JP5750445B2 - 取外し容易な燃焼管を有する炉 - Google Patents

取外し容易な燃焼管を有する炉 Download PDFInfo

- Publication number

- JP5750445B2 JP5750445B2 JP2012531060A JP2012531060A JP5750445B2 JP 5750445 B2 JP5750445 B2 JP 5750445B2 JP 2012531060 A JP2012531060 A JP 2012531060A JP 2012531060 A JP2012531060 A JP 2012531060A JP 5750445 B2 JP5750445 B2 JP 5750445B2

- Authority

- JP

- Japan

- Prior art keywords

- furnace

- cam

- combustion tube

- pin

- combustion

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000002485 combustion reaction Methods 0.000 title claims description 103

- 238000007789 sealing Methods 0.000 claims description 20

- 230000007246 mechanism Effects 0.000 claims description 15

- 230000013011 mating Effects 0.000 claims 1

- 238000004140 cleaning Methods 0.000 description 6

- 230000006698 induction Effects 0.000 description 6

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 5

- 229910052760 oxygen Inorganic materials 0.000 description 5

- 239000001301 oxygen Substances 0.000 description 5

- 239000010453 quartz Substances 0.000 description 4

- 239000000523 sample Substances 0.000 description 4

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 4

- 230000008878 coupling Effects 0.000 description 3

- 238000010168 coupling process Methods 0.000 description 3

- 238000005859 coupling reaction Methods 0.000 description 3

- 239000012530 fluid Substances 0.000 description 3

- 230000008901 benefit Effects 0.000 description 2

- 239000006227 byproduct Substances 0.000 description 2

- 239000007789 gas Substances 0.000 description 2

- 238000010438 heat treatment Methods 0.000 description 2

- NJPPVKZQTLUDBO-UHFFFAOYSA-N novaluron Chemical compound C1=C(Cl)C(OC(F)(F)C(OC(F)(F)F)F)=CC=C1NC(=O)NC(=O)C1=C(F)C=CC=C1F NJPPVKZQTLUDBO-UHFFFAOYSA-N 0.000 description 2

- 239000000538 analytical sample Substances 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 238000007373 indentation Methods 0.000 description 1

- 229910003480 inorganic solid Inorganic materials 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- YQCIWBXEVYWRCW-UHFFFAOYSA-N methane;sulfane Chemical compound C.S YQCIWBXEVYWRCW-UHFFFAOYSA-N 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D7/00—Forming, maintaining or circulating atmospheres in heating chambers

- F27D7/06—Forming or maintaining special atmospheres or vacuum within heating chambers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27B—FURNACES, KILNS, OVENS OR RETORTS IN GENERAL; OPEN SINTERING OR LIKE APPARATUS

- F27B14/00—Crucible or pot furnaces

- F27B14/06—Crucible or pot furnaces heated electrically, e.g. induction crucible furnaces with or without any other source of heat

- F27B14/061—Induction furnaces

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27B—FURNACES, KILNS, OVENS OR RETORTS IN GENERAL; OPEN SINTERING OR LIKE APPARATUS

- F27B14/00—Crucible or pot furnaces

- F27B14/08—Details specially adapted for crucible or pot furnaces

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27B—FURNACES, KILNS, OVENS OR RETORTS IN GENERAL; OPEN SINTERING OR LIKE APPARATUS

- F27B14/00—Crucible or pot furnaces

- F27B14/08—Details specially adapted for crucible or pot furnaces

- F27B14/14—Arrangements of heating devices

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27B—FURNACES, KILNS, OVENS OR RETORTS IN GENERAL; OPEN SINTERING OR LIKE APPARATUS

- F27B17/00—Furnaces of a kind not covered by any of groups F27B1/00 - F27B15/00

- F27B17/02—Furnaces of a kind not covered by any of groups F27B1/00 - F27B15/00 specially designed for laboratory use

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D11/00—Arrangement of elements for electric heating in or on furnaces

- F27D11/06—Induction heating, i.e. in which the material being heated, or its container or elements embodied therein, form the secondary of a transformer

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N31/00—Investigating or analysing non-biological materials by the use of the chemical methods specified in the subgroup; Apparatus specially adapted for such methods

- G01N31/12—Investigating or analysing non-biological materials by the use of the chemical methods specified in the subgroup; Apparatus specially adapted for such methods using combustion

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B6/00—Heating by electric, magnetic or electromagnetic fields

- H05B6/02—Induction heating

- H05B6/22—Furnaces without an endless core

- H05B6/24—Crucible furnaces

- H05B6/26—Crucible furnaces using vacuum or particular gas atmosphere

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27B—FURNACES, KILNS, OVENS OR RETORTS IN GENERAL; OPEN SINTERING OR LIKE APPARATUS

- F27B14/00—Crucible or pot furnaces

- F27B14/06—Crucible or pot furnaces heated electrically, e.g. induction crucible furnaces with or without any other source of heat

- F27B14/061—Induction furnaces

- F27B2014/066—Construction of the induction furnace

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27B—FURNACES, KILNS, OVENS OR RETORTS IN GENERAL; OPEN SINTERING OR LIKE APPARATUS

- F27B14/00—Crucible or pot furnaces

- F27B14/08—Details specially adapted for crucible or pot furnaces

- F27B2014/0825—Crucible or pot support

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D7/00—Forming, maintaining or circulating atmospheres in heating chambers

- F27D7/06—Forming or maintaining special atmospheres or vacuum within heating chambers

- F27D2007/063—Special atmospheres, e.g. high pressure atmospheres

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D2201/00—Manipulation of furnace parts

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D99/00—Subject matter not provided for in other groups of this subclass

- F27D99/0073—Seals

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Health & Medical Sciences (AREA)

- Power Engineering (AREA)

- Physics & Mathematics (AREA)

- Clinical Laboratory Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Electromagnetism (AREA)

- Combustion & Propulsion (AREA)

- Molecular Biology (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Investigating Or Analyzing Non-Biological Materials By The Use Of Chemical Means (AREA)

- Furnace Details (AREA)

Description

本出願は、Gordon C.Fordらにより2009年9月25日に出願された「EASY REMOVABLE COMBUSTION TUBE」と題する米国仮出願第61/245,732号の利益及び米国特許法第119(e)条の下での優先権を主張するものであり、該米国仮出願の開示全体を本明細書の一部を構成するものとしてここに援用する。

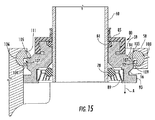

16 下側封止組立体

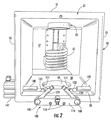

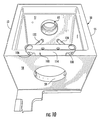

20 燃焼炉

50 炉ハウジング

58 底壁

59 開口

60 燃焼管

Claims (19)

- 燃焼管を受け入れるための開口を備えた底壁を有する炉ハウジングを備える、分析装置用の炉であって、

概略円筒状の燃焼管と、

前記燃焼管に結合された下側封止組立体であって、前記底壁の前記開口を介して前記燃焼管を前記炉ハウジング内に上昇させると共に前記燃焼管を前記炉ハウジングから下降させるために上昇位置と下降位置との間で移動可能な下側封止組立体とを有する炉。 - 前記燃焼管は、下側端にベース組立体を有し、前記炉ハウジングの前記底壁が、前記燃焼管を前記炉ハウジング内の使用位置に保持するために前記ベース組立体と選択的に係合するロック組立体を有する、請求項1に記載の炉。

- 前記ロック組立体は、前記燃焼管が前記下側封止組立体によって前記開口内で上昇されたときに前記ベース組立体と係合する少なくとも1個の回転可能なカムを有する、請求項2に記載の炉。

- 前記ベース組立体は、前記ロック組立体の前記回転可能なカムと協力して、前記燃焼管の前記炉ハウジングの前記底壁へのロックと前記底壁からの解放を選択的にするためのカムを有する、請求項3に記載の炉。

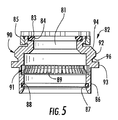

- 前記ベース組立体は、カムを有するカラーと、前記燃焼管を取り囲み前記上側カラーにねじ結合された上側リングと、前記上側リングとカラーとの間に位置決めされた環状封止部材とを有する、請求項2に記載の炉。

- 前記カラーの前記カムは、環状外側面と、前記環状面の両側に広がる上側面取り面及び下側面取り面とを有する、請求項5に記載の炉。

- 前記カラーは、前記上側リングと反対側に内部環状くぼみを有し、前記くぼみ内に位置決めされた下側環状封止部材を有する、請求項6に記載の炉。

- 前記カラーは、前記下側環状封止が位置決めされた円筒状スリーブを有し、このスリーブは、炉の下側封止組立体の上に封止可能に延在するように形成された、請求項7に記載の炉。

- 前記燃焼管と前記底壁の間に延在する解放可能なロック機構であって、前記燃焼管を使用位置に保持したり、前記開口を通して下方に取り外すために前記燃焼管を解放したりするための解放可能なロック機構を更に有する、請求項1に記載の炉。

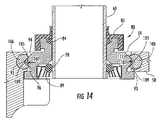

- 前記ロック機構は、前記燃焼管の一端の近傍に固定されて前記管を燃焼炉ハウジングの底壁に解放可能に保持するためのカムと、前記開口の近傍で前記燃焼炉ハウジングに回転可能に取り付けられて、前記燃焼管の前記カムと解放可能に係合する少なくとも1本のカムピンとを有する、請求項9に記載の炉。

- 前記ロック機構は、前記開口の両側に少なくとも1対のカムピンを有する、請求項10に記載の炉。

- 前記カムは、互いに対して90°の角度で延在する1対の離間した傾斜面を有する、請求項11に記載の炉。

- 前記カムピンは、90°の角度の側壁を有するテーパ付きスロットを有し、前記側壁が、前記カムの前記傾斜面と係合して前記燃焼管を適所に保持する、請求項12に記載の炉。

- 前記カムピンは、前記カムピンをカム係合位置とカム係合解除位置の間で回転させるためのハンドルを有する、請求項13に記載の炉。

- 前記ロック機構は、前記カムピンを回転させるためのアクチュエータを更に有する、請求項14に記載の炉。

- 前記底壁内に延在し、前記開口の両側の側壁と交差する1対のピン収容穴と、

前記ピン収容穴内に回転可能に取り付けられた1対のピンであって、前記開口の方を向くと共に前記ピン穴と前記開口の交点で露出したV字形スロットをそれぞれ有する1対のピンと、

前記燃焼管の下側端に取り付けられテーパ面を備えたカムであって、前記ピンが第1の位置にあるときにテーパ面が前記ピンの前記V字形スロットと係合して記燃焼管を前記炉ハウジング内の適所に保持し、前記ピンが第2の位置に回転されたときにテーパ面が前記ピンから外れて前記燃焼管を解放するカムと

を更に有する、請求項1に記載の炉。 - 前記V字形スロットは、各々2つの面を含んでおり、前記2つの面がなす角が90°である、請求項16に記載の炉。

- 前記カムは、前記テーパ面の間に環状面を有する、請求項17に記載の炉。

- 前記テーパ面は、互いに対して90°の角度で延在する、請求項18に記載の炉。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US24573209P | 2009-09-25 | 2009-09-25 | |

| US61/245,732 | 2009-09-25 | ||

| PCT/US2010/050160 WO2011038203A1 (en) | 2009-09-25 | 2010-09-24 | Easily removable combustion tube |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2013506113A JP2013506113A (ja) | 2013-02-21 |

| JP2013506113A5 JP2013506113A5 (ja) | 2013-09-05 |

| JP5750445B2 true JP5750445B2 (ja) | 2015-07-22 |

Family

ID=43780349

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012531060A Active JP5750445B2 (ja) | 2009-09-25 | 2010-09-24 | 取外し容易な燃焼管を有する炉 |

Country Status (5)

| Country | Link |

|---|---|

| US (4) | US8884193B2 (ja) |

| JP (1) | JP5750445B2 (ja) |

| CN (1) | CN102511003B (ja) |

| DE (1) | DE112010003790B4 (ja) |

| WO (1) | WO2011038203A1 (ja) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102511003B (zh) | 2009-09-25 | 2014-08-20 | 莱克公司 | 可容易地移除的燃烧管 |

| US9541287B2 (en) * | 2010-08-12 | 2017-01-10 | Leco Corporation | Combustion furnace auto cleaner |

| US8377397B2 (en) | 2011-03-02 | 2013-02-19 | Leco Corporation | Combustion tube |

| USD678791S1 (en) | 2011-09-01 | 2013-03-26 | Leco Corporation | Combustion tube |

| JP6063582B2 (ja) * | 2013-10-29 | 2017-01-18 | 株式会社堀場製作所 | 分析装置 |

| US10545106B2 (en) | 2014-03-21 | 2020-01-28 | Leco Corporation | Combustion tube |

| CN106568735A (zh) * | 2016-10-25 | 2017-04-19 | 福建紫金矿冶测试技术有限公司 | 高频红外碳硫分析仪标样选择及工作曲线制作方法 |

| CN206875940U (zh) | 2017-05-24 | 2018-01-12 | 尤根牙科医疗科技(北京)有限公司 | 一种两用烧结炉 |

| CN107023283A (zh) * | 2017-05-27 | 2017-08-08 | 成都理工大学 | 用于火烧油层模拟试验的燃烧系统 |

| US20230324360A1 (en) * | 2020-08-28 | 2023-10-12 | HORIBA Tocadero GmbH | Industrial water analysis device and support therefor |

| CN112415126A (zh) * | 2020-11-24 | 2021-02-26 | 华北电力科学研究院有限责任公司 | 固定装置及设有该固定装置的元素分析仪 |

| CN113465385B (zh) * | 2021-05-13 | 2023-02-17 | 中国地质科学院水文地质环境地质研究所 | 可拆卸有机碳高温密闭燃烧系统及其应用 |

| CN113774316B (zh) * | 2021-09-30 | 2023-08-29 | 德亚炉业科技江苏有限公司 | 可控气氛井式多用炉及其应用 |

Family Cites Families (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2332943A (en) * | 1940-08-26 | 1943-10-26 | Hevi Duty Electric Co | Carbon combustion furnace |

| US2809100A (en) * | 1951-05-12 | 1957-10-08 | Lab Equipment Corp | Combustion analyzer |

| US2686211A (en) * | 1952-07-12 | 1954-08-10 | Allegheny Ludlum Steel | Combustion furnace |

| US2923464A (en) * | 1955-10-17 | 1960-02-02 | Dorr Oliver Inc | Centrifuge construction |

| US3002819A (en) * | 1958-02-20 | 1961-10-03 | Phillips Petroleum Co | Apparatus for testing fuels |

| US3058814A (en) * | 1959-08-13 | 1962-10-16 | Lab Equipment Corp | Apparatus for combustion analysis |

| BE787397A (fr) * | 1971-08-12 | 1973-02-12 | Siderurgie Fse Inst Rech | Chambre de degazage |

| US3923464A (en) * | 1972-09-25 | 1975-12-02 | Leco Corp | Combustion apparatus for analytical instruments |

| JPS5514424A (en) * | 1978-07-17 | 1980-01-31 | Hitachi Ltd | Apparatus for connecting quartz tube |

| US4234541A (en) * | 1979-03-02 | 1980-11-18 | Leco Corporation | Combustion chamber cleaning apparatus |

| US4417346A (en) * | 1981-06-29 | 1983-11-22 | The Kanthal Corporation | High temperature melting furnace |

| JPS5848858A (ja) * | 1981-09-17 | 1983-03-22 | Horiba Ltd | 自動金属分析装置 |

| JPS61106612U (ja) * | 1984-12-19 | 1986-07-07 | ||

| US4793640A (en) * | 1986-10-30 | 1988-12-27 | United Technologies Electro Systems, Inc. | Cam-actuated electric door lock |

| US5720091A (en) | 1996-04-09 | 1998-02-24 | L&P Property Management | Indexer with cam-actuated lock |

| DE19800853A1 (de) * | 1998-01-13 | 1999-07-15 | Ald Vacuum Techn Gmbh | Geschlossener, evakuierbarer Tiegel zum induktiven Schmelzen oder Überhitzen von Metallen, Legierungen oder anderen elektrisch leitfähigen Werkstoffen |

| JP4157215B2 (ja) * | 1999-03-15 | 2008-10-01 | 株式会社堀場製作所 | 元素分析装置のガス抽出炉 |

| US6803237B2 (en) * | 2000-01-25 | 2004-10-12 | Woods Hole Oceanographic Institution | Sequential processing reaction vessel for chemical fractionation and analysis |

| CN2520510Y (zh) * | 2002-01-31 | 2002-11-13 | 国电环境保护研究所 | 燃煤全硫快速分析仪 |

| CN1254674C (zh) * | 2004-08-03 | 2006-05-03 | 上海德凯仪器有限公司 | 红外碳硫分析仪的燃烧装置 |

| CN1869709A (zh) * | 2006-06-09 | 2006-11-29 | 孙笑欢 | 碳硫自动分析方法及与多金属元素分析的组合仪器 |

| CN102511003B (zh) | 2009-09-25 | 2014-08-20 | 莱克公司 | 可容易地移除的燃烧管 |

-

2010

- 2010-09-24 CN CN201080042407.0A patent/CN102511003B/zh not_active Expired - Fee Related

- 2010-09-24 WO PCT/US2010/050160 patent/WO2011038203A1/en not_active Ceased

- 2010-09-24 JP JP2012531060A patent/JP5750445B2/ja active Active

- 2010-09-24 DE DE112010003790.6T patent/DE112010003790B4/de active Active

- 2010-09-24 US US12/889,628 patent/US8884193B2/en active Active

-

2014

- 2014-10-07 US US14/508,428 patent/US9874400B2/en active Active

- 2014-10-07 US US14/508,315 patent/US9874399B2/en active Active

- 2014-10-07 US US14/508,368 patent/US9879915B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| US9874399B2 (en) | 2018-01-23 |

| US20150036714A1 (en) | 2015-02-05 |

| US9879915B2 (en) | 2018-01-30 |

| WO2011038203A1 (en) | 2011-03-31 |

| US20150036713A1 (en) | 2015-02-05 |

| CN102511003A (zh) | 2012-06-20 |

| US20150023383A1 (en) | 2015-01-22 |

| DE112010003790T5 (de) | 2012-11-08 |

| US20110075696A1 (en) | 2011-03-31 |

| US9874400B2 (en) | 2018-01-23 |

| DE112010003790B4 (de) | 2015-09-17 |

| JP2013506113A (ja) | 2013-02-21 |

| US8884193B2 (en) | 2014-11-11 |

| CN102511003B (zh) | 2014-08-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5750445B2 (ja) | 取外し容易な燃焼管を有する炉 | |

| US8377397B2 (en) | Combustion tube | |

| US4286287A (en) | Irradiation specimen installation apparatus with television inspection | |

| CN109571220B (zh) | 用于清洁控制阀的阀体的工具和方法 | |

| CN107076615B (zh) | 光学高温计 | |

| US9541287B2 (en) | Combustion furnace auto cleaner | |

| US20200368860A1 (en) | Systems and methods for nuclear reactor dry tube assembly removal and installation | |

| TW202432273A (zh) | 易於將透氣塞安裝在治金容器中的透氣塞及系統 | |

| EP1331205A2 (en) | Latch mechanism for a forehearth feeder tube lift system | |

| SE503761C2 (sv) | Anordning för lösningsmedelsextraktion | |

| US11772581B2 (en) | Transfer ports for confinement gloveboxes and related methods | |

| CN223050670U (zh) | 一种燃气锅炉烟气排放监测装置 | |

| CN222068543U (zh) | 催化反应装置 | |

| DE102020103947A1 (de) | CVD-Reaktor und Verfahren zum Handhaben einer Prozesskammer-Deckenplatte | |

| US20210254829A1 (en) | Interchangeable seal head system | |

| KR101178522B1 (ko) | 푸셔카의 오븐 도어 개폐장치 | |

| JP2004333258A (ja) | 制御棒案内管脱着用ガイド装置および制御棒案内管脱着方法 | |

| JPH11248887A (ja) | 貫通孔内ナトリウム除去装置 | |

| JP2000035498A (ja) | 貫通孔内ナトリウム除去装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130717 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20130717 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20140616 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20140722 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20141021 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20141028 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20141120 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20150421 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20150518 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5750445 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |