods 0.000 description 5

- 238000006243 chemical reaction Methods 0.000 description 4

- 239000000178 monomer Substances 0.000 description 4

- 229920000642 polymer Polymers 0.000 description 4

- 239000007921 spray Substances 0.000 description 4

- YMWUJEATGCHHMB-UHFFFAOYSA-N Dichloromethane Chemical compound ClCCl YMWUJEATGCHHMB-UHFFFAOYSA-N 0.000 description 3

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 3

- 239000002313 adhesive film Substances 0.000 description 3

- 229910052782 aluminium Inorganic materials 0.000 description 3

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 3

- 239000011248 coating agent Substances 0.000 description 3

- 239000012528 membrane Substances 0.000 description 3

- NIXOWILDQLNWCW-UHFFFAOYSA-M Acrylate Chemical compound [O-]C(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-M 0.000 description 2

- 239000004925 Acrylic resin Substances 0.000 description 2

- 229920000178 Acrylic resin Polymers 0.000 description 2

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 2

- 238000013459 approach Methods 0.000 description 2

- 239000002131 composite material Substances 0.000 description 2

- 238000007641 inkjet printing Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 238000005192 partition Methods 0.000 description 2

- 239000002904 solvent Substances 0.000 description 2

- QTWJRLJHJPIABL-UHFFFAOYSA-N 2-methylphenol;3-methylphenol;4-methylphenol Chemical compound CC1=CC=C(O)C=C1.CC1=CC=CC(O)=C1.CC1=CC=CC=C1O QTWJRLJHJPIABL-UHFFFAOYSA-N 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 230000006978 adaptation Effects 0.000 description 1

- 239000004841 bisphenol A epoxy resin Substances 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 229920001577 copolymer Polymers 0.000 description 1

- 229930003836 cresol Natural products 0.000 description 1

- 230000032798 delamination Effects 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 239000003822 epoxy resin Substances 0.000 description 1

- 230000008020 evaporation Effects 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 238000009472 formulation Methods 0.000 description 1

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 1

- 239000010931 gold Substances 0.000 description 1

- 229910052737 gold Inorganic materials 0.000 description 1

- 238000007654 immersion Methods 0.000 description 1

- 238000013101 initial test Methods 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 229920003223 poly(pyromellitimide-1,4-diphenyl ether) Polymers 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920000647 polyepoxide Polymers 0.000 description 1

- 230000035485 pulse pressure Effects 0.000 description 1

- 239000000377 silicon dioxide Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 125000006850 spacer group Chemical group 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 230000008961 swelling Effects 0.000 description 1

- 238000012360 testing method Methods 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 230000004584 weight gain Effects 0.000 description 1

- 235000019786 weight gain Nutrition 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/16—Production of nozzles

- B41J2/1607—Production of print heads with piezoelectric elements

- B41J2/161—Production of print heads with piezoelectric elements of film type, deformed by bending and disposed on a diaphragm

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/16—Production of nozzles

- B41J2/1621—Manufacturing processes

- B41J2/1623—Manufacturing processes bonding and adhesion

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Particle Formation And Scattering Control In Inkjet Printers (AREA)

- Adhesive Tapes (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US13/307,231 | 2011-11-30 | ||

| US13/307,231 US8794743B2 (en) | 2011-11-30 | 2011-11-30 | Multi-film adhesive design for interfacial bonding printhead structures |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2013111978A JP2013111978A (ja) | 2013-06-10 |

| JP2013111978A5 JP2013111978A5 (enExample) | 2016-01-07 |

| JP5875503B2 true JP5875503B2 (ja) | 2016-03-02 |

Family

ID=48466468

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012251907A Expired - Fee Related JP5875503B2 (ja) | 2011-11-30 | 2012-11-16 | 印字ヘッド組立体 |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US8794743B2 (enExample) |

| JP (1) | JP5875503B2 (enExample) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9004648B2 (en) * | 2013-08-01 | 2015-04-14 | Xerox Corporation | Inkjet printheads containing epoxy adhesives and methods for fabrication thereof |

Family Cites Families (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3521708B2 (ja) * | 1997-09-30 | 2004-04-19 | セイコーエプソン株式会社 | インクジェット式記録ヘッドおよびその製造方法 |

| US6382777B1 (en) * | 1998-06-19 | 2002-05-07 | Canon Kabushiki Kaisha | Liquid jet recording head |

| US6347861B1 (en) * | 1999-03-02 | 2002-02-19 | Hewlett-Packard Company | Fluid ejection device having mechanical intercoupling structure embedded within chamber layer |

| JP2001018386A (ja) * | 1999-07-07 | 2001-01-23 | Nec Corp | インクジェット記録ヘッド及びその製造方法 |

| JP2003053966A (ja) * | 2000-06-12 | 2003-02-26 | Seiko Epson Corp | インクジェット式記録ヘッド |

| JP3575454B2 (ja) * | 2000-10-02 | 2004-10-13 | セイコーエプソン株式会社 | インクジェット式記録ヘッド |

| CA2377461A1 (en) * | 2001-03-19 | 2002-09-19 | Fuji Photo Film Co., Ltd. | Laser thermal transfer recording method and apparatus therefor |

| US7073902B2 (en) * | 2001-03-30 | 2006-07-11 | L&P Property Management Company | Method and apparatus for ink jet printing |

| US6450622B1 (en) * | 2001-06-28 | 2002-09-17 | Hewlett-Packard Company | Fluid ejection device |

| US6896944B2 (en) * | 2001-06-29 | 2005-05-24 | 3M Innovative Properties Company | Imaged articles comprising a substrate having a primed surface |

| JP4087085B2 (ja) * | 2001-07-06 | 2008-05-14 | 株式会社日立製作所 | インクジェットヘッド |

| JP4362996B2 (ja) * | 2001-08-22 | 2009-11-11 | 富士ゼロックス株式会社 | 格子状配列構造の圧電/電歪アクチュエータ及びその製造方法 |

| JP2004021814A (ja) * | 2002-06-19 | 2004-01-22 | Konica Minolta Holdings Inc | Icカードの作成方法及びicカード |

| US20040085396A1 (en) * | 2002-10-30 | 2004-05-06 | Ahne Adam J. | Micro-miniature fluid jetting device |

| MX2007006737A (es) * | 2004-12-07 | 2007-11-23 | Flex Multi Fineline Electronix | Microcircuiteria y componentes inductivos y metodos para fabricar los mismos. |

| US20060207720A1 (en) * | 2005-03-18 | 2006-09-21 | Konica Minolta Holdings, Inc. | Manufacturing method of inkjet head, and adhesive agent composition |

| US20070165075A1 (en) * | 2006-01-19 | 2007-07-19 | 3M Innovative Properties Company | Flexible circuits having ink-resistant covercoats |

| US7959266B2 (en) * | 2007-03-28 | 2011-06-14 | Xerox Corporation | Self aligned port hole opening process for ink jet print heads |

| JP5095352B2 (ja) * | 2007-11-09 | 2012-12-12 | 東芝テック株式会社 | ヘッドユニット、ヘッドユニットの製造方法 |

| US7869748B2 (en) * | 2008-01-24 | 2011-01-11 | Xerox Corporation | Direct imaging system with addressable actuators on a development roll |

| JP2009292061A (ja) * | 2008-06-05 | 2009-12-17 | Sii Printek Inc | ヘッドチップ、液体噴射ヘッド及び液体噴射装置 |

| JP5298685B2 (ja) * | 2008-07-28 | 2013-09-25 | コニカミノルタ株式会社 | インクジェットヘッド |

| US8563115B2 (en) * | 2008-08-12 | 2013-10-22 | Xerox Corporation | Protective coatings for solid inkjet applications |

| JP2010118641A (ja) * | 2008-10-17 | 2010-05-27 | Seiko Epson Corp | 圧電素子、液体噴射ヘッド、および液体噴射装置 |

| US20100149296A1 (en) * | 2008-12-17 | 2010-06-17 | Robert Lee Cornell | Uv-curable coatings and methods for applying uv-curable coatings using thermal micro-fluid ejection heads |

| JP2010149407A (ja) * | 2008-12-25 | 2010-07-08 | Seiko Epson Corp | 液体噴射ヘッド及び液体噴射装置 |

| JP2010184392A (ja) * | 2009-02-10 | 2010-08-26 | Seiko Epson Corp | ラインヘッドおよび画像形成装置 |

| JP2010221508A (ja) * | 2009-03-23 | 2010-10-07 | Fujifilm Corp | 流路部材の接着方法、液体吐出型記録ヘッド及び画像形成装置 |

| US8210661B2 (en) * | 2009-12-16 | 2012-07-03 | Palo Alto Research Center, Incorporated | Stacked slice printhead |

| US8910380B2 (en) * | 2010-06-15 | 2014-12-16 | Xerox Corporation | Method of manufacturing inkjet printhead with self-clean ability |

| JP2012076436A (ja) * | 2010-10-06 | 2012-04-19 | Seiko Epson Corp | 液体噴射ヘッド及び液体噴射装置 |

| JP2012139974A (ja) * | 2011-01-06 | 2012-07-26 | Seiko Epson Corp | 積層フィルム、インクジェットヘッド及び積層フィルムの製造方法 |

-

2011

- 2011-11-30 US US13/307,231 patent/US8794743B2/en active Active

-

2012

- 2012-11-16 JP JP2012251907A patent/JP5875503B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2013111978A (ja) | 2013-06-10 |

| US8794743B2 (en) | 2014-08-05 |

| US20130135391A1 (en) | 2013-05-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2006111B1 (en) | Liquid discharge device | |

| US8303076B2 (en) | Solid ink jet printhead having a polymer layer and processes therefor | |

| JP6198689B2 (ja) | エポキシ接着剤を含有するインクジェット印刷ヘッド、およびその製造方法 | |

| TW201107144A (en) | A thermal inkjet print head with solvent resistance | |

| JP5175970B2 (ja) | プリントヘッドモジュール | |

| US20110102520A1 (en) | Inkjet print head | |

| JP5875503B2 (ja) | 印字ヘッド組立体 | |

| US8082641B2 (en) | Method of manufacturing a ductile polymer-piezoelectric material composite | |

| JPH024510A (ja) | インクジェット記録ヘッドの製造方法 | |

| US20110148994A1 (en) | Print Head Having a Polymer Aperture Plate and Method for Assembling a Print Head | |

| US7438394B2 (en) | Inkjet head and method for making the same | |

| US8752939B2 (en) | Printhead and method of making the printhead | |

| US8919915B2 (en) | Ultrasonic laminating of materials for ink jet printheads | |

| JP6273901B2 (ja) | 接合方法、接合体の製造装置、接合体、インクジェットヘッドユニットおよびインクジェット式記録装置 | |

| JP7133807B2 (ja) | インクジェットヘッドおよびインクジェット印刷装置 | |

| JP6130308B2 (ja) | インクジェット式印字ヘッドを作成する方法 | |

| JP2012139974A (ja) | 積層フィルム、インクジェットヘッド及び積層フィルムの製造方法 | |

| JP2008307772A (ja) | インクジェットヘッド | |

| JPH10337875A (ja) | ノズル形成部材及びその製造方法並びにインクジェットヘッド | |

| JP2014097667A (ja) | インクジェットヘッド、インクジェットヘッドの製造方法およびインクジェット記録方法 | |

| JP2002001955A (ja) | インクジェットプリンタヘッドおよびその製造方法 | |

| JP2014162038A (ja) | 流路ユニット、液体噴射ヘッド、液体噴射装置、流路ユニットの製造方法 | |

| KR20140127487A (ko) | 잉크젯 프린트 헤드 | |

| US20150042729A1 (en) | Flow path unit, liquid ejecting head, liquid ejecting apparatus, and method of manufacturing flow path unit | |

| JP2005305827A (ja) | 液体噴射ヘッド |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20140424 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20151116 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20151116 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20151130 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20151217 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20160105 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20160119 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5875503 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |