JP5598485B2 - Thick steel plate having a thickness of 50 mm or more excellent in long and brittle crack propagation stopping characteristics and method for producing the same - Google Patents

Thick steel plate having a thickness of 50 mm or more excellent in long and brittle crack propagation stopping characteristics and method for producing the same Download PDFInfo

- Publication number

- JP5598485B2 JP5598485B2 JP2012023955A JP2012023955A JP5598485B2 JP 5598485 B2 JP5598485 B2 JP 5598485B2 JP 2012023955 A JP2012023955 A JP 2012023955A JP 2012023955 A JP2012023955 A JP 2012023955A JP 5598485 B2 JP5598485 B2 JP 5598485B2

- Authority

- JP

- Japan

- Prior art keywords

- thickness

- brittle crack

- less

- plate

- plate thickness

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/0221—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips characterised by the working steps

- C21D8/0226—Hot rolling

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/04—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips to produce plates or strips for deep-drawing

- C21D8/0421—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips to produce plates or strips for deep-drawing characterised by the working steps

- C21D8/0426—Hot rolling

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/04—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips to produce plates or strips for deep-drawing

- C21D8/0447—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips to produce plates or strips for deep-drawing characterised by the heat treatment

- C21D8/0463—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips to produce plates or strips for deep-drawing characterised by the heat treatment following hot rolling

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/02—Ferrous alloys, e.g. steel alloys containing silicon

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/04—Ferrous alloys, e.g. steel alloys containing manganese

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/12—Ferrous alloys, e.g. steel alloys containing tungsten, tantalum, molybdenum, vanadium, or niobium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/14—Ferrous alloys, e.g. steel alloys containing titanium or zirconium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/42—Ferrous alloys, e.g. steel alloys containing chromium with nickel with copper

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/46—Ferrous alloys, e.g. steel alloys containing chromium with nickel with vanadium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/48—Ferrous alloys, e.g. steel alloys containing chromium with nickel with niobium or tantalum

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/50—Ferrous alloys, e.g. steel alloys containing chromium with nickel with titanium or zirconium

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N3/00—Investigating strength properties of solid materials by application of mechanical stress

- G01N3/08—Investigating strength properties of solid materials by application of mechanical stress by applying steady tensile or compressive forces

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2201/00—Treatment for obtaining particular effects

- C21D2201/05—Grain orientation

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N2203/00—Investigating strength properties of solid materials by application of mechanical stress

- G01N2203/0058—Kind of property studied

- G01N2203/006—Crack, flaws, fracture or rupture

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N2203/00—Investigating strength properties of solid materials by application of mechanical stress

- G01N2203/0058—Kind of property studied

- G01N2203/006—Crack, flaws, fracture or rupture

- G01N2203/0062—Crack or flaws

- G01N2203/0066—Propagation of crack

Description

本発明は、大型コンテナ船やバルクキャリアーなどに用いて好適な脆性き裂伝播停止特性に優れる板厚50mm以上の厚鋼板およびその製造方法に関する。また、実船相当の長大脆性き裂伝播停止性能を評価する方法ならびに試験装置に関する。 The present invention relates to a thick steel plate having a thickness of 50 mm or more, which is excellent in brittle crack propagation stopping characteristics suitable for use in large container ships, bulk carriers, and the like, and a method for producing the same. The present invention also relates to a method and a test apparatus for evaluating the long brittle crack propagation stopping performance equivalent to an actual ship.

コンテナ船やバルクキャリアーは、積載能力の向上や荷役効率の向上等のため、上部開口部を大きくとった構造となっている。このため、これらの船では特に船体外板を厚肉化する必要がある。 Container ships and bulk carriers have a structure with a large upper opening in order to improve loading capacity and cargo handling efficiency. For this reason, in these ships, it is necessary to increase the thickness of the hull skin.

近年、コンテナ船は大型化し、6、000〜20、000TEUの大型船では船体外板の板厚は50mm以上となり、板厚効果により破壊靱性が低下することに加え、溶接入熱もより大きくなるため、溶接部の破壊靭性が一層低下する傾向にある。なお、TEU(Twenty feet Equivalent Unit)は、長さ20フィートのコンテナに換算した個数を表し、コンテナ船の積載能力の指標を示している。 In recent years, the size of container ships has increased, and in the case of large ships of 6,000 to 20,000 TEU, the plate thickness of the hull outer plate becomes 50 mm or more, and in addition to the fracture toughness being reduced due to the plate thickness effect, the welding heat input is also increased. Therefore, the fracture toughness of the welded portion tends to be further reduced. Note that TEU (Twenty Fee Equivalent Unit) represents the number converted into a 20-foot container and indicates an index of the loading capacity of the container ship.

船舶やラインパイプに使用される鋼板の板厚が50mm未満の比較的薄手の鋼材に対しては、TMCP法により細粒化を図り、低温靭性を向上させて、優れた脆性き裂伝播停止特性を付与することができる。 For relatively thin steel materials with a thickness of less than 50 mm, which is used for ships and line pipes, fine graining is achieved by the TMCP method to improve low temperature toughness and excellent brittle crack propagation stopping properties. Can be granted.

合金コストを上昇させることなく、鋼材の表層部の組織を超微細化する技術が、脆性き裂伝播停止特性を向上させる手段として提案されている。例えば、特許文献1では、脆性き裂が伝播する際に、鋼材表層部に発生するシアリップ(塑性変形領域)が脆性き裂伝播停止特性の向上に効果があることに着目し、シアリップ部分の結晶粒を微細化させて、伝播する脆性き裂が有する伝播エネルギーを吸収させる方法が開示されている。

A technique for making the structure of the surface layer portion of a steel material ultrafine without increasing the alloy cost has been proposed as a means for improving brittle crack propagation stopping characteristics. For example, in

鋼板を熱間圧延後、制御冷却により表層部分をAr3変態点以下に冷却し、その後制御冷却を停止して表層部分を変態点以上に復熱させる工程を1回以上繰り返して行い、この間に鋼材に圧下を加えることにより、繰り返し変態させ又は加工再結晶させて、表層部分に超微細なフェライト組織又はベイナイト組織を生成させるものである。 After the steel sheet is hot-rolled, the process of cooling the surface layer part below the Ar 3 transformation point by controlled cooling, and then repeating the process of stopping the controlled cooling and reheating the surface layer part above the transformation point, By applying a reduction to the steel material, it is repeatedly transformed or processed and recrystallized to produce an ultrafine ferrite structure or bainite structure in the surface layer portion.

特許文献2には、フェライト−パーライトを主体のミクロ組織とする鋼材において両表面部を円相当平均粒径:5μm以下、アスペクト比:2以上のフェライト粒を有するフェライト組織を50%以上有する層で構成し、更に仕上げ圧延中の1パス当りの最大圧下率を12%以下にすることで局所的な再結晶現象を抑制し、フェライト粒径のバラツキを抑えると優れた脆性き裂伝播停止特性向上の得られることが開示されている。 Patent Document 2 discloses a steel material mainly composed of ferrite-pearlite having a ferrite structure having a ferrite structure having a circle equivalent average particle size of 5 μm or less and an aspect ratio of 2 or more on a surface portion of both surfaces. In addition, the maximum reduction rate per pass during finish rolling is 12% or less to suppress local recrystallization phenomenon, and to suppress the variation in ferrite grain size, it improves the excellent brittle crack propagation stopping characteristics. Is obtained.

特許文献3には、塑性変形を受けた後の耐脆性き裂伝播特性に優れた鋼材として、以下の(a)〜(d)に述べる方法によって製造される結晶粒内にサブグレインを形成させた微細フェライトを主組織とする鋼材が開示されている。

In

(a)微細なフェライト結晶粒を確保する圧延条件、(b)鋼材板厚の5%以上の部分に微細フェライト組織を生成させる圧延条件、(c)微細フェライトに集合組織を発達させるとともに加工(圧延)により導入した転位を熱的エネルギーにより再配置しサブグレインを形成させる圧延条件、(d)形成した微細なフェライト結晶粒と微細なサブグレイン粒の粗大化を抑制する冷却条件、によって、鋼板表層の冷却および復熱などの複雑な温度制御を必要とせずに、塑性変形を受けた後の脆性き裂伝播停止特性を向上させる。 (A) Rolling conditions for securing fine ferrite crystal grains, (b) Rolling conditions for generating a fine ferrite structure in a portion of 5% or more of the steel plate thickness, (c) Developing and forming a texture in fine ferrite ( The rolling condition in which dislocations introduced by rolling are rearranged by thermal energy to form subgrains, and (d) cooling conditions to suppress coarsening of the formed fine ferrite crystal grains and fine subgrain grains are used. Without requiring complicated temperature control such as cooling and recuperation of the surface layer, the brittle crack propagation stopping characteristics after being subjected to plastic deformation are improved.

また、特許文献1〜3と異なる技術思想として特許文献4には、集合組織を発達させることにより、鋼材の破壊面上にセパレーションを板厚方向と平行な方向に発生させ、脆性き裂先端の応力を緩和させることにより、耐脆性き裂伝播特性を高める方法において、制御圧延により(110)面X線強度比を2以上とし、かつ円相当径20μm以上の粗大粒を10%以下とすることが記載されている。

Further, as a technical idea different from

特許文献5では溶接継手部の脆性き裂伝播停止性能の優れた溶接構造用鋼として、板厚内部においての圧延面での(100)面のX線面強度比が1.5以上を有することを特徴とする鋼板が開示され、集合組織発達により、応力負荷方向に垂直な方向に対して、き裂伝播方向を変化させて、脆性き裂を溶接継手部から母材側に誘導し、継手としての脆性き裂伝播停止性能を向上させることが記載されている。 In Patent Document 5, as a steel for welded structures having excellent brittle crack propagation stopping performance in a welded joint, the X-ray surface strength ratio of the (100) plane at the rolled surface within the plate thickness is 1.5 or more. A steel sheet characterized by the following is disclosed, and by the texture development, the crack propagation direction is changed with respect to the direction perpendicular to the stress load direction, and a brittle crack is induced from the welded joint to the base metal side, and the joint is It is described that the brittle crack propagation stopping performance is improved.

また、特許文献6には、板厚中央部における圧延面での(211)面のX線強度比が1.3以上、かつ板厚1/4部における圧延面での(100)面X線強度比が1.5以上、板表層部における圧延面での(100)面X線強度比が1.5以上を有することを特徴とする鋼板が開示され、集合組織発達により、T継手等を介し鋼板表面から突入する脆性き裂先端近傍にクラックが発生し、そのクラックがき裂伝播抵抗として作用し板厚方向に伝播する脆性き裂に対する脆性き裂伝播停止性能が向上することが記載されている。 In Patent Document 6, the X-ray intensity ratio of the (211) plane at the rolled surface at the center of the plate thickness is 1.3 or more, and the (100) plane X-ray at the rolled surface at the 1/4 thickness portion. A steel sheet characterized by having a strength ratio of 1.5 or more and a (100) plane X-ray intensity ratio at the rolled surface in the plate surface layer portion of 1.5 or more is disclosed. It is described that a crack occurs near the tip of a brittle crack that penetrates from the surface of the steel plate, and that the crack acts as a crack propagation resistance, improving the brittle crack propagation stopping performance against the brittle crack propagating in the plate thickness direction. Yes.

一方、船体構造においては、万一溶接部から脆性破壊が発生した場合にも、脆性き裂の伝播を停止させ船体分離を防止することが必要と考えられている。板厚50mm未満の造船用鋼板溶接部の脆性き裂伝播挙動については、日本造船研究協会第147委員会において、実験的に検討がなされている。 On the other hand, in the hull structure, it is considered necessary to prevent the hull separation by stopping the propagation of a brittle crack even if a brittle fracture occurs from a weld. The brittle crack propagation behavior of welded steel plates for shipbuilding with a thickness of less than 50 mm has been experimentally studied by the Japan Shipbuilding Research Association No. 147 Committee.

第147委員会では、溶接部にて強制的に発生させた脆性き裂の伝播経路、伝播挙動を実験的に調査した結果、溶接部の破壊靱性がある程度確保されていれば、溶接残留応力の影響により脆性き裂は溶接部から母材側に逸れてしまうことが多いが、溶接部に沿って脆性き裂が伝播した例も複数確認された。このことは、脆性破壊が溶接部に沿って直進伝播する可能性が無いとは言い切れないことを示唆している。 In the 147th Committee, as a result of experimental investigation of the propagation path and propagation behavior of the brittle crack that was forcibly generated in the weld, if the fracture toughness of the weld was secured to some extent, Due to the influence, brittle cracks often deviate from the weld to the base metal side, but multiple examples of brittle cracks propagating along the weld were also confirmed. This suggests that there is no possibility that brittle fracture will propagate straight along the weld.

しかしながら、第147委員会で適用した溶接と同等の溶接を板厚50mm未満の鋼板に適用して建造された船舶が何ら問題なく就航しているという多くの実績があることに加え、靱性が良好な鋼板母材(造船E級鋼など)は脆性き裂を停止する能力が十分にあるとの認識から、造船用鋼材溶接部の脆性き裂伝播停止特性は船級規則等には要求されてこなかった。 However, in addition to the fact that ships constructed by applying welding equivalent to the welding applied in the 147th Committee to steel sheets with a thickness of less than 50 mm have been put into service without any problems, toughness is good. Since steel plate base materials (shipbuilding class E steel, etc.) have sufficient ability to stop brittle cracks, the brittle crack propagation stop characteristics of steel welds for shipbuilding are not required by the classification rules. It was.

しかしながら、最近の6、000TEUを超える大型コンテナ船では鋼板の板厚は50mmを超え、板厚効果により破壊靱性が低下することに加え、溶接入熱もより大きくなるため、溶接部の破壊靭性が一層低下する傾向にある。 However, in recent large container ships exceeding 6,000 TEU, the plate thickness of the steel plate exceeds 50 mm, and the fracture toughness is lowered due to the plate thickness effect. In addition, the weld heat input becomes larger, so the fracture toughness of the welded portion is reduced. There is a tendency to further decrease.

最近、このような厚肉大入熱溶接継手では、溶接部から発生した脆性き裂は母材側に逸れずに直進し長大化し、骨材等の鋼板母材部でも停止しないことが実験的に示され(非特許文献1)、50mm以上の板厚の鋼板を適用した船体構造の安全確保の上で大きな問題となっている。また、このような船体の安全性確保を評価する試験として、長大ESSO試験があるが、評価方法の相違や試験装置の制約などにより試験結果が変化し、必ずしも実船に相当する長大脆性き裂伝播停止性能が評価されていないという問題があった。 Recently, in such thick-walled large heat input welded joints, it is experimental that brittle cracks generated from the welds do not escape to the base metal side and go straight, and do not stop even in the steel base material parts such as aggregates. (Non-Patent Document 1), which is a big problem in ensuring the safety of the hull structure to which a steel plate having a thickness of 50 mm or more is applied. In addition, there is a long-sized ESSO test as a test for evaluating the safety of such a hull, but the test results change due to differences in the evaluation method and restrictions on the test equipment, and a long brittle crack corresponding to an actual ship. There was a problem that propagation stop performance was not evaluated.

上述した特許文献1〜6記載の鋼板は長大化した脆性き裂伝播停止特性について記載がなく、非特許文献1で明らかにされた課題を解決することができない。また、実船相当の長大脆性き裂伝播停止特性を評価する方法や試験装置については、特許文献1〜6記載の技術には記載がなく、実船相当の安全性評価という課題を解決することができない。

The steel sheets described in

そこで、本発明は、50mm以上の板厚の鋼板およびその溶接部において、脆性破壊が発生した場合でも、大規模破壊に至る前に長大化した脆性き裂を停止させる厚鋼板およびその製造方法を提供することを目的とする。加えて、実船相当の長大脆性き裂伝播停止性能を評価する方法ならびに試験装置を提供することを目的とする。なお、ここでいう長大脆性き裂とは、隣接する他の鋼板から突入する長さ1m以上の脆性き裂のことである。 Accordingly, the present invention provides a steel plate having a thickness of 50 mm or more and a welded portion thereof, and a method of manufacturing the steel plate that stops a brittle crack that has become long before a large-scale fracture occurs even when a brittle fracture occurs. The purpose is to provide. In addition, an object of the present invention is to provide a method and a test apparatus for evaluating the long brittle crack propagation stopping performance equivalent to an actual ship. Here, the long and brittle crack is a brittle crack having a length of 1 m or more that enters from another adjacent steel plate.

本発明者らは、化学組成および圧延条件を変化させた多くの鋼板について集合組織形態と脆性き裂伝播停止特性(アレスト性能という場合がある)の関係を調査するとともに、長大脆性き裂伝播停止現象に及ぼすアレスト性能(靭性や集合組織に影響される)の板厚方向の分布の影響を調査した。また、タブ板先端間距離もしくは荷重負荷点間距離を変化させた動的FEM解析により、実船相当の長大脆性き裂伝播特性を模擬できる長大ESSO試験の評価方法、試験装置について検討した。 The present inventors investigated the relationship between texture morphology and brittle crack propagation stopping characteristics (sometimes referred to as arrest performance) for many steel plates with different chemical compositions and rolling conditions, and stopped long brittle crack propagation. The effect of distribution in the thickness direction of arrest performance (affected by toughness and texture) on the phenomenon was investigated. In addition, a long-scale ESSO test evaluation method and test apparatus capable of simulating long-brittle crack propagation characteristics equivalent to actual ships were studied by dynamic FEM analysis with varying distance between tab plate tips or load-loading points.

その結果、化学組成および圧延条件を制御し、アレスト性能に影響を与える靭性および集合組織の板厚方向の分布を規定した場合、長大脆性き裂伝播停止性能が飛躍的に向上し、これまで停止が困難と考えられてきた厚物鋼板もしくはその溶接部を伝播してきた長大脆性き裂を応力反射の無い実船相当条件下において、鋼板にて停止させうることを知見した。さらに、動的FEM解析の結果、タブ板先端間距離および荷重負荷点間距離を所定の値とすることで、応力反射の無い実船に相当する長大ESSO試験の評価方法、試験装置について知見した。なお、厚さ50mm未満の厚鋼板は、現行鋼板(例えば造船用E級鋼など)で長大脆性き裂を停止させることができるため、本発明は厚さ50mm以上の厚鋼板を対象とした。 As a result, when the chemical composition and rolling conditions are controlled and the toughness that affects arrest performance and the distribution of texture in the thickness direction are specified, the long brittle crack propagation stoppage performance has been dramatically improved and has been stopped so far. It has been found that a thick brittle crack or a long brittle crack propagating through its weld can be stopped with a steel plate under conditions equivalent to an actual ship without stress reflection. Furthermore, as a result of dynamic FEM analysis, the evaluation method and test apparatus for a long-sized ESSO test corresponding to an actual ship without stress reflection were found by setting the distance between the tab plate tips and the distance between the load points to predetermined values. . In addition, since the steel plate with a thickness of less than 50 mm can stop a long and brittle crack with a current steel plate (for example, E grade steel for shipbuilding), the present invention is intended for a steel plate with a thickness of 50 mm or more.

本発明は上記知見を基に更に検討を加えてなされたもので、すなわち本発明は、

(1)板厚(t)が50mm以上の厚鋼板であって、板厚方向断面における長大脆性き裂伝播停止部の先端形状において、板厚中央部の板厚(t)の20%の幅の領域における停止き裂長さが、鋼板表面から板厚(t)の1/4〜1/10または板厚(t)の3/4〜9/10となる領域の最大き裂長さに対し、少なくとも板厚(t)の長さだけ前記長大脆性き裂の進行方向に対し短く、凹んだ凹陥部を形成していることを特徴とする長大脆性き裂伝播停止特性に優れる板厚(t)が50mm以上の厚鋼板。

(2)前記板厚中央部で板厚(t)の少なくとも20%の領域における部位の圧延面での(211)面もしくは(100)面のX線強度比が1.5以上、前記板厚(t)の1/4〜1/10となる領域または前記板厚(t)の3/4〜9/10となる領域の圧延面での(110)面のX線強度比が1.3以上であることを特徴とする、(1)記載の長大脆性き裂伝播停止特性に優れる板厚(t)が50mm以上の厚鋼板。

(3)前記板厚中央部で板厚(t)の少なくとも20%の領域における部位の圧延面での(211)面X線強度比X(211)と(100)面X線強度比X(100)および同部位の2mmVノッチシャルピー衝撃試験により得られる破面遷移温度vTrs(℃)が式:vTrs−12X(100)−22X(211)≦(T−75)/0.64[Tは鋼板の供用温度(℃)]を満足し、且つ前記板厚(t)の1/4〜1/10となる領域または前記板厚(t)の3/4〜9/10となる領域の圧延面での(110)面のX線強度比が1.3以上であることを特徴とする、(1)または(2)に記載の長大脆性き裂伝播停止特性に優れる板厚(t)が50mm以上の厚鋼板。

(4)鋼組成が、質量%で、C:0.15%以下、Si:0.60%以下、Mn:0.80〜1.80%、S:0.001〜0.05%を含み、Ti:0.005〜0.050%またはNb:0.001〜0.1%の内から選んだ少なくとも1種を含み、更に、Cu:2.0%以下、V:0.2%以下、Ni:2.0%以下、Cr:0.6%以下、Mo:0.6%以下、W:0.5%以下、B:0.0050%以下、Zr:0.5%以下の内から選んだ少なくとも1種を含有し、残部Feおよび不可避的不純物からなることを特徴とする(1)乃至(3)のいずれか一つに記載の長大脆性き裂伝播停止特性に優れる板厚(t)が50mm以上の厚鋼板。

(5)(4)に記載の成分組成を有する鋼素材を、900〜1350℃の温度に加熱し、次いで鋼板表面温度1000〜850℃の温度域において累積圧下率10%以上圧延した後、鋼板表面温度900〜600℃且つ鋼板内部温度が鋼板表面温度より50〜150℃高温となる状態とし、その後、1パス圧下率7%以上、累積圧下率50%以上で、圧延終了時の鋼板表面温度800〜550℃で熱間圧延することを特徴とする長大脆性き裂伝播停止特性に優れる板厚(t)が50mm以上の厚鋼板の製造方法。

(6)更に、熱間圧延を終了した後、5℃/s以上の冷却速度で400℃まで冷却することを特徴とする(5)記載の長大脆性き裂伝播停止特性に優れる板厚(t)が50mm以上の厚鋼板の製造方法。

(7)試験片幅2m以上の大型試験片を用いて、き裂伝播長1m以上の長大脆性き裂に対する伝播停止性能を評価・確認する試験において、試験片長さもしくは試験片を取り付ける試験装置のタブ板先端間距離が試験片幅の2.8倍以上であることを特徴とする、鋼材もしくは構造物の長大脆性き裂伝播停止性能の評価方法。

(8)(7)に記載の評価方法において、さらに、試験装置の荷重負荷点間距離が試験片幅の4.1倍以上であることを特徴とする鋼材もしくは構造物の長大脆性き裂伝播停止性能の評価方法。

(9)試験片幅2m以上の大型試験片を用いて、き裂伝播長1m以上の長大脆性き裂に対する伝播停止性能を評価・確認する試験装置において、試験片を取り付ける試験装置のタブ板先端間距離が試験片幅の2.8倍以上であることを特徴とする、長大脆性き裂伝播停止性能を評価する試験装置。

(10)(9)に記載の試験装置において、さらに、試験装置の荷重負荷点間距離が試験片幅の4.1倍以上であることを特徴とする長大脆性き裂伝播停止性能を評価する試験装置。

The present invention has been made by further study based on the above knowledge, that is, the present invention,

(1) A steel plate having a thickness (t) of 50 mm or more, and a width of 20% of the thickness (t) at the center of the thickness in the tip shape of the long brittle crack propagation stop portion in the cross section in the thickness direction With respect to the maximum crack length in the region where the stop crack length in the region is from 1/4 to 1/10 of the plate thickness (t) or 3/4 to 9/10 of the plate thickness (t) from the steel plate surface, A plate thickness (t) excellent in a long brittle crack propagation stop characteristic, characterized in that it is formed in a concave recess portion that is shorter than the length of the long brittle crack by at least the length of the plate thickness (t). Is a thick steel plate of 50 mm or more.

(2) The X-ray intensity ratio of the (211) plane or the (100) plane at the rolled surface of the portion in the region of at least 20% of the plate thickness (t) at the plate thickness central portion is 1.5 or more, and the plate thickness The X-ray intensity ratio of the (110) plane at the rolled surface in the region of 1/4 to 1/10 of (t) or 3/4 to 9/10 of the plate thickness (t) is 1.3. A thick steel plate having a thickness (t) of 50 mm or more, which is excellent in the long brittle crack propagation stopping property as described in (1), which is as described above.

(3) The (211) plane X-ray intensity ratio X (211) and the (100) plane X-ray intensity ratio X (2 ) at the rolling surface of the portion in the region of at least 20% of the sheet thickness (t) at the center of the sheet thickness 100) and the fracture surface transition temperature vTrs (° C.) obtained by the 2 mm V notch Charpy impact test of the same part is represented by the formula: vTrs-12X (100) -22X (211) ≦ (T-75) /0.64 [T is steel plate In the range of 1/4 to 1/10 of the plate thickness (t) or 3/4 to 9/10 of the plate thickness (t). The thickness (t) having excellent long-brittle crack propagation stopping property as described in (1) or (2) is 50 mm, wherein the X-ray intensity ratio of (110) plane at 1.3 is 1.3 or more The above thick steel plate.

(4) Steel composition includes mass%, C: 0.15% or less, Si: 0.60% or less, Mn: 0.80 to 1.80%, S: 0.001 to 0.05% Ti: 0.005 to 0.050% or Nb: At least one selected from 0.001 to 0.1%, Cu: 2.0% or less, V: 0.2% or less Ni: 2.0% or less, Cr: 0.6% or less, Mo: 0.6% or less, W: 0.5% or less, B: 0.0050% or less, Zr: 0.5% or less (1) to (3) characterized in that it comprises at least one selected from the group consisting of the remaining Fe and unavoidable impurities (1) to (3). A steel plate having a t) of 50 mm or more.

(5) A steel material having the component composition described in (4) is heated to a temperature of 900 to 1350 ° C., and then rolled at a cumulative rolling reduction of 10% or more in a temperature range of a steel plate surface temperature of 1000 to 850 ° C. The surface temperature is 900 to 600 ° C. and the internal temperature of the steel sheet is 50 to 150 ° C. higher than the steel sheet surface temperature, and then the steel sheet surface temperature at the end of rolling at a one-pass reduction ratio of 7% or more and a cumulative reduction ratio of 50% or more. A method for producing a thick steel plate having a thickness (t) of 50 mm or more, which is excellent in long brittle crack propagation stopping characteristics, characterized by hot rolling at 800 to 550 ° C.

(6) Further, after the hot rolling is finished, the sheet is cooled to 400 ° C. at a cooling rate of 5 ° C./s or more, and the plate thickness (t ) Is a manufacturing method of a thick steel plate of 50 mm or more.

(7) In a test that evaluates and confirms the propagation stop performance for a large brittle crack with a crack propagation length of 1 m or more using a large test piece with a width of 2 m or more of the test piece, A method for evaluating the long brittle crack propagation stopping performance of a steel material or structure, wherein the distance between the tab plate tips is at least 2.8 times the width of the test piece.

(8) In the evaluation method according to (7), the distance between the load points of the test apparatus is 4.1 times or more the width of the test piece, and the long brittle crack propagation of the steel material or structure Stop performance evaluation method.

(9) The tip of the tab plate of the test device to which the test piece is attached in a test device that evaluates and confirms the propagation stop performance of a large brittle crack with a crack propagation length of 1 m or more using a large test piece with a width of 2 m or more. A test apparatus for evaluating long brittle crack propagation stopping performance, characterized in that the distance between them is 2.8 times or more the width of the test piece.

(10) In the test apparatus described in (9), the long brittle crack propagation stop performance is further characterized in that the distance between the load points of the test apparatus is 4.1 times or more of the test piece width. Test equipment.

本発明によれば、板厚(t)が50mm以上の厚鋼板において優れた脆性き裂伝播停止性能を付与することが可能で、これまで困難であった板厚50mm以上の厚物材における長大脆性き裂を応力反射の無い実船相当条件下において停止させることができ産業上極めて有用である。 According to the present invention, it is possible to provide excellent brittle crack propagation stopping performance in a thick steel plate having a thickness (t) of 50 mm or more, and it is long in a thick material having a thickness of 50 mm or more, which has been difficult until now. Brittle cracks can be stopped under conditions equivalent to actual ships without stress reflection, which is extremely useful in industry.

本発明では、板厚方向断面における長大脆性き裂伝播停止部の先端形状を規定する。以下に本発明の限定理由について説明する。 In this invention, the front-end | tip shape of the long brittle crack propagation stop part in a plate | board thickness direction cross section is prescribed | regulated. The reason for limitation of the present invention will be described below.

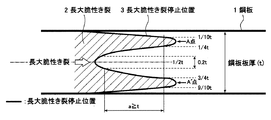

図1に本発明に係る板厚(t)が50mm以上の鋼板1の板厚方向断面における長大脆性き裂2の伝播停止部の先端形状(長大脆性き裂停止位置3)を模式的に示す。

FIG. 1 schematically shows a tip shape (long brittle crack stop position 3) of a propagation stop portion of a long brittle crack 2 in a cross section in the thickness direction of a

本発明では、長大脆性き裂伝播停止部の先端形状を、板厚中央部の板厚(t)の20%の幅の領域における長大脆性き裂停止位置と、鋼板表面から板厚(t)の1/4〜1/10および板厚(t)の3/4〜9/10となる幅領域の長大脆性き裂停止位置の位置間のうち、最も短い間隔(以下、深さa)が少なくとも板厚(t)の長さの、深さaだけ長大脆性き裂の進行方向に対し短く、凹んだ略U字状の凹陥部を有する形状とする。 In the present invention, the shape of the tip of the long brittle crack propagation stop portion is determined from the position of the long brittle crack stop in the region having a width of 20% of the plate thickness (t) at the plate thickness central portion, and the plate thickness (t) from the steel plate surface. Is the shortest interval (hereinafter referred to as depth a) among the positions of the large brittle crack stop positions in the width region of 1/4 to 1/10 of the thickness and 3/4 to 9/10 of the plate thickness (t). At least the length of the plate thickness (t) is set to a shape having a recessed portion having a substantially U-shape that is short by a depth a in the advancing direction of the long brittle crack.

鋼板全体のアレスト性能を向上させるため鋼板の板厚方向断面の板厚中央部において板厚(t)の少なくとも20%の幅の領域、ta(板厚(t)の1/2位置を含んだ、その上下10%以上の幅の領域)のアレスト性能を向上させる。なお、アレスト性能を向上させる領域、taは、圧延負荷の制約から50%以下とすることが好ましい。 In order to improve the arrest performance of the entire steel plate, a region having a width of at least 20% of the plate thickness (t) in the plate thickness central portion of the cross section in the plate thickness direction of the steel plate, including a half position of the plate thickness (t) However, the arrest performance in the upper and lower width regions of 10% or more) is improved. The area of improving the arrest performance, t a is preferably 50% or less from the constraints of the rolling load.

アレスト性能を向上させた板厚中央付近の領域幅、taが板厚の20%未満となると、板厚(t)の1/4〜1/10部近傍(板厚(t)の1/4位置と1/10位置を含み、1/4位置と1/10位置の間の領域)および板厚(t)の3/4〜9/10部近傍(板厚(t)の3/4位置と9/10位置を含み、3/4位置と9/10位置の間の領域)の破壊駆動力が十分に下がらず、板厚(t)の1/4〜1/10部近傍および板厚(t)の3/4〜9/10部近傍において、き裂が停止せず伝播してしまうため、少なくとも20%とする。 Arrest performance area width around the mid-thickness with improved and t a is the thickness of less than 20%, of the 1 / 4-1 / 10 parts near the plate thickness (t) (sheet thickness (t) 1 / 4 position and 1/10 position, the region between 1/4 position and 1/10 position) and the vicinity of 3/4 to 9/10 part of sheet thickness (t) (3/4 of sheet thickness (t)) And the 9/10 position, the area between the 3/4 position and the 9/10 position) is not sufficiently reduced, and the vicinity of 1/4 to 1/10 part of the plate thickness (t) and the plate In the vicinity of 3/4 to 9/10 part of the thickness (t), the crack does not stop and propagates, so at least 20%.

板厚方向断面において他の領域よりアレスト性能に優れる領域は長大脆性き裂の停止長さが短くその進行方向に対し、凹んだ凹陥部を形成するので、長大脆性き裂伝播停止部の先端形状を板厚中央部の板厚(t)の少なくとも20%の領域を長大脆性き裂の進行方向に対して凹んだ略U字状の凹陥部とする。 In the cross section in the plate thickness direction, the area where the arrest performance is superior to other areas has a short stop length for the large brittle crack, and a concave recess is formed in the direction of travel, so the tip shape of the long brittle crack propagation stop section Is a substantially U-shaped recessed portion in which a region of at least 20% of the plate thickness (t) at the central portion of the plate thickness is recessed with respect to the traveling direction of the long brittle crack.

また、略U字状の凹陥部の形状は、板厚(t)の1/4〜1/10近傍および板厚(t)の3/4〜9/10近傍の破壊駆動力の低下には、板厚中央部の板厚の20%の領域における脆性き裂停止長さが、板厚(t)の1/4〜1/10および板厚(t)の3/4〜9/10の領域における脆性き裂停止長さより、少なくとも板厚(t)の長さだけ短くなることが必要なため、長大脆性き裂の進行方向に対し、凹陥部の深さaが少なくとも板厚(t)の長さと等しい凹んだ形状とする。 Moreover, the shape of the substantially U-shaped recess is to reduce the breaking driving force in the vicinity of 1/4 to 1/10 of the plate thickness (t) and in the vicinity of 3/4 to 9/10 of the plate thickness (t). The brittle crack stop length in the region of 20% of the plate thickness at the center of the plate thickness is 1/4 to 1/10 of the plate thickness (t) and 3/4 to 9/10 of the plate thickness (t). Since it is necessary to shorten at least the length of the plate thickness (t) from the brittle crack stop length in the region, the depth a of the recessed portion is at least the plate thickness (t) with respect to the traveling direction of the large brittle crack. A concave shape equal to the length of.

深さaは図1中の板厚(t)の1/4〜1/10および板厚(t)の3/4〜9/10となる領域での長大脆性き裂停止位置(最大き裂長さとも言う)を示す板厚方向に直角な線と、板厚中央部において板厚の20%の領域幅を示す板厚方向に平行な線と長大脆性き裂伝播停止位置との交点を通る板厚方向に直角な線との間隔の内、もっとも短い間隔の長さと規定する。 Depth a is a long brittle crack stop position (maximum crack length) in the region of 1/4 to 1/10 of the plate thickness (t) and 3/4 to 9/10 of the plate thickness (t) in FIG. Also passes through the intersection of a line perpendicular to the plate thickness direction and a line parallel to the plate thickness direction showing a region width of 20% of the plate thickness at the center of the plate thickness and the long brittle crack propagation stop position. It is defined as the length of the shortest interval among the intervals with the line perpendicular to the thickness direction.

厚さ50mm以上の厚鋼板の脆性破壊破面では板厚(t)の1/4〜1/10または板厚(t)の3/4〜9/10の領域内に最長き裂伝播部(図1のA点およびA’点付近)が観察されるため、板厚中央部近傍とこれら領域との比較において長大脆性き裂伝播停止位置が板厚方向に描く形状を本発明では規定する。なお、板厚(t)の1/2位置に対し、上下対称となる鋼板表面から板厚方向に板厚(t)の1/4〜1/10の領域と板厚(t)の3/4〜9/10の領域はアレスト性能、長大脆性き裂伝播停止部の先端形状が概略等しい。 In the brittle fracture fracture surface of a steel plate having a thickness of 50 mm or more, the longest crack propagation portion (in the region of 1/4 to 1/10 of the plate thickness (t) or 3/4 to 9/10 of the plate thickness (t) ( 1 is observed), the shape of the long brittle crack propagation stop position drawn in the thickness direction is defined in the present invention in the comparison between the vicinity of the thickness center portion and these regions. In addition, with respect to the 1/2 position of the plate thickness (t), the region of ¼ to 1/10 of the plate thickness (t) in the plate thickness direction from the steel plate surface that is vertically symmetric, and 3 / of the plate thickness (t). In the region of 4-9 / 10, the arrest performance and the tip shape of the long brittle crack propagation stop portion are substantially equal.

上述した長大脆性き裂伝播停止部の先端形状は、図2に示す長大ESSO試験片4の破面で確認することができる。長大ESSO試験片4は、試験板6と助走板5はCO2溶接部8で接合され、助走板5にはCO2溶接部8と直角方向にエレクトロガス溶接部7を設け、機械ノッチ9から発生した脆性き裂(図示しない)がエレクトロガス溶接部7に沿って伝播し、試験板6の荷重負荷方向と直角に試験板6に突入する。荷重負荷方向は図中矢印R.D.の圧延方向とする。本発明において長大脆性き裂伝播停止特性とは、試験板6へ突入するまでの脆性き裂の伝播距離が長い長大ESSO試験片4を用いて、実際の船舶と同様応力反射の影響の無いタブ板先端間距離や荷重負荷点間距離の十分長い試験機により評価されるものを指す。 The tip shape of the long brittle crack propagation stop portion described above can be confirmed on the fracture surface of the long ESSO test piece 4 shown in FIG. In the long ESSO test piece 4, the test plate 6 and the run-up plate 5 are joined by a CO 2 weld 8. The run-up plate 5 is provided with an electrogas weld 7 in a direction perpendicular to the CO 2 weld 8. The generated brittle crack (not shown) propagates along the electrogas weld 7 and enters the test plate 6 at a right angle to the load direction of the test plate 6. The load direction is indicated by the arrow R. D. The rolling direction. In the present invention, the long brittle crack propagation stop characteristic is a tab having no influence of stress reflection as in an actual ship, using a long large ESSO test piece 4 having a long brittle crack propagation distance before entering the test plate 6. Refers to those evaluated by a testing machine with a sufficiently long distance between the plate tips and the distance between load points.

ここでいう応力反射とは、脆性き裂が発生・伝播することにより生じる圧縮応力波の試験機タブ板部等での反射のことである。この応力反射が発生すると、圧縮の応力波が脆性き裂伝播部に戻ってくるため、脆性き裂は停止しやすくなる。実際の船舶等の構造物においては、構造物の大きさが脆性き裂に対して十分に大きいため応力反射は発生しない(あるいはしにくい)。このため、長大脆性き裂の伝播停止特性は、タブ板先端間距離や荷重負荷点間距離の十分長い試験機により評価する必要がある。 The stress reflection here refers to reflection of a compressive stress wave generated by the occurrence and propagation of a brittle crack at a testing machine tab plate portion or the like. When this stress reflection occurs, the compressive stress wave returns to the brittle crack propagation portion, so that the brittle crack tends to stop. In a structure such as an actual ship, stress reflection does not occur (or is difficult) because the size of the structure is sufficiently large for a brittle crack. For this reason, it is necessary to evaluate the propagation stop characteristic of a long and brittle crack with a test machine having a sufficiently long distance between the tab plate tips and the distance between the load points.

本発明に係る鋼板は以下に述べる集合組織を備えることが望ましい。

板厚中央部の板厚の少なくとも20%の領域における圧延面での(211)面もしくは(100)面のX線強度比が1.5以上、板厚1/4t〜1/10t部または板厚3/4t〜9/10t部の圧延面での(110)面のX線強度比が1.3以上

板厚中央付近における圧延面での(211)面もしくは(100)面のX線強度比が1.5以上になると、微細なサブクラックが発生し、脆性き裂伝播面の凹凸が大きくなり、き裂伝播抵抗が増し、脆性き裂伝播停止靭性が大きく向上する。X線強度比が1.5未満ではこの効果は認められない。以上より、板厚中央部の板厚の20%以上の領域における圧延面での(211)面もしくは(100)面のX線強度比を1.5以上に限定した。

The steel sheet according to the present invention preferably has a texture described below.

The X-ray intensity ratio of the (211) plane or the (100) plane at the rolled surface in the region of at least 20% of the plate thickness at the center of the plate thickness is 1.5 or more, the plate thickness from 1/4 t to 1/10 t, or the plate The X-ray intensity ratio of the (110) plane at the rolling surface of

一方、板厚1/4t〜1/10t部の圧延面での(110)面のX線強度比が1.3未満となると、板厚中央部の板厚の20%以上の領域における脆性き裂停止長さが、板厚1/4t〜1/10tの領域における脆性き裂停止長さより、板厚分以上短くならず、板厚1/4t〜1/10t部近傍(図1のA点およびA’点付近の最長き裂伝播部)の破壊駆動力の低下が起こらなくなる。よって、板厚1/4t〜1/10t部の圧延面での(110)面のX線強度比を1.3以上に限定した。上記規定は板厚3/4t〜9/10t部も同様とする。

On the other hand, when the X-ray intensity ratio of the (110) plane on the rolled surface with a thickness of 1/4 t to 1/10 t is less than 1.3, the brittleness in a region of 20% or more of the thickness of the central portion of the thickness is obtained. The crack stop length is not shorter than the brittle crack stop length in the region of the plate thickness of ¼t to 1 / 10t, and is not shorter than the plate thickness by about the plate thickness of ¼t to 1 / 10t (point A in FIG. 1). And the failure driving force of the longest crack propagation part near the point A ′ does not decrease. Therefore, the X-ray intensity ratio of the (110) plane on the rolled surface having a thickness of 1/4 t to 1/10 t was limited to 1.3 or more. The same applies to the

更に、鋼板の供用温度における脆性き裂伝播停止靭性を向上させるため、下式を満足さすることが好ましい。 Furthermore, in order to improve the brittle crack propagation stop toughness at the service temperature of the steel sheet, it is preferable to satisfy the following formula.

vTrs−12X(100)−22X(211)≦(T−75)/0.64

(但し、式においてX(211)は板厚中央部で板厚(t)の少なくとも20%の領域における部位の圧延面での(211)面X線強度比、X(100)は同部位の(100)面X線強度比、vTrs(℃)は同部位の2mmVノッチシャルピー衝撃試験により得られる破面遷移温度、Tは鋼板の供用温度(℃)を示す)

本パラメータ式は、集合組織における対象部位の脆性き裂伝播停止靭性を供用温度にて確保するため、鋼板の靭性を集合組織に応じてvTrsで規定するもので、供用温度より当該対象部位のシャルピー破面遷移温度vTrsを低温とするため、vTrsを、上式を満足するように規定する。尚、上述したように脆性き裂伝播停止靭性向上のためには、(211)面または(100)面のX線強度比1.5以上を必要とするが、両者のうち、(211)面集合組織が脆性き裂伝播停止靭性向上への寄与が大きいため、式においてX(100)に対してX(211)の係数を大きくしている。

vTrs-12X (100) -22X (211) ≤ (T-75) /0.64

(However, in the formula, X (211) is the (211) plane X-ray intensity ratio at the rolling surface in the region at least 20% of the plate thickness (t) at the center of the plate thickness, and X (100) is the same site (100) Plane X-ray intensity ratio, vTrs (° C.) is the fracture surface transition temperature obtained by the 2 mm V notch Charpy impact test at the same site, and T is the service temperature (° C.) of the steel sheet)

This parameter formula defines the toughness of the steel sheet by vTrs according to the texture in order to ensure the brittle crack propagation stop toughness of the target area in the texture. In order to make the fracture surface transition temperature vTrs low, vTrs is defined so as to satisfy the above equation. As described above, in order to improve brittle crack propagation stop toughness, the X-ray intensity ratio of the (211) plane or the (100) plane needs to be 1.5 or more. Since the texture greatly contributes to the improvement of brittle crack propagation stop toughness, the coefficient of X (211) is made larger than X (100) in the equation.

上述した特性を有する鋼板の好ましい成分組成と製造条件は以下のようである。説明において%は質量%とする。 The preferable component composition and manufacturing conditions of the steel sheet having the above-described characteristics are as follows. In the description,% is mass%.

[成分組成]

C:0.15%以下

Cは強度を確保するために必要である。強度確保の観点から望ましくは下限を0.02%とする。しかし、C量が0.15%を超えると溶接熱影響部(HAZ)靭性が低下するので、0.15%以下に限定した。なお、(211)面および(100)面の集合組織をより一層発達させるために好ましい範囲は0.03%以下である。

[Ingredient composition]

C: 0.15% or less C is necessary to ensure strength. From the viewpoint of securing strength, the lower limit is preferably 0.02%. However, if the C content exceeds 0.15%, the weld heat affected zone (HAZ) toughness decreases, so the content was limited to 0.15% or less. In order to further develop the texture of the (211) plane and the (100) plane, the preferable range is 0.03% or less.

Si:0.60%以下

Siは強度上昇に有効な元素である。その効果を得るためには0.01%以上含有するのが好ましい。Si量が、0.60%を超えると溶接熱影響部(HAZ)靭性を著しく劣化させるので、0.60%以下に限定した。

Si: 0.60% or less Si is an element effective for increasing the strength. In order to acquire the effect, it is preferable to contain 0.01% or more. If the Si content exceeds 0.60%, the weld heat affected zone (HAZ) toughness is remarkably deteriorated, so it is limited to 0.60% or less.

Mn:0.80〜1.80%

Mnは高強度化に有効な元素であり、強度確保の観点から下限を0.80%とした。しかし、Mn量が1.80%を超えると、母材靭性の劣化が懸念される。このため、Mnは0.80〜1.80%の範囲とした。なお、好ましい範囲は1.00〜1.70%である。

Mn: 0.80 to 1.80%

Mn is an element effective for increasing the strength, and the lower limit is set to 0.80% from the viewpoint of securing the strength. However, if the amount of Mn exceeds 1.80%, there is a concern about deterioration of the base material toughness. For this reason, Mn was taken as 0.80 to 1.80% of range. A preferable range is 1.00 to 1.70%.

S:0.001〜0.05%以下

本発明においては、脆性き裂前縁にクラック(鋼板表面に平行な割れ)を発生させる必要があるため、Sの0.001%以上の含有が必要である。しかし、Sは非金属介在物を形成し延性・靭性を劣化させるため、0.05%以下に制限した。

S: 0.001 to 0.05% or less In the present invention, since it is necessary to generate cracks (cracks parallel to the steel plate surface) at the leading edge of the brittle crack, it is necessary to contain 0.001% or more of S. It is. However, since S forms nonmetallic inclusions and deteriorates ductility and toughness, it is limited to 0.05% or less.

Ti:0.005〜0.050%、Nb:0.001〜0.1%の1種または2種

Tiは、炭化物や窒化物の析出物を形成することにより、鋼板製造時の加熱段階でのオーステナイト粒の成長を抑制して細粒化に寄与するとともに、溶接熱影響部(HAZ)の結晶粒粗大化も抑制しHAZ靱性を向上する効果がある。これらの効果を得るには、0.005%以上の含有が必要である。一方、過度の含有は、靱性を劣化するため、0.050%を上限とする。

One or two types of Ti: 0.005 to 0.050%, Nb: 0.001 to 0.1% Ti forms a precipitate of carbide or nitride, thereby heating at the time of manufacturing the steel sheet. This suppresses the growth of the austenite grains and contributes to the refinement, and also suppresses the grain coarsening of the weld heat affected zone (HAZ) and improves the HAZ toughness. In order to obtain these effects, a content of 0.005% or more is necessary. On the other hand, excessive content deteriorates toughness, so 0.050% is made the upper limit.

Nbは析出強化および靱性の向上にも有効である。また、オーステナイトの再結晶を抑制し、後述する圧延条件による効果を促進する。これらの効果を得るためには、0.001%以上の添加が必要であるが、0.1%を超えて添加すると、焼き入れ組織が針状化して靱性が劣化する傾向にあるため、0.1%を上限とする。 Nb is also effective in improving precipitation strengthening and toughness. Moreover, the recrystallization of austenite is suppressed, and the effect by the rolling conditions described later is promoted. In order to obtain these effects, addition of 0.001% or more is necessary, but if added over 0.1%, the quenched structure tends to become needle-like and the toughness tends to deteriorate. The upper limit is 1%.

Cu:2.0%以下、V:0.2%以下、Ni:2.0%以下、Cr:0.6%以下、

Mo:0.6%以下、W:0.5%以下、B:0.0050%以下、Zr:0.5%以下の内から選んだ少なくとも1種

Cu:2.0%以下

Cuは、主として析出強化のために用いることができる。その効果を得るには0.05%以上添加するのが好ましい。Cu量が、2.0%をこえて含有すると、析出強化が過多となり靱性が劣化するので、2.0%以下の範囲とすることが好ましい。

Cu: 2.0% or less, V: 0.2% or less, Ni: 2.0% or less, Cr: 0.6% or less,

Mo: 0.6% or less, W: 0.5% or less, B: 0.0050% or less, Zr: at least one selected from 0.5% or less Cu: 2.0% or less Cu is mainly used It can be used for precipitation strengthening. In order to obtain the effect, 0.05% or more is preferably added. If the Cu content exceeds 2.0%, precipitation strengthening becomes excessive and toughness deteriorates, so it is preferable to set the Cu content in a range of 2.0% or less.

V:0.2%以下

Vは固溶強化と析出強化が利用できる成分である。その効果を得るには0.001%以上の含有が好ましい。しかし、0.2%を超えて含有すると、母材靭性および溶接性を大きく損なうので、0.2%以下の範囲とすることが好ましい。

V: 0.2% or less V is a component that can use solid solution strengthening and precipitation strengthening. In order to acquire the effect, containing 0.001% or more is preferable. However, if the content exceeds 0.2%, the base material toughness and weldability are greatly impaired.

Ni:2.0%以下

Niは、強度および靱性を向上し、またCuを添加した場合には圧延時のCu割れを防止するのに有効である。その効果を得るには、0.05%以上の添加が好ましい。しかし、高価である上、過剰に添加してもその効果が飽和するため、2.0%以下の範囲とすることが好ましい。

Ni: 2.0% or less Ni is effective in improving strength and toughness and preventing Cu cracking during rolling when Cu is added. In order to obtain the effect, addition of 0.05% or more is preferable. However, since it is expensive and its effect is saturated even if it is added excessively, the content is preferably set to 2.0% or less.

Cr:0.6%以下

Crは、強度を上昇させる効果を有する。その効果を得るには、0.01%以上の含有が好ましい。しかし、0.6%を超えて含有すると溶接部靱性が劣化するため、Cr含有量は0.6%以下の範囲とすることが好ましい。

Cr: 0.6% or less Cr has an effect of increasing strength. In order to acquire the effect, containing 0.01% or more is preferable. However, if the content exceeds 0.6%, the weld zone toughness deteriorates, so the Cr content is preferably in the range of 0.6% or less.

Mo:0.6%以下

Moは、常温および高温での強度を上昇させる効果を有する。その効果を得るためには、0.01%以上添加するのが好ましい。しかし、0.6%を超えて含有すると、溶接性が劣化するため、含有量は0.6%以下の範囲とするのが好ましい。

Mo: 0.6% or less Mo has an effect of increasing the strength at normal temperature and high temperature. In order to obtain the effect, 0.01% or more is preferably added. However, if the content exceeds 0.6%, the weldability deteriorates, so the content is preferably in the range of 0.6% or less.

W:0.5%以下

Wは、高温強度を上昇させる効果を有している。その効果を得るには、0.05%以上の含有が好ましい。しかし、0.5%を超えると靱性を劣化させるだけでなく、高価であるので、0.5%以下の範囲で含有するのが好ましい。

W: 0.5% or less W has an effect of increasing the high-temperature strength. In order to acquire the effect, containing 0.05% or more is preferable. However, if it exceeds 0.5%, not only is the toughness deteriorated, but it is expensive, so it is preferably contained in a range of 0.5% or less.

B:0.0050%以下

Bは圧延中にBNとして析出し、圧延後のフェライト粒を細かくする。その効果を得るには、0.0010%以上の含有が好ましい。しかし、0.0050%を超えると靱性が劣化するので0.0050%以下に限定した。

B: 0.0050% or less B precipitates as BN during rolling, and fines ferrite grains after rolling. In order to acquire the effect, containing 0.0010% or more is preferable. However, if it exceeds 0.0050%, the toughness deteriorates, so it is limited to 0.0050% or less.

Zr:0.5%以下

Zrは、強度を上昇させるほか、亜鉛めっき材の耐めっき割れ性を向上させる元素である。その効果を得るには、0.03%以上の含有が好ましい。しかし、0.5%を超えて含有すると溶接部靱性が劣化するので、Zr含有量は0.5%を上限とするのが好ましい。

本発明に係る鋼は上記成分組成の他は残部Feおよび不可避的不純物である。なお、不可避的不純物としては、P:0.035%以下、Al:0.08%以下、N:0.012%以下、O:0.05%以下、Mg:0.01%以下、などが容認できる。

Zr: 0.5% or less Zr is an element that increases the strength and improves the plating cracking resistance of the galvanized material. In order to acquire the effect, containing 0.03% or more is preferable. However, since the weld toughness deteriorates if the content exceeds 0.5%, the Zr content is preferably 0.5% as an upper limit.

The steel according to the present invention is the balance Fe and unavoidable impurities in addition to the above component composition. Inevitable impurities include P: 0.035% or less, Al: 0.08% or less, N: 0.012% or less, O: 0.05% or less, Mg: 0.01% or less, and the like. Acceptable.

製造条件では、加熱温度、熱間圧延条件、冷却条件を規定することが好ましい。説明において規定がない場合、温度、冷却速度は板厚方向の平均値とする。 In the production conditions, it is preferable to define heating temperature, hot rolling conditions, and cooling conditions. Unless otherwise specified in the description, the temperature and cooling rate are average values in the thickness direction.

[加熱温度]

鋼素材は、900〜1350℃の温度に加熱する。加熱温度を900℃以上とするのは、材質の均質化と後述する制御圧延を行うために必要な加熱であり1350℃以下とするのは、過度に高温になると表面酸化が顕著になるとともに、結晶粒の粗大化が避けられなくなるからである。なお、靱性の向上のためには、上限を1150℃とすることが好ましい。

[Heating temperature]

The steel material is heated to a temperature of 900 to 1350 ° C. A heating temperature of 900 ° C. or higher is heating necessary for homogenizing the material and controlled rolling described later, and 1350 ° C. or lower is that surface oxidation becomes remarkable when the temperature is excessively high, This is because coarsening of crystal grains cannot be avoided. In order to improve toughness, the upper limit is preferably set to 1150 ° C.

[熱間圧延条件]

鋼板表面温度1000〜850℃の温度域において累積圧下率10%以上圧延

当該温度域で圧延することによって、オーステナイト粒が部分的に再結晶するため、組織が微細かつ均一になる。

[Hot rolling conditions]

When the steel sheet surface temperature is 1000 to 850 ° C., the rolling reduction is 10% or more. By rolling in the temperature range, the austenite grains are partially recrystallized, so that the structure becomes fine and uniform.

なお、1000℃を超える温度での圧延は、オーステナイト粒の成長を助長するので、細粒化のためには好ましくない。一方、850℃未満では完全にオーステナイト未再結晶域に入るので、結晶粒の均一化のためには好ましくない。 Note that rolling at a temperature exceeding 1000 ° C. promotes the growth of austenite grains, and thus is not preferable for making fine grains. On the other hand, if it is lower than 850 ° C., it completely enters the austenite non-recrystallized region, which is not preferable for making the crystal grains uniform.

鋼板表面温度900〜600℃で且つ鋼板内部温度が鋼板表面温度より50〜150℃高温となる状態とした後に、1パス圧下率7%以上、累積圧下率50%以上で、圧延終了時の鋼板表面温度850〜550℃の条件にて熱間圧延する

鋼板表面温度900〜600℃で且つ鋼板内部温度が鋼板表面温度より50〜150℃高温となる状態とすることにより、表面近傍がほぼ2相域で且つ鋼板内部がほぼオーステナイト未再結晶域となる。

After the steel plate surface temperature is 900 to 600 ° C. and the steel plate internal temperature is 50 to 150 ° C. higher than the steel plate surface temperature, the steel plate at the end of rolling has a one-pass reduction ratio of 7% or more and a cumulative reduction ratio of 50% or more. Hot rolling under conditions of a surface temperature of 850 to 550 ° C. When the steel plate surface temperature is 900 to 600 ° C. and the steel plate internal temperature is 50 to 150 ° C. higher than the steel plate surface temperature, the surface vicinity is almost two phases. And the inside of the steel sheet is almost an austenite non-recrystallized region.

この条件で1パス圧下率7%以上の圧延を施すと、相対的に強度の低くなっている鋼板内部に優先的に圧延歪が導入され、板厚中央部の少なくとも板厚の20%の領域に集合組織が導入される。この工程により、オーステナイト粒に集合組織が形成される。 If rolling with a one-pass reduction ratio of 7% or more is performed under these conditions, rolling strain is preferentially introduced into the steel plate having relatively low strength, and at least 20% of the thickness of the plate thickness central portion. Will be introduced into the organization. Through this process, a texture is formed in the austenite grains.

すなわち、脆性き裂先端におけるクラック生成に効果的な変態集合組織の一種である(211)面集合組織の基礎が形成される。なお、板厚中央部の少なくとも板厚の20%の領域に集合組織を導入するために、より好ましくは、1パス圧下率10%以上とするのがよい。 That is, the basis of the (211) plane texture, which is a kind of transformation texture effective for crack generation at the brittle crack tip, is formed. In order to introduce a texture to at least 20% of the plate thickness at the center of the plate thickness, it is more preferable to set the one-pass rolling reduction rate to 10% or more.

その後、鋼板表面温度850〜550℃まで圧延することにより、鋼板内部が2相域で圧延され(100)面集合組織が形成される。 Then, by rolling to a steel plate surface temperature of 850 to 550 ° C., the inside of the steel plate is rolled in a two-phase region to form a (100) plane texture.

上記集合組織の集積度を脆性き裂先端におけるクラック生成に効果的なレベル(集積度1.55以上)にするには、累積圧下率50%以上が必要となる。 In order to set the accumulation degree of the texture to a level effective for crack generation at the brittle crack tip (an accumulation degree of 1.55 or more), a cumulative rolling reduction of 50% or more is required.

[冷却条件]

熱間圧延を終了した後、5℃/s以上の冷却速度で400℃まで冷却する。400℃までの温度域を5℃/s以上の冷却速度で冷却すると、(211)面が優勢な集合組織のオーステナイト集合組織からの受け継ぎが促進され、脆性き裂伝播停止靱性が向上する。

[Cooling conditions]

After the hot rolling is finished, it is cooled to 400 ° C. at a cooling rate of 5 ° C./s or more. When the temperature range up to 400 ° C. is cooled at a cooling rate of 5 ° C./s or more, inheritance from the austenite texture of the texture having a predominant (211) surface is promoted, and the brittle crack propagation stopping toughness is improved.

上記条件で冷却すると、(211)面のX線面強度がより強くなり、サブクラックの発生がより一層促進され、き裂が停止し易くなる。尚、上記冷却方法においては、より好ましい冷却開始温度は700℃以上である。 When cooled under the above conditions, the X-ray surface strength of the (211) plane becomes stronger, the generation of subcracks is further promoted, and cracks are likely to stop. In the above cooling method, a more preferable cooling start temperature is 700 ° C. or higher.

尚、本発明に係る厚鋼板を、鋼板厚さ50mm未満とした場合、優れた脆性き裂伝播特性を有することはいうまでもない。

[評価方法、試験装置]

応力反射の無い実船相当条件下にて、長大脆性き裂伝播停止特性を評価するため、動的FEM解析により応力反射の影響を評価し、試験機のタブ板先端間距離、荷重負荷点間距離を決定した。長大ESSO試験片サイズは図2に示したものとした。

Needless to say, when the steel plate according to the present invention has a thickness of less than 50 mm, it has excellent brittle crack propagation characteristics.

[Evaluation method, test equipment]

In order to evaluate the long-brittle crack propagation stopping characteristics under conditions equivalent to actual ships without stress reflection, the effect of stress reflection was evaluated by dynamic FEM analysis, and the distance between the tab plate tips of the testing machine and between load points The distance was determined. The size of the long ESSO test piece was as shown in FIG.

図3(a)、(b)、(c)に動的FEM解析モデルを、図4に結果を示す。図3(a)は応力反射の無い条件を見極めるためのパラメトリックモデルであり、応力反射に影響する試験機タブ板11(厚さ200mm)間の距離(図3(a)の2A)の影響を解析するためのモデルである。図3(b)は使用する試験機の荷重負荷点10の距離を10mに設定した場合のモデル、図3(c)は使用する試験機の荷重負荷点10の距離を5mに設定した場合のモデルである。

3A, 3B and 3C show the dynamic FEM analysis model, and FIG. 4 shows the result. FIG. 3A is a parametric model for determining the condition without stress reflection. The influence of the distance (2A in FIG. 3A) between the tester tab plates 11 (

図4にFEM解析結果を示す。図4は伝播中のき裂の動的応力拡大係数(脆性き裂伝播中の破壊駆動力)Kdの変化を破壊発生から試験板に突入するまでの間で求めたものである。×印で示した結果は、2A=10000mmの場合であり、脆性き裂が試験板突入まで応力反射が起こらない実船相当条件での結果である。 FIG. 4 shows the FEM analysis results. FIG. 4 shows the change in the dynamic stress intensity factor (fracture driving force during brittle crack propagation) Kd of the crack during propagation from the occurrence of fracture to the entry into the test plate. The result shown by x is a case of 2A = 10000 mm, and is a result under conditions equivalent to an actual ship where a brittle crack does not cause stress reflection until the test plate enters.

2A=1800〜4300mmの条件では、応力反射が発生するため、試験板突入時の動的応力拡大係数Kdが、実船相当条件である2A=10000mmの場合に比較して、低くなっていることが確認できる。これは、2A=1800〜4300mmの条件では、実船条件よりも長大脆性き裂が停止しやすくなることを意味する。一方、2A=6800mmの条件では、若干の動的応力拡大係数Kdの低下が認められるものの、実船相当条件とそれほど変わらなくなることが確認できる。 Under the conditions of 2A = 1800-4300mm, stress reflection occurs, so that the dynamic stress intensity factor Kd when entering the test plate is lower than in the case of 2A = 10000mm, which is an actual ship equivalent condition. Can be confirmed. This means that under the condition of 2A = 1800-4300 mm, a long and brittle crack is more likely to stop than under actual ship conditions. On the other hand, under the condition of 2A = 6800 mm, although a slight decrease in the dynamic stress intensity factor Kd is recognized, it can be confirmed that it is not so different from the actual ship equivalent condition.

よって、2Aを6800mm以上確保すれば、実船相当条件の評価が可能であり、例えば図3(b)に示す荷重負荷点間距離10mの大型引張試験ジグ形状であれば、十分に実船相当条件の評価が可能となる。図4には使用する試験機の荷重負荷点間距離を5mと10mに設定した場合のモデルにより得られた解析結果を示しているが、図3(b)に示す荷重負荷点間距離10mモデルの大型引張試験ジグ形状にて長大ESSO試験を実施すれば、応力反射の無い実船相当条件下での評価となることが認められる。 Therefore, if 2A is secured 6800 mm or more, it is possible to evaluate the actual ship equivalent conditions. For example, a large tensile test jig shape with a distance of 10 m between the load points shown in FIG. Conditions can be evaluated. FIG. 4 shows the analysis result obtained by the model when the distance between the load points of the test machine to be used is set to 5 m and 10 m, but the 10 m model between the load points shown in FIG. It is recognized that if a long-sized ESSO test is performed with a large-sized tensile test jig shape, evaluation under conditions equivalent to actual ships without stress reflection is recognized.

以上のFEM解析により、応力反射の無い実船相当条件下の長大脆性き裂伝播停止性能の評価方法は、試験片長さもしくは試験片を取り付ける試験装置のタブ板先端間距離が試験片幅の2.8倍以上(≒6800mm/2400mm)、さらに試験装置の荷重負荷点間距離が試験片幅の4.1倍以上(≒10000mm/2400mm)とした。 Based on the above FEM analysis, the evaluation method of the long-brittle crack propagation stopping performance under conditions equivalent to an actual ship without stress reflection is the test piece length or the distance between the tab plate tips of the test apparatus to which the test piece is attached is 2 .Times.8 times or more (≈6800 mm / 2400 mm), and further, the distance between the load points of the test apparatus was 4.1 times or more (≈10000 mm / 2400 mm) of the test piece width.

同様に、応力反射の無い実船相当条件下の長大脆性き裂伝播停止性能を評価しうる試験装置として、試験片を取り付ける試験装置のタブ板先端間距離が試験片幅の2.8倍以上(≒6800mm/2400mm)、さらに試験装置の荷重負荷点間距離が試験片幅の4.1倍以上(≒10000mm/2400mm)とした。 Similarly, as a test device that can evaluate the long brittle crack propagation stopping performance under conditions equivalent to an actual ship without stress reflection, the distance between the tab plate tips of the test device to which the test piece is attached is 2.8 times or more of the test piece width. (≈6800 mm / 2400 mm), and further, the distance between the load points of the test apparatus was 4.1 times or more the width of the test piece (≈10000 mm / 2400 mm).

表1に示す種々の化学組成に調整した鋼スラブを用いて、表2に示す条件にしたがって厚鋼板を製造した。かくして得られた各厚鋼板について、板厚(t)の中央部(高アレスト性能域)の(211)面と(100)面のX線強度比の測定を行うとともに、シャルピー破面遷移温度vTrsを調査した。また、板厚(t)の1/8部(板厚(t)の1/4〜1/10の領域の代表部位)の(110)面のX線強度比の測定を行った。 Using steel slabs adjusted to various chemical compositions shown in Table 1, thick steel plates were produced according to the conditions shown in Table 2. For each thick steel plate thus obtained, the X-ray intensity ratio between the (211) plane and the (100) plane of the central portion (high arrest performance region) of the thickness (t) is measured, and the Charpy fracture surface transition temperature vTrs. investigated. Further, the X-ray intensity ratio of the (110) plane of 1/8 part of the plate thickness (t) (representative part of the region of 1/4 to 1/10 of the plate thickness (t)) was measured.

次に、長大脆性き裂伝播停止特性を評価するため、前記の厚鋼板(板厚(t)の元厚まま)を用いて、図2に示す寸法形状の長大ESSO試験片を作製し、試験に供した。試験は、応力257N/mm2、温度−10℃の条件にて実施した。ここで、応力257N/mm2は、船体に多用されている降伏強度40kgf/mm2級鋼板の最大許容応力であり、温度−10℃は船舶の設計温度である。長大ESSO試験は図3(b)に示す大型引張試験ジグにて、タブ板先端間距離6800mm、荷重負荷点間距離10000mmのもと行った。 Next, in order to evaluate the long brittle crack propagation stopping characteristics, a long ESSO test piece having the dimensions shown in FIG. 2 was prepared using the above-mentioned thick steel plate (the original thickness of the plate thickness (t)). It was used for. The test was performed under the conditions of a stress of 257 N / mm 2 and a temperature of −10 ° C. Here, the stress 257 N / mm 2 is the maximum allowable stress of the yield strength 40 kgf / mm 2 grade steel plate frequently used in the hull, and the temperature −10 ° C. is the design temperature of the ship. The long-sized ESSO test was conducted using a large tensile test jig shown in FIG. 3B with a distance between the tab plate tips of 6800 mm and a load load point distance of 10000 mm.

長大ESSO試験を実施した結果を、表3に示す。本発明例(No2、3、6、8、9、12、14)では脆性き裂が隅肉溶接部で停止しており、比較例(No.1、4、5、7、10、11、13、15、16)では、脆性き裂が停止しなかった。 Table 3 shows the results of the long ESSO test. In the present invention examples (Nos. 2, 3, 6, 8, 9, 12, 14), the brittle cracks stopped at the fillet welds, and comparative examples (No. 1, 4, 5, 7, 10, 11, In 13, 15, 16), the brittle crack did not stop.

1鋼板

2長大脆性き裂

3長大脆性き裂停止位置

4長大ESSO試験片

5助走板

6試験板

7エレクトロガス溶接部

8CO2溶接部

9機械ノッチ

10荷重負荷点

11タブ板

1 steel plate 2 long

Claims (4)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012023955A JP5598485B2 (en) | 2011-02-08 | 2012-02-07 | Thick steel plate having a thickness of 50 mm or more excellent in long and brittle crack propagation stopping characteristics and method for producing the same |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011024495 | 2011-02-08 | ||

| JP2011024495 | 2011-02-08 | ||

| JP2012023955A JP5598485B2 (en) | 2011-02-08 | 2012-02-07 | Thick steel plate having a thickness of 50 mm or more excellent in long and brittle crack propagation stopping characteristics and method for producing the same |

Related Child Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013237819A Division JP2014052385A (en) | 2011-02-08 | 2013-11-18 | Thick steel plate with plate thickness of 50 mm or more excellent in long brittle crack propagation arrest properties, manufacturing method of the same, and method and testing device for evaluating long brittle crack propagation arrest performance |

| JP2014102292A Division JP2014145131A (en) | 2011-02-08 | 2014-05-16 | Not less than 50 mm-thick thick steel plate excellent in long brittle crack propagation stop property, and method of producing the same |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2012180590A JP2012180590A (en) | 2012-09-20 |

| JP2012180590A5 JP2012180590A5 (en) | 2014-01-09 |

| JP5598485B2 true JP5598485B2 (en) | 2014-10-01 |

Family

ID=46638754

Family Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012023955A Active JP5598485B2 (en) | 2011-02-08 | 2012-02-07 | Thick steel plate having a thickness of 50 mm or more excellent in long and brittle crack propagation stopping characteristics and method for producing the same |

| JP2013237819A Pending JP2014052385A (en) | 2011-02-08 | 2013-11-18 | Thick steel plate with plate thickness of 50 mm or more excellent in long brittle crack propagation arrest properties, manufacturing method of the same, and method and testing device for evaluating long brittle crack propagation arrest performance |

| JP2014102292A Pending JP2014145131A (en) | 2011-02-08 | 2014-05-16 | Not less than 50 mm-thick thick steel plate excellent in long brittle crack propagation stop property, and method of producing the same |

Family Applications After (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013237819A Pending JP2014052385A (en) | 2011-02-08 | 2013-11-18 | Thick steel plate with plate thickness of 50 mm or more excellent in long brittle crack propagation arrest properties, manufacturing method of the same, and method and testing device for evaluating long brittle crack propagation arrest performance |

| JP2014102292A Pending JP2014145131A (en) | 2011-02-08 | 2014-05-16 | Not less than 50 mm-thick thick steel plate excellent in long brittle crack propagation stop property, and method of producing the same |

Country Status (5)

| Country | Link |

|---|---|

| JP (3) | JP5598485B2 (en) |

| KR (1) | KR101584235B1 (en) |

| CN (2) | CN108130479A (en) |

| TW (1) | TWI523953B (en) |

| WO (1) | WO2012108543A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2014145131A (en) * | 2011-02-08 | 2014-08-14 | Jfe Steel Corp | Not less than 50 mm-thick thick steel plate excellent in long brittle crack propagation stop property, and method of producing the same |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107988471A (en) * | 2012-08-06 | 2018-05-04 | 杰富意钢铁株式会社 | The manufacture method of steel plate |

| CN103286128B (en) * | 2013-05-30 | 2015-05-20 | 山西太钢不锈钢股份有限公司 | Super duplex stainless steel S32750 medium plate rolling process |

| WO2014208072A1 (en) * | 2013-06-26 | 2014-12-31 | Jfeスチール株式会社 | Method for evaluating brittle fracture propagation arrestability of thick steel plate |

| JP6788589B2 (en) * | 2014-12-24 | 2020-11-25 | ポスコPosco | High-strength steel with excellent brittle crack propagation resistance and its manufacturing method |

| KR101657827B1 (en) * | 2014-12-24 | 2016-09-20 | 주식회사 포스코 | Steel having excellent in resistibility of brittle crack arrestbility and manufacturing method thereof |

| WO2016143345A1 (en) * | 2015-03-12 | 2016-09-15 | Jfeスチール株式会社 | High-strength thick steel sheet and method for manufacturing same |

| KR102092000B1 (en) * | 2015-09-18 | 2020-03-23 | 제이에프이 스틸 가부시키가이샤 | High-strength thick steel plate for structural use and manufacturing method therefor |

| CN108779525A (en) * | 2016-02-24 | 2018-11-09 | 杰富意钢铁株式会社 | The high intensity pole steel plate and its manufacturing method of excellent in brittle-cracking propagation stopping characteristics |

| JP6665658B2 (en) * | 2016-04-21 | 2020-03-13 | 日本製鉄株式会社 | High strength steel plate |

| US11313776B2 (en) * | 2017-11-22 | 2022-04-26 | Jfe Steel Corporation | Method for evaluating brittle crack arrestability of steel plate |

| KR101999015B1 (en) | 2017-12-24 | 2019-07-10 | 주식회사 포스코 | Steel for structure having superior resistibility of brittle crack arrestability and manufacturing method thereof |

| KR101999022B1 (en) | 2017-12-26 | 2019-07-10 | 주식회사 포스코 | High strength steel for structure having excellent fatigue crack arrestability and manufacturing method thereof |

| US20220220574A1 (en) * | 2019-03-28 | 2022-07-14 | Jfe Steel Corporation | Steel material for line pipes, method for producing the same, line pipe, and method for producing the line pipe |

| CN110863149A (en) * | 2019-11-13 | 2020-03-06 | 浙江金洲管道科技股份有限公司 | Hot-dip galvanized steel pipe and manufacturing method thereof |

| JP7288197B2 (en) * | 2019-12-16 | 2023-06-07 | 日本製鉄株式会社 | Welded structure |

| JP7288196B2 (en) * | 2019-12-16 | 2023-06-07 | 日本製鉄株式会社 | Welded structure |

| JP7188655B1 (en) * | 2021-06-10 | 2022-12-13 | Jfeスチール株式会社 | Evaluation method of brittle crack arrestability of steel plate |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07100814B2 (en) | 1990-09-28 | 1995-11-01 | 新日本製鐵株式会社 | Method for producing steel sheet with excellent brittle crack propagation arresting properties and low temperature toughness |

| JP2659661B2 (en) | 1993-01-06 | 1997-09-30 | 新日本製鐵株式会社 | Structural steel for welding with excellent brittle fracture propagation stopping performance at joints and method of manufacturing the same |

| JP3548349B2 (en) | 1996-09-18 | 2004-07-28 | 新日本製鐵株式会社 | Structural steel sheet with excellent brittle fracture resistance after plastic deformation |

| JP3467767B2 (en) | 1998-03-13 | 2003-11-17 | Jfeスチール株式会社 | Steel with excellent brittle crack arrestability and method of manufacturing the same |

| JP4077167B2 (en) | 2001-02-28 | 2008-04-16 | 株式会社神戸製鋼所 | Steel plate with excellent arrest properties and its manufacturing method |

| JP5135872B2 (en) * | 2006-05-12 | 2013-02-06 | Jfeスチール株式会社 | Thick steel plate excellent in brittle crack propagation stopping characteristics of fillet and cross welds and method for producing the same |

| JP2008013831A (en) * | 2006-07-07 | 2008-01-24 | Jfe Steel Kk | Thick steel plate with high young's modulus for welded structure, and its manufacturing method |

| JP5151090B2 (en) * | 2006-08-18 | 2013-02-27 | Jfeスチール株式会社 | Structural high-strength thick steel plate with excellent brittle crack propagation stopping characteristics and method for producing the same |

| JP5217391B2 (en) * | 2006-11-30 | 2013-06-19 | Jfeスチール株式会社 | Steel sheet having a thickness of 50 mm or more and excellent in brittle crack propagation stopping characteristics in the thickness direction, and method for producing the same |

| JP4985086B2 (en) * | 2006-12-28 | 2012-07-25 | Jfeスチール株式会社 | High tensile thick steel plate with excellent brittle crack propagation stopping characteristics and method for producing the same |

| JP4946512B2 (en) | 2007-02-28 | 2012-06-06 | Jfeスチール株式会社 | Structural high-strength thick steel plate with excellent brittle crack propagation stopping characteristics and method for producing the same |

| JP4899034B2 (en) * | 2008-02-14 | 2012-03-21 | Dowaエレクトロニクス株式会社 | Gallium raw material for compound semiconductor production |

| JP5337412B2 (en) * | 2008-06-19 | 2013-11-06 | 株式会社神戸製鋼所 | Thick steel plate excellent in brittle crack propagation stopping characteristics and method for producing the same |

| JP5618044B2 (en) * | 2009-03-17 | 2014-11-05 | Jfeスチール株式会社 | Thick steel plate with excellent fatigue crack propagation characteristics in the thickness direction and method for producing the same |

| JP2011127207A (en) * | 2009-12-21 | 2011-06-30 | Sumitomo Metal Ind Ltd | High-strength thick steel plate having excellent brittle-crack arrestability, and method for producing the same |

| WO2012108543A1 (en) * | 2011-02-08 | 2012-08-16 | Jfeスチール株式会社 | Thick steel plate of at least 50mm in thickness with superior long brittle fracture propagation stopping properties, manufacturing method for same, and method for evaluating long brittle fracture propagation stopping performance and test apparatus for same |

-

2012

- 2012-02-07 WO PCT/JP2012/053201 patent/WO2012108543A1/en active Application Filing

- 2012-02-07 KR KR1020137020860A patent/KR101584235B1/en active IP Right Grant

- 2012-02-07 CN CN201810089072.6A patent/CN108130479A/en active Pending

- 2012-02-07 JP JP2012023955A patent/JP5598485B2/en active Active

- 2012-02-07 CN CN2012800078166A patent/CN103348030A/en active Pending

- 2012-02-08 TW TW101103990A patent/TWI523953B/en active

-

2013

- 2013-11-18 JP JP2013237819A patent/JP2014052385A/en active Pending

-

2014

- 2014-05-16 JP JP2014102292A patent/JP2014145131A/en active Pending

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2014145131A (en) * | 2011-02-08 | 2014-08-14 | Jfe Steel Corp | Not less than 50 mm-thick thick steel plate excellent in long brittle crack propagation stop property, and method of producing the same |

Also Published As

| Publication number | Publication date |

|---|---|

| TWI523953B (en) | 2016-03-01 |

| TW201250007A (en) | 2012-12-16 |

| KR101584235B1 (en) | 2016-01-11 |

| JP2014145131A (en) | 2014-08-14 |

| CN103348030A (en) | 2013-10-09 |

| KR20130114239A (en) | 2013-10-16 |

| WO2012108543A1 (en) | 2012-08-16 |

| JP2014052385A (en) | 2014-03-20 |

| JP2012180590A (en) | 2012-09-20 |

| CN108130479A (en) | 2018-06-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5598485B2 (en) | Thick steel plate having a thickness of 50 mm or more excellent in long and brittle crack propagation stopping characteristics and method for producing the same | |

| JP5445720B1 (en) | High strength steel plate with excellent arrestability | |

| RU2518830C1 (en) | Hot-rolled steel sheet and method of its production | |

| JP5304925B2 (en) | Structural high-strength thick steel plate with excellent brittle crack propagation stopping characteristics and method for producing the same | |

| JP5598617B1 (en) | High strength thick steel plate for high heat input welding with excellent brittle crack propagation stopping characteristics and method for producing the same | |

| JP2010001520A (en) | Thick steel plate excellent in brittle-crack propagation stop property, and producing method thereof | |

| JP5304924B2 (en) | Structural high-strength thick steel plate with excellent brittle crack propagation stopping characteristics and method for producing the same | |

| JP5217391B2 (en) | Steel sheet having a thickness of 50 mm or more and excellent in brittle crack propagation stopping characteristics in the thickness direction, and method for producing the same | |

| JP6165116B2 (en) | Manufacturing method of thick steel plate with excellent long-brittle crack propagation stopping performance | |

| WO2017047088A1 (en) | High-strength thick steel plate for structural use and manufacturing method therefor | |

| JP2018024905A (en) | Structural high strength thick steel plate excellent in brittle crack arrest property and production method thereof | |

| JP5759109B2 (en) | Steel material excellent in brittle crack propagation stop property and method for producing the same | |

| JP5668668B2 (en) | Steel with excellent toughness of weld heat affected zone, welded joint, and method for manufacturing welded joint | |

| JP6112265B2 (en) | High-strength extra heavy steel plate and method for producing the same | |

| WO2013175745A1 (en) | High-strength thick steel plate for structural use which has excellent brittle crack arrestability, and method for producing same | |

| JP5135872B2 (en) | Thick steel plate excellent in brittle crack propagation stopping characteristics of fillet and cross welds and method for producing the same | |

| JP6477743B2 (en) | High-strength ultra-thick steel plate excellent in brittle crack propagation stopping characteristics and weld heat-affected zone toughness and method for producing the same | |

| KR101687687B1 (en) | Thick steel sheet having superior fatigue resistance properties in direction of sheet thickness, method for producing same, and fillet welded joint using said thick steel sheet | |

| JP5838801B2 (en) | Thick steel plate and method for manufacturing thick steel plate | |

| JP2018076573A (en) | Steel plate excellent brittle crack propagation stopping characteristics and manufacturing method therefor | |

| JP4899885B2 (en) | Thin-walled tempered high-strength steel sheet with excellent toughness and brittle crack propagation stopping characteristics and method for producing the same | |

| JP6135595B2 (en) | High-efficiency manufacturing method for steel plates with excellent impact resistance | |

| JP2008156751A (en) | Steel plate having plate thickness of 50 mm or more and excellent brittle crack spreading-resistant characteristic in plate thickness direction |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20131007 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20131114 |

|

| RD13 | Notification of appointment of power of sub attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7433 Effective date: 20140106 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20140318 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140516 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20140715 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20140728 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5598485 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |